RUHLAMAT GMBH

Germany

Manufacturer/ Producer

RUHLAMAT GMBH

Germany

Different aspects such as productivity, assembly operations, material flow, type variety, setup times and space conditions influence the concepts of linear transfer systems and form the foundation for many flexible automated solutions and linear transfer systems of modular construction. A high level of accessibility and the resulting low-maintenance design can count as additional advantages. ruhlamat offers varying base modules that can be adapted individually to the relevant circumstances in order to accommodate a wide range of requirements. Since production space is also becoming increasingly scarce and the assembly of products is becoming ever more challenging, ruhlamat offers a variety of solutions to maximise the spatial potential of the linear transfer systems. For example, the integration of the control cabinet in the base frame of the assembly cell, or the flexible back-pack variant on the "spine" of the cell, or as a stand-alone solution next to or above the linear...

Request for a quote

RUHLAMAT GMBH

Germany

Automated solutions based on rotary transfer systems are optimum and space-saving alternatives for high quantity demands and long product life cycles. Quick - minimal workpiece changing times Space saving - the lowest space requirements Precise - accurate workpiece positioning Cheap - low investment costs with model extensions Optimal - for high quantity demands Joining / bonding O-ring assembly Dosing Wire embedding Testing / Measuring Labelling / Marking Welding Here you will find a selection of applied technologies and processes in ruhlamat specialized machines.

Request for a quote

RUHLAMAT GMBH

Germany

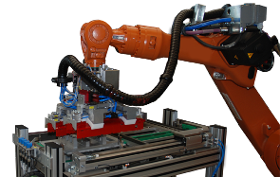

Constant changes in our customers' markets mean that solutions must be quickly implemented. Robot applications by ruhlamat are characterized by extremely rapid handling times compared to the competition. Robots, as the core of automated solutions, offer the advantage of being easily convertible and have a high level of flexibility for the integration of variants and / or new processes. In doing so, ruhlamat integrates all popular robot applications from different manufacturers, depending on the requirements of the customer, or assimilates existing robotics expertise into your production and/or assembly. The application range is endless! Whether as a pure handling device (e.g. extraction cells from injection moulding machines, pick and place) or as the centrepiece of hybrid assembly cells (i.e. work content split between operator and robot): simple convertibility and operational flexibility guarantee the highest possible investment security with high operational...

Request for a quote

RUHLAMAT GMBH

Germany

Are you looking for a flexible means of increasing your production and would thereby like to find out about a proven investment? Manual workstations from ruhlamat based on the Chaku Chaku principle provide the best solution to support you here. The worker assumes only the transport of workpieces from station to station for solutions based on the Chaku Chaku principle. The stations themselves work fully, or at least semi-automatically, where cycle time differences between the stations are absorbed by buffers. Manual workstations can be an ideal solution particularly in the case of uncertain part quantity forecasts since it can be the most flexible method of responding to fluctuations in part numbers thanks to different deployment of personnel (single or multi-station operation). The manual workstations from ruhlamat can be planned jointly with the customer taking into account the prospective issue of quantities. As a result, subsequent expansion with linear transfer systems or...

Request for a quote

RUHLAMAT GMBH

Germany

With the ruhlamat FILUS and the WCE2D, you can achieve large-area and precise wire-embedding results. In addition to wire embedding, pick-and-place handling and cutting, this 2D wire-embedding solution is also precise at soldering and dosing. 3D Wire embedding technology The WCEvario3D captivates through its flexible application options: From flat surfaces to concave and convex contours, the flexible robotic arm with a state-of-the-art wire-laying head and constant pressure-force control can handle all dimensions. 2D Wire embedding technology 2D Wire embedding technology With the ruhlamat FILUS and the WCE2D, you can achieve large-area and precise wire-embedding results. In addition to wire embedding, pick-and-place handling and cutting, this 2D wire-embedding solution is also precise at soldering and dosing. 3D Wire embedding technology 3D Wire embedding technology The WCEvario3D captivates through its flexible application options: From flat surfaces to concave and...

