- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- bar stocks

Results for

Bar stocks - Import export

SFC (EUROPE) LTD

United Kingdom

SFC (Europe) Ltd now have bar in stock for immediate despatch. Get in touch with us with your requirements. Tel: + 44 (0)1902 314533 www.sfc-europe.com

Request for a quote

IGUS® GMBH

Germany

Diameter [mm]: length [mm]: iglidur® T220 - Material data iglidur® T220 - Table of general properties of materials iglidur® T220 - Material data Polymer bearings applications overview Polymere bearings application examples overview Polymer bearings applications overview iglidur® T220: For the tobacco industry Free from undesirable and banned ingredients in the tobacco industry Diameter [mm]: length [mm]: iglidur® T220 - Material data iglidur® T220 - Table of general properties of materials iglidur® T220 - Material data Polymer bearings applications overview Polymere bearings application examples overview Polymer bearings applications overview

Request for a quote

IGUS® GMBH

Germany

Diameter [mm]: length [mm]: iglidur® X - Material data iglidur® X - Table of general properties of materials iglidur® X - Material data Polymer bearings applications overview Polymere bearings application examples overview Polymer bearings applications overview iglidur® X: The high-tech troubleshooter Continuous operating temperatures of -100 to 250°C Extremely high resistance to chemicals High compressive strength Extremely wear resistant for the entire temperature range Diameter [mm]: length [mm]: iglidur® X - Material data iglidur® X - Table of general properties of materials iglidur® X - Material data Polymer bearings applications overview Polymere bearings application examples overview Polymer bearings applications overview

Request for a quote

IGUS® GMBH

Germany

Diameter [mm]: length [mm]: iglidur® R - Material data iglidur® R - Table of general properties of materials iglidur® R - Material data Polymer bearings applications overview Polymere bearings application examples overview Polymer bearings applications overview iglidur® R Good abrasion resistance Low coefficients of friction in dry operation Very cost efficient Lowest humidity absorption Diameter [mm]: length [mm]: iglidur® R - Material data iglidur® R - Table of general properties of materials iglidur® R - Material data Polymer bearings applications overview Polymere bearings application examples overview Polymer bearings applications overview

Request for a quote

IGUS® GMBH

Germany

Diameter [mm]: length [mm]: Polymer bearings applications overview Polymere bearings application examples overview Polymer bearings applications overview iglidur® P210 Versatile, rugged and universal Lowest humidity absorption Special designs such as clip-on bearings and piston rings possible Good cost/performance ratio Diameter [mm]: length [mm]: Polymer bearings applications overview Polymere bearings application examples overview Polymer bearings applications overview

Request for a quote

IGUS® GMBH

Germany

Diameter [mm]: length [mm]: iglidur® A350 - Material data iglidur® A350 - Table of general properties of materials iglidur® A350 - Material data Polymer bearings applications overview Polymere bearings application examples overview Polymer bearings applications overview iglidur® A350: temperature-resistant comply with the requirements of the FDA for application up to +180 °C For medium till high loads Also well suited for rotations and pivoting applications Diameter [mm]: length [mm]: iglidur® A350 - Material data iglidur® A350 - Table of general properties of materials iglidur® A350 - Material data Polymer bearings applications overview Polymere bearings application examples overview Polymer bearings applications overview

Request for a quote

IGUS® GMBH

Germany

Diameter [mm]: length [mm]: iglidur® A180 - Material data iglidur® A180 - Table of general properties of materials iglidur® A180 - Material data Polymer bearings applications overview Polymere bearings application examples overview Polymer bearings applications overview iglidur® A180: Delicious The iglidur® A180 products comply with the requirements of the FOOD AND DRUG ADMINISTRATION (FDA) For direct use in the vicinity of (or in contact with) food For wet areas Diameter [mm]: length [mm]: iglidur® A180 - Material data iglidur® A180 - Table of general properties of materials iglidur® A180 - Material data Polymer bearings applications overview Polymere bearings application examples overview Polymer bearings applications overview

