- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- condensing units

Results for

Condensing units - Import export

MOMMERTZ GMBH

Germany

The neutralisation unit Neutrakon® is suitable for the neutralisation (increase of the pH value above 6,5) of acidic condensates of gas condensing boilers (heat exchangers) and/or flue gas systems up to 1000 kW. With booster technology for an increase lifetime. The Premium Line consists of 6 different units for the neutralisation of acidic condensates of gas condensing heating units up t0 1000 kW Neutrakon® N35 – up to 35 kW Neutrakon® N65 – up to 65 kW Neutrakon® N170B - up to 170 kW Neutrakon® N300B - up to 300 kW Neutrakon® N650B - up to 650 kW Neutrakon® N1000B - up to 1000 kW

Request for a quote

MOMMERTZ GMBH

Germany

The neutralisation unit Neutrakon® is suitable for the neutralisation (increase of the pH value above 6,5) of acidic condensates of gas condensing boilers (heat exchangers) and/or flue gas systems The Neutrakon® Classic Line consists of 4 different units for the neutralisation of acidic condensates of gas condensing heating units from 25 – 300 kW Neutrakon® 01/25 – up to 35 kW Neutrakon® 02/50 – up to 65 kW Neutrakon® 03/150 - up to 150 kW Neutrakon® 04/300 - up to 300 kW

Request for a quote

MOMMERTZ GMBH

Germany

The neutralisation unit Neutrakon® SN90 is suitable for the neutralisation (increase of the pH value above 6,5) of acidic condensates of industrial condensing units up to 11 MW. Thanks to the single removable Neutra baskets, maintenance work is easy. The innovative matrix improves the flow of the condensate Made in stainless steel type 4VA With ball valve for easy maintenance Suitable for condensates of industrial heating units, CHP and flue gas systems up to 11 MW (1500 l/h)

Request for a quote

SIKO GMBH

Germany

Aluminum housing with through hollow shaft Profile IH58M: Resolutions of max. 2560 pulses/revolution Hollow shafts up to Ø 22 mm, stainless steel IP65 protection category Housing made of aluminum Condensation permitted with sealed electronics unit

Request for a quote

AGGREKO CANNOCK

United Kingdom

The 2500 KW cooling tower is designed to provide high performance for a minimal unit size. The specially designed drift eliminators reduce drift to 0.002% of flow. When supplied with chilled water, the cooling tower can also be used as a bulk air cooler for applications requiring large air flow. Designed and assembled to Aggreko’s standards. Packaged into 20 ft. ISO container frame. Brentwood drift eliminators designed for forced draft. Fully enclosed and protected from direct sunlight. Fan unit driven by a variable speed drive. Controlled operation of condenser unit fans. Safe and reliable operation for rental applications. Ease of transportation, handing and protection. Reduces drift to a rate significantly lower than that required by law. Increases safety with respect to microbial growth. Regulates fan speed proportional to sump temperature. Maximises efficiency, minimises noise and prevents overcondensation when coupled with water-cooled chillers.

Request for a quote

ALTMANN GRAPHISCHE MASCHINEN GMBH

Germany

age 2005 chiller for water cooled cabinets pump- and circulation unit external condensator with 3 blowers Delivery time: immediately from stock Ref: QU200391A Please ask for price. We ship and install worldwide!

Request for a quote

SIKO GMBH

Germany

Profile IV58M: Resolutions of max. 2560 pulses/revolution Solid shafts up to Ø 10 mm, stainless steel IP65 protection category Housing made of aluminum Condensation permitted with sealed electronics unit

Request for a quote

TROTEC GMBH

Germany

HIGH-PERFORMANCE ELECTRIC HEATING UNIT TEH 400Powerful heating without flames, smoke or condensation: With the electric heating unit TEH 400 At present, this extraordinarily robust heating unit of German high-quality manufacturing is probably the world's most powerful mobile electric heating device on the market! You require extremely large-volume, fully smoke-, flame- and condensate-free amounts of warm air – for instance for blasting, coating and painting work or load tests? If so, the high-performance electric heating unit TEH 400 is our best recommendation: This hot air giant can withstand the harshest conditions whilst producing up to 9,000 cubic metres of hot air per hour at an air pressure of up to 600 Pa in continuous operation. Owing to this capacity, the high-performance heating device can transport hot air via air hose distances of up to 100 metres length.

