- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- condensate systems

Results for

Condensate systems - Import export

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

When it comes to the performance of a turbine surface condenser in the operational field of a steam turbine cycle, you need utmost reliability and efficiency. Here’s where Jet Flow’s know how is invaluable. We createcustomise package solutions for each particular customer’s needs. Our General Scope of Supply Condenser Circular Condenser having own Flow, Axial flow or side inlet steam entry. Turbine to Condenser steam duct, including necessary expansion joints. Steam Jet Ejector Vacuum System. Flash tank, drain header and Instrument stand pipe. Dump Tube. Condensate Pump system Pumps are in vertical or horizontal arrangement; either API 610, ISO 5199 or standard manufacturer pump design. Control system Including level control valves pressure and temperature indicators, transmitters and controllers. Interconnecting piping with filter, fittings and valves.

Request for a quote

BEKO TECHNOLOGIES GMBH

Germany

The generation of compressed air is always connected with the formation of condensate. In most cases, this condensate contains oil, is contaminated with dirt particles and spreads out in the entire compressed-air system. A system problem which can result in damage and additional costs. The BEKOMAT drains condensate in the compressed-air system in an electronically level-controlled manner. More than 3,000,000 installations worldwide make it the industrial standard for reliable and cost-effective condensate drainage.

Request for a quote

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The CCX is the most advanced, sophisticated and versatile laboratory corrosion testing cabinet. With installed options, it can replicate up to 15 environmental conditions, placing powerful capability in the hands of the user. Advanced cyclic tests are used to qualify a specific coating or material for a wide range of end uses, to quickly qualify a coating or material on a pass-fail basis, to predict service life or determine the probability of corrosion of a specific material. Applications include: Aerospace, Automotive, Research, Electronics, Government, Military, Paints/Coatings, Robotics, and Telecommunications. Reinforced fiberglas cabinet - Exposure zone lined with gel coat Solution reservoir - 60 gallon (227 l) Exposure zone heated by titanium rod heater Polypropylene cover with water seal - CCX9000 only Peaked cover prevents dripping of condensation onto samples Clear cover with dual magnetic Santoprene gaskets Heated humidifying (bubble) tower with air relief valve Exposure zone temperature up to 160 °F (71 °C) - high temperature option up to 194 °F (90 °C) Specifications and Dimensions (Testing Volume, Exposure Zone Dimensions, External Dimensions) CCX2000 - 565L, 1.27 x 0.74 x 0.63 m, 2.4 x 0.9 x 1.4 m CCX3000 - 850L, 1.91 x 0.74 x 0.63 m, 3 x 0.9 x 1.4 m CCX4000 - 1130L, 1.91 x 0.94 x 0.63 m, 3 x 1.1 x 1.4 m CCX9000 - 2550L, 1.93 x 1.14 x 1.16 m, 3.05 x 1.3 x 2.16 m CCX11000 - 3115L, 2.27 x 1.86 x 0.76 m, 3.12 x 2.59 x 2.13 m Standard Controls Features Programmable Logic Controller with Operator Interface Panel Five Pre-loaded Test Methods for Immediate Operation Storage of up to 15 Test Profiles with up to 18 Steps Pressure Gauge for Bubble Tower Premium Controls Features Notebook Computer with Color Screen, PC-compatible Seven Pre-loaded Test Methods for Immediate Operation Display of up to 50 Test Profiles with up to 100 Steps Display Graphing on Notebook Monitor Operator Interface/Datalogging Software Pressure Transducer for Bubble Tower Solution Reservoir Fill with Automatic Shut-off SO2 Injection System High voltage kit High capacity oil: water separator External condensate collection system(to check collection rate of fog with cover closed) Air actuated cover, automatic ambient Solution spray (direct impingement) Power exhaust kit Water fog, automatic Custom sizes (extra height or any LxW) and configurations (pass-through electrical/mechanical ports) Cabinet options choices: Standard controls. Two pen circular chart recorder with digital display (wet bulb and dry bulb), recorder/6 channel strip chart (4 temperatures, air pressure), modem for remote trouble shooting / Premium controls Controlled, Adjustable RH with direct RH Sensor; required for SAE J2334 Color Touchscreen Upgrade Data Recording PC Software; output to customer's computer- DB/WB/BT temps Immersion Option, Automated - CCX2000/3000/4000; recommended for SAE J2334 Immersion Option, Automated - CCX9000; recommended for SAE J2334- 1250 Immersion Set-up Kit; required for future addition of Immersion Option LN2 Freezing/Cooling System; using customer-supplied liquid nitrogen; to 30ºC Mechanical Freezing/Cooling System; to 30ºC; includes Controlled RH Automatic Retractable Housing; for RH sensor Very High Temperature 90ºC; for Dry Cycle operation, CCX2000/3000/4000 Very High Temperature 90ºC; for Dry Cycle operation, CCX9000/11000 Solution Spray; multiple nozzles (8, 12 or 16) w/ separate shut-off valves Volume Marker and Overflow Protection; for Solution Reservoir CCX Exhaust Recirculation System; for Salt Fog and Water Humidity steps only - not for use during Freezing/Cooling or Very High Temp 90ºC options