Request for a quote

IGUS® GMBH

Germany

Diameter [mm]: length [mm]: iglidur® J350 - Material data iglidur® J350 - High wear resistance in rotation iglidur® J350 - Material data Polymer bearings applications overview Polymere bearings application examples overview Polymer bearings applications overview iglidur® J350: temperature-resistant Very low coefficient of friction on steel For continuous use in up to +180°C For medium till high loads Particularly well suited for rotations Diameter [mm]: length [mm]: iglidur® J350 - Material data iglidur® J350 - High wear resistance in rotation iglidur® J350 - Material data Polymer bearings applications overview Polymere bearings application examples overview Polymer bearings applications overview

Request for a quote

IGUS® GMBH

Germany

Diameter [mm]: length [mm]: Polymer bearings applications overview Polymere bearings application examples overview Polymer bearings applications overview iglidur® J4 - low cost and low wear Lubricant- and maintenance-free Low-cost-material for large volumes Low coefficients of friction Media resistant Lowest humidity absorption Diameter [mm]: length [mm]: Polymer bearings applications overview Polymere bearings application examples overview Polymer bearings applications overview

Request for a quote

IGUS® GMBH

Germany

Diameter [mm]: length [mm]: iglidur® J - Material data iglidur® J - The fast- and slow-motion specialist iglidur® J - Material data Polymer bearings applications overview Polymere bearings application examples overview Polymer bearings applications overview iglidur® J: The fast and slow motion specialist Low wear with many shaft materials Low coefficients of friction in dry operation vibration dampening Good chemical resistance Best performance with soft shafts Lowest humidity absorption Diameter [mm]: length [mm]: iglidur® J - Material data iglidur® J - The fast- and slow-motion specialist iglidur® J - Material data Polymer bearings applications overview Polymere bearings application examples overview Polymer bearings applications overview

Request for a quote

IGUS® GMBH

Germany

Diameter [mm]: length [mm]: iglidur® W300 - Material data iglidur® W300 - The continuous runner for maximum holding times. iglidur® W300 - Material data Polymer bearings applications overview Polymere bearings application examples overview Polymer bearings applications overview iglidur® W300: The endurance runner For extremely high service life in continuous operation Low coefficient of friction extreme high wear-resistance Suited for rough shafts and stainless steel shafts Dirt resistant Diameter [mm]: length [mm]: iglidur® W300 - Material data iglidur® W300 - The continuous runner for maximum holding times. iglidur® W300 - Material data Polymer bearings applications overview Polymere bearings application examples overview Polymer bearings applications overview

Request for a quote

IGUS® GMBH

Germany

iglidur® P210 - versatile & rugged Flexible, wear-resistant & more. This versatile material has already proven itself in a wide range of customer-specific solutions and as bar stock material. Clip-on or pretensioned designs as well as the use in the vehicle interior are possible. Now iglidur® P210 is also available in the standard size range Lowest humidity absorption extremely wear-resistant, especially at pivoting loads up to 20 MPa Versatile: works well with various shaft materials Good with edge loads

Request for a quote

GSW SCHWABE AG

Germany

high accuracy for feed repeat of +/ 0,05 mm high clamping force to serve even large material crosssections serving a wide variety of materials, such as coil, band, bar or profile stocks or even wires, cardboards, papers and fabrics operation in push or pull mode or combined in pushpull mode special air cylinder design for reduced air consumption feed length adjustment via finethreaded spindle

Request for a quote

SPANSET SECUTEX GMBH

Germany

“Heat”resistant buffer pad For hot processing. Nonferrous metals, such as gold, copper or brass, get hot during processing and have a sensitive surface. Rollers and cylinders coated with secutex Heat protect bar stock during production; abrasion and run marks are reliably avoided. Operating temperature up to 140°C Apart from the positive mechanical and chemical properties, secutex Heat is an elastomer material for operating temperatures up to a maximum of 140°C. Operating temperature up to 180°C As an option, „Heat“ can be finished with an aramide fibre surface. The operating temperature thereby even increases to a maximum of 180°C.

