- europages

- >

- Milling - machine tools

- >

- STARRAG GMBH

- >

- products

STARRAG GMBH

Germany

Manufacturer/ Producer

STARRAG GMBH

Germany

With the addition of a moveable table, traversing through the twin column portal design of the VC machine range, the VCV provides the ultimate flexibility for machining large components. In addition to the «on center» machining capability of a standard lathe the VCV machines are able to machine eccentric features. With the use of our extensive range of standard milling and drilling attachments, the VCV machine range is capable of full 5 sided machining of components up to 12,000 mm in diameter and 350 tons in weight. On machines with a Yaxis the component can be machined in any position. The turning table is set on a sliding bed. The default Yaxis travel corresponds to the swing diameter of the machine size, but can be tailored to suit any application.

Request for a quote

STARRAG GMBH

Germany

With the addition of a moveable table, traversing through the twin column portal design of the VC machine range, the VCV provides the ultimate flexibility for machining large components. In addition to the «on center» machining capability of a standard lathe the VCV machines are able to machine eccentric features. With the use of our extensive range of standard milling and drilling attachments, the VCV machine range is capable of full 5 sided machining of components up to 12,000 mm in diameter and 350 tons in weight. On machines with a Yaxis the component can be machined in any position. The turning table is set on a sliding bed. The default Yaxis travel corresponds to the swing diameter of the machine size, but can be tailored to suit any application.

Request for a quote

STARRAG GMBH

Germany

With the addition of a moveable table, traversing through the twin column portal design of the VC machine range, the VCV provides the ultimate flexibility for machining large components. In addition to the «on center» machining capability of a standard lathe the VCV machines are able to machine eccentric features. With the use of our extensive range of standard milling and drilling attachments, the VCV machine range is capable of full 5 sided machining of components up to 12,000 mm in diameter and 350 tons in weight. On machines with a Yaxis the component can be machined in any position. The turning table is set on a sliding bed. The default Yaxis travel corresponds to the swing diameter of the machine size, but can be tailored to suit any application.

Request for a quote

STARRAG GMBH

Germany

With the addition of a moveable table, traversing through the twin column portal design of the VC machine range, the VCV provides the ultimate flexibility for machining large components. In addition to the «on center» machining capability of a standard lathe the VCV machines are able to machine eccentric features. With the use of our extensive range of standard milling and drilling attachments, the VCV machine range is capable of full 5 sided machining of components up to 12,000 mm in diameter and 350 tons in weight. On machines with a Yaxis the component can be machined in any position. The turning table is set on a sliding bed. The default Yaxis travel corresponds to the swing diameter of the machine size, but can be tailored to suit any application.

Request for a quote

STARRAG GMBH

Germany

With the addition of a moveable table, traversing through the twin column portal design of the VC machine range, the VCV provides the ultimate flexibility for machining large components. In addition to the «on center» machining capability of a standard lathe the VCV machines are able to machine eccentric features. With the use of our extensive range of standard milling and drilling attachments, the VCV machine range is capable of full 5 sided machining of components up to 12,000 mm in diameter and 350 tons in weight. On machines with a Yaxis the component can be machined in any position. The turning table is set on a sliding bed. The default Yaxis travel corresponds to the swing diameter of the machine size, but can be tailored to suit any application.

Request for a quote

STARRAG GMBH

Germany

With the addition of a moveable table, traversing through the twin column portal design of the VC machine range, the VCV provides the ultimate flexibility for machining large components. In addition to the «on center» machining capability of a standard lathe the VCV machines are able to machine eccentric features. With the use of our extensive range of standard milling and drilling attachments, the VCV machine range is capable of full 5 sided machining of components up to 12,000 mm in diameter and 350 tons in weight. On machines with a Yaxis the component can be machined in any position. The turning table is set on a sliding bed. The default Yaxis travel corresponds to the swing diameter of the machine size, but can be tailored to suit any application.

