- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- condensation separators

Results for

Condensation separators - Import export

RIEGLER & CO.KG

Germany

Compressed air preparation helps to prevent malfunctions on pneumatic components and increases their service life. Machine failures and downtimes are reduced. Whether compressed air preparation, regulation or cleaning, we have multi-part service units, from pressure regulators, filter controllers, oilers, condensate diverters and oil-water separators to system expansions and various accessories as well.

Request for a quote

RIEGLER & CO.KG

Germany

Compressed air preparation helps to prevent malfunctions on pneumatic components and increases their service life. Machine failures and downtimes are reduced. Whether compressed air preparation, regulation or cleaning, we have multi-part service units, from pressure regulators, filter controllers, oilers, condensate diverters and oil-water separators to system expansions and various accessories as well.

Request for a quote

RIEGLER & CO.KG

Germany

Compressed air preparation helps to prevent malfunctions on pneumatic components and increases their service life. Machine failures and downtimes are reduced. Whether compressed air preparation, regulation or cleaning, we have multi-part service units, from pressure regulators, filter controllers, oilers, condensate diverters and oil-water separators to system expansions and various accessories as well.

Request for a quote

RIEGLER & CO.KG

Germany

Compressed air preparation helps to prevent malfunctions on pneumatic components and increases their service life. Machine failures and downtimes are reduced. Whether compressed air preparation, regulation or cleaning, we have multi-part service units, from pressure regulators, filter controllers, oilers, condensate diverters and oil-water separators to system expansions and various accessories as well.

Request for a quote

RIEGLER & CO.KG

Germany

Compressed air preparation helps to prevent malfunctions on pneumatic components and increases their service life. Machine failures and downtimes are reduced. Whether compressed air preparation, regulation or cleaning, we have multi-part service units, from pressure regulators, filter controllers, oilers, condensate diverters and oil-water separators to system expansions and various accessories as well.

Request for a quote

RIEGLER & CO.KG

Germany

Compressed air preparation helps to prevent malfunctions on pneumatic components and increases their service life. Machine failures and downtimes are reduced. Whether compressed air preparation, regulation or cleaning, we have multi-part service units, from pressure regulators, filter controllers, oilers, condensate diverters and oil-water separators to system expansions and various accessories as well.

Request for a quote

RIEGLER & CO.KG

Germany

Compressed air preparation helps to prevent malfunctions on pneumatic components and increases their service life. Machine failures and downtimes are reduced. Whether compressed air preparation, regulation or cleaning, we have multi-part service units, from pressure regulators, filter controllers, oilers, condensate diverters and oil-water separators to system expansions and various accessories as well.

Request for a quote

RIEGLER & CO.KG

Germany

Compressed air preparation helps to prevent malfunctions on pneumatic components and increases their service life. Machine failures and downtimes are reduced. Whether compressed air preparation, regulation or cleaning, we have multi-part service units, from pressure regulators, filter controllers, oilers, condensate diverters and oil-water separators to system expansions and various accessories as well.

Request for a quote

RIEGLER & CO.KG

Germany

Compressed air preparation helps to prevent malfunctions on pneumatic components and increases their service life. Machine failures and downtimes are reduced. Whether compressed air preparation, regulation or cleaning, we have multi-part service units, from pressure regulators, filter controllers, oilers, condensate diverters and oil-water separators to system expansions and various accessories as well.

Request for a quote

OHMEX INDUSTRIELLE ELEKTROWÄRME GMBH

Germany

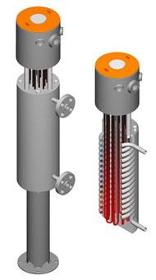

Explosionproof/flameproof gas preheater EEx d -ATEX und IECEx zertifiziert In general a cooling down takes place at expansion of gases whilst a heating takes place at compression. Typical gases are carbon monoxide, natural gas and air. The temperature change, which occurs at expansion of gas or gas mixture from a high to low pressure i.e. after a gas pressure control is called Joule-Thomson effect. In order to prevent the effects of Joule-Thomson as icing or condensate separation, the gas will be heated up before expansion. The gas pre heaters are suitable for all kind of gaseous media (i.e. air, natural gas, technical gases, fuel gas) and low flow process applications, suitable for pressures up to 300 bar. The “Cast electric heaters” type flameproof electrical gas pre heaters are certified for use in zone 1 or 2 hazardous area, custom built to meet client specification. The gas pre heater consists of a process tube coil and an electrical heating bundle, casted in aluminium. The process gas flows through the tube coil and is heated by the aluminium block that provides the heat transfer. This indirect electric heating gives an accurate control of the process and eliminates pressure vessel design and associated costs.

