- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- ring

Results for

Ring - Import export

PEEKCHINA CO., LTD.

China

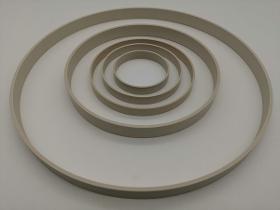

PEEK Ring Our PEEK Rings are engineered to deliver superior sealing and insulation solutions for a wide range of applications. With exceptional chemical resistance and durability, these rings excel in demanding environments, providing long-lasting reliability for critical sealing needs. Whether you require standard options or custom-tailored solutions, our PEEK Rings offer low maintenance, high reliability, and the assurance of precision sealing. Elevate your sealing capabilities with confidence in the quality and performance of PEEK Rings.

Request for a quote

PEEKCHINA CO., LTD.

China

Engineered to optimize assembly processes, our PEEK lock ring (PEEK locating ring) offers superior alignment and stability, enhancing the performance of industrial machinery. With its durable construction and reliable positioning, it ensures long-lasting performance even in the most demanding environments.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

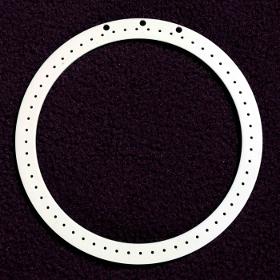

Innovacera developed a series of ceramic accessories for Inside Micrometers, Holtest and Dial Bore Gages. The ceramic material used mostly is zirconia. The zirconia ceramic setting ring advantages: Used for quick and accurate setting of dial bore gages, Holtest, and inside micrometers. If a setting ring of an optimal size is prepared, it can be used for calibration. Actual inside diameter is marked on each ring No more anticorrosion treatment is required when handling Ceramic Setting Rings normally, resulting in simple maintenance and storage. The Zirconia Ceramic Ring Gauges tolerance: Tolerance between the nominal size and the actual diameter: 0.001mm for 1-45mm DIA. setting rings Cylindricity: 0.001mm for 1-45mm DIA. setting rings Some Zirconia Ceramic Ring Gauges Innovacera made: 9mm, 10mm, 18mm, 20mm, 24mm, 25mm, 28mm

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

The aluminum nitride (AlN) ceramic has high thermal conductivity(5-10 times as the alumina ceramic), low dielectric constant and dissipation factor, good insulation and excellent mechanical properties, non-toxic, high thermal resistance, chemical resistance ,and the linear expansion coefficient is similar with Si,which is widely used in communication components, high power led, power electronic devices and other fields.Special spec products can be produced upon requests. Product Features: 1.Uniform microstructure 2.High thermal conductivity* (70-180 Wm-1K-1), tailored via processing conditions and additives 3.High electrical resistivity 4.Thermal expansion coefficient close to that of Silicon 5.Resistance to corrosion and erosion 6.Excellent thermal shock resistance 7.Chemically stable up to 980°C in H2 and CO2 atmospheres, and in air up to 1380°C (surface oxidation occurs around 780°C; the surface layer protects the bulk up to 1380°C).

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Alumina, also known as Aluminum Oxide, is a hard wearing advanced technical ceramic material frequently used in a wide variety of industrial applications. Once fired and sintered, it can only be machined using diamond-grinding methods. It features high hardness and wear resistance, low erosion levels, high temperature resistance, corrosion resistance, and bioinertness.Additionally, it can be highly polished, making it useful for a wide range of applications. Properties: 1. Good electrical insulation 2. Moderate thermal conductivity 3. High corrosion and wear resistance 4. Good gliding properties 5. High mechanical strength 6. High compressive strength 7. High hardness

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. Silicon Nitride (Si3N4) Characteristics: 1 Good thermal shock resistance 2 Creep resistance 3 Low density 4 High fracture toughness 5 High hardness and wear resistance 6 Electrical resistivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

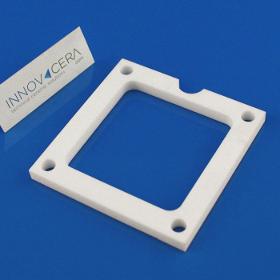

Machinable Glass Ceramic Square Ring: Machinable Glass Ceramic has a continuous use temperature of 800oC and a peak temperature of 1000oC. Its coefficient of thermal expansion readily matches most metals and sealing glasses.It processes good machinability and can be lathed, milled, planed,ground, bored, incised and threaded. It also has the advantages of insulation, pore-free, high/low-temperature resistant, acid and alkali resistant and thermal impact resistant. Macor Ceramic Square Ring Features: 1.High Dielectric Strength, Excellent Insulation 2.Good Machinability, Machinable With Ordinary Metal Tools And Fast Turnaround 3.High Precision, Hold High Tolerance 4.Excellent Acid And Alkali Resistance 5.No Outgasing And Zero Porosity 6.Withstand High Temperature Up To 800℃ Machinable Glass Ceramic Square Ring Applications: 1.high strength and high tenacity product, magnetic material, piezoelectric ceramic, dielectric ceramics

