- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cause analysis

Results for

Cause analysis - Import export

GMN PAUL MÜLLER INDUSTRIE GMBH & CO. KG

Germany

With more than ten GMN authorized GMN service centers throughout the world, we offer our customers over 80 years of experience in the development and production of machine spindles. Our extensive service network ensures that we can offer expert advice as well as long term maintenance and quick repairs. If the spindle function is compromised, GMN service technicians are on-site quickly to ensure that our customers maintain maximum productivity. Equipped with the latest technology, GMN repair service guarantees a detailed cause analysis and professional service – worldwide.

Request for a quote

EC PLAZA

South Korea

This oil condition sensor measures permittivity in the oil to check oil conditions such as oil life. By detecting oil condition, it can be widely used for finding solution. - Estimate lifespan of oil to determine the optimal time to replace the lubricant - Permittivity changes against degradation, additives, contaminants, wear particles, moisture, and mixing of different oils - Decision whether to operate oil purifier to remove degraded by-products - Quick diagnosis and cause analysis of abnormality for lube oil property and contamination-related thing - Optimal lubricant selection for the equipment - Can measure oil life without consumables - Short measuring time - Can measure up to 0.01% resolution under various harsh operating conditions - LoRa wireless communication available. Data collector is sold separately - Necessary to adjust the direction of sensor probe so that oil passes through between 2 PCB on the probe.

Request for a quote

MAINTENANCE PARTNERS

Belgium

Our field service teams carry out a wide variety of tests and measurements : Vibration analysis Laser alignment Dynamic balancing Oil analysis Electrical analysis Transformer analysis Thermography / Infrared Non-destructive tests (NDT – according to API RP 585, API RP 7G, ASNT SNT-TC-1A & ESC practices) Vibration Analysis Vibrations in a machine are generated by certain elements moving relatively to each other. These vibrations contain a lot of information about the condition of the machine and indicate whether there are problems or not. By performing a vibration analysis we can not only measure the severity of a particular problem, but in many cases, the exact location and cause of the problem. Vibration analysis can detect the following malfunctions: Imbalance Alignment error Eccentricity Bearing condition Condition of Gear Sets Belt and Pulley condition Mechanical looseness Electromagnetically induced forces

Request for a quote

MAINTENANCE PARTNERS

Belgium

Our field service teams carry out a wide variety of tests and measurements : Vibration analysis Laser alignment Dynamic balancing Oil analysis Electrical analysis Transformer analysis Thermography / Infrared Non-destructive tests (NDT – according to API RP 585, API RP 7G, ASNT SNT-TC-1A & ESC practices) Vibration Analysis Vibrations in a machine are generated by certain elements moving relatively to each other. These vibrations contain a lot of information about the condition of the machine and indicate whether there are problems or not. By performing a vibration analysis we can not only measure the severity of a particular problem, but in many cases, the exact location and cause of the problem. Vibration analysis can detect the following malfunctions: Imbalance Alignment error Eccentricity Bearing condition Condition of Gear Sets Belt and Pulley condition Mechanical looseness Electromagnetically induced forces Aerodynamically induced forces Hydraulically induced...

Request for a quote

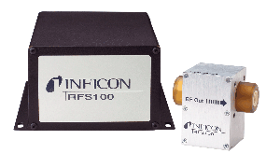

INFICON AG

Liechtenstein, Principality of

RF Sensor with FabGuard Provides Real-time Plasma Process Analysis to Significantly Reduce Process Variability INFICON RF sensor technology provides highly accurate, broadband, frequency discriminant RF measurement for semiconductor processing tools. This RF data provides detailed insight on actual plasma conditions of both process development and production process problems to significantly reduce process variability. The latest in its suite of advanced process control in situ sensors, this non-intrusive in-line cable mount RF sensor combines with FabGuard Sensor Integration and Analysis Systemto offer critical diagnostic information, e.g. accurate chamber and process power and impedance measurement, root cause analysis of faults (such as matching network problems), process fingerprinting for chamber matching, and wafer metrology modeling in PVD, CVD and etch applications. INFICON RF sensor technology with FabGuard generates highly accurate models that predict wafer metrology...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

INFICON AG

Liechtenstein, Principality of

Tool Management, Process Specific INFICON Sensor Integration and Analysis Systems provide process verification and control, including run-to-run control of key process parameters for process optimization and immediate and automatic feedback to the process equipment or a process engineer on any faults detected and their probable cause. FabGuard Sensor Integration and Analysis System takes data from in situ sensors, integrates that data with data from the process equipment itself, and condenses and analyzes it to provide the process engineer with actionable information. Alternatively, the engineer can choose to have FabGuard automatically send control commands directly to the process equipment. Powerful Data Management for Enhanced Productivity Make your fab's data work for you. The FabGuard Sensor Integration and Analysis System enhances tool productivity, by providing process control, and reducing losses from process drift, contamination, tool malfunction, or unnecessary test...

Request for a quoteResults for

Cause analysis - Import exportNumber of results

7 Products