Request for a quote

MEBA STEEL & INDUSTRIAL SUPPLIES TRADE GMBH

Germany

STEEL GRADES The standrard stock of chromed bars consists of steel grades C45 or C45E or C45R and 20MnV6 in untreated delivery condition (+AR) and 42CrMo4 in quenched and temperd delivery condition (+QT). DELIVERY CONDITIONS The solid bars subjected to chroming process are available in different delivery conditions in orde to obtain specific properties. NORMALIZATION Heat treatment consisting heating process followed by gradual cooling in controlled atmosphere. Thanks to this process the steel structure becomes more "refined" and improve its impact properties (perlitic structure). INDUCTION HARDENING The surface of the steel bar is heated by electric induction followed by fast cooling. This process leads to a high surface hardness but also to fragility and low impact values (Martensite surface structure). QUENCHING AND TEMPERING Quenching process followed by tempering. This process leads to a good hardness and resistance and it reduces its fragility in comparsion to induction...

Request for a quote

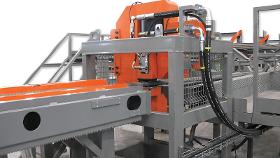

SCHNELL SPA

Italy

Integrated plant to cut, optimize and stock the bars, based on a shear CHV 160, mounted on a fixed frame, with blade of 160 mm (6''), VBM1 measuring and cutting track with mobile ledge, with oneside unloading.

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

Brass Forging Parts is a metal alloy that consists primarily of copper and zinc. The mechanical properties of brass depend on percentage of zinc along with several additional elements, which can vary significantly. Brass is harder and has a lower melting point than copper, but it has excellent working properties and is excellent for many end usesOrdering brass bar stock to the specified alloy composition in one of the many forms and shapes available is the typical first step in the process. Saw cutting provides blanks, sometimes called slugs, that then enter the forging or forming process. Some grades of brass alloy may be processed at room temperature, but it is most common for slugs to be heated to improve formability. Temperature for hot forging is usually in excess of 1000 degrees F but both the alloy and complexity of the configuration will determine the exact process requirements. In the forging process, the cut slugs are placed between dies and force

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DIXON GROUP EUROPE LTD

United Kingdom

Interchange Data: • Interchangeable to ISO15171-1 • Parker PD-Series, Aeroquip FD90, Tomco Series DK Materials: • Machined components are manufactured using solid Steel bar stock • Stainless Steel balls, retaining rings, and springs maximise corrosion resistance and extend service life • Steel nipples are machined from solid Steel bar stock and hardened • Steel componentry is plated using ROHS Compliant Trivalent Chrome Seal Components: • Nitrile (Buna-N) seals are standard, providing a temperature range of -40°C to +121°C (-40°F to +250°F) • PTFE anti-extrusion ring protects main coupler O-Ring from dynamic impulse pressure damage

Request for a quote

DIXON GROUP EUROPE LTD

United Kingdom

Interchange Data: • Interchangeable to MIL-C-51234 • Snap-Tite H/IH and Faster TNV/TNL Materials: • Machined components are manufactured using solid Steel, Brass, or 316 Stainless Steel bar stock • Stainless Steel balls, retaining rings, and springs maximise corrosion resistance and extend service life • Steel componentry is plated using ROHS Compliant Trivalent Chrome • Steel coupler sleeves are hardened to resist deformation and maximise service life • Steel nipples are machined from high-strength Steel and induction hardened • Tubular ‘TV’ valves are constructed from Steel bar stock and are designed for optimum performance in pneumatic applications Seal Components: • Nitrile (Buna-N) seals are standard, providing a temperature range of -40°C to +121°C (-40°F to +250°F) • All couplers incorporate a PTFE anti-extrusion ring to protect the seal components from dynamic impulse damage • ¼” to 1” valve seals are crimped in place to maintain integrity during excessive flow conditions and

Request for a quote

DIXON GROUP EUROPE LTD

United Kingdom

Interchange Data: • European Screw-Together Interchange • Inteva STG-Series, Faster CVV-Series, DNP PVV3, Voswinkel Type-HS Materials: • Machined components are manufactured using solid Steel bar stock. • Steel retaining rings, and springs maximise service life in rugged environments. • Steel componentry is plated using ROHS Compliant Trivalent Chrome. Seal Components: • Nitrile (Buna-N) seals are standard, providing a temperature range of -25°C to +125°C (-13°F to +257°F). • Nipples have a PTFE Anti-Extrusion ring to prevent O-Ring damage during dynamic impulse service.