INOX VERTRIEBS GMBH

Germany

INOX Petrol Power is suitable for all normal and premium petrol engines. It dissolves dirt and resin buildup in the entire fuel system and reliably removes all carbon residues and soot deposits. The service life of the engine is increased. Dissolves contamination and gumming in the entire fuel system clean combustion more gasoline power for all normal and premium petrol engines Reliably removes all carbon residue and soot deposits ensures clean and powerful combustion regulates the PH value in the fuel system improves exhaust emissions removes moisture and condensation from the entire fuel system lubricates and protects the upper cylinder area increases the lifespan of the engine

Request for a quote

INOX VERTRIEBS GMBH

Germany

INOX fuel system cleaner can be used for all gasoline engines. It dissolves dirt and resin buildup in the entire fuel system and reliably removes all coking residues and soot deposits. This increases the service life of the engine. optimizes emissions values binds condensation Dissolves contamination and gumming in the entire fuel system Reliably removes all coking residues and soot deposits ensures clean and powerful combustion removes moisture and condensation from the entire fuel system lubricates and protects the upper cylinder area increases the lifespan of the engine

Request for a quote

ENNOX BIOGAS TECHNOLOGY GMBH

Austria

Condensation from saturated biogas collects at the lowest points in the pipework, in bends etc. This can negatively influence the effective operation of biogas systems. ennox condensate accumulator is installed at the lowest point in the pipework. The condensate gathers in the container where it can be discharged through a manual tap and/or an automatic siphon. As an option ennox will supply a level indicator or an automatic discharger.

UNEX HEATEXCHANGER ENGINEERING GMBH

Austria

For the condensation of refrigerants in commercial and industrial refrigeration systems. The condensers are suitable for outdoor installation and can be installed in residential and industrial areas according to the sound pressure levels. There is a selection of over 1,500 models with four different sound pressure levels and construction sizes, depending on the application. The condensers, available in stainless steel/aluminium, are suitable for refrigerants (Frigene) and ammonia (NH3), depending on application.

Request for a quote

ALUMINAL YAPI

Turkey

It has a section depth of 50 mm. It is possible to apply vertically without notching the horizontal profile. It has the feature of being easy to work and economical. It has few accessories, easy assembly and fast manufacturing features. A condensate channel system can be created without notching by using both notched and special accessories. It has the features of covered - silicone facade, horizontal covered - vertical silicone, vertical covered - horizontal silicone, outward opening transom wing (insulated, uninsulated) and openable wing.

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

— Secure use of condensate in steam boiler systems — Decreases in energy and water consumption due to reduced quantities of make-up water — Minimisation of flash steam losses, desalting and blowdown quantities; reduced consumption of chemicals — Reduced corrosion potential in the steam condensate system when using high-pressure condensate systems

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

— For the cooling of blow-down water and the recovery of heat from desalinated water/condensate — Increase in system efficiency of up to 2% — Reductions in fuel, cooling water and waste water costs — Rigorous compliance with official requirements thanks to automatic operation — Fast and easy assembly, requires just a small number of connections before it can be used

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

— For the recovery of heat from desalinated water/condensate — Increase in system efficiency of up to 2% — Reductions in fuel, cooling water and waste water costs — Fast and easy assembly, requires just a small number of connections before it can be used Highly efficient boiler systems with perfectly matched boiler house components ensure that low levels of energy consumption and emissions are achieved.

