- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- lubricating system

Results for

Lubricating system - Import export

IGUS® GMBH

Germany

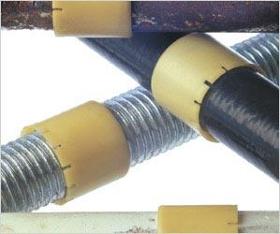

iglidur® PEP, metric d1 [mm]: d2 [mm]: iglidur® PEP, inch d1 [inch]: d2 [inch]: When to use iglidur® PEP plain bearings? When a low-priced plastic plain bearing system is required When freedom is required from shaft material and shaft surface For the protection of expensive and sensitive shafts For extraordinary wear resistance with rare and slow movements. For constantly low coefficients of friction When freedom from corrosion is desired When not to use them? For high surface speeds iglidur® J For high loads iglidur® G iglidur® Q For high temperatures iglidur® V400 iglidur® X iglidur® Z When low-clearance bearings are required iglidur® P iglidur® X Maintenance-free plain bearings usually distinguish themselves by their ability to glide free of lubricants without any further additional layer on the shaft. In these systems it is obvious that shaft materials are as important as the bushings. igus® blazes a new trail with an enclosed and maintenance-free plain bearing concept. iglidur® PEP is an entirely novel lubricant-free plastic plain bearing system with an inner and outer ring. Special feature: The running partner is determined by the inner ring and for the first time, the material and surface finish of the shaft are insignificant. Even thread, rust or scratches do not affect the long-term reliable function. By the specification of the gliding partner and extensive series of tests, the long-term behavior of the bearing system can be precisely forecast. With the PEP polymer plain bearing, the inner ring rotates with the shaft like in ball bearings Relative movements of the shaft to the bearing are dispensed with. This protects the shaft surface from wear and saves costs. Another plus point: Even the most sensitive or unusual materials for the rotating shaft can be used with these new polymer bearings. The PEP polymer bearings are thereby absolutely free from material-dependent corrosion. Wear resistance The wear test results are absolutely convincing with loads up to 5 N/mm². Here the PEP polymer bearings attain values that are virtually comparable with those of the most wear-resistant plastic-steel bearing systems. An exceedingly satisfying result when you consider the costs saved by dispensing with the otherwise essential surface treatment of the shaft. The constantly low friction-coefficient level is also an advantage for the user. As the glide partners are fixed by the defined system, their tribological data too are accurately predictable. The coefficients of friction of the lubricant-free bearing are not determined any more by the shaft materials or surface conditions. If necessary, the coefficients of friction can be further lowered by additional minimum lubrication. Detailed test information with a wide range of lubricants are available and can be had from igus® on request. iglidur® PEP bearings operate independent of the shaft material. iglidur® PEP bearings consists of an inner and outer bearing. X = Load [MPa] Y = Wear [μm/km] A = PEP B = Combination 1 C = Comb. 2 D = Comb. 3 E = Comb. 4 F = Comb. 5 G = Comb. 6 H = Comb. 7 A1 = Wear of the outer bearing B2 = Wear of the inner bearing Fig. 02: Wear tests of various material combinations, p = 0.75 MPa, v = 0.3 m/s X = Load [MPa] Y = Wear [μm/km] A = iglidur® J B = iglidur® PEP Fig. 03: Wear of the iglidur® PEP bearing dependent on the load, v = 0.3 m/s iglidur® PEP, metric d1 [mm]: d2 [mm]: iglidur® PEP, inch d1 [inch]: d2 [inch]: Dimensions according to ISO 3547-1 and special dimensions

Request for a quote

LEMVIG GAS DISTRIBUTION A/S

Denmark

It is mainly used to replace R22 and R502 refrigerants in low-temperature refrigeration equipment; because R290 refrigerant is flammable, it is usually only used in low-temperature refrigeration equipment with a small amount of liquid, or as a component of low-temperature mixed refrigerant; R290 is compatible with traditional refrigeration oil. High-purity R290 is used as a temperature-sensing working fluid; premium and first-grade R290 can be used as a refrigerant to replace R22, R502, compatible with the original system and lubricating oil, and used for central air conditioning, heat pump air conditioning, household air conditioning and other small refrigeration equipment . R290 is a hydrocarbon refrigerant; it has no damage to the ozone layer and has a very small greenhouse effect.

Request for a quote

THOMSON MACHINERY BV

Netherlands

Jung JF520 surface and profile grinding machine in very good condition. Machine No. 1569. Year of construction 1981 - Grinding length max. 600 mm - Sliding width: 200mm - Magnet size: 500x175mm - Grinding wheel dimensions: 250x25x50.8mm Bcspaqsayd8 - Spindle speed: stepless 4200 omw./min. - 380V 4kW - Weight about 2000kg Equipment: - 1 axis digital display, - Flanges - Infinitely adjustable spindle speed - Infinitely variable hydraulic supply in transverse direction - auto lubrication system, - Automatic height feed with rapid traverse - machine books

Request for a quote

ANCOTECH

Netherlands

Lincoln P215 Lubrication system pump 30 Liter 400V Suitable for grease to NLGI 2 Includes two pump elements K7 with an output of maximum 47-189 cc/hour. Can be extended to maximum of 15 pumpelements, see related products. Connection pump element 1/4"G Supply voltage 340-420V/50Hz - 440-480V/60Hz Maximum pressure 350 bar Protection class IP55 Temperature -20 to 70°C The advise is to use a pressure relief valve for every pump element. Click here for an overview.

