- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- blades- circular

Results for

Blades- circular - Import export

WEBER FOOD TECHNOLOGY GMBH

Germany

Flexible processing: Highly flexible machine programme for trimmers and splitters for industrial use. The position and number of circular blades can be set individually for the splitter. The variably adjustable cutting width also allows the trimmer to be used as a strip cutter. Advantages Splitting center pieces Variable cutting width Divided discharge belt Modern Hygiene Design

Request for a quote

AVOLA MASCHINENFABRIK A. VOLKENBORN GMBH & CO. KG

Germany

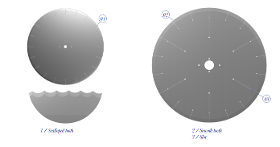

The high noise level at a construction site can damage the health of construction workers and others. Residents near a building site are often suffer for weeks and months due to noise emissions. Since in most cases it is not possible to protect the whole work area of the building site against noise emissions, it must be attempted to make the individual construction machines and devices less noisy. For equipping circular building site saws, AVOLA has developed a special blade-type HM/A/SG = carbide tipping/wolf tooth/silenced. This saw blade has eight serpentine laser incisions in the master blade 8 that reduce drumming of the master blade. At the same time, these laser incisions are distributed in such a way that the master blade still retains the pretension that is needed for the stability of the saw blade when idling and cutting.

Request for a quote

STEINSTOSSER & SCHMACHTENBERG GMBH & CO. KG

Germany

Rotary shear knives made from tool and PM steels in the highest OEM quality with a hardness of up to 60 HRc. CNCcontrolled machines guarantee you tight and consistent form and position tolerance for the knives. Inquire now.

Request for a quote

STEINSTOSSER & SCHMACHTENBERG GMBH & CO. KG

Germany

State of the art machines, tightest tolerances Machine knives for use in steel production are challenging from a production engineering point of view and place enormous demands on quality. A knife change always entails a long and thus costly system shutdown; consequently, long knives and circular knives from our company are characterised not only by very high accuracy, but also by their extreme resistance to wear. In the past, we have made serious investments in our machine fleet, in order also to produce to the most complicated geometries and tightest tolerances. In addition to standard qualities, we also deliver special qualities for particular stress at high temperatures.

Request for a quote

AVOLA MASCHINENFABRIK A. VOLKENBORN GMBH & CO. KG

Germany

AVOLA Circular saw blade HM/A/PH for cutting polystyrene and wood Special benefits of our patented development: One saw blade for two materials For polystyrene (Styrodur and styrofoam) and wood No jamming and sticking, because the newly developed openings in the master blade ensure sufficient air cooling Even without blade replacement More safety and occupational protection Faster, more effective and environmentally friendly operation

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

Every Weber slicer contains a Weber blade. The involute or circular blades are manufactured in Weber's own blade factory in Mecklenburg-Lower Pomerania and marketed worldwide under the Durablade brand. Weber Durablade involute and circular blades let you make the best cut at all times: with maximum hygiene, slicing quality, resilience and durability. Durablade blades are now also available to fit other manufacturers' slicers. Price advantage thanks to new manufacturing technology We are continuously investing in research, progress and manufacturing technology. We recently supplemented our blade production with a robot-controlled and high-performance production system, which combines quality assurance with maximum profitability. Weber Durablade involute and circular blades let you make the best cut at all times: with maximum hygiene, cut quality, resilience, durability and reduced prices.

Request for a quote

ADAÇAM MACHINE AND BAND SAW FACTORY

Turkey

its a brand known all over the world its 100% german steel leitz which is produced in europe oroved it self

MONGIN

France

GLASS WOOL LENGTHWISE AND / OR TRANSVERSAL CUTTING : CIRCULAR KNIVES Our production capacity enables us to manufacture circular knives up to a diameter of 900 mm. Cooling slots with or without copper rivets in order to limit vibration and heat’s deformation; different teeth to meet your product requirements.