Request for a quote

DIXON GROUP EUROPE LTD

United Kingdom

Interchange Data: • High Pressure Screw-Together Interchange • Parker/Pioneer 3000-Series, Enerpac C604, Stucchi IVHP • Hansen WS56000, Snap-Tite 76-Series, DNP PVM Materials: • Machined components are manufactured using solid Steel or 316 Stainless Steel bar stock • Chrome Steel ball valve is mechanically seated to improve low pressure sealing performance • Steel nipples are machined from solid high strength Steel bar stock • Steel componentry is plated using ROHS Compliant Trivalent Chrome Seal Components: • Urethane seal is standard in ball valve couplers and provides resistance to extrusion when subjected to high pressure - temperature range -40°C to +82°C (-40°F to +180°F) • Nitrile seals are standard in poppet valve couplings, providing a temperature range of -40°C to +121°C (-40°F to +250°F)

Request for a quote

DIXON GROUP EUROPE LTD

United Kingdom

Interchange Data: • Bowes Interchange Bayonet Style • Interchangeable with Bowes 51000-Series, National Series ‘B’, Dixon Dixlock, MacDonald Quick-Action, Adlock Materials: • Machined components are manufactured using solid Steel, Brass, or 303 Stainless Steel bar stock • Phosphor Bronze retaining ring and spring maximise corrosion resistance and extend service life • Steel componentry is plated using ROHS Compliant Trivalent Chrome • Dust cap bead chain constructed of Stainless Steel Seal Components: • Nitrile (Buna-N) pneumatically energised seals are standard, temperature range -40°C to +121°C (-40°F to +250°F)

Request for a quote

DIXON GROUP EUROPE LTD

United Kingdom

Interchange Data: • Trufl ate Automotive interchange style • Parker 10-Series • Rectus 55KM • Tomco A2100/PT400 Materials: • Machined components are manufactured using solid Steel or Brass bar stock • Stainless Steel balls, retaining rings, and springs maximise corrosion resistance and extend service life • Steel componentry is plated using ROHS Compliant Trivalent Chrome • 1/4” couplers constructed of Brass with Steel sleeve and Steel tubular valve as standard • 3/8” and 1/2” couplers constructed of Steel as standard with Steel tubular valves Seal Components: • Nitrile (Buna-N) seals are standard providing a temperature range of -40°C to +121°C (-40°F to +250°F)

Request for a quote

DIXON GROUP EUROPE LTD

United Kingdom

Interchange Data: • Parker 20-Series Manual Interchange (F-Series) • Parker 30-Series Automatic Interchange (D-Series) • Foster 3, 4, 5, and 6 Series • Hansen 1000, 400, 500 (F-Series) • Hansen 3000, 4000, 5000, 6000 (D-Series) Materials: • Machined components are manufactured using solid Steel, Brass, or 303 Stainless Steel bar stock • Stainless Steel balls, retaining rings, and springs maximise corrosion resistance and extend service life • Steel componentry is plated using ROHS Compliant Trivalent Chrome • Automatic couplers constructed of Brass with Steel tubular valve as standard (3/8” to 3/4” couplers have Steel prong valves) • 1/4” manual couplers constructed of Brass with Steel sleeve and Steel tubular valve as standard • 3/8” and 1/2” manual couplers constructed of Steel as standard with Steel tubular valve. Seal Components: • Nitrile (Buna-N) seals are standard, providing a temperature range of -40°C to +121°C (-40°F to +250°F)

Request for a quote

DIXON GROUP EUROPE LTD

United Kingdom

Interchange Data: • Straight-Through Pressure-Wash Interchange • Parker ST-Series, Foster FST-Series, Tomco Series-ST, Hansen ST-Series Materials: • Machined components are manufactured using solid Steel, Brass, or 303 Stainless Steel bar stock. • Stainless Steel balls, retaining rings, and springs maximise corrosion resistance and extend service life. • Steel componentry is plated using ROHS Compliant Trivalent Chrome. • 1¼” to 2” Brass couplers have Steel sleeves as standard to maximise service life, hardened to resist deformation. • Steel nipples are hardened to provide heavy duty performance. Seal Components: • Nitrile (Buna-N) seals are standard, providing a temperature range of -40°C to +121°C (-40°F to +250°F)

