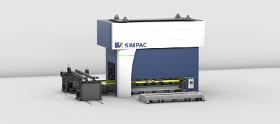

Besuchen Sie uns auf der Blechexpo in Stuttgart!

Participation in an event ・ 14 Oct 2019 ・ read moreEXPLORE THE DIFFERENCE. Unter diesem Motto stellt sich das Team von Simpac Europe auf der Blechexpo 2019 vor. In Halle 8 am Stand 8003 erfahren Besucher mehr über die Vorteile einer Partnerschaft mit Simpac. Denn Simpac versteht sich nicht nur als Pressenlieferant, sondern als Berater, der mit umfassendem Prozesswissen die individuell bestmögliche Lösung anbietet. Kernstück der Produktpräsentation sind die neu entwickelten Servopressen-Baureihen MX und SX (3.000-30.000 kN). Das erste Ergebnis dieser deutsch-koreanischen Entwicklung wird im Herbst 2020 bei einem Kunden von Simpac im süddeutschen Raum im Rahmen einer Veranstaltung live zu sehen sein. Aber auch konventionell angetriebene Pressen sind immer noch Teil des Produktprogramms – von Stanzautomaten über Exzenterpressen bis hin zu Linkpressen mit modifizierter Stößelkinematik – um den Kunden die individuell bestmögliche Lösung anbieten zu können. Kommen Sie vorbei und entdecken Sie den Unterschied!