REP INTERNATIONAL - Rubber in Motion

France

Manufacturer/ Producer

REP INTERNATIONAL

France

Performance range G10 Extended Intelligent, elegant and efficient The G10 is the 10th generation of REP injection molding machines. With its ergonomic design and intelligent onboard solutions, the G10 generation is branded "Infinitely Smart". The G10 is available in two versions, G10 Core (Lean range) and G10 Extended (Performance range), designed to better meet the varied needs of customers. The G10 Extended is a line of presses adapted to the most demanding processes. The G10 Extended is progressively replacing the G9 generation machines and ranges from 1,600 kN (V410) to 10,200 kN (V910).

Request for a quote

REP INTERNATIONAL

France

Lean range G10 Core The G10 is the 10th generation of REP injection molding machines. With its ergonomic design and intelligent onboard solutions, the G10 generation is branded "Infinitely Smart". The G10 is available in two versions, G10 Core (Lean range) and G10 Extended (Performance range), designed to better meet the varied needs of customers. Lean range G10 Core Vertical rubber injection molding machines REP ideal for less demanding processes. The G10 Core range exists with three clamping forces 1,600 kN 3,050 kN 5,100 kN.

Request for a quote

REP INTERNATIONAL

France

The CMX (Compact Multi Station of the generation 10) This new machine replaces the former CMS generation and makes the third generation of rotary machines with 2 major innovations. Integration of the processcontrol system of the latest generation (generation 10) with all 4.0 functions. Product range with the CMX1 (160T clamping force) and the CMX2 (250T clamping force). New generation of 4station molding machines The REP solution for large productions with optimal efficiency 90% increase in productivity compared with a singlestation press. 68% increase in productivity compared with a press equipped with a double plate stripping kit. The CMX machine is available with two clamping forces 160T (CMX1) or 250T (CMX2).

Request for a quote

REP INTERNATIONAL

France

Horizontal range H49, H59, H610 The range is designed for easy implementation of automated production processes, namely injection moulding of more or less sophisticated technical parts. Clamping force available from 1,950 kN to 4,000 kN. Shown above press types H49, H59 and H610 (with and without brush).

Request for a quote

REP INTERNATIONAL

France

In short, large flat gasket REP machines mean Clamping quality Thick traverses, multiple synchronized clamping operations; Injection of long thin sections Injection pressure up to 3,000 bar and circuit division with several injection units; Productivity Very fast 3step clamping, doubleplate kits; Ergonomics/access to the mold Widthwise heating plates, demolding kit or sliding platen. These types of machines have been developed for largeseries injection molding involving parts with inserts, for example the injection molding of battery pack seals. Based on its longstanding experience in this field, REP offers a comprehensive range of machines with largesized heating plates and adjustable configurations to fully comply with the technical specifications of each application and all client’s needs.

Request for a quote

REP INTERNATIONAL

France

REP studies your solution! REP answers questions that cannot be resolved using conventional techniques. An "advanced" competence accompanied by the guarantees of the REP GROUP! A team of engineers is at your disposal for the study and realization of presses for special applications. A REP solution for every problem! We are able to meet your most complex requirements,

Request for a quote

REP INTERNATIONAL

France

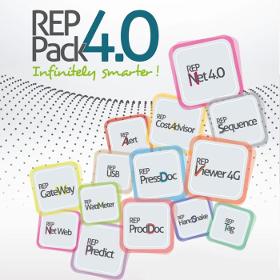

Thanks to REP Pack 4.0, REP introduces new technologies into the industrial processes of their customers. REP Pack 4.0 includes 14 modules REP Net 4.0 / REP CostAdvisor / REP ProdDoc / REP Predict / REP HandShake / REP Tag / REP Viewer 4G / REP PressDoc / REP Sequence / REP Net Web / REP WattMeter / REP USB / REP Gateway / REP Alert. They allow for the real time supervision of the workshop, centralized settings and the analysis and calculation of the process profitability. RESPONSIVENESS AND FLEXIBILITY Availability of the resources Continuous and instantaneous communication between the different production sites Real time adaptation to the process requirements Storyboarding of a production cycle PRECISION AND EFFICIENCY Traceability Conformity check (fast identification of a faulty production) Optimized energy consumption Decision support thanks to production simulations

Request for a quote

REP INTERNATIONAL

France

The "Cold Runner Block" systems, also called "CRB", are used in injection molding processes to feed the compound as close as possible to the cavity by limiting so far the formation of runners or sprues. Let’s take a look at the 4 major advantages of Servobloc Sequential diagnostic Closed loop control of the speed and position of the valves Gate size is a settable parameter No risk of oil contamination Suitable for a wide range of soft or hard rubbers, from silicone to fluorocarbon rubber, the ServoBloc is completely integrated to your press (retrofit possible).

Request for a quote

REP INTERNATIONAL

France

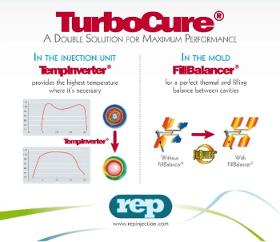

High technology range TurboCure®. The purpose of the Turbocure® solution consists in reducing the curing time by up to 50%. It includes the modules TempInverter® and FillBalancer®. They can be used together or individually depending on the application. This solution respects the integrity of the compound by focusing on improved quality.

Request for a quote

REP INTERNATIONAL

France

V410 LSR Machine features Clamping force 1,600 kN. Size of the platens 430 x 510 mm. Injection volume 1,000 cm³. Machine which is particularly used for the production of flat gaskets as used in fuel cell applications. This machine is available in our showroom « Area 111 » in Corbas (France) to perform your test runs for the injection molding of LSR parts.

Request for a quote