- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- head

Results for

Head - Import export

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

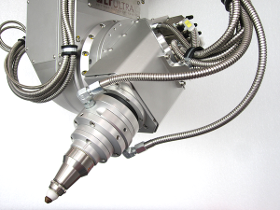

RSLD is our short cut for a laser head consisting of a total of 3 motorized axes for use in large-format laser machines in gantry design for the 3-dimensional laser cutting of components. The horizontal main axis of the laser head permits endless movement, even during the rotary movement the axes below are permanently supplied with cooling water, process gases and all electrical signals. Suitable optics are used for the laser source used, either directly water-cooled metal mirrors with low-absorption coating or alternatively glass optics. The use of an adaptive optics enables the freely programmable focus position for cutting and piercing. The exclusive use of torque motors reduces mechanically moving components and thus guarantees consistently high machining accuracy and best machining results over a long service life, against mechanical damage reliably protects our proven 3D collision protection.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

RSD is our short name for a laser head consisting of a total of 2 motorized axes for use in large-format laser machines in gantry design for 3-dimensional laser cutting / laser welding of components. The horizontal main axis of the laser head permits endless movement, even during the rotary movement the axes below are permanently supplied with cooling water, process gases and all electrical signals. Suitable optics are used for the laser source used, either directly water-cooled metal mirrors with coatings of least absorption, or alternatively glass optics. The use of an adaptive optics optionally allows the freely programmable focus position for cutting and piercing. The exclusive use of torque motors reduces mechanically moving components and thus guarantees consistently high machining accuracy and best machining results over a long service life, against mechanical damage reliably protects our proven 3D collision protection.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

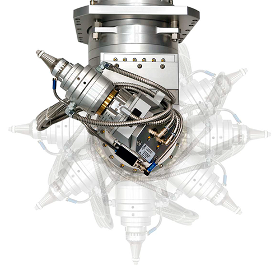

SD is our short cut for a laser head consisting of either the swivel axis only or in combination with a highly dynamic linear axis for laser processing of pipes. Suitable optics are used for the laser source used, either directly water-cooled metal mirrors with coatings of least absorption, or alternatively glass optics. The use of an adaptive optics optionally allows the freely programmable focus position for cutting and piercing. The exclusive use of torque motors reduces mechanically moving components and thus guarantees consistently high machining accuracy and best machining results over a long service life, against mechanical damage reliably protects our proven 3D collision protection. The clear aperture of the current laser swivel head SH35 is 35mm, the larger version SH60 is still available with a clear aperture of 60mm.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

When using high-performance CO2 lasers for welding applications, metal mirrors are usually preferred for beam guidance. Depending on the desired application, the configuration of the machining head is composed of modular individual components according to customer requirements. The possibilities are almost unlimited, ranging from the simplest welding head to complex 3D machining heads. The FH40/C focusing heads are used for laser power up to 5 KW and raw beam diameters up to max. 30mm, the FH60 focusing head for laser power up to 15 KW and raw beam diameters up to max. 50mm. All optical units have connections for direct water cooling, are available with different coatings and are generally available from stock. In addition to the cross-jet for the efficient reduction of splashes and smell on the mirror optics, protective gas feeds with a lateral or coaxial flow direction are also offered for targeted coverage of the welding torch.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

The laser cutting head FC4 is predominantly used in medium power lasers machines, impresses with its slim design and the related low weight. The use of a deformable (adaptive) mirror is of great importance in this case, since no motorized lens adjustment for focus adjustment is required any more. The focus adjustment via adaptive optics above the focusing lens is fast, reliable and precise. Focus positions for a wide variety of materials can be determined, stored in the machine CNC and called up for controlling the optics as desired. The dynamics of the adaptive optics are also clear when piercing the material before the beginning of the cut – for a full stroke, only 0.2 seconds are required. Especially when cutting thicker materials, the time saving can be considerable. The use of aspheric lenses guarantees the best optical properties; protective glass cassettes on both the collimation side and the pressure seal below the focusing lens protect the optics from contamination.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SONIKKS® ULTRASONICS TECHNOLOGY GMBH

Germany

The 20 kHz roll seam welding heads with up to 3KW power are particularly suitable for continuous welding of pipes, solar absorbers, or copper sheets. Thanks to the discshaped sonotrode, ultrasonic roll seams provide continuous welds without seam interruption.

Request for a quote

SONIKKS® ULTRASONICS TECHNOLOGY GMBH

Germany

Our 20 kHz roll seam welding heads are particularly suitable for continuous welding of thin aluminum foils or copper foils. Ultrasonic roll welding is similar to ultrasonic welding. Due to the discshaped sonotrode, however, a continuous weld can be generated without interruption. Thanks to the inductive energy coupling, the 20 kHz roll seam welding heads are maintenancefree.

Request for a quoteResults for

Head - Import exportNumber of results

8 ProductsCountries

Company type