Request for a quote

MONGIN

France

Precut packaging blades N°7 - Perforating circular knife

Request for a quote

MONGIN

France

For precutting biscuits trays or packaging, we produce perforating circular blades to ensure easy opening

Request for a quote

MONGIN

France

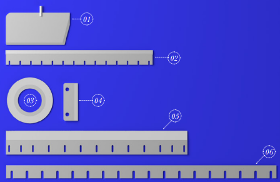

Ice blade N°1 - Doctor blade « freezer Cheese blade N°2 - Cheese wheel cutting blade Vegetable and fruit blades N°3 - Vegetable cutting blade Meat cutting blade N°4 - Circular blade with STORK fixing N°5- Circular blade with hole fixing N°6 - Blade for STORK machine N°7 - Blade for STORK machine

Request for a quote

MONGIN

France

For cereal bars, we manufacture circular blades adequate for lengthwise cutting and straight blades for your cross cut. Specific blades for extruded products can be manufactured.

Request for a quote

MONGIN

France

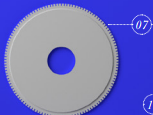

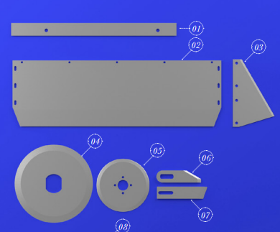

Cookie dough blades N°1 - Straight knife with attachment N°2 - Straight-edged knife Cereal bar blades N°3 - Circular knife N°4 - Extruding blade N°5 - Straight-edged blade Blades to scrape food from cylinders N°6 - Doctor blade

Request for a quote

AVOLA MASCHINENFABRIK A. VOLKENBORN GMBH & CO. KG

Germany

As a market leader for circular building site saws and with more than 80 years of experience, we know what is important. With this knowledge, we work continually to keep products up to date, thereby offering the highest-quality, most durable and safest machines.Changes in the machinery directive For improved safety, we have developed a safety hood that has proven to significantly reduce occupational accidents as part of the revision of standard EN 1870-19 prior to the amendment of the Machinery Directive 2006/42/EC. This was awarded the EURO Test Prize of the EU Builder's Trade Associations. Since the new machinery directive went into effect in 2010, all new circular building site saws have been equipped with the newly improved safety hood and other essential safety components and have been delivered exclusively in this version.

Request for a quote

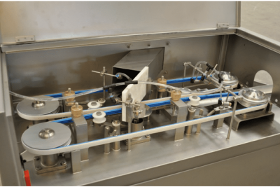

WEBER FOOD TECHNOLOGY GMBH

Germany

Get the most out of your slicer blades! With the weSHARP 7000 sharpening center, you can quickly and easily get back the ideal slicing properties of your blades, even after intensive use in the slicer. The weSHARP 7000 is suitable for the refurbishment of all Weber Durablade Performance, involute and circular blades, and guarantees a precise and reproducible sharpening result with minimal material loss of the cutting edge. Thanks to program recognition and data storage, the sharpening process can be completed in the shortest possible time, and the use of tool-free fast-change systems also ensures that setup times are kept to a minimum. Advantages Simple operation with RFID technology Sharpening of all Durablade circular and involute blades Precise and reproducible sharpening result Precise sharpening process thanks to servo drive Convenient handling via touchscreen

Request for a quote

FERPLAST SNC

Italy

HORIZONTAL DOUBLE CUTTERS BD 122 - BD 220 Universal cutters for cutting paper, corrugated cardboard, reinforced papers and polythene, polyethylene foil, polyethylene bubble, polyethylene foam. This series is very useful because you can use at the same time two different materials. The use of the cutter is extremely simple: it is necessary to carry the material to the desired length and manually operate the blade holding carriage, the cut is clean and precise in both directions. All the cutters are mounted on a frame complete with coil holder and rubber feet, on request may have the wheels with brake. For reasons of space the product is shipped disassembled. The cutter can be equipped with: RHOMBOIDAL BLADES: suitable for cutting plastic film, polyethylene foil, bubble wrap or foam. CIRCULAR BLADES: suitable for cutting paper, corrugated paper and reinforced.

Request for a quote

AVOLA MASCHINENFABRIK A. VOLKENBORN GMBH & CO. KG

Germany

Avola building site table saw ZBV 500 S with height and tilt adjustment and safety guard. The new ZBV 500-S is a height and tilt adjustable building site circular saw with a 500 mm saw blade. The ZBV 500-S also enables bevel cuts with a high cutting height on the construction site. Above all, the increasingly used insulating material can be optimally processed in connection with the AVOLA special circular saw blade HM / A / PH (see above).