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co., Ltd engaged in Machine Parts manufacuring more than 20years, we have old lathe turning machine, automatic turning machine, and normal & high precision CNC turning machine,CNC Machining Center, we can optimize the turning processes to make the machining cost to be lowest. As a professional machine parts supplier from China,we can custom producing different structures of Stainless Steel Rings,Aluminum Rings,Brass Rings,Carbon Steel Rings,etc. Available Materials & Technical Parameters: Stainless Steel:SS201,SS301,SS304,SS304,SS430 Aluminum Alloy:AL6061,AL6068,AL7075… Carbon Steel:AISI1020,AISI1045,42CrMo… Copper & Brass:T1,T2,E-Cu,H62Pb1,H63,H59… Highest Accuracy:±5μm Surface Finish:Ra0.4 / Rz 3.2 / N5 We provide precision CNC turning & Milling Services for producing Machine Parts,such as aluminum machined rings for all industries,as long as you can provide detailed drawings and requirements, we can get back to you within two working days.

Request for a quote

YUTIAN FUTAI INTERNATIONAL TRADE CO., LTD.

China

(1)Main Parameters: *Size:3-1/2" *Material:Stainless steel *Package:200pcs/56*28*27cm,20kgs *MOQ:500Pieces *Quality:Euro-USA quality *Each order finished time guarantee:30-45 days -WHATSAPP : +8615713352738 -Yutian Futai International Trade Co.,Ltd. -http://husbandry-poutry.en.alibaba.com -Contacting Person:Mr.will -E-mail:futai_vet@126.com

Request for a quote

NINGBO TOWER INDUSTRY CO.,LTD

China

We are very suitable for the production of Dia. 300~ 1000 mm ring gear, flywheel. Please feel free to send us your inquiry.

Request for a quote

PEEKCHINA CO., LTD.

China

Elevate your industrial processes with our Large Diameter PEEK Pipes, meticulously crafted for performance excellence. These pipes boast superior mechanical strength, ensuring reliable and durable operation in the most demanding applications. With exceptional chemical resistance, they stand resilient against corrosive substances, making them ideal for a wide range of industries. The large diameter ensures efficient fluid conveyance, while the PEEK material guarantees optimal thermal stability. Upgrade your systems with confidence, knowing you've chosen a solution designed for precision and performance.

Request for a quote

PEEKCHINA CO., LTD.

China

PEEK Seal Material Our PEEK pipe sealing elements redefine reliability for valve seat inserts. Crafted from high-grade PEEK material, these inserts offer exceptional resistance to temperature variations, chemicals, and pressure, ensuring leak-free and durable sealing solutions for your valves.

Request for a quote

PEEKCHINA CO., LTD.

China

Manufacturing Process PEEK CNC Machining & Injection Molding PEEK Back Up Rings Elevate your sealing systems to new heights with PEEK back up rings. Crafted from high-performance polyetheretherketone (PEEK) material, these rings offer exceptional durability and chemical resistance, ensuring long-term reliability in even the harshest environments. With precise engineering and tight tolerances, PEEK back up rings provide optimal support to prevent extrusion and maintain seal integrity. Explore their versatility and unleash the full potential of your sealing applications today.

Request for a quote

PEEKCHINA CO., LTD.

China

PEEK DN Seating Introducing our range of PEEK seat inserts, meticulously designed to meet the diverse needs of industrial valves. From the compact DN50 to the robust DN700, these inserts ensure superior sealing performance and longevity. Crafted with precision engineering, each size guarantees optimal functionality in various applications. Choose reliability and durability across the spectrum with our DN50 to DN700 PEEK seat inserts, setting a new standard for valve efficiency. Size: DN50, DN80, DN100, DN150, DN200, DN250, DN300, DN350, DN400, DN500, DN600, DN700.

Request for a quote

PEEKCHINA CO., LTD.

China

PEEK Sealing Plastic Introducing our 6-Inch PEEK Seal, the epitome of sealing excellence. Engineered for demanding applications, it offers unparalleled reliability, durability, and chemical resistance. Whether you need a custom-tailored solution or a dependable sealing option, our 6-inch PEEK Seal ensures low maintenance, high performance, and peace of mind. Elevate your sealing capabilities today.

