- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- ceramics- industrial

Results for

Ceramics- industrial - Import export

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

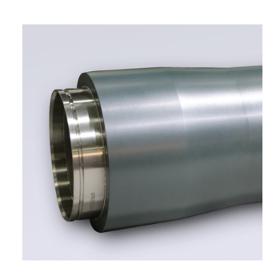

Chemical Composition: AZO Molding process: CIP+Sintering+Bonding Purity: ≥5.4g/cm3 Density: ≥ 99.95% Application: Widely used in Thin film solar cell electrode film, Low-e glass film Maximum Machining Size L 4000MM T 5MM Straight & Dogbone Customize to Customers' Specification

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Hexagonal Boron Nitride has a microstructure similar to that of Graphite. In both materials this structure, made up of layers of tiny platelets, is responsible for excellent machinability and low-friction properties. we called hexagonal boron nitride (HBN) or white graphite. Material of Boron Nitride Ceramics: Pyrolytic Boron Nitride: 99.99% Boron Nitride* 99 Boron Nitride: Boron Nitride + Boric Oxide (B2O3) CABN: Boron Nitride + Calcium Borate ALBN: Boron Nitride + Al2BO3 ZRBN: Boron Nitride + Zirconium Oxide + Boric Oxide (B2O3) ZABN: Boron Nitride + Zirconium Oxide + Aluminum Nitride + Al2BO3 SCBN: Boron Nitride + Silicon Carbon + Al2BO3 Processing of Boron Nitride Ceramics: 1.Hot Pressed Sintering 2.Chemical Vapor Deposition

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

The aluminum nitride (AlN) ceramic has high thermal conductivity(5-10 times as the alumina ceramic), low dielectric constant and dissipation factor, good insulation and excellent mechanical properties, non-toxic, high thermal resistance, chemical resistance ,and the linear expansion coefficient is similar with Si,which is widely used in communication components, high power led, power electronic devices and other fields.Special spec products can be produced upon requests. Product Features: 1.Uniform microstructure 2.High thermal conductivity* (70-180 Wm-1K-1), tailored via processing conditions and additives 3.High electrical resistivity 4.Thermal expansion coefficient close to that of Silicon 5.Resistance to corrosion and erosion 6.Excellent thermal shock resistance 7.Chemically stable up to 980°C in H2 and CO2 atmospheres, and in air up to 1380°C (surface oxidation occurs around 780°C; the surface layer protects the bulk up to 1380°C).

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

The aluminum nitride (AlN) ceramic has high thermal conductivity(5-10 times as the alumina ceramic), low dielectric constant and dissipation factor, good insulation and excellent mechanical properties, non-toxic, high thermal resistance, chemical resistance ,and the linear expansion coefficient is similar with Si,which is widely used in communication components, high power led, power electronic devices and other fields.Special spec products can be produced upon requests. Product Features: 1.Uniform microstructure 2.High thermal conductivity* (70-180 Wm-1K-1), tailored via processing conditions and additives 3.High electrical resistivity 4.Thermal expansion coefficient close to that of Silicon 5.Resistance to corrosion and erosion 6.Excellent thermal shock resistance 7.Chemically stable up to 980°C in H2 and CO2 atmospheres, and in air up to 1380°C (surface oxidation occurs around 780°C; the surface layer protects the bulk up to 1380°C).

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

The aluminum nitride (AlN) ceramic has high thermal conductivity(5-10 times as the alumina ceramic), low dielectric constant and dissipation factor, good insulation and excellent mechanical properties, non-toxic, high thermal resistance, chemical resistance ,and the linear expansion coefficient is similar with Si,which is widely used in communication components, high power led, power electronic devices and other fields.Special spec products can be produced upon requests. Product Features: 1.Uniform microstructure 2.High thermal conductivity* (70-180 Wm-1K-1), tailored via processing conditions and additives 3.High electrical resistivity 4.Thermal expansion coefficient close to that of Silicon 5.Resistance to corrosion and erosion 6.Excellent thermal shock resistance 7.Chemically stable up to 980°C in H2 and CO2 atmospheres, and in air up to 1380°C (surface oxidation occurs around 780°C; the surface layer protects the bulk up to 1380°C).