Request for a quote

DIXON GROUP EUROPE LTD

United Kingdom

Interchange Data: • Interchangeable with Snap-Tite 71-Series Materials: • Machined components are manufactured using solid Steel or 316 stainless bar stock. • Stainless Steel balls, retaining rings, and springs maximise corrosion resistance and extend service life. • Steel componentry is plated using ROHS Compliant Trivalent Chrome. • Steel coupler sleeves are hardened to resist deformation and maximise service life. • Steel nipples are hardened to provide heavy duty performance. Seal Components: • Nitrile (Buna-N) seals are standard, providing a temperature range of -40°C to +121°C (-40°F to +250°F). • All couplers and nipples incorporate PTFE or TPC-ET anti-extrusion rings to protect the seal components from dynamic impulse damage.

Request for a quote

DIXON GROUP EUROPE LTD

United Kingdom

Interchange Data: • Interchangeable to ISO16028 • Parker FEM-Series, Snap-Tite 74-Series, Hansen FF, Aeroquip/Eaton FD89, Stucchi FIRG/Series ‘A’, • Faster FFN/FFI/2FFN/2FFI, Safeway FF49-Series Seal Components: • 3/8”, 1/2”, and 3/4” nipples have molded Polyurethane valve seals,with a temperature range of -54°C to +100°C (-65°F to +212°F) • 1/4”, 5/8” and 1” to 2” nipples have Nitrile-Energised PTFE valve seals, with a temperature range of -40°C to +121°C (-40°F to +250°F) • Couplers have a polyurethane valve stem O-Ring, with a temperature range of -54°C to +100°C (-65°F to +212°F) • Ancillary coupler and nipple seals are Nitrile (Buna-N), temperature range of -40°C to +121°C (-40°F to +250°F) • PTFE or TPC-ET Anti-Extrusion ring protects main coupling valve seal from dynamic impulse pressure damage Materials: • Machined components are manufactured using solid Steel or 316 Stainless Steel bar stock • Stainless Steel balls, retaining rings, and springs maximise corrosion resistance a

Request for a quote

DIXON GROUP EUROPE LTD

United Kingdom

Interchange Data: • European High-Flow Interchange • 1/4” interchanges with Coilhose Megaflow, CEJN 320, and Rectus 25KA/26KA • 3/8” interchanges with Rectus 27KA and Series 410 Materials: • Machined components are manufactured using solid Steel or Brass bar stock • Stainless Steel balls, retaining rings, and springs maximise corrosion resistance and extend service life • Steel componentry is plated using ROHS Compliant Trivalent Chrome. • 3/8” and 1/2” couplers constructed of Steel as standard with Steel tubular valves Seal Components: • Nitrile (Buna-N) pneumatically energised seals are standard, providing a temperature range of -40°C to +121°C (-40°F to +250°F)

Request for a quote

STARRAG GMBH

Germany

The Bumotec s1000 C horizontal transfer machine was designed to manufacture prismatic parts from round or profiled bar stock. Small and complex components can be efficiently machined in medium to large batch sizes. The machine is configured with seven 4axis machining stations, each equipped with 4 machining spindles (2 horizontal and 2 vertical). The eight stations comprise a 4axis cut off station with a single spindle. An optional ninth station allows the component to be reclamped to allow the sixth side of the component to be machined with an additional 3axis, 3 or 4 spindle machining unit. The machine is equipped with an automatic bar feed and quick change tool clamping system for optimum production rates. Features 9 machining stations Up to 36 tools integrated into the machine

Request for a quoteResults for

Bar stocks - Import exportNumber of results

36 ProductsCategory

- Fittings, pipe, tube and hose - plastic (11)

- Metals - Machines & Equipment (3)

- Industrial cutting machine tools (2)

- Machine tools, metal machining - parts and accessories (2)

- Boring - steels and metals (1)

- Bulk materials for construction (1)

- Machine tools, metal shaping - parts and accessories (1)

- SMALL METAL PARTS (1)

- Sheet metal and strips, tinplate (1)