Request for a quote

STARRAG GMBH

Germany

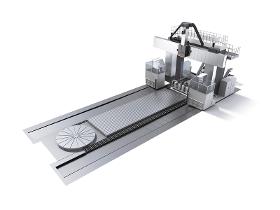

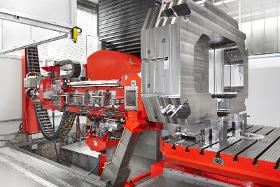

How can large, heavyduty and bulky workpieces be processed without adversely affecting the weight and size of the machining result? The Droop+Rein G/GF series has been specifically developed to tackle this difficult task. The gantry machines reliably prevent dynamic losses through the table and workpiece. The G/GF series has many technical highlights to meet the requirements of complex machining tasks, such as the hydrostatic guide in all linear axes or the thermosymmetrical design of the spool milling unit with an integrated Caxis. Milling heads can be changed automatically via a head change interface. Droop+Rein has developed over 300 different milling heads for a variety of applications such as machining large diesel engines. The option to set up in a second working area during the machining time allows increased productivity.

Request for a quote

STARRAG GMBH

Germany

Gantry design For machining of largest and heaviest workpieces Droop+Rein offers a floor guided gantry machine line. Best accessibility and utilisation of floor space for largest workpieces combined with highest flexibility in size and configuration. Cross rail, moveable (GS) or fixed (GFS) Economic machining of largest components – flexible, dynamic and precise Floor space savings compared to table moving machines In line with the modular principle – various controls, table configurations, milling head/spindles and tool changer configurations

Request for a quote

STARRAG GMBH

Germany

With the FOGS NEO series, Droop+Rein has developed a powerful machine concept for complex machining. The range of services covers processes from machining standard geometries and prefinishing contours to final finishing. For dynamic machining with the highest feed rates, the concept caters for the movement and acceleration of constant masses, regardless of workpiece size and weight. Dynamic and flexible With its new, highly flexible and fast Caxis (±400°), the Droop+Rein FOGS NEO highspeed machining centre is ideal for the complete multifunctional machining of very large workpieces. Of course, the series also features automatic pallet or tool change, tool diameter and length measurement and automatic billing of contour deviations. Thanks to a variety of components and peripheral devices from their modular system, Droop+Rein can create an efficient and processoriented overall system that is tailored to the customer.

Request for a quote

STARRAG GMBH

Germany

In order to produce heavy workpieces with limited available space, Droop+Rein combined the FOGS and TF machine types which are already established on the market into a new machine concept. With the FOGS HD, Droop+Rein offers a machining centre for heavyduty machining, which features high quality and precision at the same time. The constant dynamic dimensions of the Droop+Rein FOGS HD enables the user to use the machine for unmanned finishing e.g. at night or at the weekend. The Droop+Rein FOGS HD is designed for large components, as the traverse paths show (Xaxis 3,000 to 31,000 mm; Yaxis 3,000 to 6,000 mm; Zaxis 1,500 to 2,500 mm). It covers all machining operations within typical toolmaking. The FOGS HD is an efficient (50 to 100 kW (S1 operation)), precise machining highgantry machine with fast and dynamical axes and extreme high torque (2,400 to 7,500 Nm).

Request for a quoteeuropages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

EMSIL TECHTRANS SRL

Romania

Gundrilling and milling centres for molds

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

High polish stainless steel flanges are not just functional components in piping systems; they also offer a visually appealing finish that is smooth and reflective. This high polish, often achieved through a process called electropolishing, provides several benefits: Electropolishing Process. Electropolishing is an electrochemical process that removes a thin layer of material from the stainless steel surface, resulting in a smooth and mirror-like finish. This process can also improve the corrosion resistance of the stainless steel by removing surface imperfections where corrosive agents could potentially take hold. Advantages of High Polish Finish Improved Corrosion Resistance: The smoother surface reduces the number of crevices where corrosion could start, thus enhancing the flange’s longevity. Easy Cleaning: High polish surfaces are easier to clean and sanitize, which is particularly beneficial in industries like food processing and pharmaceuticals.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Aluminium CNC milling part in black anodize finish Tolerance:+/-0.05mm, Critical holes and threads Surface rougness:Ra1.6 CNC Machining parts, Machining in Aluminium stainless steel,brass,copper, titanium,POM and so on. Aluminium housing, Blocks, flanges, valve seat, supporter CNC Turning parts ,Machining in Aluminium stainless steel,brass,copper, titanium,POM and so on.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free