PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

Manufacturer/ Producer

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

Shredded bark is burned as fuel to generate energy. It is indispensable to supply uniform particle sizes to energy plants. The degree of preparation is determined by the shape and arrangement of the beaters and size reduction elements as well as the rotor speed. Features, Function Shredded bark is fed to shredder from above Rotor with vertical shaft and equipped with oscillating beaters Inside wall of lower housing equipped with size reduction elements and wear plates Gravity discharge of shredded material to below Easy access to lower part of housing for maintenance Advantages Suitable for almost all types of bark High operational safety No risk of clogging, even with longer or wet bark pieces Insensitive to foreign matter of any kind Optimally adaptable to any feed material Maintenance friendly High throughput capacity Low energy requirement

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

For the economical re-chipping of sawmill waste, veneer/plywood waste, screen oversizes and particleboard waste. The machine can be mounted e.g. under the chip screen without intermediate bin. Advantages Adaptability to various material Simple but heavy duty design Extraordinary sturdiness Low maintenance requirements High throughput capacity Low operation costs Quick screen and knife change

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

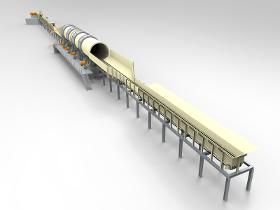

At the beginning of the process for manufacturing wood-based panels is the technology for the professional size reduction of the different wood types. The quality of the chips, strands, flakes, or fibers determines the quality of the panel. Anything neglected at this stage of the process cannot be made up later on. For this reason Siempelkamp offers the complete range of machines for the production of high-quality chips. Technological competence and intensive development work, based on market and customer requirements, result in optimal customer-specific solutions. The line for tree-length logs is designed for the processing of whole logs with lengths of up to 20 meters: With the log feed, debarker, washing system, dosing system all the way to the highly-efficient disc chippers, the production of high-quality chips is guaranteed. Features, Function Feeding of the wood from the truck or storage area Large gantry or rotating cranes for loads of up to 30 metric tons of...

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

At the beginning of the process for manufacturing wood-based panels is the technology for the professional size reduction of the different wood types. The quality of the chips, strands, flakes, or fibers determines the quality of the panel. Anything neglected at this stage of the process cannot be made up later on. For this reason Siempelkamp offers the complete range of machines for the production of high-quality chips. Technological competence and intensive development work, based on market and customer requirements, result in optimal customer-specific solutions. The long-wood line is designed for processing logs with lengths between 3 and 8 meters and diameters between 50 and 850 mm: With the log feed, step feeder, debarker, washing system, dosing system all the way to the highly-efficient disc chippers, the production of high-quality chips is guaranteed. Features, Function Feeding of wood by means of handling cranes or loading vehicles Robust chain cross conveyors for the...

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

At the beginning of the process for manufacturing wood-based panels is the technology for the professional size reduction of the different wood types. The quality of the chips, strands, flakes, or fibers determines the quality of the panel. Anything neglected at this stage of the process cannot be made up later on. For this reason Siempelkamp offers the complete range of machines for the production of high-quality chips. Technological competence and intensive development work, based on market and customer requirements, result in optimal customer-specific solutions. The plantation wood line is designed for processing uniform wooden logs grown in plantations. These logs have lengths between 3 and 8 meters and diameters between 100 and 450 mm: With the log feed, dosing step conveyor, debarker, washing system, dosing system all the way to the highly-efficient disc and drum chippers as well as the mills for the preparation of bark, the production of high-quality chips is...

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

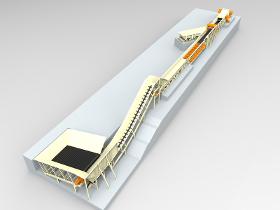

At the beginning of the process for manufacturing wood-based panels is the technology for the professional size reduction of the different wood types. The quality of the chips, strands, flakes, or fibers determines the quality of the panel. Anything neglected at this stage of the process cannot be made up later on. For this reason Siempelkamp offers the complete range of machines for the production of high-quality chips. Technological competence and intensive development work, based on market and customer requirements, result in optimal customer-specific solutions. The scrap and short-wood line is designed for processing root pieces, slabs, edgings, panel waste pieces, windfall wood, and of course logs. With the log feed, step feeder, debarker, washing system, dosing system all the way to the highly-efficient drum chippers, the production of high-quality chips is guaranteed. Features, Function Simple feeding of wood directly from the truck Robust underground bins or vibrating...

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

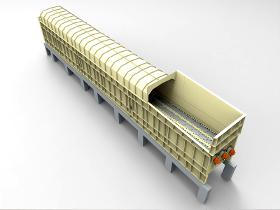

The drum debarker, type PDD, was developed for the economical and gentle debarking of logs. The drum debarker is not only used for the production of fiberboards or OSB but in all industries where thoroughly debarked round logs are required. The system, based on a modular design, was built for the debarking of logs with medium and large diameters at high capacity in order to meet the high demands of panel manufacturers. Features, Function Electromotive drive Power transmission via truck tires Wear-resistant carriers for log transports Adjustable retention time of the logs Debarking by friction of the logs against each other Advantages Adjustable degree of debarking Economical and at the same time gentle debarking Modular design allows an adjustment to the required plant capacity Manufacturing of large-scale machine components on site Options Horizontal conveyer for long logs Gravity feed chute for short logs

