- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- rapid tooling

Results for

Rapid tooling - Import export

XUFENG TOOL TECH GROUP LIMITED

China

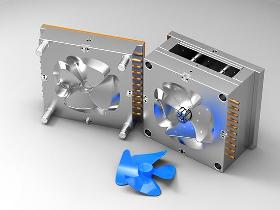

Rapid tooling Service We offer rapid tooling service, when parts demand quantity is hundreds to thousands,you will need to consdie this service and when your demand items are similar structure, types are many and demand quanity is not big then quick Turn Tooling. Rapid tooling for plastics and Die Casting of metal (Aluminum alloy or Zinc Alloy). Also we has stable surface treatment partner with different finishing like sand blasting, texture, painting, powder coating and so on, depending on our customers' requirements. We can make tool life to be 5k to 100ks or more. So if you have such project coming, you are welcomed to inquiry us freely . What Is Rapid tooling Rapid tooling is starting to be used to create molds for commercial operations,to simplify the mould structure for low cost & short lead-time. Rapid tooling provides a way to quickly provide molds to moulding the required products for low volume production demand. apid tooling material usually are Al7075 and...

Request for a quote

XUFENG TOOL TECH GROUP LIMITED

China

Rapid tooling for plastics and Die Casting of metal (Aluminum alloy or Zinc Alloy). Also we has stable surface treatment partner with different finishing like sand blasting, texture, painting, powder coating and so on, depending on our customers' requirements. We can make tool life to be 5k to 100ks or more. So if you have such project coming, you are welcomed to inquiry us freely . We manufacture our rapid toolings in material aluminium, P20, NAK80 and S136 tool steel, which can be run in a standard injection moulding machine to produce production quality parts in low-volumes. P20 prototype tooling for volumes up to 50,000+ shots. NAK80 or S136 prototype tooling for volumes up to 100,000+ shots. Prototype tooling in 5 to 28 calendar days. Tooling Lead-Time get short leadtime, Low Cost - reduced Cost from material ,MFG , Allowing real trials ,Allows functional test of parts on initial design stage, Many design faults are debugged before mass big production.

Request for a quote

STARLIM SPRITZGUSS GMBH

Austria

Rapid Tooling Early mass production-like LSR parts within only 10 working days – this is rapid tooling starlim//sterner-style. Rapid Tooling – fast tool making – was developed so our customers could be offered first LSR injection parts after a brief time span; those parts were made under mass production-like conditions. We offer Injection molding of mass production-like LSR parts Maximum output: 300 items Dimensional tolerances in accordance with DIN ISO 3302-1 M1 Standard surface quality max. VDI3400–24 (</= Ra 1.6) Choose between 10-20 working days delivery time after clearance of order form by the customer Limited choice of "standard" materials and colors Parts can be post cured Engravings, data codes and tolerances/surface finish deviating from the standard are not possible Your advantage You have to wait for a maximum of 20 working days until you receive your first serial parts. You have price control because delivery time determines the price. If you need it really quickly, the

Request for a quote

EWOQE GMBH & CO. KG

Germany

EWOQE is your expert in Rapid Tooling, especially for prototype initial samples. Our comprehensive range of 3D printing processes, including FDM, SLS, MJF, and SLA, offers fast, cost-efficient, and high-quality solutions for your Rapid Tooling needs. Our experienced team is here to support you in the design and manufacturing of Rapid Tooling components, regardless of their size or quantity. We understand the urgency and requirements of the industry for high-quality prototypes and provide you with precisely manufactured components that meet your specifications. Thanks to our additive manufacturing technologies, we can reproduce complex geometries and fine details, helping you quickly obtain high-quality prototype initial samples. Our express service ensures rapid turnaround times to optimize your time-to-market and efficiently advance your projects.

Request for a quote

PHILPLAST LTD.

Bulgaria

Philplast can produce a wide variety of plastic items using extrusion blow moulding with the following characteristics: Volume: from 10 to 2000ml.; Materials: PP, PE, PVC, ABS, PS, POM, PA and others; Specialty bottles: bottles with a slanted neck, with a transparent line for content level control, high pressure resistant bottles and others; Industries: technology, cosmetics, chemical, automotive and others. We also offer a complete set of services that help in the manufacturing of plastic products and mould maintenance: Design, 3D model and a “Rapid Prototype”; Tooling; Mold servicing and repairs; Additional processing and assembly of plastic articles.

Request for a quote

PHILPLAST LTD.