Request for a quote

FRIGO SYSTEM

Turkey

Available for M1 (-1/+5) & M2 (-1/+7) temp. class Refrigerated storage under base tray Bain Marie and hot plate versions Both plug in and remote versions avaliable 840 mm stainless steel base tray Adjustable stainless steel trays 230 mm. stainless steel working plate Standard LED single row canopy lighting High quality tempered and vertical straight front glass Fan assisted anti condensation system Fan assisted refrigeration Optional stainless steel bumper rail Optional sliding cover RAL color options Piller leg or closed front panel

Request for a quote

FRIGO SYSTEM

Turkey

Available for M1 (-1/+5) & M2 (-1/+7) temp. class Refrigerated storage under base tray 840 mm stainless steel base tray Adjustable stainless steel trays 230 mm. stainless steel working plate High quality low, tempered and vertical straight front glass Fan assisted anti condensation system Fan assisted refrigeration Optional stainless steel bumper rail RAL color options Piller leg or closed front panel

Request for a quote

FRIGO SYSTEM

Turkey

Available for M1 (-1/+5) & M2 (-1/+7) temp. class Refrigerated storage under base tray Bain Marie and hot plate versions Both plug in and remote versions avaliable 835 mm stainless steel base tray Adjustable stainless steel trays 240 mm. stainless steel working plate Standard LED single row canopy lighting High quality tempered and vertical curved front glass Fan assisted anti condensation system Fan assisted refrigeration Optional stainless steel bumper rail Optional sliding cover RAL color options Piller leg or closed front panel

Request for a quote

FRIGO SYSTEM

Turkey

Available for M1 (-1/+5) & M2 (-1/+7) temp. class Refrigerated storage under base tray 835 mm stainless steel base tray Adjustable stainless steel trays 240 mm. stainless steel working plate High quality low, tempered and vertical curved front glass Fan assisted anti condensation system Fan assisted refrigeration Optional stainless steel bumper rail RAL color options Piller leg or closed front panel

Request for a quote

FRIGO SYSTEM

Turkey

Available for M1 (-1/+5) & M2 (-1/+7) temp. class Both plug in and remote versions avaliable Bain Marie and hot plate versions Double display powder coated deck version available (for Simena DBL) 788, 888 or 960 mm stainless steel base tray options Adjustable stainless steel trays 275 mm stainless steel working plate Standard LED single row canopy lighting High quality tempered and vertical curved front glass Fan assisted anti condensation system Fan assisted refrigeration Optional stainless steel bumper rail Optional sliding cover RAL color options Piller leg or closed front panel

Request for a quote

FRIGO SYSTEM

Turkey

Available for M1 (-1/+5) & M2 (-1/+7) temp. class Both plug in and remote versions avaliable Bain Marie and hot plate versions Double display powder coated deck version available (for Simena DBL) 788, 888 or 960 mm stainless steel base tray options Adjustable stainless steel trays 275 mm stainless steel working plate Standard LED single row canopy lighting High quality tempered and vertical curved front glass Fan assisted anti condensation system Fan assisted refrigeration Optional stainless steel bumper rail Optional sliding cover RAL color options Piller leg or closed front panel

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FRIGO SYSTEM

Turkey

Available for M1 (-1/+5) & M2 (-1/+7) temp. class Both plug in and remote versions avaliable Bain Marie and hot plate versions Double display powder coated deck version available (for Simena DBL) 788, 888 or 960 mm stainless steel base tray options Adjustable stainless steel trays 275 mm stainless steel working plate Standard LED single row canopy lighting High quality tempered and vertical curved front glass Fan assisted anti condensation system Fan assisted refrigeration Optional stainless steel bumper rail Optional sliding cover RAL color options Piller leg or closed front panel

Request for a quote

FRIGO SYSTEM

Turkey

Available for M1 (-1/+5) & M2 (-1/+7) temp. class Both plug in and remote versions avaliable Bain Marie and hot plate versions Double display powder coated deck version available (for Simena DBL) 788, 888 or 960 mm stainless steel base tray options Adjustable stainless steel trays 275 mm stainless steel working plate Standard LED single row canopy lighting High quality tempered and vertical curved front glass Fan assisted anti condensation system Fan assisted refrigeration Optional stainless steel bumper rail Optional sliding cover RAL color options Piller leg or closed front panel