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

The aluminum nitride (AlN) ceramic has high thermal conductivity(5-10 times as the alumina ceramic), low dielectric constant and dissipation factor, good insulation and excellent mechanical properties, non-toxic, high thermal resistance, chemical resistance ,and the linear expansion coefficient is similar with Si,which is widely used in communication components, high power led, power electronic devices and other fields.Special spec products can be produced upon requests. Product Features: 1.Uniform microstructure 2.High thermal conductivity* (70-180 Wm-1K-1), tailored via processing conditions and additives 3.High electrical resistivity 4.Thermal expansion coefficient close to that of Silicon 5.Resistance to corrosion and erosion 6.Excellent thermal shock resistance 7.Chemically stable up to 980°C in H2 and CO2 atmospheres, and in air up to 1380°C (surface oxidation occurs around 780°C; the surface layer protects the bulk up to 1380°C).

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

The aluminum nitride (AlN) ceramic has high thermal conductivity(5-10 times as the alumina ceramic), low dielectric constant and dissipation factor, good insulation and excellent mechanical properties, non-toxic, high thermal resistance, chemical resistance ,and the linear expansion coefficient is similar with Si,which is widely used in communication components, high power led, power electronic devices and other fields.Special spec products can be produced upon requests. Product Features: 1.Uniform microstructure 2.High thermal conductivity* (70-180 Wm-1K-1), tailored via processing conditions and additives 3.High electrical resistivity 4.Thermal expansion coefficient close to that of Silicon 5.Resistance to corrosion and erosion 6.Excellent thermal shock resistance 7.Chemically stable up to 980°C in H2 and CO2 atmospheres, and in air up to 1380°C (surface oxidation occurs around 780°C; the surface layer protects the bulk up to 1380°C).

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Black High Purity Aluminum Nitride Ceramic Plate Hot pressed aluminum nitride (AlN) is used in applications requiring high electrical resistivity in additional to exceptional thermal conductivity. The applications for hot pressed AlN typically involve rigorous or abrasive environments and high-temperature thermal cycling.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

The aluminum nitride (AlN) ceramic has high thermal conductivity(5-10 times as the alumina ceramic), low dielectric constant and dissipation factor, good insulation and excellent mechanical properties, non-toxic, high thermal resistance, chemical resistance ,and the linear expansion coefficient is similar with Si,which is widely used in communication components, high power led, power electronic devices and other fields.Special spec products can be produced upon requests. Product Features: 1.Uniform microstructure 2.High thermal conductivity* (70-180 Wm-1K-1), tailored via processing conditions and additives 3.High electrical resistivity 4.Thermal expansion coefficient close to that of Silicon 5.Resistance to corrosion and erosion 6.Excellent thermal shock resistance 7.Chemically stable up to 980°C in H2 and CO2 atmospheres, and in air up to 1380°C (surface oxidation occurs around 780°C; the surface layer protects the bulk up to 1380°C).

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

The aluminum nitride (AlN) ceramic has high thermal conductivity(5-10 times as the alumina ceramic), low dielectric constant and dissipation factor, good insulation and excellent mechanical properties, non-toxic, high thermal resistance, chemical resistance ,and the linear expansion coefficient is similar with Si,which is widely used in communication components, high power led, power electronic devices and other fields.Special spec products can be produced upon requests. Product Features: 1.Uniform microstructure 2.High thermal conductivity* (70-180 Wm-1K-1), tailored via processing conditions and additives 3.High electrical resistivity 4.Thermal expansion coefficient close to that of Silicon 5.Resistance to corrosion and erosion 6.Excellent thermal shock resistance 7.Chemically stable up to 980°C in H2 and CO2 atmospheres, and in air up to 1380°C (surface oxidation occurs around 780°C; the surface layer protects the bulk up to 1380°C).

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

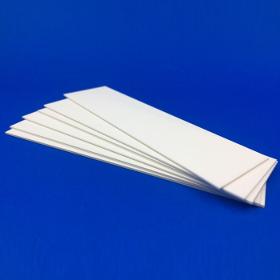

Product Name:Aluminum Nitride Ceramic Substrate, AlN Ceramic Sheet Application:Often used in electrical and electronic fields requiring heat conduction, heat dissipation, insulation, high temperature resistance,high voltage breakdown resistance, high thermal conductivity, good stability. Product specifications: Conventional models are TO-220, 247, 264, 3P Range thickness: 0.25mm, 0.385mm, 0.5mm, 0.635mm, 0.8mm, 1mm, 1.5mm, 2mm, 3mm Product Advantages: Aluminum nitride ceramics have excellent thermal conductivity (7-10 times of alumina ceramics),low dielectric constant and dielectric loss, reliable insulation performance, excellent mechanical properties, non-toxic, high temperature resistance, chemical corrosion resistance, and the thermal expansion coefficient of silicon is similar, as a new generation of ceramic materials, more and more by people Attention and attention.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