Request for a quote

EC PLAZA

South Korea

Electrostatic Capacity Sensor Any condensate from compression process can be sensed correctly and discharged. Zero loss of compressed air Uses of two sensors (High level, low level) protects energy loss By air loss discharging condensate selectively. * Our Company We have been worked for efficient treatment of condensation water generated in Air Compressor System. We are producing Auto drain trap that is an economical and reliable condensate discharger, Oil-water separator that is processing unit for condensate contaminated by oil with advanced technique and know-how. However, energy and environment are giving big influence in enterprise activity in 21th century industrial field, and it is considered that frugality of expensive compressed air and processing for contaminated condensate are helpful to solve these troubleshooting Forward, we will do our best to answer customer`s cheering by developing product helpful for enterprise activity. Website : http://www.enesystem.

Request for a quote

SIKO GMBH

Germany

Flat design with through hollow shaft Profile IG09M: Resolutions of max. 2560 pulses/revolution Through hollow shafts up to ø20 mm IP53 and IP63 protection categories Housing made of reinforced plastic Condensation permitted with sealed electronics unit Can be combined with the DA09S position indicator

Request for a quote

GLOBAL GASES GROUP THAI CO LTD

Thailand

R600 refrigerant fluid doesn't degrade or damage the compressor and other parts of condensing unit or refrigeration unit Because it has no impurities substance.The overall physical properties are also very standard. R600a refrigerant has 58.1 molecular weight. -11.7 °C ocilirg temperature. 135°C critical temperature, and 0 ®C of glide temperature.The possibility of r600a refrigerant gas mixing with oil is very low as there is outstanding adaptability with oil and lubricant.

Request for a quote

TMS INDUSTRIAL REFRIGERATION EUROPE B.V.

Netherlands

VI Series Inrow type Crane Cabin Coolers are bringing breath of fresh air to crane cabins. Process cranes in Steel, Non-Ferrous metals, Mining, Oil&Gas, Cement, Paper, Offshore industries have the most challenging environmental conditions. Extremely dusty and corrosive, very high and low ambient temperatures are enemies of crane cabin coolers and cause failures and stoppages sometimes. Perfect solution on keeping the A/C in protected environment! The whole A/C unit except condenser unit is kept inside on the cabin where is more safe than outside conditions. No worries, we still keep all the precautions for condenser unit too. There are still a lot of options for condenser unit such as Cu/Cu or SS coils as well as various coating options for coil and fans. The models are perfect match with the sizes of E-Panels in Electrical cabins. They are stackable next to each other or to be placed in spread delivering

Request for a quote

STEFANI SPA

Italy

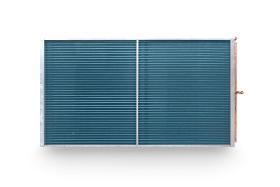

Our company has been manufacturing finned coil heat exchangers for over 40 years. The design of each finned pack can be totally developed inhouse by Stefani or taken from a drawing supplied by our customer. This is possible thanks to a strategic coengineering service, which is necessary especially when developing specific designs. In the design and manufacture of our finned coil heat exchangers we put all the flexibility and competence that have always been the hallmark of our work. We make customised finned packs for production in batches, dedicated to the machines of our OEM customers and, in general, to data centres, air treatment units for industrial refrigeration, industrial and commercial air conditions and condensing units for refrigeration.

Request for a quote

MITA COOLING TECHNOLOGIES

Italy

MITA offers different configurations of air-cooled or water-cooled industrial process chillers: all equipped with electronic microprocessor for setting and displaying the outlet liquid temperatures and all suitable for Industry 4.0. Some advantages of industrial process chillers. - Autonomous unit, with air condensation. - Maximum reliability and performance proven by strict internal tests. - Customizations and flexibility Up to 80% of energy savings in the versions with free cooling system.

Request for a quote

ROTAIR SPA

Italy

Specifically conceived, designed and manufactured for fibre optic cable laying. Compact design, extremely manoeuvrable, easy to lift and transport. With inbuilt single or double cooler depending on air temperature demand, condensates separator. All in one unit, immediately ready to work. A professional tool for a very specific and professional sector. Integrated moisture separator (FIBRA-FIBRA PLUS) Integrated aftercooler for cool air delivery (FIBRA PLUS) Unit ready to operate High quality air output (oil carry-over <1 PP) Compact design, extremely manoeuvrable Easy to transport, lift and load Outstanding accessibility for maintenance

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

AIR- AND WATER COOLED COLD WATER UNITS gwk chillers in the sklc series are air-cooled compact cold water units with integrated condenser gwk chillers in the skw series are water-cooled compact cold water units cooled with external cooling water These chillers are equipped with screw condensers; the power regulation of the capacity to be dissipated is continuous. Water-cooled cold water units in the skw series with low coolant content can be operated very efficiently and are preferably used when the available cooling water from gwk cooling towers, gwk free cooler systems or customer-provided supplies has a higher temperature level than required for the production process but is available inexpensively..

Request for a quote

CCF S.R.L.

