THIELMANN ENERGIETECHNIK GMBH - GAS FILTRATION & VORWÄRMUNG

Germany

Manufacturer/ Producer

THIELMANN ENERGIETECHNIK GMBH

Germany

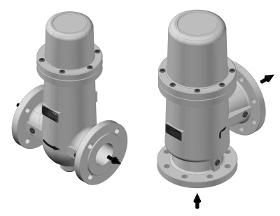

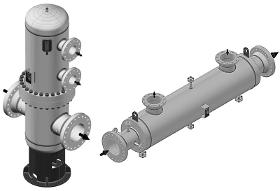

CHARACTERISTICS budget priced short installation length type VZF and ZFG high filtration rate (efficiency) replacable filter cartridges large dust collection area VZF / ZFG dust drain nozzle N3 upstream coarse particle separation 4-way differential pressure connections DVGW certified for all gases according to G260 for non-aggressive special gases many sizes in stock VARIANTS Silumin Cast (VZF/VZEF) Cast Iron (ZFG/ZEFG) Straight Through – VZF/ZFG | DN25 – DN150 Corner Type – VZEF/ZEFG | DN25 – DN100 PN16 | -10 / +70 °C PN16 | -20 / +70 °C PN16 | -40 / +70 °C PN16 | -10 / +150 °C zzgl. TÜV HTB (5 bar g) | -20 / +70°C PN40 | -10 / +70 °C DN25-DN80 PN40 | -20 / +70 °C DN25-DN80 PN40 | -40 / +70 °C DN25-DN80 DNV (maritime) DN25 – DN100, 10 bar g | 0 /+60°C Leaflet: E-5055 Cellular Gas Filter / Type VZF/VZEF/ZFG/ZEFG FUNCTION The gas flows through the inlet nozzle into the filter housing.

Request for a quote

THIELMANN ENERGIETECHNIK GMBH

Germany

ZPZ – VPZ 240°C-Filterelemente (Finalfilter) for cellular gas filters: ZPZ 25 – ZPZ 50 – ZPZ 80 – ZPZ 100 – ZPZ 150, type FFX Efficiency: 99,9 > 1µm In the area of fine dust separation, the gas is cleaned with filter cartridges. Our filter cartridges are all tested according to ISO 12103-01 and proven to be efficient, according to the requirements of the internationally valid “Test Aerosol: SAE-Fine Test Dust”. For special fields of application we can offer and develop special filter elements in order to achieve a performance-fulfilling filtration.

Request for a quote

THIELMANN ENERGIETECHNIK GMBH

Germany

CHARACTERISTICS Efficient dust filtration High deposition rate (efficiency) Filter efficiency tested acc. SAE Fine Test Long service life of the filter elements Upstream coarse particle separation For all gases according to G260 For non-aggressive special gases OPTIONEN Customer-specific design for other regulations (ASME, EN 13445, SVTI, AS1210, PD5500, etc) Customer-specific approvals Customer-specific testings Application for sour gas (NACE) Design for low temperature down to -50 ° C Design pressure up to 300 bar Design temperature up to 250 ° C Customer-specific nozzle arrangement Leaflet (english version in progress): D-5025 Patronenfilter / Typ VPF General Cartridge filters are used to clean gas from dry solid dust particles. The design is carried out as a steel welded construction. FUNCTION The gas flows through the inlet nozzle into the filter housing.

Request for a quote

THIELMANN ENERGIETECHNIK GMBH

Germany

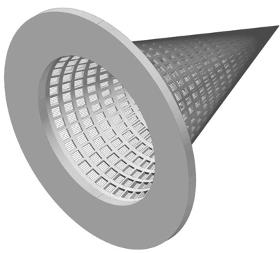

CHARACTERISTICS For clamp mounting into the pipeline Efficient protection of dirt-sensitive system components during commissioning Low differential pressure Easy installation and replacement Material Certificates DIN EN 10204/3.1 for Clamp Collar OPTIONS For DIN and ASME flange connections Design for low temperature down to -50 ° C Design pressure up to 100 bar Stainless steel construction Reverse flow direction GENERAL The starting screen VAS is used for commissioning and starting a system in order to clean gas from coarse soiling such as welding bead, scale, grease, etc. After starting, the starting screen can be removed from the pipeline. The design is carried out as a welding design. FUNCTION The starting screen VAS consists of a supporting basket made of perforated sheet metal with a welded clamping ring. These are galvanized after assembly. On the outside of the support basket a stainless steel wire mesh is welded.

Request for a quote

THIELMANN ENERGIETECHNIK GMBH

Germany

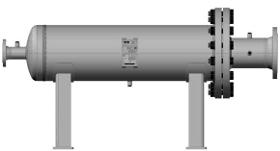

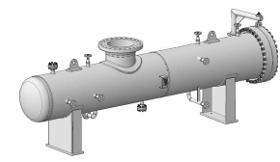

TUBE BUNDLE HEAT EXCHANGER, TYPE VEV/VEV-L/VEV-ex Gas / Water; horizontal / vertical CHARACTERISTICS Optimal load case design Flow stream optimized design Vibration-optimized design OPTIONS Customer-specific design for various design codes (ASME, EN 13445, SVTI, AS1210, PD5500 etc.) Design according to TEMA Customer-specific approvals Customer-specific testings Application for sour gas (NACE) Design for low temperature down to -50 ° C Design pressure up to 300 bar Customer-specific nozzle arrangement GENERAL Heat exchangers (heat exchangers) heat gas for a subsequent system requirement or to counteract the Joule-Thomson effect. For example, For example by pressure reduction in a gas-pressure control. Heat exchangers can also be determined in the reverse mode of operation as coolers. The design is carried out as a steel welded construction in vertical or horizontal design.