Bulgaria

Philplast can produce a wide variety of plastic items using the technologies of injection moulding with the following characteristics: Weight: from 0,5 to 1000gr.; Clamping force of the machines: from 50 to 200 tons; Materials: ABS, PA, PC, PS, POM, TPV, TPE, PP, PE, as well as reinforced plastics (glass or mineral filled); Industries: home appliances, automotive, electronics, cosmetics, detergents and others. We also offer a complete set of services that help in the manufacturing of plastic products and mould maintenance: Design, 3D model and a “Rapid Prototype”; Tooling; Mold servicing and repairs; Additional processing and assembly of plastic articles;

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

This equipment now permits fittings up to 3“ to be inserted or extracted. Due to its innovative rapid tool sled, the insertion of 90 degree, 45 degree or straight fittings without changing tools is now simple and quick. Ergonomic Freely positional foot pedal for clamping hose saves time and increases productivity Lifting eyes for easy positioning of the machine Simple to use Universal hose clamping jaws for all hose diameters without the need for changeover eliminates lengthy setup times Axially adjustable clamping unit for all diameters prevents kinking of thin hoses and for efficient operation Individual clamping force adjustment for damage-free clamping avoiding scrap Zero maintenance and wear contributes to cost savings Rapid sled for inserting curved and straight fittings without time-consuming exchange of fork sets saves time Safety compliant Moving components have safety guarding CE-compliant, robust UNIFLEX quality

Request for a quote

XUFENG TOOL TECH GROUP LIMITED

China

Plastic Injection Molding Service Xufeng specilized in fabricating plastic injection moulding parts and mould tools over 10 years ,98% are for export. Here we are expert on rapid injection molding ,We offer toolings design and building at our workshop and we are used to working on low and medium volume production Runs. part material molding range widely like ABS,PP,PC,PMMA,PET,PA6/PA66,PA66+GF... Our Advantages Of Plastic Injection Molding Rich molding experience in processing various materials including ABS, PP, PS, PC ,PMMA, PE,POM, PA6/66+GF,PET, PBT, TPE. 100-850 tones machine capacity Our technique staffs will do periodical checking and maintenance to ensure our machine run normally and all of our products have passed through very strict quality control before shipment. Small quantity trial order are welcome ,we all pay attention to our job. Injection moulding parts cover auto parts ,electrical& electronic parts...

Request for a quote

STARLIM SPRITZGUSS GMBH

Austria

Rapid Prototyping A product has to pass a range of tests before it can be mass produced. This prototype must be fully functional for its intended application and must be free of any defects. Only then can it be released to enter mass production. Therefore, for complex products our developers make so called dummy-samples for development tests to complement simulation . "Dummy-samples“ or "Lab prototypes“ are prototypes which are entirely produced in our own lab and are hand-finished. We use them to evaluate a new design quickly on the real part and in order to conduct initial test in the development phase. This is helpful in cases where complex parts have to be made using the Rapid Prototyping process. Prototypes can be made within a period of 4 to 5 working days. They are made manually and this is the reason why the maximum number of a run is 10-20 items. They are made from the real material and they are completely vulcanized. The difference with the rapid tooling : lab samples are ma

Request for a quote

STARRAG GMBH

Germany

This highspeed machining center is perfect for rapid cutting of small and mediumsized workpieces with maximum productivity. The critical innovation is the Sprint Z3 parallel kinematic machining head, which enables components to be produced with excellent dynamics and precision and an outstanding surface quality, at batch sizes of a single unit through to bulk production. The excellent machining and surface quality means that there is no need for the manual rework that is usually required with conventional machining centers. This results in increased efficiency, improved process reliability and longterm stability. The key features include 1,000 x 1,000 mm pallet size, up to 120 kW spindle power and rapid tool change, from either a chain or rack magazine.

Request for a quote

3D PROTOTIPAI

Lithuania

Multi Jet Printing (MJP). MJP works almost like an ink jet printer. The parts have excellent resolution and the materials have a variety or properties. This technology is primarily used for smaller parts that can be accurate and not very difficult to finish. MJP technology is used to build parts, patterns and molds with fine feature detail to address a wide range of applications. This method is perfect for creating durable, high-definition functional prototypes, rapid tooling such as injection molds, casting patterns and end-use parts. Parts made with MJP technology are beautifully precise, with sharp edges and true-to-cad fidelity. Ultimate adventure of this 3D printing technology - possibility to print assemblies. MJP method is widely used in transportation, energy, consumer products, recreation and healthcare industries. M3 Black and M3-X are durable plastics that looks and feels like injection molded plastics and allows for more rigorous testing and use. The materials is well suit

Request for a quote

3D PROTOTIPAI

Lithuania

Multi Jet Printing (MJP). MJP works almost like an ink jet printer. The parts have excellent resolution and the materials have a variety or properties. This technology is primarily used for smaller parts that can be accurate and not very difficult to finish. MJP technology is used to build parts, patterns and molds with fine feature detail to address a wide range of applications. This method is perfect for creating durable, high-definition functional prototypes, rapid tooling such as injection molds, casting patterns and end-use parts. Parts made with MJP technology are beautifully precise, with sharp edges and true-to-cad fidelity. Ultimate adventure of this 3D printing technology - possibility to print assemblies. MJP method is widely used in transportation, energy, consumer products, recreation and healthcare industries. M3 Black and M3-X are durable plastics that looks and feels like injection molded plastics and allows for more rigorous testing and use. The materials is well suit

