KURARAY (EVAL EUROPE N.V.) - Protecting so much more than your product

Belgium

Manufacturer/ Producer

KURARAY (EVAL EUROPE N.V.)

Belgium

EVAL is already used world-wide to improve the safety, shelf life and process efficiency of packaging for baby food and other infant formulas. With a reliable performance, shelf-stable packaging can be designed to safely limit the total amount of oxygen ingress. Quality is assured and shelf life is extended, notably by protecting fat and vitamin content against oxidation. Additional safety and extended shelf life with oxygen scavenger For the most oxygen-sensitive products, EVALâ„¢ grades with oxygen scavenging capacity can create a negative oxygen increase, providing extra safety margins and extending product shelf life.

KURARAY (EVAL EUROPE N.V.)

Belgium

EVAL's largest use world-wide is for food packaging. Since 1972, EVALâ„¢ has helped reduce food waste by blocking oxygen ingress and contaminants, extending shelf life and avoiding product waste. EVAL provides the functional gas and contamination barrier to the entire structure. The result has often been a reduction in packaging waste by reducing the weight and amount of packaging materials used, without compromising on function. Â EVAL barrier properties avoid vitamin and fat oxidation, extending shelf life of parenteral nutrition. Compared to standard plastic packaging, additive content can be guaranteed for longer, even while reducing the necessary doses. EVAL barrier can be added to many different types of light weight, unbreakable and halogen-free all-plastic packaging, improving safety in use and reducing environmental impact.

KURARAY (EVAL EUROPE N.V.)

Belgium

As product formulas become more complex, they often become more volatile andsensitive to oxygen. EVALâ„¢ provides a functional barrier in both directions: assuring formula integrity and quality while blocking the permeation of external gases and contaminants. Unbreakable all-plastic barrier structures with EVALâ„¢ allow transparencyand squeezability for safe and convenient use. In addition to flexible pouches and SUP, typical applications inlcude ampoules, bottles, eye liquid dosers and inhalers.

KURARAY (EVAL EUROPE N.V.)

Belgium

In addition to oxygen and CO 2 gas barrier, EVAL™ provides an outstanding odour barrier, especially useful for ostomy applications. EVAL™’s functional barrier works in both directions, protecting contents against contamination while keeping them from escaping into the environment. Flexible barrier structures provide an efficient disposable solution for biomanufacturing. When incinerated, the tiny but functional amounts of EVAL™ in the structure release only CO 2 and water vapour.  No dioxin, no metal residue.

KURARAY (EVAL EUROPE N.V.)

Belgium

EVAL offers a reliable alternative to aluminium foil, with excellent stress crack and pinhole resistance. Multilayer barrier films with EVALâ„¢ can be laminated onto a varietyof different substrates to provide sachets with functional barrier. Sealable and anti-scalping Specific grades of EVALâ„¢ film can be laminated to a substrate, providing the sachet or pouch with both barrier properties and a sealable internal contact layer with excellent anti-scalping properties.

KURARAY (EVAL EUROPE N.V.)

Belgium

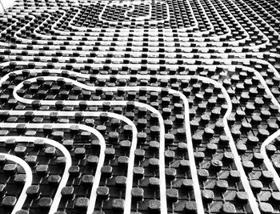

Floor heating systems made of heating pipes of polybutene (PB), polypropylene (PP) or cross-linked polyethylene (PEX) can cause potential corrosion of the metal parts in the heating element due to the oxygen that easily permeates through the plastic pipes and into the heating circuit. To avoid this corrosion several options can be taken: using corrosion resistant material adding rust-preventive agents into the water reducing the oxygen permeability of the pipe. Reducing the oxygen permeability of the pipes is the most secure and economical solution. By using a multilayer pipe made of plastic containing an EVALâ„¢ barrier layer, the oxygen transmission rate will be reduced to a minimum and the corrosion of the metal parts in the heating system is minimised. The gas barrier property of the EVALâ„¢ resins prevents oxygen from permeating through the wall of the pipe and subsequently dissolving into the circulating hot water, thereby corroding metal parts in the heating element. Plastic

KURARAY (EVAL EUROPE N.V.)