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

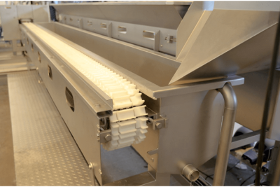

DAMS MACHINE

Turkey

It is used in splitting (cutting/ slicing) the sandwich and hamburger breads before packaging. Circular blade is used, this blade is easy to remove and install. 304 Cr-Ni is manufactured on the surfaces that the product touches. The bands used are suitable for food. Product feeding is done manually. There are three adjustment arms; First Setting Arm It is top pressing setting. The top band is adjusted according to the thickness of the bread to be split and the bread is prevented from flying during cutting.

Request for a quote

MERCEL, CUTTING KNIVES S.R.O.

Czech Rep.

Circular knives are always very sharp, whether before or after use, and serious injuries can occur if used improperly. Our circular knives for paper are serially equipped with a blade guard by the manufacturer. It may only be removed when the knife is put into operation. This also applies to the assembly and disassembly of knives onto the machine or off the machine, and in the case of machine repair in the area of circular knives. When handling circular knives (transport, assembly, disassembly), personal safety equipment such as cut-resistant shoes, safety shoes, etc. must be observed. This is true even when the blade guard is attached. The circular knife for paper may be used for the purposes described herein. Other use is not permitted. Improper use can lead to serious injuries. Follow the machine manufacturer's instructions

Request for a quote

RONIX GMBH

Germany

Ronix segmented granite cutting discs are manufactured by hot press production process with fully automated machines. In comparison to cold press production process, the hot-press cutting wheels can deliver higher efficiency. These circular granite cutting blades have also a longer life cycle compared to others. To provide the users with a great cutting experience, the best possible and highest quality raw materials are used to produce Ronix granite cutters. The unique formulation of materials in the diamond tips of these discs, minimizes friction between the workpiece and the blade which results in a faster and cooler cut

Request for a quote

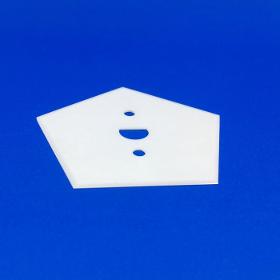

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Ceramic Pentagon Blades are very suitable for fibers, tapes, film, leather, paper cutting machine application. Our material is yttrium stabilizes zirconia ceramic. Unlike other ceramic matetials, Zirconia ceramic is a material with high flexural roughness.Therefore it is not fragile and proper for producing blades. Another advantage is very sharp. Cutting performace is better than Tungsten carbide Industry: The range of applications for our ceramic cutters used as shears, blades, knives or circular cutters in Industry as below; >Textile Industry >Medical >Paper >Semiconductor >Automotive >Chemical Fibers >Film and Foil >Fiberglass >Artword and DIY >Food and beverage production

Request for a quote

PROEX PACK SP. Z O.O.

Poland

Our offer includes, amongst the others, services within the range of cutting as well as winding the foil and paper. We have modern machines intended for cutting the films on the widths from 30 mm – 1600 mm, in the way defined by our Client. All our machines are equipped both with circular knifes and blades (tolerance +/- 1,5 mm). Technical parameters for cutting: Max. working width: 1600 mm Max. diameter of the parent roller: 800 mm Max. diameter of the winded roller: 600 mm Cutting width: 30 mm – 1600 mm Internal diameter of the core: 76 mm and 152 mm

Request for a quote

GAICTECH

Spain

Designed for the efficient processing of small pelagic fish, this Cutting and Double Gutting Machine, made from high-quality stainless steel AISI 316-304, ensures durability and hygiene in seafood processing. Capable of handling up to 350 fish per minute, it offers flexibility with options to cut just the head or both head and tail, tailored to the size requirements of the output. The machine employs circular blades for precise cutting, coupled with a vacuum suction system for clean gut removal, storing waste in a built-in deposit or separately for ease of disposal. Its design includes adjustable transport buckets and an oversight system to immobilize fish during processing, ensuring consistent quality. This versatile machine is suitable for a variety of small pelagic fish, streamlining the cutting and gutting process with easy adjustments for different fish sizes, enhancing operational efficiency and product quality.