Request for a quote

PEEKCHINA CO., LTD.

China

Manufacturing Process CNC Machining & Injection Molding PEEK performance Polyetheretherketone (PEEK) is a high-performance, engineering thermoplastic characterized by an unusual combination of properties. These properties range from high temperature performance to mechanical strength and excellent chemical resistance. Material Grade ARKPEEK-1000: 100%PEEK Produced from virgin polyetheretherketone resin and offers the highest toughness and impact resistance of all types. ARKPEEK-CF30: 30% Carbon Fiber + 70% PEEK Carbon fiber reinforcement lends the material a high level of rigidity and creep strength, high mechanical strength and heat conductivity values. ARKPEEK-GF30: 30% glass fiber + 70% PEEK Glass filled PEEK exhibits increased mechanical strength and high rigidity. ARKPEEK-MOD: 10% Carbon Fiber + 10% PTFE +10% Graphite high performance engineering plastic with product characteristics including excellent sliding and abrasion & wear resistance, high mechanical.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PEEKCHINA CO., LTD.

China

Manufacturing Process CNC Machining & Injection Molding PEEK performance Polyetheretherketone (PEEK) is a high-performance, engineering thermoplastic characterized by an unusual combination of properties. These properties range from high temperature performance to mechanical strength and excellent chemical resistance. Material Grade ARKPEEK-1000: 100%PEEK Produced from virgin polyetheretherketone resin and offers the highest toughness and impact resistance of all types. ARKPEEK-CF30: 30% Carbon Fiber + 70% PEEK Carbon fiber reinforcement lends the material a high level of rigidity and creep strength, high mechanical strength and heat conductivity values. ARKPEEK-GF30: 30% glass fiber + 70% PEEK Glass filled PEEK exhibits increased mechanical strength and high rigidity. ARKPEEK-MOD: 10% Carbon Fiber + 10% PTFE +10% Graphite high performance engineering plastic with product characteristics including excellent sliding and abrasion & wear resistance, high mechanical.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Alumina, also known as Aluminum Oxide, is a hard wearing advanced technical ceramic material frequently used in a wide variety of industrial applications. Once fired and sintered, it can only be machined using diamond-grinding methods. It features high hardness and wear resistance, low erosion levels, high temperature resistance, corrosion resistance, and bioinertness.Additionally, it can be highly polished, making it useful for a wide range of applications. Properties: 1. Good electrical insulation 2. Moderate thermal conductivity 3. High corrosion and wear resistance 4. Good gliding properties 5. High mechanical strength 6. High compressive strength 7. High hardness

Request for a quote

WEIHAI D&S CO., LTD

China

Material: HDPE Shell Dimension: 720 x 440mm Weight: 2.5/4.3kgs

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Due to the nature of the CVD process, PBN parts generally are requested a wall thickness not more than 3mm. PBN is also a good choice for the extremely high purity of boron nitride. 99.99% is the typical grade. The CVD process gives this pyrolytic boron nitride an almost perfect layered structure, which leads to anisotropic thermal conductivity, making it an ideal material to make crucibles for crystal growing. Pyrolytic Boron Nitride Applications: Crystal growth (VGF, LEC Crucible) Molecular Beam Epitaxy(MBE) Crucible MOCVD Heater PBN Infrared Window Traveling Wave Tube (TWT) (PBN Support Rod) PBN Coating Graphite High temperature, vacuum equipment insulator

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

High Hermeticity Metallized Ceramic Bushing Features: 1.Material: 96% Aluminia(AL2O3) 2.Coating Layer:Molybdenum-Mananese(Mo/Mn) 3.These metallized ceramics are ideal for high voltage, high vacuum and high pressure applicationos. So far the most widely-used and effective method for creating a leak-tight, robust joint between ceramic and metal is by brazing . A thin layer of metal deposited on a ceramic part enables brazing between ceramic and metal part that h as a different coefficient of thermal expansion. A layer of Molybdenum-Manganese is deposited with a typical thickness of 8 to 30 µm after sintering. The metallized surface receives a secondary coating of nickel to seal and improve wettability for later brazing. Applications: Electrical transmission and distribution Electronics industry Textile machinery Defense Medical electronics Automobile industry Sealing Solid Oxide Fuel Cells High temperature application