The aluminum nitride (AlN) ceramic has high thermal conductivity(5-10 times as the alumina ceramic), low dielectric constant and dissipation factor, good insulation and excellent mechanical properties, non-toxic, high thermal resistance, chemical resistance ,and the linear expansion coefficient is similar with Si,which is widely used in communication components, high power led, power electronic devices and other fields.Special spec products can be produced upon requests. Product Features: 1.Uniform microstructure 2.High thermal conductivity* (70-180 Wm-1K-1), tailored via processing conditions and additives 3.High electrical resistivity 4.Thermal expansion coefficient close to that of Silicon 5.Resistance to corrosion and erosion 6.Excellent thermal shock resistance 7.Chemically stable up to 980°C in H2 and CO2 atmospheres, and in air up to 1380°C (surface oxidation occurs around 780°C; the surface layer protects the bulk up to 1380°C).

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

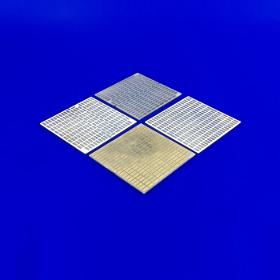

AMB Ceramic Substrate is a method to realize the bonding of ceramic and metal by reacting a small amount of active elements Ti and Zr in filler metal with ceramics to form a reaction layer which can be wetted by liquid filler metal. Advantage: The combination is achieved by chemical reaction between ceramic and active metal solder paste at high temperature, so its bonding strength is higher and reliability is better. Disadvantage: The reliability of AMB process depends largely on the composition of active filler metal, brazing process, brazing layer structure and many other key factors。 Specification >Metallization thickness: 25 ±10um >Nickel thickness:2~10um; >Pin full strength: 4200kgf/cm2 avg. (at Φ3.0mm pin)

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

DBC (Direct Bonded Copper) tenique denotes a special process in which the copper foil and the al2o3 or AlN (one or both sides) are directly bonded under appropriate high temperature. The finished super-thin DBC substrate has excellent electrical isolation,high thermal conductivity, fine solderability and high bonding strength.It may be structured just lick PCB to get etched wiring and has high curreng loading capability .Therefore DBC ceramic substrates have become the base material of tuture for both the construction and the interconnection techniques of high power semiconductor electronic circuits and also have been the basis for "chip on boaed" technology which repre-sents the packaging trend in century. Specification >Metallization thickness: 25 ±10um >Nickel thickness:2~10um >Pin full strength: 4200kgf/cm2 avg. (at Φ3.0mm pin)

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

High Hermeticity Metallized Ceramic Bushing Features: 1.Material: 96% Aluminia(AL2O3) 2.Coating Layer:Molybdenum-Mananese(Mo/Mn) 3.These metallized ceramics are ideal for high voltage, high vacuum and high pressure applicationos. So far the most widely-used and effective method for creating a leak-tight, robust joint between ceramic and metal is by brazing . A thin layer of metal deposited on a ceramic part enables brazing between ceramic and metal part that h as a different coefficient of thermal expansion. A layer of Molybdenum-Manganese is deposited with a typical thickness of 8 to 30 µm after sintering. The metallized surface receives a secondary coating of nickel to seal and improve wettability for later brazing. Applications: Electrical transmission and distribution Electronics industry Textile machinery Defense Medical electronics Automobile industry Sealing Solid Oxide Fuel Cells High temperature application