Italy

Designed for the specific preservation of ice cream and sorbets on stick, it is small and allows to store a lot of products occupying minimal space in the workshop, fitting between the professional ice cream equipment. The freezer locker Icy 648 is built in polyurethane monocoque internally coated with stainless steel and externally with plastic sheet. The instruments are grouped on the front upper panel that houses the electrical wiring. The motor compartment and the condensing unit are housed in the lower part, closed by a frame on the front and a grid on the back. The internal compartment is fitted with racks to support the guides that slide no. 9 drawers with food-grade polyester lids, for a total storage of 648 ice creams. The door is fitted with a spring device for automatic return and magnetic gaskets.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

EUTECTIC PLATES

Turkey

Refrigerated truck bodies Kioks and Mobile Kioks Solutions Insulated refrigeration panels Eutectic plates Cooling and Condensing Units Condensing Systems Refrigerants Heat exchangers Thermometers Ice Cream and Gelato Machines

Request for a quote

REFRA, UAB

Lithuania

Wide range capacity liquid cooled condensing units, designed for commercial and industrial applications with the cooling capacity from 10kW to 40kW. These units work on a principle of the heat rejection loop, where condenser heat is dissipated to the environment via water. Rejected heat can be used for additional needs in the same building, which gives these facilities additional economic benefits. These units provide an economical, compact alternative to traditional air-cooled condensing units. Built on an assembled frame with covers, this condensing unit can be designed in a variety of ways, depending on intended use. Collected with shell and tube or plate heat exchanger, 1 to 4 reciprocating or scroll compressors and a liquid receiver as well as refrigerant filters and a sight glass. Safety valve and pressure switches are added to increase the security of the unit. An additional 50 mm rock wool insulation can be supplemented for a super silent unit operation.

Request for a quote

REFRA, UAB

Lithuania

Wide range capacity liquid cooled condensing units, designed for commercial and industrial applications with the cooling capacity from 10 kW to 40kW. These units work on a principle of the heat rejection loop, where condenser heat is dissipated to the environment via water. Rejected heat can be used for additional needs in the same building, which gives these facilities additional economic benefits. These units provide an economical, compact alternative to traditional air-cooled condensing units. Built on an open welded frame with standard profile, this condensing unit is also available in a double-deck construction for higher capacity. Assembled with shell and tube or plate heat exchanger, 1 to 4 scroll or reciprocating compressors and a liquid receiver as well as refrigerant filters and a sight glass. Safety valve and pressure switches are added to increase the security of the unit.

Request for a quote

REFRA, UAB

Lithuania

Wide range capacity liquid cooled condensing units, designed for commercial and industrial applications with the cooling capacity from10 kW to 40 kW. These units work on a principle of the heat rejection loop, where condenser heat is dissipated to the environment via water. Rejected heat can be used for additional needs in the same building, which gives these facilities additional economic benefits. These units provide an economical, compact alternative to traditional air-cooled condensing units. Built on an open welded frame with bent profile and powder coating, these condensing units carry a plate heat exchanger. Can be assembled with 1 to 4 reciprocating or scroll compressors with crankcase heater, a liquid receiver, refrigerant filters and a sight glass. Safety valve and pressure switches are added to increase the security of the unit.

Request for a quote

REFRA, UAB

Lithuania

Small capacity condensing units, designed for small commercial applications such as convenience stores, petrol forecourts and cold rooms. Assembled with scroll or digital scroll compressors, designed for MT or LT applications. This model is built on a smallest condensing unit frame and provides a cooling capacity from 10kW to 30kW. Assembled with copper aluminium fin condenser, Copeland compressors with crankcase heater, high efficiency AC/EC axial fans and a liquid receiver. Built in a closed galvanized steel frame with polymer powder coating and additional insulation for silent unit operation. Electric panel includes phase rotation and phase loss monitoring relay, compressor and fan motor overheat protection, contactor and main switch. Additional assembly options are available.

Request for a quote

REFRA, UAB

Lithuania

Small capacity condensing units with the cooling capacity from 15kW to 40kW. Designed on a compact frame, perfectly suitable for small commercial applications such as convenience stores, petrol forecourts, cold rooms and more. Assembled with copper aluminium fin condenser, Bitzer reciprocating compressors with crankcase heater and high efficiency AC/EC axial fans. Built in a closed steel frame with a polymer powder coating and condenser protection grid. Electric panel includes phase rotation and phase loss monitoring relay, compressor and fan motor overheat protection, contactor and main switch. Additional assembly options are available.

