UNITED PROCESS CONTROLS GMBH

Germany

Manufacturer/ Producer

UNITED PROCESS CONTROLS GMBH

Germany

Protherm controllers are universal configurable programmers that monitor, control and record processes running in a single furnace or simultaneously in multiple chambers. They are configurable for various types of batch and continuous furnaces. Installations are done on new or refurbished furnaces and are used for updating existing systems. FEATURES • Up to 32 PID control-loops to regulate parameters such as temperature, furnace pressure, atmosphere parameters (e.g.: carbon potential, nitriding potential and oxygen potential) • Real-time monitoring of jobs at all stages • Process parameters configured with alarm limits • Online diffusion calculation to control the process using required target values (e.g.: case depth, surface carbon content) • Up to 999 treatments/templates can be created and modified • Integration with SCADA systems • For all types of processes: nitriding, nitrocarburizing, carburizing, carbonitriding, plasma and vacuum • For compliance with CQI-9, AMS 2750 &..

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

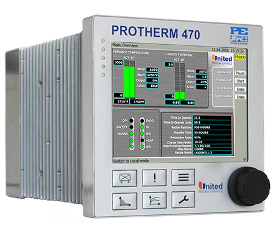

The Protherm 470 controller is designed to monitor, control, record and archive heat treatment processes running in a furnace or simultaneously in multiple chambers. They are configurable for various types of batch and continuous furnaces. Installations are done on new or refurbished furnaces and are used for updating existing systems. FEATURES • ½ DIN multi-loop embedded programmer with a color display and turn-and-push knob navigation • Up to 32 programmable PIDs included • built-in calculators for real-time carbon and/or nitrogen diffusion, and hardness profile • mathematical model for calculating atmospheric parameters • integrated web server for browser-based remote access • works with internal and/or external I/O’s • suitable for all types of processes such as nitriding, nitrocarburizing, carburizing, carbonitriding, plasma and vacuum • standard connectivity allows for integration with SCADA systems • for compliance with CQI-9, AMS 2750 & AMS 2759/10-12

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The Protherm 455 is a ½ DIN powerful controller designed to monitor, control and record a variety of heat treating processes. Used in new furnaces as well as for refurbishing or updating existing systems, it is ideal for nitriding, nitrocarburizing, carburizing, carbonitriding, hardening, tempering and vacuum furnaces. FEATURES • color touch-screen interface • built-in chart recorder function • calculates variables such as % carbon, dew point, or millivolts, and percent oxygen • stores up to 200 19-step recipes • direct drop-in replacement for Marathon Monitors’ CarbPro, DualPro, MultiPro, and Carb PC • works with internal and/or external I/O’s • suitable for all types of processes such as nitriding, nitrocarburizing, carburizing, carbonitriding, plasma and vacuum • standard connectivity allows for integration with SCADA systems • for compliance with CQI-9, AMS 2750, & AMS 2759/10-12

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The AE25™ is a ¼ DIN multi-loop process controller provides easy operation and review of process variables and set-point information. FEATURES • controls carbon potential, dewpoint, temperature, and oxygen concentration • paperless chart recorder with USB port for data retrieval • Ethernet (Modbus-TPC) communication port for remote process monitoring and control. • simplified PID tuning with Auto-tune reduces startup configuration time and quickly gets your process up and running fast

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The Protherm 10 is a cost-effective temperature and industrial controller with expanded functionality, including a programmer and an optional datalogger.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The AE06L is a 1/16 DIN controller designed as an as a over temperature limit protection. The universal input can be easily configured for most thermocouple and signal types, while the 3 alarm outputs can each be setup with different set-points providing multiple limit alarm logic capability to meet most application requirements.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The Protherm ActivePLC™ provides a single, universal process control platform that can be standardized on many different applications, machines and projects, reducing development time, training, and spare part requirements. This industrial standard programmable logic controller runs on the Protherm ActivePLC™ process control platform with its universal PLC program that is ready to run “out of the box” without PLC programming required. The platform provides a completely flexible and uniform system to define and setup inputs, outputs, alarms, timers, advanced math functions, logic operations, PID loops, recipe operation, analog signal scaling, and even thermocouple type selection and calibration on an industry standard controller. Configuration is accomplished via the Protherm ActiveHMI™ touchscreen. Settings and logic can be backed up locally and replicated to any other Protherm ActivePLC™ hardware regardless of the manufacturer. FEATURES • Customizable HMI • Data Logging and...