Belgium

Barrier geosynthetic liners, or geomembranes, provide a protective layer in landfill, agricultural and industrial sites. The goal is to keep chemicals such as VOCs (volatile organic compounds) and greenhouse gases from diffusing out of stored materials and contaminate the surrounding environment. Adding EVALâ„¢ barrier performance to existing geomembrane designs greatly improves the performance of geomembranes to better protect soil, water and air quality. A cost-effective alternative to expensive remediation of contaminated sites. + Protecting the environment + EVAL barrier against VOCs + EVAL barrier against hydrocarbon VOCs + EVAL barrier against greenhouse gases

KURARAY (EVAL EUROPE N.V.)

Belgium

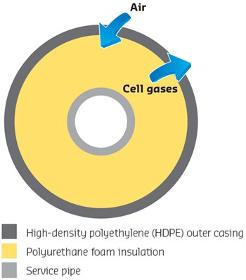

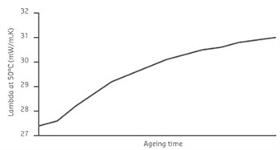

Many pre-insulated pipes use rigid polyurethane foam and a HDPE casing. Over time, the insulation efficiency of the pipe structure decreases, caused by the permeation of air (oxygen, nitrogen) into the foam cells and the diffusion of cell gases (blowing agent, carbondioxide) out of the foam cells. The insulation efficiency of PUR foam decreases as air permeates in and cell gasses permeate out of the pipe structure, increasing thermal conductivity. Oxygen permeation can also lead to oxidative degradation of the PUR-foam insulation itself. This reduces the adhesion between the PUR-foam and inner pipe, weakening the structure and compromising the mechanical integrity of the entire pipe system.

KURARAY (EVAL EUROPE N.V.)

Belgium

Decreasing insulation efficiency The insulation efficiency of PUR foam decreases over time as air permeates in and cell gasses permeate out of the pipe structure, increasing thermal conductivity. Oxygen permeation can also lead to oxidative degradation of the PUR-foam insulation itself. This reduces the adhesion between the PUR-foam and inner pipe, weakening the structure and compromising the mechanical integrity of the entire pipe system. Maintained efficency and improved performance with EVAL™ With EVAL™ the insulation efficiency of the PUR foam is maintained, avoiding an increase in thermal conductivity . Oxygen ingress that can degrade the PUR-foam insulation is also sharply reduced. EVAL™ provides good adhesion to the PUR-foam without additional surface treatement. For more information, please contact Cynthia Teniers

KURARAY (EVAL EUROPE N.V.)

Belgium

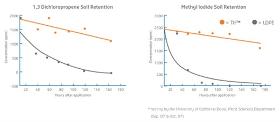

The use of fumigant gases in agriculture helps produce high quality vegetables, fruit and flowers. Â Held in place with plastic sheeting, they sterilise the soil - eliminating pests like nematodes, bacteria, fungi and weeks - boosting yields. Â However, using standard plastic sheeting lets some gas escape into the environment, often with unwelcome side effects. Methyl bromide was a commonly used fumigant, but is an ozone depleting gas, and the Montreal Protocol of 1997 started the search for cost-effective alternatives. Â Many are less harmful for the ozone, yet may cause acute and chronic health risks to field workers and nearby communities. Changing the fumigant gas is not enough; to be both effective and safe, the entire fumigation process must be made as efficient as possible. Adding an EVALâ„¢ barrier layer to fumigant films sharply improves gas retention, blocking permeation to keep fumigants in the soil. Â The improvement is so dramatic compared to other films, that the EVALâ

Manufacturer/ Producer

Haven 1053

Nieuwe weg 1 - bus 10

2070 Zwijndrecht - Belgium

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

SCHWEIZER GMBH & CO. KG

Germany

The transparent hose can be used as a transfer hose for petrol and oil.

Request for a quote

SCHWEIZER GMBH & CO. KG

Germany

Self extinguishing PVS protective covering giving protection against corrosion and abrasion for all type of hoses.

Request for a quote

SCHWEIZER GMBH & CO. KG

Germany

Brake ventilation hoses with visible or concealed wire spiral. The inside is coated with neoprene or silicone, depending on the version. Due to the wire spiral, the hoses are very flexible and can be laid very well even with larger hose diameters.

Request for a quote

SCHWEIZER GMBH & CO. KG

Germany

As a standard, silicone hoses are made with polyester fabric. Reinforced fabrics such as aramid (NOMEX), Kevlar or fiberglass are also available as options. There are special Viton inserts for petrol and oil. All hoses are available by the meter, elbows and reducers. Custommade molded hoses can also be produced according to customer requirements.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free