Request for a quote

REFRA, UAB

Lithuania

Small to medium capacity condensing units, designed for commercial and industrial applications such as food and beverage manufacturers, convenience stores, petrol forecourts and cold rooms. Assembled with reciprocating compressors the units provide a cooling capacity from 12kW to 55kW. These condensing units are an optimal choice for conventional refrigeration systems – affordable, small in size and easy to install. The units can be built outdoors, but additional shelter against rain or snow should be provided. Assembled with copper aluminium fin condenser, Bitzer or Copeland compressors with crankcase heater, high efficiency AC/EC axial fans and a liquid receiver. Built on an open welded galvanized steel frame with powder coating.

Request for a quote

REFRA, UAB

Lithuania

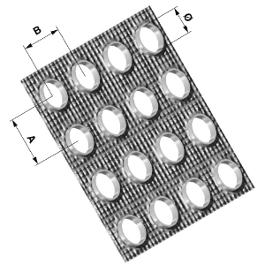

Refra heat exchangers for condensers are made of copper tubes and convert the system’s refrigerant gas to liquid form. Usually they are used for refrigeration equipment as a remote condenser or as a part of a condensing unit. Refra condenser coils are made using inner grooved or smooth copper tubes, which range from 5 mm to 12,7 mm in diameter. The frame can be made using aluminum, galvanized or stainless steel and can be coated with a special Aqua-Aero anti corrosion protection. Heat exchangers can be manufactured from low to high capacities to fully meet customer needs.

Request for a quote

REFRA, UAB

Lithuania

CO2 Compact systems are designed for small retail shops and can be manufactured for medium temperature cooling. Based on Carel HECU system for complete management of condensing units fitted with BLDC compressors, these products can be adjusted remotely. The serial connection between the condensing unit and the evaporators controlled by MPXPRO represents one of the main features of this solution, contributing to the energy efficiency and reliability of the entire system. The built-in plug and play interface provides the ability to install and set up the unit extremely quickly and easily. GREEN SOLUTIONS | This unit is a part of Refra‘s environmentally friendly product group, as it is made using CO2 refrigerant. Such low GWP solutions are designed to have better efficiencies and capacities, as well as less environmental damage.

Request for a quote

REFRA, UAB

Lithuania

High capacity condenserless chillers with the cooling power up to 2 MW are designed for immense industrial and commercial buildings with high-power demand. Refra offers condenserless chillers that can be connected to an existing condenser or a complete system with Refra condensers. Assembled in a special walk-in container this unit is ideal for buildings where indoor installation is not possible. It can be placed outdoors – right next to the building, resulting in reduced installation costs and easy unit maintenance. The condenser can be installed either on top of the container or somewhere else. Additional options, such as illumination, ventilation and heating can be integrated inside the container to make the service of the unit even more convenient. Container size ranges from 2,4 meters to 13 meters in length and can be insulated with polyurethane foam or 50 mm rock wool material for a super silent unit operation.

Request for a quote

ADM INZENIRING D.O.O.

Slovenia

Heat recovery units: - Pressurized surface condenser for heat recovery into hot water - Combined spray condenser for atmospheric heat recovery - Booster fan for higher clean steam pressure Pressure vessels: - Various types of process vessels for biofuel production - Blow Cyclon, Mixer, Pressure drop units up to 30bar - Stainless steel storage vessels required for industrial processes PC Conveyors: - Screw Conveyors With Mulitple Inlet Ports - Screw Conveyors With Multiple Outlet Ports - Tubular Screw Conveyors, U-type PS conveyors

Request for a quote

OFFICINA MASTER S.P.A

Italy

Vaporizing machine Saturno – Designed to relax the textile fibers and allow dimensional stability. The fabric in entrance, as plaite, big or small roll, is overfed and spread on a perforated conveyor belt that carries it through the different working fields. The first two sections of the treatment system are constituted by high temperature vaporizing tunnels, realized in stainless steel with anti-condensation units. Between the two sections there is a device that makes the belt vibrate to facilitate the relaxation and shrinkage of the fibers. At the output of the last steaming tunnel, an adjustable forced hot air drying group is installed. In the final part of the machine there is a double cooling field blocking the movement of the fibers (thermic shock). Both the drying field and the cooling one are above the conveyor belt in order to avoid a direct contact between the air flows and the right side of the fabric.

Request for a quoteResults for

Condensing units - Import exportNumber of results

38 ProductsCountries

Company type

Category

- Refrigeration plants and equipment, commercial and industrial (11)

- Condensers (3)

- Waste water recycling (3)

- Heat exchangers (2)

- Air compressors - Tools and accessories (1)

- Air conditioning equipment (1)

- Compressors (1)

- Cooling towers (1)

- Heating and air conditioning - works (1)

- Heating, domestic - installations and equipment (1)

- Ice cream and sorbets (1)

- Ice cream-making - machinery and equipment (1)

- Offset printing machinery (1)

- Plastics - machines and material for industry (1)

- Refrigerants (1)

- Textile finishing - machinery and equipment (1)