- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- rotary torque sensors

Results for

Rotary torque sensors - Import export

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Precise, reliable measurements of both static and dynamic torques in either direction can be made with this range of sensors. This opens a wide range of possible applications to the user. These torque sensors are standard equipment in a wide range of industrial automation, quality control and automotive components industry applications, as well as in laboratories. Typical applications: Screwing technology — Checking and adjusting bolting tools such as torque limiting wrenches, screwdrivers — Testing bolted connections Measuring the drag torque of motors and pumps — Frictional torques of gears, bearings and seals — Testing torsion springs — Adjusting equipment in the automobile industry (sunroof, power windows etc.) Strain gauges are mounted on the torsion shaft of the sensor element, itself made of steel, connected to form a full bridge.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The 8661 precision torque sensor is the ideal choice for reliable measurement of static and dynamic clockwise and counter-clockwise torques. Thanks to its high measurement quality and low linearity error, the sensor is equally at home in quality control or research & development. Designed for non-contact operation and zero-maintenance, the 8661 is also ideally suited to the production environment, whether on shift-based production lines, test benches or end-of-line test systems. The 8661 torque sensor is the specialist device for constant torque measurements during continuous operation and for test-bench measurements of holding, friction, break-away or tightening torques. An optional built-in incremental encoder disk with up to 2000 increments makes the sensor the perfect alternative where space or budget rule out an additional angle or speed sensor. For mobile use and for instant digital access to measurement data, the 8661 torque sensor is also available with a USB interface.

Request for a quote

DATUM ELECTRONICS LTD

United Kingdom

The latest technology Datum Electronics Series non-contact rotary Torque Sensors have been designed to fit with most applications where the measurement of accurate rotary torque and power measurements are required. The M425 Rotary Torque Sensor fits in line with the drive train or test bed, using standard key-way shafts. The Datum M425 Rotary Torque Transducer represents a quantum leap forward for anyone looking to measure torque and power with high accuracy and repeatability using up to 24 bit resolution. The M425 torque sensors give the customer control over their tests with torque sample rates selectable at any time from 1sps up to 4000sps as standard. With rpm measurement based on up to 30 pulses per revolution, the M425 is now the complete torque transducer for measuring torque and power on any rotating shaft. When paired with the Datum Universal Interface (DUI), the M425 Torque Sensor gives customers a ... ** Click for more **

Request for a quote

NOVOTECHNIK MESSWERTAUFNEHMER OHG

Germany

High-precision potentiometric low-torque rotary sensor, synchro housing 11

Request for a quote

SENSY S.A.

Belgium

General purpose, noncontact rotary torque sensors with flanges or PTO shaft. o Bidirectional o Measurement range up to 5 kN·m o Rotating speed up to 3600 rpm o Integrated signal conditioning o Analogue output signal (see Wiring table) Torque limit 5000 N·m

Request for a quote

SENSY S.A.

Belgium

General purpose, lowcost, noncontact rotary torque sensors with square or round shaft. o Bidirectional o Cost effective solution o Measurement range up to 500 N·m o Rotating speed up to 5000 rpm o Round or square shafts (see drawing) o Integrated signal conditioning o Analogue output signal (see Wiring table)

Request for a quote

SENSY S.A.

Belgium

General purpose, high rotating speed, noncontact rotary torque sensors with square or round shaft. o Bidirectional o Maintenance free o Round or square shafts (see drawing) o Measurement range up to 100 N·m o Max. rotating speed Square shaft 5 000 rpm Round shaft 10 000 rpm o Integrated signal conditioning o Analogue output signal (see Wiring table)

Request for a quote

SENSY S.A.