Request for a quote

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

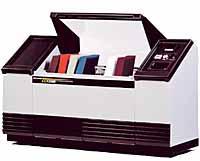

The CCX is the most advanced, sophisticated and versatile laboratory corrosion testing cabinet. With installed options, it can replicate up to 15 environmental conditions, placing powerful capability in the hands of the user. Advanced cyclic tests are used to qualify a specific coating or material for a wide range of end uses, to quickly qualify a coating or material on a pass-fail basis, to predict service life or determine the probability of corrosion of a specific material. Applications include: Aerospace, Automotive, Research, Electronics, Government, Military, Paints/Coatings, Robotics, and Telecommunications. Reinforced fiberglas cabinet - Exposure zone lined with gel coat Solution reservoir - 60 gallon (227 l) Exposure zone heated by titanium rod heater Polypropylene cover with water seal - CCX9000 only Peaked cover prevents dripping of condensation onto samples Clear cover with dual magnetic Santoprene gaskets Heated humidifying (bubble) tower with air relief valve Exposure zone temperature up to 160 °F (71 °C) - high temperature option up to 194 °F (90 °C) Specifications and Dimensions (Testing Volume, Exposure Zone Dimensions, External Dimensions) CCX2000 - 565L, 1.27 x 0.74 x 0.63 m, 2.4 x 0.9 x 1.4 m CCX3000 - 850L, 1.91 x 0.74 x 0.63 m, 3 x 0.9 x 1.4 m CCX4000 - 1130L, 1.91 x 0.94 x 0.63 m, 3 x 1.1 x 1.4 m CCX9000 - 2550L, 1.93 x 1.14 x 1.16 m, 3.05 x 1.3 x 2.16 m CCX11000 - 3115L, 2.27 x 1.86 x 0.76 m, 3.12 x 2.59 x 2.13 m Standard Controls Features Programmable Logic Controller with Operator Interface Panel Five Pre-loaded Test Methods for Immediate Operation Storage of up to 15 Test Profiles with up to 18 Steps Pressure Gauge for Bubble Tower Premium Controls Features Notebook Computer with Color Screen, PC-compatible Seven Pre-loaded Test Methods for Immediate Operation Display of up to 50 Test Profiles with up to 100 Steps Display Graphing on Notebook Monitor Operator Interface/Datalogging Software Pressure Transducer for Bubble Tower Solution Reservoir Fill with Automatic Shut-off SO2 Injection System High voltage kit High capacity oil: water separator External condensate collection system(to check collection rate of fog with cover closed) Air actuated cover, automatic ambient Solution spray (direct impingement) Power exhaust kit Water fog, automatic Custom sizes (extra height or any LxW) and configurations (pass-through electrical/mechanical ports) Cabinet options choices: Standard controls. Two pen circular chart recorder with digital display (wet bulb and dry bulb), recorder/6 channel strip chart (4 temperatures, air pressure), modem for remote trouble shooting / Premium controls Controlled, Adjustable RH with direct RH Sensor; required for SAE J2334 Color Touchscreen Upgrade Data Recording PC Software; output to customer's computer- DB/WB/BT temps Immersion Option, Automated - CCX2000/3000/4000; recommended for SAE J2334 Immersion Option, Automated - CCX9000; recommended for SAE J2334- 1250 Immersion Set-up Kit; required for future addition of Immersion Option LN2 Freezing/Cooling System; using customer-supplied liquid nitrogen; to 30ºC Mechanical Freezing/Cooling System; to 30ºC; includes Controlled RH Automatic Retractable Housing; for RH sensor Very High Temperature 90ºC; for Dry Cycle operation, CCX2000/3000/4000 Very High Temperature 90ºC; for Dry Cycle operation, CCX9000/11000 Solution Spray; multiple nozzles (8, 12 or 16) w/ separate shut-off valves Volume Marker and Overflow Protection; for Solution Reservoir CCX Exhaust Recirculation System; for Salt Fog and Water Humidity steps only - not for use during Freezing/Cooling or Very High Temp 90ºC options

EC PLAZA

South Korea

Electrostatic Capacity Sensor Any condensate from compression process can be sensed correctly and discharged. Zero loss of compressed air Uses of two sensors (High level, low level) protects energy loss By air loss discharging condensate selectively. * Our Company We have been worked for efficient treatment of condensation water generated in Air Compressor System. We are producing Auto drain trap that is an economical and reliable condensate discharger, Oil-water separator that is processing unit for condensate contaminated by oil with advanced technique and know-how. However, energy and environment are giving big influence in enterprise activity in 21th century industrial field, and it is considered that frugality of expensive compressed air and processing for contaminated condensate are helpful to solve these troubleshooting Forward, we will do our best to answer customer`s cheering by developing product helpful for enterprise activity. Website : http://www.enesystem.