Request for a quote

THIELMANN ENERGIETECHNIK GMBH

Germany

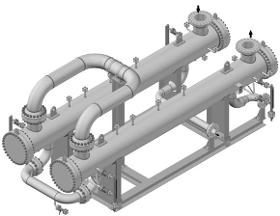

CHARACTERISTICS optimum thermal efficiency optimum efficiency of the turbine optimum load-case design flow optimized design vibration-optimized design OPTIONS custom specific design on international design codes (ASME, EN 13445, SVTI, AS1210, PD5500 etc.) design acc. to TEMA custom specific TPIs (Inspections / Third Party Inspections) custom specific testings sour gas application (NACE) temperature range -50 °C till + 350°C custom specific nozzle orientation GENERAL Performance Heaters, type VEV-LS are serially arranged heat exchangers, which heat up gas for a subsequent system requirement. Performance heaters can also be designed as coolers in reverse. The design is carried out as a steel welded construction in a horizontal design. FUNCTION Fuel Gas Performance Heater Type VEV-LS are used in high efficient combined-cycle gas and steam power plants (CCPP).

Request for a quote

THIELMANN ENERGIETECHNIK GMBH

Germany

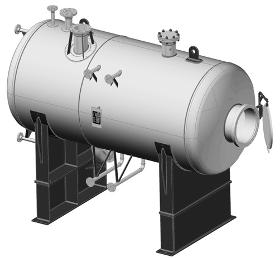

CHARACTERISTICS Decentralized application Optimal load-case design Optimized flow stream design Vibration-optimized design Leaflet: E-3015-Waterbath Heater / Type VH OPTIONS FOR HIGH PRESSURE TUBE BUNDLE Customer-specific design for various design codes (ASME, EN 13445, SVTI, AS1210, PD5500 etc.) Design according to TEMA Customer-specific approvals Customer-specific testings Application for sour gas (NACE) Design for low temperature down to -50 ° C Design pressure up to 300 bar Customer-specific nozzle arrangement Water jacket design as pressure vessel Water tank vessel for hot water> 100 ° C GENERAL Indirect water bath heaters type VH are heat exchangers (heat exchangers) which can heat the gas decentrally if no hot water treatment (for example a boiler system) is available. The heating of the gas is necessary in order to counteract the Joule-Thomson effect during pressure reduction or to provide a defined gas temperature for the following system components. The most common...

Request for a quote

THIELMANN ENERGIETECHNIK GMBH

Germany

CHARACTERISTICS efficient noise reduction up to 30 dB for use after the control valve OPTIONS custom specific design on international design codes (ASME, EN 13445, SVTI, AS1210, PD5500 etc.) design acc. to TEMA custom specific TPIs (Inspections / Third Party Inspections) custom specific testings sour gas application (NACE) temperature range -50 °C till + 300°C design pressure up to 300 bar custom specific nozzle orientation GENERAL Absorption silencers type VSD are used to reduce noise by the control valve up to 30 dB. The design is carried out as a steel welded construction in a horizontal design. FUNCTION in progress QUALITY MANAGEMENT DIN EN ISO 9001 certified Our vessels are tested according to AD 2000 regulations and CE-certified according to EC / PED 2014/68 / EU. The examination is carried out by authorized inspectors (TÜV, Lloyd’s Register, etc.). Test and material certificates are prepared by the inspectors according to the design specification.

Request for a quote

THIELMANN ENERGIETECHNIK GMBH

Germany

CHARACTERISTICS Pressure vessel design Volume according to customer requirements OPTIONEN Customer-specific design for other regulations (ASME, EN 13445, SVTI, AS1210, PD5500, etc) Customer-specific approvals Customer-specific testings Application for sour gas (NACE) Design for low temperature down to -50 ° C Design pressure up to 300 bar Design temperature up to 250 ° C Customer-specific nozzle arrangement ACCESSORIES on demand level indicators condensate drainage systems sump heating GENERAL & FUNCTION The condensate tank type VKAB collects liquids and condensates, which are generated during the cleaning of gas in liquid separators. The condensates are discharged from the separators into the tank and serve for pressureless intermediate storage. The design is carried out as a steel welded construction in a horizontal design and is designed as a pressure vessel with 3 bar. QUALITY MANAGEMENT DIN EN ISO 9001 certified

Request for a quote

THIELMANN ENERGIETECHNIK GMBH

Germany

A pressure vessel type VEDB is a custom specific pressure vessel without internals and is generally used as a buffer or expansion vessel. For the discharge of possibly occurring condensate, the pressure vessel is equipped with a drain connection. The condensate can be collected in a subsequent condensate tank type VKAB. The condensate can be collected in a subsequent condensate tank type VKAB.

Request for a quoteeuropages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

SCHWEIZER GMBH & CO. KG

Germany

Universal tank caps and threaded flanges.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free