Belgium

General purpose, high capacity noncontact rotary torque sensors. o Bidirectional o Measurement range up to 25 kN·m (>25 kN·m on request) o Rotating speed up to 8000 rpm o Integrated signal conditioning o Analogue output signal (see Wiring table)

Request for a quote

DATUM ELECTRONICS LTD

United Kingdom

FF410 Static Torque Transducer provides a competitive option within the reaction transducer market Static Torque Sensor/Transducer FF410The Datum Electronics Series 410 Static torque sensor was developed following developments of our FF420 series of rotary torque transducers. The same basic shaft components and strain gauge technology have been applied to our 410 Reaction transducer range providing a competitive option within the static transducer market. SERIES 410 REACTION TORQUE TRANSDUCER - Flange Mounted static transducer - Flange torque transducer match standard DIN Flanges - Ideal design for easy fitting to test rigs and drive systems - No bearings with lightweight hollow shaft unit - Unique design offers high torsional stiffness model - Standard 410 reaction torque sensor range available from 250Nm-10,000Nm - Strain gauge output compatible with Datum Type310, Type324, Type 300 Indicators. ** Click for more **

Request for a quote

DATUM ELECTRONICS LTD

United Kingdom

The Datum Electronics Series RS425 bearingless torque transducer has been designed to fit easily in line with any drive-train or test rig, using either a spline or key-way shaft. We are able to modify the ends of the transducer to best suit your requirements, and can even design bespoke ends to fit. This type of transducer has many advantages over other torque systems including zero bearing friction, high speed and high torque applications. The Series 425 Torque Transducers can be adapted to replace exiting drive shafts on test rigs and in drive lines, this saves the time and cost of designing in special couplings and intermediate shafts to accommodate conventional transducers. By measuring torque on longer drive shaft you prove the accuracy of the measurement and its tolerance to offset loads. Using a direct replacement with a lightweight rotor the dynamics of the driveline are maintained. ** Click for more **

Request for a quote

DATUM ELECTRONICS LTD

United Kingdom

The latest technology Datum Electronics Series FF425 non-contact rotary torque transducer and FF410 torque sensors have been designed to fit easily inline with any drive train or test rig using standard DIN size couplings. With Flange couplings at either end of the torque transducer, it has many advantages over other torque measurement systems. FF425 Non-Contact Torque Transducers and Sensors The FF425 rotary torque transducer utilises a strain gauged shaft for accurate and reliable torque measurement and a set of rotating on shaft conditioning electronics, the digital signals are transmitted to the non-rotating part of the system or stator providing a reliable and highly accurate torque measurement solution. ** Click for more **

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

The CheckStar Multi is the latest generation of Crane Electronics market leading CheckStar in line rotary torque transducer. It raises the standard for dynamic torque and angle measurement of all continuous drive and impulse tools, with proven reliable performance in thousands of applications worldwide. If angle is specified, the CheckStar Multi rotary torque transducer will include an angle encoder giving 0.125° resolution (720 PPR). It also incorporates a light ring, giving the user visual feedback of the status of a tightening, when used with a Crane readout or data collector. The CheckStar Multi fits in line between the assembly tool and the fastener, measuring the actual torques applied and angular rotation of the fastener, under production conditions. Whatever the vibration and shock loads experienced, CheckStar Multi’s patented contact system ensures a connection is always maintained between the readout and the strain gauges. [...]

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

Rotary Transducer with Angle Measurement Option CheckStar sets the standard for dynamic torque and angle measurement of all continuous drive and impulse tools, with proven reliable performance in thousands of applications worldwide. CheckStar transducers fit in-line between the assembly tool and the fastener, measuring the actual torques applied under production conditions. Whatever the vibration and shock loads experienced, CheckStar's patented contact system ensures contact is always maintained between the readout and the strain gauges. Inferior systems suffer from "brush bounce" that leads to unreliable torque readings. The low inertia design of CheckStar ensures accurate and repeatable measurement of high speed transients, such as the point of shut-off on continuous drive tools and the pulsing of impulse tools.