Request for a quote

ROTAIR SPA

Italy

Specifically conceived, designed and manufactured for fibre optic cable laying. Compact design, extremely manoeuvrable, easy to lift and transport. With inbuilt single or double cooler depending on air temperature demand, condensates separator. All in one unit, immediately ready to work. A professional tool for a very specific and professional sector. Integrated moisture separator (FIBRA-FIBRA PLUS) Integrated aftercooler for cool air delivery (FIBRA PLUS) Unit ready to operate High quality air output (oil carry-over <1 PP) Compact design, extremely manoeuvrable Easy to transport, lift and load Outstanding accessibility for maintenance

Request for a quote

AF COMPRESSORS

Belgium

More info More info More info More info More info 40bar PET Compressors Select the machine The AF 40 bar Piston Oil Free PET compressor Package Turn-key installations designed to meet the most stringent standards and conditions to ensure round-the-clock operation. Complete solutions from 225 to 3200 m³/H, electric motors from 45 to 550 kW. Features Benefits Intercoolers and separators Features Hot galvanized connection piping to aftercooler inlet. Air temperature indicator on connection piping. Spring loaded safety valve on separator upper head. Air pressure indicator on separator body. Air temperature indicator on separator body. Drain valve and automatic condensate trap on separator lower head. Benefits Optimized compressed Air Quality maximum. Cooling Efficiency at each compression stage. Air Dryer Features Stainless steel flexible connections from the galvanized air receiver to the 40 bar air dryer. Stainless steel dryer with integrated 1 micron filter, dew point alarm...

Request for a quote

SHANGHAI GAOHE IMP. & EXP. CO., LTD.

China

The DJY and DJM series boiler drum electrode sensor is matched with our company’s UDZ double color digital display intelligent liquid level controller. It can be widely used in large and medium-sized boilers of power generation, dyeing and weaving, chemical industry and other industrial and mining enterprises. It can be used to monitor the water level of boiler drum, high-pressure heater, generator, evaporator, condenser, Start-up Separator of once through boiler, water tank of double water-cooled generator, and liquid level measurement of other conductive liquids. Screw Type Electrode Sensor This electrode sensor mainly used on boiler and to measure the boiler drum water level.

Request for a quote

BÜCHI AG

Switzerland

Glass overheads are typically built (in our standard chemReactor and production plant setups) for multipurpose and semi–batch operation mode under full vacuum. They mostly consist of feeder vessel, a distillation column, condenser and secondary condenser, phase separator, receiver, including valves and pressure equalization piping and a rupture disc as safety device. For rectification, packed distillation glass columns up to DN600 are used with reflux condenser, a reflux splitter with a reflux controller to set the reflux ratio. In Buchi chemReactors, both systems can be combined.

Request for a quote

OMEGA AIR

Slovenia

CS condensate separators are designed for high efficient removal of bulk liquids and large impurities from compressed air systems. The insert inside the housing creates controlled rotation of the air flow. Centrifugal flow of liquids (water, oil) and large particles is forced to the housing wall, slowed down and accumulated at the bottom of separator housing as condensate. The turbulent free zone in the lower part of the cyclone housing prevents condensate from being picked up and “carried over” into the airstream. To discharge condensate from the CS cyclone separator it is essential to install automatic or electronic condensate drain. CS cyclone separators are also available in stainless steel version CS-SS.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OMEGA AIR

Slovenia

Refrigeration dryers RDT have been designed to effectively separate water from the compressed air thus lower pressure dew point all the way down to +3 °C. The main difference between RDP and RDT series is that RDT has timer controlled drain instead of an automatic drain. Drying is achieved on the principle of cooling which takes place inside a highly efficient and ultra-compact 3 stage heat exchanger. In the first stage (air-air heat exchanger) hot and humid inlet air is being pre-cooled by the cold outgoing air. In the second stage (air-refrigerant heat exchanger) intensive water condensation takes place due to the cooling of the air. All condensed water is separated from the main compressed air stream in the third stage by the integrated demister. A proven and robust design enables efficient and reliable operation, fast installation and simple maintenance.