Request for a quote

RUHLAMAT GMBH

Germany

Test systems and inspection systems form an integral part of most of the automated solutions we employ. Each assembly process is usually followed by an inspection process so that the highest quality requirements can be satisfied. Both laboratory as well as stand alone or inline series inspection systems (EOL) have already been widely implemented by ruhlamat. Inspection results (product/process data) are documented in individual or customer-specific databases (traceability). Seamless traceability of product and process data Inline process control and monitoring Efficiency through timely trend control 100% inspection

Request for a quote

RUHLAMAT GMBH

Germany

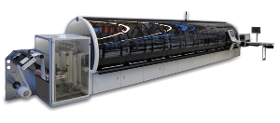

The PowerSeal sets new benchmarks for high-speed encapsulation of chip modules: extremely compact and powerful, with a throughput of up to 40,000 modules/hour using two 16-fold dispensing heads and UV LED curing technology. UV LED curing saves production cost by lower energy consumption and long LED lifetime without aging. The curing is much faster compared to standard UV discharge lamps and the start-up time is reduced by providing full power directly after switching on. This enables high-speed production with significantly lower cost per module, resulting in an unsurpassed value for money. Alternatively, the machine can also be equipped with UV discharge lamps or heating units. Diverse nozzle plates are available for the different module tape pitches. Thermal curing resins such as black epoxy can be processed optionally. Reliable process stations and automated inline quality control ensure highest quality at a minimum of cost per module. High-speed chip module encapsulation...

Request for a quote

RUHLAMAT GMBH

Germany

The PowerTest is a sophisticated testing and encoding system for chip modules on 35 mm tapes. Maximum flexibility allows versatile use: It can be used by card manufacturers for the incoming inspection or encoding of chip module tapes, and with integrated disconnect station by module tape manufacturers as a quality measurement system for the inspection of outgoing goods. Testing of contact, contactless and Dual Interface IC modules can be executed with the highest performance and yield by processing of up to 128 modules in parallel. In addition to basic test and parameter test, software is also available for chip module initialisation, personalisation, and OS loading. Integration of SAM, HSM, or similar modules can be realised easily. Using high-end reader technology from Smartware or Micropross, this automatic IC module test handler offers unmatched performance for the complete production test of smart card and RFID modules. Flexible reel to reel system for high-speed test,...

Request for a quote

RUHLAMAT GMBH

Germany

Permanent fixation of a chip module is crucial for every smart card to meet the different demands of ID cards, banking cards, GSM /SIM cards, and dual interface cards. The GTL700 is a highly reliable and flexible solution for glue tape lamination of chip module tapes in preparation for the hot melt implanting process. The glue tape is laminated onto the backside of the module tape. To accommodate the chip, holes are punched into the glue tape prior to lamination. The system operates stand-alone or inline, and is suitable for a wide range of IC module tapes. Various punching and laminating tools are available, which can be exchanged with a few simple steps. Optional reel units allow use of an additional protection tape and separation of carrier tape. Highest yield, maximum machine uptime and short product changeover times lead to very low cost of ownership Up to 8,000 chip modules/hour High flexibility for all IC module types and sizes, including dual interface Adjustable...

Request for a quote

RUHLAMAT GMBH

Germany

The WCE2000 sets the standard for high-speed wire embedding and RFID inlay production: Superior quality, highest accuracy and unmatched productivity at an unbeatable price-performance ratio. The system can be designed to perfectly match your needs: sheet to sheet (S2S), reel to sheet (R2S), or reel to reel (R2R). This flexible solution offers the most economical way to produce RFID inlays for ID documents in large quantities. You get unrivalled real-world throughput: up to 4,050 antennas/hour as antenna embedding machine and up to 2,000 finished RFID inlays/hour as inlay manufacturing line. The WCE2000 is available in virtually unlimited configurations. Wire coil embedding, module pick & place, soldering, and testing are the main features that can be integrated to build a tailor-made solution. Punching, sheet cutting, handling and collation of additional layers, and other features complement the system to a complete inlay manufacturing line. The possibility to combine all of...

Request for a quoteManufacturer/ Producer

Sonnenacker 2

99819 Marksuhl - Germany

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

GEMONE

Belgium

This service includes connection to any type of machine, integration with your current hardware and software, providing end-user training during onboarding, and swiftly and securely handle your data in the Cloud. This allows you to concentrate entirely on your business.

Request for a quote

GEMONE

Belgium

Stay informed about the precise location of your machines at all times, whether they're inside your facility, on your premises, or in transit. Each machine is equipped with a durable tracker that maintains continuous communication with the GemOne platform.

Request for a quote

AIS HENSCH AUTOMATION-INDUSTRY- SOLUTIONS INH. IGOR HENSCH

Germany

The industrial CPUs from AIS Hensch Automation-Industry-Solution represent a first-class solution for controlling automated production processes in various industrial sectors. These CPUs are characterized by their technological excellence, reliability and versatility, making them an indispensable component for optimizing manufacturing processes. Thanks to their powerful processing, our industrial CPUs offer precise control that can be seamlessly integrated into a wide variety of production environments. From the oil and gas industry to mechanical engineering, these CPUs flexibly adapt to the specific requirements of different industries. The robustness and longevity of our industrial CPUs ensure reliable performance even under demanding conditions.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free