Request for a quote

FRIGO SYSTEM

Turkey

Available for M1 (-1/+5) & M2 (-1/+7) temp. class Both plug in and remote versions avaliable Bain Marie and hot plate versions Double display powder coated deck version available (for Sardis DBL) 788, 888 or 960 mm stainless steel base tray options Adjustable stainless steel trays 275 mm stainless steel working plate Standard LED single row canopy lighting High quality tempered and vertical straight front glass Fan assisted anti condensation system Fan assisted refrigeration Optional stainless steel bumper rail Optional sliding cover Shelf options on the front glass ( for PR and 2PR module) RAL color options Piller leg or closed front panel

Request for a quote

FRIGO SYSTEM

Turkey

Available for M1 (-1/+5) & M2 (-1/+7) temp. class Both plug in and remote versions avaliable Bain Marie and hot plate versions Double display powder coated deck version available (for Sardis DBL) 788, 888 or 960 mm stainless steel base tray options Adjustable stainless steel trays 275 mm stainless steel working plate Standard LED single row canopy lighting High quality tempered and vertical straight front glass Fan assisted anti condensation system Fan assisted refrigeration Optional stainless steel bumper rail Optional sliding cover Shelf options on the front glass ( for PR and 2PR module) RAL color options Piller leg or closed front panel

Request for a quote

ALNOR VENTILATION SYSTEMS LTD

Poland

The HRUSlimAIR heat recovery unit is designed for residential buildings. The HRU has a capacity of 250 m3/h @ 100 Pa, generated by energyefficient EC fans. Thanks to a counterflow heat exchanger made of a plastic (PET), it achieves up to 90% heat recovery An ERV version with an enthalpy exchanger that recovers moisture is also available. Builtin electric preheater protects heat exchanger against freezing, wireless radio communication connects controllers and sensors, and all of it is enclosed inside a selfsupporting, insulating EPP casing. HRUSlimAIR can be installed in up to 3 positions, thanks to a special condensate drain system.

Request for a quote

ALNOR VENTILATION SYSTEMS LTD

Poland

The HRUSlimAIR heat recovery unit is designed for residential buildings. The HRU has a capacity of 250 m3/h @ 100 Pa, generated by energyefficient EC fans. Thanks to a counterflow heat exchanger made of a plastic (PET), it achieves up to 90% heat recovery An ERV version with an enthalpy exchanger that recovers moisture is also available. Builtin electric preheater protects heat exchanger against freezing, wireless radio communication connects controllers and sensors, and all of it is enclosed inside a selfsupporting, insulating EPP casing. HRUSlimAIR can be installed in up to 3 positions, thanks to a special condensate drain system.

Request for a quote

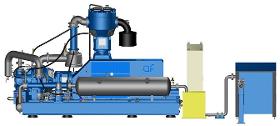

AF COMPRESSORS

Belgium

The 40 bar oil free PET compressor range from 225 m³/H to 3200 m³/H. AF suits to the basic ISO 8573 Class 1. rule, and in addition, offers a 40 bar stainless stell refregerative air dryer with 3°C dew point. The dryer is equipped with dew point alarm, integrated 1µ filter and integrated automatic draining system. Stainless steel condenser and optional additional active carbon filter will complete our standard 40 bar PET packages to supply to best air quality on the PET market. The 40 bar compressed air package is mounted on a base plate equipped with anti-vibration mountings and includes: electric motor – from 55 to 550 kW and V-belt transmission, V-Belt drive system complete with sheet steel guard and inspection door. The system allows the compressor speed to be adapted to give precisely the required Free Air Delivery. Standard range design for optimum efficiency. intercoolers between each stage and after-cooler. Three stage “L” cylinder compressor with : 3 micron air inlet...

Request for a quote

AF COMPRESSORS

Belgium

Protection for hot temperatures Oil cooler – radiator for inside temperatures exceeding 40°C. This option comes along with the air-conditioning in the electrical control cabinet, the water cooled condenser for the HP Dryer. Specific selection of electric motor ; IP55 motor for hot and dusty environment, tropicalizing (see electrical options) Protection for cold temperatures Oil warming for inside temperatures between 1 and 5°C. Specific selections of cooling systems with protections items depending on site conditions (see separate cooling system options) Miscellaneous Condensate drain collector. Made from stainless steel, equipped with silencers and flexible rubber connections for collecting the condensates from the individual drains – Bekomat drain system used on the compressor, dryer – option- and receiver to simply be connected to the sewer ( flexible rubber hoses supplied suiting to a standard installation lay out – see the standard installation lay out drawing). Low sound...