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Metallized Ceramic Componenets: Innovacera supplies precision metallized ceramic parts in aluminum oxide ceramics for the medical, and aerospace industries. Through spray, needle, and brush coatings or screen printing our capabilities allow us to metallized on flat, cylindrical, and complex ceramic bodies. Moly-Manganese is the typical base coat materials used for metallization.In order to achieve the welding between ceramic and metal, the ceramic surface firmly adheres to a layer of the metal film, which is ceramic metallization.Refractory-metalized aluminum oxide ceramics widely use in power grid tubes, vacuum interrupters, and similar applications where metal to ceramic joints of exceptional strength and hermeticity is required. Specification >Metallization thickness: 25 ±10um >Nickel thickness:2~10um >Pin full strength: 4200kgf/cm2 avg. (at Φ3.0mm pin) Available Ceramic Composition >94%,96%,99%,99.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Metallized Ceramic Componenets: Innovacera supplies precision metallized ceramic ring in aluminum oxide ceramics for the military,medical, and aerospace industries. Through spray, needle, and brush coatings or screen printing our capabilities allow us to metallized on flat, cylindrical, and complex ceramic bodies. Moly-Manganese is the typical base coat materials used for metallization.In order to achieve the welding between ceramic and metal, the ceramic surface firmly adheres to a layer of the metal film, which is ceramic metallization. Refractory-metalized aluminum oxide ceramics widely use in power grid tubes, vacuum interrupters, and similar applications where metal to ceramic joints of exceptional strength and hermeticity is required.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Aluminum nitride ceramics have excellent electrical and thermal properties, and are considered to be the most promising high thermal conductivity ceramic substrate materials. In order to seal the package structure, mount components and connect input and output terminals, the surface and interior of the aluminum nitride ceramic substrate need to be metallized. The reliability and performance of ceramic surface metallization have an important impact on the application of ceramic substrates, and firm bonding strength and excellent air tightness are the most basic requirements. Considering the heat dissipation of the substrate, it is also required to have high thermal conductivity at the interface between the metal and the ceramic. The metallization methods on the surface of aluminum nitride ceramics include: thin film method, thick film method, high melting point metallization method, electroless plating method, direct copper cladding method (DBC), etc.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

AMB (Active Metal Brazing) is for joining ceramics that are not wetted by 'conventional' brazes.By applying active metal like titanium to be added to the braze alloy, to achieve chemically reacts with the surface of the parent ceramic.Due to the coefficient of thermal expansion of Al2O3 (7.1 ppm/K), Si3N4 (2.6 ppm/K) and AlN (4.7 ppm/K) is close to that of silicon (4 ppm/K), Direct Bond Copper (DBC) and AMB are suitable substrates for robust packaging of bare dice since such assemblies.AMB is the promising thick film technology which can be applied to Power Electronics, Automotive Electronics, Home Appliances, Aerospace, Others. INNOVACERA provide DBC, DPC, and AMB technology for customized ceramic substrates, welcome to consult more.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

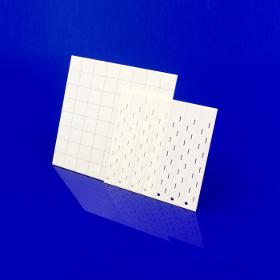

The Aluminum oxide (Al2o3 ) ceramic rectangle substrate is widely used in thick-film circuit of electronics industry. Large scale integrated circuit,power hytrid IC,semiconductor package,pieced -film reistor, network,resistor, focusing potentiometer etc.According to the demands of customers,our company can manufacture products of special types and specifications. Alumina ceramic substrate / plate specification: > 10x10x1mm, 20x20x2mm, 40x40x8mm, 100x60x8mm, 150x150x12.5mm, 200x200x25mm etc. > The thickness of ceramic plate ranges from 0.25 to 1.0mm Can be made according to your requirements.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

The Aluminum oxide (Al2o3 96%) ceramic substrate are widely used in thick-film circuit of electronics industry. Large scale integrated circuit,power hytrid IC,semiconductor package,pieced -film reistor, network,resistor, focusing potentiometer etc.According to the demands of customers,our company can manufacture products of special types and specifications. The Maximum dimension of ceramic plate is 138x138mm and the thickness of ceramic plate ranges from 0.25 to 1.0mm. Alumina Ceramic Substrate Features: > High reliablility and sfety; > High density and mechanical properties > High electrical and thermal loading perormances > Low dilelectic loss and other characteristics Alumina ceramic substrate / plate specification: 10x10x1mm, 20x20x2mm, 40x40x8mm, 100x60x8mm, 150x150x12.5mm, 200x200x25mm etc. Can be made according to your requirements.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Alumina, also known as aluminum oxide (Al2O3), is the most mature and commonly used technical ceramics. With excellent electrical insulation properties together with high hardness and good wear resistance but relatively low strength and fracture toughness. Alumina content ranging from 80% to more than 99% according to different application. It's widely used in automotive, petro-chemical, fluid contro, material transfer, industry, electrical and electronic, semiconductor,etc... - High Temperature Ability - Abrasion Resistant - Wear Resistance - Chemical Resistance - Electrical Insulator - Corrosion resistant - High compressive strength - High mechanical Strength - Resists strong acid and alkali attack at high temperatures - Excellent electrical insulation properties - Decent thermal conductivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Technical ceramics are favoured in a wide range of electronics and engineering applications for their chemical and mechanical properties. Compared to metals, they are stronger in compression, especially at higher temperatures. Ceramics have a good thermal stability (i.e. a low coefficient of thermal expansion) and good thermal and electrical resistance. They are also hard, and have excellent dimensional stability. Al2O3 Properties: Excellent electrical insulation Relatively low strength and fracture toughness Resistance to wear and corrosive Excellent thermal stability Resistance to high temperatures High electrical resistivity Good chemical stability High corrosion resistance