Request for a quote

OMEGA AIR

Slovenia

Refrigeration dryers have been designed to effectively separate water from the compressed air thus lower pressure dew point all the way down to +3°C. Drying is achieved on the principle of cooling which takes place inside highly efficient and ultra-compact 3 stage heat exchanger. In the first stage (air-air heat exchanger) hot and humid inlet air is being precooled by the cold outgoing air. In the second stage (air-refrigerant heat exchanger) intensive water condensation takes place due to cooling the air. All condensed water is separated from the main compressed air stream in the third stage by the integrated demister. A proven and robust design of refrigeration dryers enables efficient and reliable operation, fast installation and simple maintenance.

Request for a quote

OSMO MEMBRANE SYSTEMS GMBH

Germany

Condensate polishing During the production process of basic organic chemicals, very often condensates occur as byproducts, which have to be treated before dumping or recycling into production process. The condensate occurring at the product process of caprolactame contents for example ammonium sulfate and caprolactame. The loss of these products instead of recycling would not only mean a reduction of the process recovery, but also very high costs for waste water treatment. These condensates can be concentrated by a reverse osmosis plant. Because of the high salt retention rate of the reverse osmosis membrane, nearly all contents of the condensate are separated and can be brought back to the production cycle. The filtered permeate can be dumped into the municipal waste water system without hesitation. In some cases, the recirculation of the separated contents is not appropriated. In this context, reverse osmosis helps reducing the volume of the accruing condensate. The remaining conden

Request for a quote

REFRA, UAB

Lithuania

High capacity condenserless chillers with the cooling power from 140 kW to 2 MW are perfectly suitable for medium to large industrial or large commercial applications. These chillers are mounted with a separate remote condenser that is built outdoors. The rest of the equipment is installed in a special technical room in the building. Refra can offer a condenserless chiller that can be connected to an existing condenser or a complete system with Refra condensers. CS Condenserless chillers are assembled on a welded open frame, equipped with maximum 4 screw compressors and shell and tube heat exchangers. They are usually chosen when there are sound restrictions in the project. The louder part of the system is built in an isolated room and the quiet condenser is built on the roof. The whole system is connected by a pipeline for refrigerant circulation and absorbed heat rejection. Refra manufactures modern devices using plug-and-play

Request for a quote

REFRA, UAB

Lithuania

Medium power range condenserless chillers with a cooling capacity from 25kW to 600 kW are designed for a wide range of commercial and industrial refrigeration or air conditioning applications. These chillers are mounted with a separate remote condenser that is built outdoors. The rest of the equipment is installed in a special technical room in the building. Refra can offer a condenserless chiller that can be connected to an existing condenser or a complete system with Refra condensers. CB chillers are built on a closed, assembled frame and equipped with scroll or reciprocating compressors. These chillers are manufactured on a compact frame that can be easily transported through standard doors. An additional 50 mm rock wool insulation can be supplemented for a super silent unit operation. On request, these units can be equipped with a buffer tank of up to 800 liters or a hydraulic module.Condenserless chillers are usually chosen when there are sound

Request for a quote

THIELMANN ENERGIETECHNIK GMBH

Germany

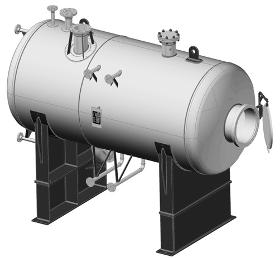

CHARACTERISTICS Pressure vessel design Volume according to customer requirements OPTIONEN Customer-specific design for other regulations (ASME, EN 13445, SVTI, AS1210, PD5500, etc) Customer-specific approvals Customer-specific testings Application for sour gas (NACE) Design for low temperature down to -50 ° C Design pressure up to 300 bar Design temperature up to 250 ° C Customer-specific nozzle arrangement ACCESSORIES on demand level indicators condensate drainage systems sump heating GENERAL & FUNCTION The condensate tank type VKAB collects liquids and condensates, which are generated during the cleaning of gas in liquid separators. The condensates are discharged from the separators into the tank and serve for pressureless intermediate storage. The design is carried out as a steel welded construction in a horizontal design and is designed as a pressure vessel with 3 bar. QUALITY MANAGEMENT DIN EN ISO 9001 certified

Request for a quoteResults for

Condensation separators - Import exportNumber of results

24 ProductsCountries