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

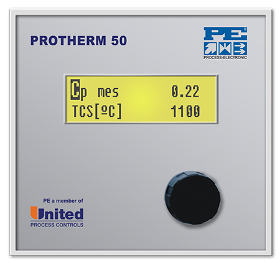

The Protherm 50 is used for calculating and controlling residual oxygen, partial pressures of oxygen, temperature, nitriding depth or the carbon potential. An oxygen probe, a Lambda probe or a CO2 analyzer can be attached for taking readings and calculating the parameters.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The CarbonSender™ transmitter provides a cost-effective solution for carbon potential and temperature transmission (4-20 mA) to your PLC or SCADA system via Modbus RTU. This DIN rail module provides full probe maintenance / probe burn off functions and reports probe status after each test. Up to four CarbonSenders can be integrated with reference air and burn off functions for up to four probes in a single enclosure.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

More than SCADA. The Protherm 9800 is a modular production management software for supervising, controlling and archiving heat treating processes and heat treatment installations. It delivers everything to optimize the performance and efficiency of a heat treatment plant operating a variety of furnaces as well as automatic handling machinery. By combining process control, equipment integration, and automation capabilities, the Protherm 9800 provides a comprehensive approach to plant wide supervisory control and management. FEATURES • Highly detailed visualization of all furnaces and connected devices • Scalable set of functions • Module for fully automated production system/cell (lights-out) • Easily implementable interface to existing planning and production systems • Possibility of simulating heat treatments

Request for a quoteManufacturer/ Producer

Dürnauer Weg 30

73092 Heiningen - Germany

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the accssories use for machines.

Request for a quote

QUELLTECH GMBH

Germany

Laser Scanner Solution: This task is a typical application of the high-resolution QuellTech 2D/3D Q5-880 Blue Laser Scanners. Two of these units are placed at the left and at the right of the measuring objects, at a defined inclination angle. Blue laser light in this case is a prerequisite, as the cast parts are red-hot, hence emitting in the red spectral range. Additionally, the client was in need of a software solution for the project, so a 3D point cloud processing application was implemented, performing inline and evaluating width, height and angle results. QuellTech customer is able to inspect continuously the product quality, simultaneously avoiding scrap. He uses the same system for more than 10 different types of castings. Errors caused by manual inspection are considerably reduced, and safety for personnel is enhanced.

Request for a quote

QUELLTECH GMBH

Germany

The QuellTech laser sensor family Q4 or Q5 used for these tasks is generally mounted on an arm of a rotational axis, to scan along the complete 360° angle of the internal surface in a sequence of strips. The Q4 sensors can also be used to control the weld seam tracking itself for rapid setup and ease of use. Even during a project, the range and scope of the Q Series sensor demonstrates the advantages of a modular system to quickly adapt to project needs, where the smallest system has provided fast analysis of pipes as small as 105mm. The low power, with standard communication protocols, enable battery powered systems to transmit wireless data to other systems for review and cloud back up.

Request for a quote

KNIGHT OPTICAL (UK) LTD

United Kingdom

Knight Optical can offer you Plane Mirrors (general, λ/1 and λ/4), for use within 3D Mapping Applications in a range of materials such as Soda-lime float glass, white float glass, and BK7 glass. Plane mirrors also known as front surface mirrors or first surface mirrors are used within 3D Mapping Applications. As stock we hold a number of general purpose, λ/1 and λ/4 with a range of up to 6 types of coatings such as Enhanced Aluminium, Ali/SiO2 and Ali/Mgf2. Our general purpose grade mirrors are made from good quality float glass and generally available in thicknesses of 1mm, 3mm and 6mm as standard. How our mirrors are used within 3D Mapping, is they are used as a sender and receiver of a laser beam that will take a reading of a specific surface, and from that reading it can create a 3D map of the surface that is has read. FOR MORE INFORMATION READ THE PDF..

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free