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Alumina ceramic jars are used whenever small quantity of samples needed to be grinded. Each jar set includes grinding jar, lid, rubber sealing gasket and different sizes of mixed alumina ceramic grinding balls. It is best container for grinding rare earth materials, precious metals, medium and low ceramic capacitors, NTC, PTC piezoelectric ceramic and lithium We can customize various types of vacuum jar according to customer's needs. Physical Parameters: Composition: Al2O3 ≥ 99% Specific Gravity: ≥3.8 g/cm³ Hardness: 9 Mho’s Bending Strength : > 350 Mpa Water Absorption Rate: ≤0.005%

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Alumina Ceramic Beads are used large quantity in the world, because of their excellent consistence and reliability. Products to these specifications are manufactured from very high quality chemical-porcelain clay materials, which has quite excellent stability, high mechanical strengthand resistance to thermal shock. This makes them all ideal choice for support of all types of catalyst.widely used for heat retention ,equilibration media,as ethylene dryers,High temperature Shift ,Low temperature shift,Ethylene cracking and drying.are widely utilized as the covering or supporting materials of the catalyst in the reactors and the packing in the columns in such varied areas as petroleum, chemical industry, chemical fertilizer, natural gas and suport or protect the active catalyst , which especially have the comparatively good mechanical strength. Feature: * Excellent abrasion resistance * High purity * Excellent corrosion resistance * Energy saving of grinding and dispersion

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Porous ceramic rods description: Porous ceramic filter rods are composed by the distributed evenly open pores which is interconnected by shape like arch , when the fluid through these pores,the suspended matter, colloidal particles, organic molecules are trapped, adsorbed inside the micropores,then track to achieve the purification and filtration homogenizing effect. The porous ceramic has the advatage with high strength, wear resistance, high temperature, corrosion, pollution, porosity distribution, long service life and easy to regenerate, which is particularly suitable for a variety of gas, liquid filtration and fluidized process. * Good electrical insulation * High dimensional tolerances * Excellent corrosion resistance * Very high working temperatures * Excellent thermal shock properties Applications of Alumina Porous Ceramic * Furnace work tubes * Kiln furniture, components & accessories * Thermocouple protection tubes * Heater Support Elements

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Alumina Aluminum AL2O3 Ceramic Water valve plate Aluminum Oxide Ceramic is wildely used in many fields including mechanical, electronics, electrical,automotive, semiconductor, textile, etc. For the good propertities, more and more customers choose Alumina ceramic materials for their applications. Alumina Ceramic can be made to Ceramic Nozzles, Ceramic Sprayers Cyclones, Ceramic Linings, Milling Systems, Ceramic Thread guides, etc. Customized designs are very often to be made. 1. Good electrical insulation 2. Moderate thermal conductivity 3. High corrosion and wear resistance 4. Good gliding properties 5. High mechanical strength 6. High compressive strength 7. High hardness

Request for a quoteResults for

Ceramics- industrial - Import exportNumber of results

270 ProductsCountries

Company type

Category

- Ceramics (145)

- Ceramics, industrial (145)

- Ceramics, porcelain and earthenware - industrial products (70)

- Ceramics, refractory (6)

- Carboxylic and anhydric acids (2)

- Ceramics - tiling (2)

- Custom packaging (2)

- Decorative porcelain (2)

- Infrared tubes (2)

- Raw materials for ceramics industry (2)

- Siliceous limestone bricks (2)

- Tile and tile floors, porcelain (2)

- Tubes, cardboard (2)

- Bulk materials for construction (1)

- Casting, steel (1)

- Ceramic and enamel kilns (1)

- Ceramic manufacturing - machinery and equipment (1)

- Ceramics, handicraft (1)

- Chemical industry - machinery and equipment (1)

- Chemicals - Basic Products & Derivatives (1)