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

The rotor debarker is ideal for use wherever reliably and thoroughly debarked logs are required. The abrasive debarking tools make the rotor debarker the first choice for logs that are especially hard to debark and for frozen wood. The narrow design ensures the parallel position of the logs in the machine. The modular design allows high flexibility for a needs-based log feed. Features, Function Modular design Needs-based configuration according to throughput amount, type of wood, and degree of debarking Debarking by means of abrasive and wear-resistant debarking tools Advantages Adjustable degree of debarking Suitable for frozen logs (permafrost) Suitable for logs with different diameters Quiet operation Options 2 or 3 rotors per section

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

Drum chippers prepare long and short round wood, slabs, saw mill waste, veneer waste, board trimmings, and various waste wood into high quality wood chips. Annual plants such as cotton stalks or bamboo can also be processed. The drum chipper size and design can be tailored according to the wood type or infeed material to be prepared and the desired wood chip quality. The most suitable sized chipper is determined by the maximum infeed diameter to be processed and the desired throughput capacity. The required chip length will also influence the performance rate of the chipper. Characteristics, Function Large feed rollers assure a process reliable infeed at a constant speed Pivoted feed system for automatic adjustment of the infeed height Hydraulic swing drive system for constant pressure and shock absorption Robust, electrodynamically balanced chipper rotor Large flywheel effect to compensate for sudden peak loads Amply dimensioned V-belt drive Start process supported by...

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

Professional size reduction technology for the production of chips from different types of wood is at the beginning of particleboard production. The quality of the chips determines the quality of the panel. Anything neglected at this stage of the process cannot be made up later on. For this reason we offers the complete range of machines for the production of high-quality surface and core layer chips. With technology for the screening, cleaning, secondary crushing, storing, dosing, sifting, and, of course, chipping and chip transportation, the production of high-quality surface and core layer chips is guaranteed. Advantages Optimal and consistent flake quality Low production costs and high operational safety Optimal use of throughput capacity Extremely high plant availability Minimal downtimes Lowest energy costs per produced ton of flakes

Request for a quoteManufacturer/ Producer

Wolfslochstraße 51

66482 Zweibrücken - Germany

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

NOVELTY STEEL

Turkey

The primary crusher selection is the key to the success of the mining, quarrying or industrial minerals operation that involves the reduction in size of rock, ore or minerals. The crushing plant can be provided with almost any type of primary rock crusher. Novelty Steel supplies; * Cone Crushers * Jaw Crushers * Gyratory Crushers * Impact Crushers * Mobile Crushers

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Jaw plate and Side plate for Jaw crusher; Mantle, Concave for Cone Crusher; Blow bar and Hammer for Impact Crusher and Hammer/Metal crusher; Roller and Ring for Raymond Mill; Roller Liner and Disc Liner for Sand making VSI Crusher, Chocky bar and Wearing button for Excavator, which is in the material of High Manganese Steel Mn13Cr2/ Mn14Cr2/Mn17Cr2/Mn18Cr2/Mn22Cr2; High Chrome White Iron Cr20/Cr22/Cr24/Cr26, and its with Mo, Ni, Re, Ceramic, Alloy, Bi-metal etc wear-resistant materials. And HUAN-TAI products support for Shanbao, SBM, Liming, Shibang, Zenith, Metso, Sandvik, Barmac, Trio, TEREX, Pegson, Powerscreen, Kleemann, MINYU, Symons, Hazemag, Cedarapids, McClosey, Keestrack, Telsmith, Russian brands and other famous brands machine. We also can produce the wearing spare parts as per customers’ own drawings

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Jaw plate and Side plate for Jaw crusher; Mantle, Concave for Cone Crusher; Blow bar and Hammer for Impact Crusher and Hammer/Metal crusher; Roller and Ring for Raymond Mill; Roller Liner and Disc Liner for Sand making VSI Crusher, Chocky bar and Wearing button for Excavator, which is in the material of High Manganese Steel Mn13Cr2/ Mn14Cr2/Mn17Cr2/Mn18Cr2/Mn22Cr2; High Chrome White Iron Cr20/Cr22/Cr24/Cr26, and its with Mo, Ni, Re, Ceramic, Alloy, Bi-metal etc wear-resistant materials. And HUAN-TAI products support for Shanbao, SBM, Liming, Shibang, Zenith, Metso, Sandvik, Barmac, Trio, TEREX, Pegson, Powerscreen, Kleemann, MINYU, Symons, Hazemag, Cedarapids, McClosey, Keestrack, Telsmith, Russian brands and other famous brands machine. We also can produce the wearing spare parts as per customers’ own drawings

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Jaw plate and Side plate for Jaw crusher; Mantle, Concave for Cone Crusher; Blow bar and Hammer for Impact Crusher and Hammer/Metal crusher; Roller and Ring for Raymond Mill; Roller Liner and Disc Liner for Sand making VSI Crusher, Chocky bar and Wearing button for Excavator, which is in the material of High Manganese Steel Mn13Cr2/ Mn14Cr2/Mn17Cr2/Mn18Cr2/Mn22Cr2; High Chrome White Iron Cr20/Cr22/Cr24/Cr26, and its with Mo, Ni, Re, Ceramic, Alloy, Bi-metal etc wear-resistant materials. And HUAN-TAI products support for Shanbao, SBM, Liming, Shibang, Zenith, Metso, Sandvik, Barmac, Trio, TEREX, Pegson, Powerscreen, Kleemann, MINYU, Symons, Hazemag, Cedarapids, McClosey, Keestrack, Telsmith, Russian brands and other famous brands machine. We also can produce the wearing spare parts as per customers’ own drawings

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free