Request for a quote

AF COMPRESSORS

Belgium

HP- 40 bar air receiver options Standard (horizontal on the base-frame or vertical ) the HP- 40 bar air receiver is hot galvanised with accessories, including safety valve and Bekomat drain system. Depending on the location and country, the air receivers have to comply with the local codes and certifications. All Codes and certifications are available : CE-PED, ASME VIII, CRN for Canadia , TR CU suiting to Russia, Kazakhstan, Belarus, SELO code in China, South Korea 40 bar certification. NR13 for Brazil… HP – 40 bar piping and accessories 40 bar piping between the compressor, HP air receiver and the HP dryer flanges, supports, safety warrant and mounting accessories, shut off gates /40 bar stop valve is included in standard. Also available : – accessories for specific HP connection installation before the dryer ; elbow… HP- 40 bar air Dryer options Stainless steel condenser, dew point alarm, Bekomat draining system. Water cooled condenser is recommended for ambient temperatures...

Request for a quote

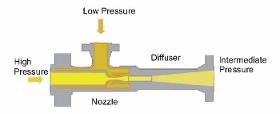

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

SingleStage Steam Jet Ejectors are based on the ejectorventuri principle. In operation, steam issuing through an expanding nozzle has its pressure energy converted to velocity energy. A vacuum is created and the high velocity of steam entrains air or gas and the mixture of gas and steam enters the converging end of the venturi, passes through the diffuser where its velocity energy is converted into pressure sufficient to discharge against a predetermined back pressure. Single stage steam jet ejectors are used to create vacuum covering 40 mm Hg. Absolute. Two Stage Ejector with Condenser The system is the assembly of two units whose construction is similar to single stage with inter condenser (direct contact type or surface type). Steam of the first stage is expanded through nozzle entrains the air or other gases and discharges them to diffusers at a higher pressure in the condenser.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

The efficiency of a Steam turbine is mainly determined by the pressure of the steam at its outlet. The Turbine Surface Condenser is therefore maintained under vacuum. To enable this, the Steam Jet Ejector Vacuum System must be capable of removing all non condensable and associated water vapour from the Surface Condenser to produce the minimum steam condensing pressure consistent with physical dimensions and heat transfer and to provide for deaeration of the condensate. The sources of non condensables include air leakage through all system components operating below atmospheric pressure, gases released from feedwater drains and vents admitted to the condenser, gases released for makeup admitted to the condenser, condensate surge tank when utilized in a closed cycle and disassociation of feedwater into oxygen, hydrogen and non condensables.

Request for a quote

CERTUSS DAMPFAUTOMATEN GMBH & CO. KG

Germany

You require a mobile steam plant or you want to install a steam plant outside your plant building? Then the complete installation within a container is the ideal solution for you. The container steam plant contains all the required components – from the water treatment plant through to the steam trap. - CERTUSS steam generator - CERTUSS CVE supply unit - Feed water treatment - Steam distributor - Pressure reducer station - Clarification valve - Steam dryer - Condensate elevating system - Steam trap - Interior lighting of the container - Insulated pipe installation in the container - Emergency-off switch - Steel door or uPVC door - High-quality stainless steel wall with insulation - Outside coating as required The installation and commissioning of the container plant at the customer is on request either carried out completely or only partially (if an external installation company is used) by our customer service.

Request for a quoteResults for

Condensate systems - Import exportNumber of results

53 ProductsCountries

Company type

Category

- Refrigeration plants and equipment, commercial and industrial (15)

- Condensers (4)

- Boilers, industrial (3)

- Steam turbines (3)

- Components and parts for small household appliances (2)

- Diesel engines (2)

- Filters, liquid (2)

- Mechanical transmission systems and components (2)

- Boilerwork (1)

- Chemical and pharmaceutical industry - machinery and equipment (1)

- Compressed air tools and systems (1)

- Electroheat - machines and equipment (1)

- Ice cream-making - machinery and equipment (1)

- Lighting, street, industrial and commercial (1)

- Oil filters (1)

- Refrigerated display units and windows (1)

- Water purifying products (1)

- Water treatment products (1)

- Windows, aluminium (1)

- Wine fermentation tanks (1)