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

Workbench mounted Torque Transducer. Crane’s stationary transducers are the quality choice for the testing of all continuous drive, impulse and hand torque tools in the workshop and production line-side environment. For best results with impulse tools we recommend the use of a Crane CheckStar rotary torque transducer with a suitable joint kit rather than a stationary transducer. Stationary transducers are used off the production line in workshop or line-side test stations. Combined with joint kits that represent the production joint condition, the stationary transducers form an effective off line test for verification of assembly tool performance. Key Features: - Static accuracy ± 0.25% FSD (bi-directional) - Plug and Play with Crane display systems (UTA) - Combine with joint kits for workshop simulation of hard to soft joints - Built-in workbench mounting flange - Rugged and durable construction, aluminium housing, stainless steel shaft - Ingress protection rating IP40.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

This torque sensor is qualified for static and dynamic measurements on non-rotary applications. Further the measurement of reaction torques on rotating machine parts is possible. Especially the torque sensors with flanges are preferred. They are mounted between motor and stator, e.g. in agitator drives. This enables a maintenancefree torque measurement. For individual measuring tasks the design of our torque sensors can be adapted to the customer’s installation conditions. More application examples: Test structures in the field of precision mechanics Determination of friction torques Acquisition of breakage moments on screw caps The design has been optimized regarding overall length, weight and volume, so that axial forces up to relatively high limit values and bending moments of up to 20 % of the measuring range have only a small effect to the influence of the measuring element.

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

The most accurate digital torque tester with Fail Safe Engineering! - Greater accuracy and durability with simplicity and ease of operation - Floating decimal point, 6 digit display is easy to read - Accurate to ± 0.25% (indicated value) from 10% to 100% - Over capacity alert and tracking System 8 error proofs your error-proofing program by letting you know when the unit has been stretched to 120% or more of capacity and may no longer be in calibration. System 8 has an LED that flashes red to alert you to the problem. It doesn’t stop until you reset the unit. The display also tells you the unit has been stretched over capacity. System 8 captures the over capacity data even if the memory was turned off. If memory was turned on and the unit is pulled over 120% capacity and a worker tries to erase the memory to stop the LED from flashing, the display tells the worker to “See Supervisor 120% Over Capacity”. No other torque tester on the market does this.

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

The gateway to the finest in torque measurement tools! Sturtevant Richmont TT-QC series torque transducers are designed to work with System 8 Digital Torque Tester when used with ML 1000 and ML 2000 Mechanical Loaders. These transducers use Quick Connect baseplates that are a feature of the loader system. Features and Benefits: - Hex mounting flange style. - Can be mounted to ML 250 and ML 600 mechanical loaders. - All up to 250 lbf·ft capacity can be mounted to Quad Plate for multi-transducer mounting on the ML 250. - Smaller sizes (up to 300 lbf·in capacity) can be mounted to STMB or UMB brackets for use with a bench or table. - Larger sizes can be mounted on UMB L-bracket. - Requires detachable cable (P/N 10293) for attachment to Switch Box or directly to tester. Related Products: - Mechanical Loader ML - DTT System 8

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ZEMO VERTRIEBS GMBH

Germany

The gateway to the finest in torque measurement tools! TT-Series Torque Transducers are designed to work with Sturtevant Richmont Digital Torque Testers or the like. Features: - Integrated SR mounting flange - Can be mounted to ML 250 Mechanical Loader. - Can be Mounted to Quad Plate for multiple mounting on ML 250. - Smaller sizes (up to 400 in.oz.) can be mounted to SSMB, STMB, or UMB brackets. - Larger sizes (500 ft. lbs. and above) can be mounted on UMB L-bracket. Related Products: - Mechanical Loader ML - DTT System 8 Optional Components: - 10293 = Detachable Signal Cable ca. 1,20 m * - 10153 = Single Mounting L-Bracket UMB (500 ft.lb and above) - 10154 = Triple Mounting L-Bracket STMB (up tp 400 in.oz) - 10601 = Switchbox 4-Way - 870776 = Square Adapter 1/4"f x 3/8"m - 870777 = Square Adapter 3/8"f x 1/2"m - 870778 = Square Adapter 1/2"f x 3/4"m - 870779 = Square Adapter 3/4"f x 1/1"m

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

This high precision torque sensor is designed for both static and dynamic measurements on non-rotating applications. It is particularly suitable for torque measurements on, for instance, extremely small electrical actuating drives and micro-mechanical actuator elements, or for measuring reaction torques e.g. on micro-motors. The high accuracy of measurement also makes this sensor ideal for use as a reference in many fields of industrial manufacture as well as laboratory research and development projects. Not containing any rotating parts, it requires no maintenance if properly used. The strain-gage based sensor’s modular design allows precise configuration for the desired application. With the integrated amplifier option, the sensor directly supplies a voltage signal of 0 ... ±10 V that is proportional to the torque. The sensor can be configured via the micro-USB interface, providing access to, for example, a filter frequency setting, averaging, and a tare function.