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Metallized Ceramic Componenets: Innovacera supplies precision metallized ceramic ring in aluminum oxide ceramics for the military,medical, and aerospace industries. Through spray, needle, and brush coatings or screen printing our capabilities allow us to metallized on flat, cylindrical, and complex ceramic bodies. Moly-Manganese is the typical base coat materials used for metallization.In order to achieve the welding between ceramic and metal, the ceramic surface firmly adheres to a layer of the metal film, which is ceramic metallization. Refractory-metalized aluminum oxide ceramics widely use in power grid tubes, vacuum interrupters, and similar applications where metal to ceramic joints of exceptional strength and hermeticity is required.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Laser Ceramic Nozzle Holder Information: 1.Imported ceramics + high quality special alloy 2.Ensure the consistency of thermal expansion of ceramic ring materials Prevent burst 3.The ceramic body and the alloy are closely connected, which is not deformed when heated. 4.The surface finish is high and the air flow is smoother. 5.Signal stability high sensitivity 6.The imported conductive adhesive and gold-plated copper needle have good conductivity,high sensitivity,good follow-up,effective insulation, and reduce the demage caused by impact. 7.Widely used: It is suitable for laser cutting heads of various brands Product Paramaters 1.Material: Imported Ceramic High Quality Specical Alloy 2. Thread: M5 - M14 3. Outside Diameter: 17.5 - 41mm 4. Height: 4 -34mm

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Ceramic Laser Nozzle Holder Information: 1.Imported ceramics + high quality special alloy 2.Ensure the consistency of thermal expansion of ceramic ring materials Prevent burst 3.The ceramic body and the alloy are closely connected, which is not deformed when heated. 4.The surface finish is high and the air flow is smoother. 5.Signal stability high sensitivity 6.The imported conductive adhesive and gold-plated copper needle have good conductivity,high sensitivity,good follow-up,effective insulation, and reduce the demage caused by impact. 7.Widely used: It is suitable for laser cutting heads of various brands Product Paramaters: 1.Material: Imported Ceramic High Quality Specical Alloy 2. Thread: M5 - M14 3. Outside Diameter: 17.5 - 41mm 4. Height: 4 -34mm

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Alumina, also known as Aluminum Oxide, is a hard wearing advanced technical ceramic material frequently used in a wide variety of industrial applications. Once fired and sintered, it can only be machined using diamond-grinding methods. It features high hardness and wear resistance, low erosion levels, high temperature resistance, corrosion resistance, and bioinertness.Additionally, it can be highly polished, making it useful for a wide range of applications. Properties: 1. Good electrical insulation 2. Moderate thermal conductivity 3. High corrosion and wear resistance 4. Good gliding properties 5. High mechanical strength 6. High compressive strength 7. High hardness

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon nitride heat shields and magnetic rings are mainly used to protect high voltage electrodes and are widely used in the photovoltaic industry.Heat shields and magnetic rings, as well as ceramic rings, are collectively referred to as electrode shields.Silicon nitride electrode protection cover mainly uses silicon nitride insulation, heat resistance and corrosion resistance.Compared with the protective cover of quartz and alumina which is still in use today, the service life of the silicon nitride electrode shield is more than 10 times, and it will not be electrically broken down during use, and will not be heated, nor will it be heated. Will be eroded away. Due to its own stability, in the use of photovoltaic reduction furnaces, the collapse rate of non-human factors is greatly reduced. Silicon Nitride (Si3N4) Characteristics: 1 Good thermal shock resistance 2 Creep resistance 3 Low density 4 High fracture toughness 5 High hardness and wear resistance 6 Electrical resistivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Zirconia (ZrO2) Ceramics have the highest toughness and strength at room temperature of all the advanced ceramic materials. At present, it has been widely used in grinding balls, dispersion and grinding media, nozzles, ball valve seats, zirconia molds, micro fan shafts, optical fiber pins, optical fiber sleeves, drawing dies and cutting tools, wear-resistant knives, and other room-temperature resistant Grinding parts and so on. Zirconia is widely used in the fields of the thermal barrier layer, catalyst body, medical treatment, health care, textile, and so on. This dense advanced ceramics material is usually precision ground using conventional diamond cutters and wheels. Machines used for precision grinding include: Surface grinders CNC milling machines Jig grinders Centerless grinders CNC lathes ID grinders

Request for a quoteResults for

Ring - Import exportNumber of results

62 ProductsCountries

Company type

Category

- Ceramics, industrial (15)

- Sealing rings (5)

- Gears (4)

- Gas and oil pipelines - installations (4)

- Seals (3)

- Rubber seals (3)

- Animal Production (3)

- Games and toys (2)

- Electrical systems and equipment (2)

- Fishing equipment (2)

- Piston rings (1)

- Ribbons and ropes (1)

- Ceramics (1)

- Congresses, seminars, receptions - organisation and services (1)

- Disposable medical and surgical articles (1)

_ad65de09.jpg)