Request for a quote

GAICTECH

Spain

The Cutting and Gutting / Nobbing Machine is specifically designed for the automated de-heading and gutting of pelagic fish species such as sardines, horse mackerel, and mackerel, crafted from durable stainless steel AISI 316-304 for longevity and food safety. Capable of processing up to 350 fish per minute in a standard setup, and optionally up to 500 fish per minute depending on the fish type, this machine offers versatility with options to cut just the head or both head and tail. It features transport buckets designed to accommodate varying fish sizes and desired product outcomes, using sharp circular blades for precise cutting and a vacuum suction for efficient gut removal, with options for internal or separate waste storage. The machine includes an easy-to-adjust cutting regulation system to cater to different fish sizes and an upper oversight system that immobilizes fish during processing, ensuring consistency and quality.

Request for a quote

GAICTECH

Spain

The Sardine Gutting Machine is meticulously designed for the specific task of gutting sardines, ensuring high efficiency and precision in seafood processing. Capable of handling up to 300 fish per minute, this machine features a transport system with specially designed belts to smoothly drag the fish through the gutting process. It performs both the trunk cut by the front and the belly cut by the side, utilizing two circular blades for the gutting system. Constructed from durable stainless steel AISI 316-304, the machine combines robustness with ease of maintenance. Its simple operation is complemented by a flip-top lid offering easy access to internal mechanisms, equipped with an electrical interlock for enhanced safety during maintenance or accidental openings. This gutting machine can seamlessly connect with any cutting-gutting machine on the market, offering versatility

Request for a quote

SOPEM

Belgium

Year - 1975 - width : 1400 mm - maximum diameter at unwinding : 1000 mm - maximum diameter at rewinding : 320 mm - cutting by razor blade or circular knife

Request for a quote

M.R. MACHINE KNIVES LTD.

United Kingdom

We are capable of producing a variety of blades for food processing and slaughtering machines. Offering blades in the best quality stainless steel, we are able to meet stringent requirements put in place by our customers to ensure our blades are food-safe. We recognise a lot of OEM reference codes, but we are also able to reverse engineer our blades from samples, or from your own technical drawing. Applications for these type of blades could include fish slicing, breaking meat, cutting meat, slaughtering animals, trimming meat, skinning fish, slicing meat and processing poultry all the way through the production line.

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Korzonek Klarwerkstechnik, METZEN’s sewage treatment branch, has been a competent and trusted sewage engineering partner to local authorities, wastewater companies and industrials for over 30 years. We design and manufacture custom spare parts for all scrapers and refurbish them to guarantee their long service life. Longitudinal scraper chassis Circular scraper chassis Drive wheel with direct drive for circular scrapers Rack-and-pinion drive chassis Rack-and-pinion rails Longitudinal scraper chassis with stabilising cross beam and rail drive Rack-and-pinion drive with rail impeller Bolt rail for rack-and-pinion drive Rail longitudinal scraper chassis with synchronously controlled drive Pivot bearings and slip ring systems We manufacture and assemble pivot bearings and slip ring systems with hose swivel joints or without hose access. Scraping blades for longitudinal and circular scrapers We manufacture and assemble single and multi-piece scraping blades.

Request for a quote

M.R. MACHINE KNIVES LTD.

United Kingdom

We can supply a variety of circular and special blades, whether they are of a standard specification or for a custom design. Our team have the technical skills and knowledge to work alongside our customers to help them meet their specific needs. Our main focus is to provide competitive pricing, quick lead times and a focus for maintaining the highest quality for our customers.

Request for a quoteResults for

Blades- circular - Import exportNumber of results

41 ProductsCountries

Category

- Blades, circular (7)

- Steam polishers (3)

- Bakery and confectionery industry - machinery and equipment (2)

- Blades and knives, industrial (2)

- Food Industry - Machines & Equipment (2)

- Meat processing machines (2)

- Steels and metals - forming and cutting (2)

- Adjustment - machine tools (1)

- Blades for saws and cutting machines (1)

- Ceramics, industrial (1)

- Concrete forms (1)

- Cutters and splicers, film (1)

- Food packaging (1)

- Hydraulic equipment (1)

- Packing and packaging - machinery and equipment (1)

- Sawing machine tools (1)

- Sharpening - machine tools (1)

- Tools, pneumatic (1)