Request for a quote

MAGTROL

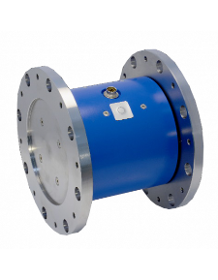

Switzerland

With its compact, bearingless, maintenance-free design, the new TF Torque Flange Sensor from Magtrol brings many appealing advantages to torque measurement applications. The TF’s high torsional rigidity supports direct mounting on the machine shaft or flange, avoiding the use of couplings on one side. This allows easy integration into a test system, shortens the overall length of the test bench and reduces costs. Based on strain-gauge technology, the TF Sensor’s precise telemetry system enables highly accurate signal transmission. A signal amplifier mounted in the measuring flange amplifies the measuring signal, modulates it to high frequency and transmits it inductively (via the HF transmitter) to the receiver. In the receiver, the digitized torque signal is transformed into an analog output signal of ±10 VDC. Rotational speed can be measured and converted to a TTL output signal with the optional speed pickup. more info www.magtrol.com

Request for a quote

MAGTROL

Switzerland

Magtrol offers three types of torque transducers for dynamic torque and speed measurement. All three transducer models employ our unique non-contact differential transformer torque measuring technology. This measuring technology offers many benefits most notably that no electronic components rotate during operation. Each model has an integrated conditioning electronic module providing a 0 to ±10 VDC torque output and an open collector speed output. Magtrol’s Torque Transducers are very reliable, providing high overload protection, excellent long-term stability and high noise immunity.

Request for a quote

MAGTROL

Switzerland

Magtrol’s TS In-LineTorque Sensors provide extremely accurate torque and speed measurement. Each model has an integrated conditioning electronic module providing 0VDC to ±5VDC (±10VDC) torque output through an 8-pole connector, as well as a USB interface which can be directly connected to a computer. The sensor is delivered with software allowing easy connection and data acquisition. A speed encoder provides a minimum of 360PPR (Pulse Per Revolution) in Tach A, Tach B and Index reference Z (1PPR). Magtrol Torque Sensors are very reliable, providing high overload protection, excellent long-term stability and high noise immunity. TSSeries sensor models are strain gauge-based measuring systems with imbedded telemetry signal transmission. Three LED lights allow a visual check of the sensor status by color code. The sensor is powered by 24VDC (12-32VDC) through its connector. TARE & B.I.T.E. (Built-In Test Equipment) can be activated by either software or input from the 8-pole connector.

Request for a quote

GEDORE-TORQUE

United Kingdom

Gedore-Torque manufacturer of torque screwdrivers, a selection of types and uses. Speak to our sales team to find the torque tool you need 01483 894476

Request for a quote

DAVALL GEARS LTD.

United Kingdom

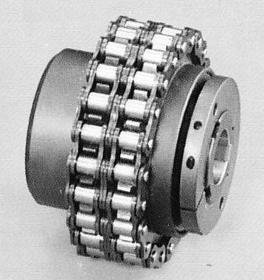

Davall DSG supply torque limiters

Request for a quote

IAI INDUSTRIEROBOTER GMBH

Germany

The DDA Direct Drive Motor is a rotary actuator that directly drives a rotary table with a motor without using any speed reducing mechanism such as a belt or reduction gears. Eliminating the speed reducing mechanism explains why high speed and excellent response can be attained with such a compact frame. The series includes models designed for high torque and high payload up to 90 or 270 kg. This makes it very easy, for example, to integrate rotary indexing tables in an automation system.

Request for a quoteResults for

Rotary torque sensors - Import exportNumber of results

26 ProductsCompany type