Request for a quote

3D PROTOTIPAI

Lithuania

Multi Jet Printing (MJP). MJP works almost like an ink jet printer. The parts have excellent resolution and the materials have a variety or properties. This technology is primarily used for smaller parts that can be accurate and not very difficult to finish. MJP technology is used to build parts, patterns and molds with fine feature detail to address a wide range of applications. This method is perfect for creating durable, high-definition functional prototypes, rapid tooling such as injection molds, casting patterns and end-use parts. Parts made with MJP technology are beautifully precise, with sharp edges and true-to-cad fidelity. Ultimate adventure of this 3D printing technology - possibility to print assemblies. MJP method is widely used in transportation, energy, consumer products, recreation and healthcare industries. M3 Black and M3-X are durable plastics that looks and feels like injection molded plastics and allows for more rigorous testing and use. The materials is well suit

Request for a quote

RHODIUS ABRASIVES GMBH

Germany

Aluminium oxide fibre disc for the quick change system – the grain enables excellent stock removal performance on steel. • Good stock removal • Long lifetime • Rapid tool changeover without sticking or slippage

JOHN RYAN TRADING LIMITED

United Kingdom

Smartwhip, 580g n20 Gas cylinders Europe. Model Number: 434665 Brand Name: Deluxe Origin: UK Small Orders: Accepted Key Specifications/ Special Features: Boasting 615 grams of pure food-grade cream charger in each cylinder, Smartwhip allows you to charge one siphon after the other in rapid succession. The ultimate tool for improving workflow efficiency, Smartwhip is cost-efficient by design, easy to operate and affords greater control over each creation's texture. High-quality Food-Grade E942 (purity tested at 99.9%) Improves workflow efficiency Handy & durable design Easy disposal: All cylinders come with a pressure release nozzle to fully release the gas for disposal. Cream Deluxe Cream Charger 580g Cylinders supplier Type: Dessert Tools Commercial Buyer: Restaurants, Fast Food and Takeaway Food Services, Food & Beverage Stores, Food & Beverage Manufacture, TV Shopping, Department Stores. To Place Your Order Contact Via : johnryantradingltd007@gmail.

Request for a quote

3D HUBS - DIGITAL MANUFACTURING PLATFORM

Netherlands

Online injection molding service by 3D Hubs: Instant quote: ✔ Minimum order quantity: 500 Materials: Plastic (Nylon, PC/ABS, PU, PMMA/Acryl, PP, PE, HDPE, PS, PVC, PEEK, POM Additives & Fibers: ✔ Rapid tooling: ✔ surface treatments: ✔ Online quoting management: ✔ Design verification program (receive 2 sets of parts for testing before production starts): ✔ Quality assurance & certification: ✔ Delivery time: From 14 working days

Request for a quote

ALEACIONES ESTAMPADAS S.A. - AESA

Spain

AESA has experience in manufacturing the following parts for UK companies: gas and liquid valves, radiators, heat exchangers, electrical material, transformer components, bronze turnbuckles for marine, fire-fighting equipment material, luxury handles for doors, etc. AESA is involved from the design phase till the surface treatment, and T6 Heat treatment. Our spacious and flexible machine park contains forging presses up to 1200Tn and many machining centres CNC, including 5 Axis machining which permit us manufacture different sizes of the series. AESA also has Rapid Tooling facilities.

Do you sell or make similar products?

Sign up to europages and have your products listed

VACUUM EL SYSTEM LTD.

Bulgaria

Vacuum El System utilises the latest CNC bending technology from Bystronic for high-precision bending of parts up to 4080mm in length. With automatic laser angle adjustment and CNC crowning compensation, as well as dedicated offline programming software, we are able to quickly and accurately bend complex shapes from a wide range of materials. Benefits: High-precision bending through automatic laser angle adjustment and CNC crowning Accurate bending of large parts with automatic sheet follower High throughput and rapid tool change

Request for a quoteResults for

Rapid tooling - Import exportNumber of results

19 ProductsCountries

Category

- Injection moulding of rubber and plastic (2)

- Plastics moulding (2)

- Hydraulic equipment (1)

- Ice cream-making - machinery and equipment (1)

- Industrial sheet metal work (1)

- Machine tools, metal machining - parts and accessories (1)

- Prototypes, industrial (1)

- Translation (1)

- Valves for pneumatic equipment (1)