Request for a quote

ANCOTECH

Netherlands

Lincoln P205 lubrication sytem pump 8 Liter 400V Suitable for grease to NLGI 2 Includes pump element K6 with an output of 172 cc/hour. Can be extended to a maximum of 5 pump elements, see related products. Connection pump element 1/4"G Supply voltage 340-420V/50Hz - 440-480V/60Hz Maximum pressure 350 bar Protection class IP55 Temperature -20 to 70°C The advise is to use a pressure relief valve for every pump element. Click here for an overview.

Request for a quote

ANCOTECH

Netherlands

SKF High Viscosity, High Load and High Temperature Grease SKF LGHB 2 is a high viscosity mineral oil based grease using the very latest calcium sulfonate complex thickener technology. Due to its specific composition, the product can withstand high temperatures and extreme stress and can therefore be used for a whole range of applications, especially in mining and in the metal and cement segments. This grease contains no additives and the (EP) high pressure properties are due to the soap structure. • Excellent anti-oxidation and anti-corrosion properties • Good EP performance in high load applications • Withstands peak temperatures up to 200°C Typical Applications: • Steel-on-steel ball joint bearings • Pulp and paper machines • Asphalt vibrating screens • Continuous casting machines • Sealed spherical roller bearings with an operating temperature up to 150 °C • Roller bearings in the steel industry • Forklift mast rollers

Request for a quote

VIRMER

Netherlands

WATTSAN M1 2030 wide-format machine has a large working area of 2000×3000 mm with a slatted table top. The design includes a spindle with an ER-25 collet chuck and a power of 6 kW. An air cooling system and a built-in vacuum cleaner for collecting wood chips and dust are also available for an additional fee. The leadshine 860 stepper motor driver is responsible for moving the portal, the machine is controlled by the operator through NcStudio. The body of the machine is a welded structure made of steel profile, the weight of the machine is 1400 kg. The maximum travel speed along the axes is 25 000 mm/min, the maximum travel speed during operation is 15 000 mm/min. The spindle speed reaches 24 000 rpm. If you want a more upgraded machine, we can install: Vacuum table. DSP controller. Syntec control system. chip removal system. manual auto lubrication. more powerful spindle or additional cutting heads. rotary device for processing cylindrical products. tool sensor.

Request for a quote

VIRMER

Netherlands

CNC milling and engraving machine WATTSAN A1 1325 is a multi-purpose equipment for engraving, cutting and 3D milling sheets of materials. WATTSAN A1 1325 has a grid type working table of 1300×2500×200 mm, but additionally we can install a vacuum table, that holds the sheet material in place and significantly ease the process. A spindle ER-25 with collet has power of 3 kW, water cooling system. The portal moved by step engine controlled by driver Yako 2405. Frame of the machine is welded from steel profiles construction; weight of the machine is 800 kg. Max speed of movement along axis is up to 25 000 mm/min, max working speed is 15 000 mm/min. Spindle rotation speed can reach 24 000 rpm. The machine controlled by NC-Studio control system. We can modernize the machine with the following: vacuum table, DSP controller, Syntec control system; chip removal system, automatic lubrication, more powerful spindle or additional cutting heads, rotator for cylinder shaped parts, tool sensor.

Request for a quote

VIRMER

Netherlands

CNC milling and engraving machine WATTSAN М1 1616 belongs to М1 series, that is considered more technically sophisticated than A1 series and has a massive frame. The frame is more stable and allows process more complex parts. The machine is applicable for cutting of wood, MDF, chipboard, acryl, plexiglas, PVC, aluminum, composite. Using WATTSAN М1 1616 you can also perform a 3D milling. WATTSAN М1 1616 has a grid type working table of 1600×1600×300 mm, but additionally we can install a vacuum table, that holds the sheet material in place and significantly ease the process. Max speed of movement along axis is up to 25 000 mm/min, max working speed is 15 000 mm/min. Spindle rotation speed can reach 18 000 rpm. The machine controlled by NC-Studio control system. We can modernize the machine with the following: vacuum table, DSP controller, chip removal system, automatic lubrication, more powerful spindle or additional cutting heads, rotator for cylinder shaped parts, tool sensor.

Request for a quote

VIRMER

Netherlands

CNC milling and engraving machine WATTSAN A1 1616 is a cost efficient, easy-to-use and multi-purpose equipment. The machine performs a cutting and engraving, also WATTSAN A1 1616 can perform a 3D milling. WATTSAN A1 1616 has working area of 1600×1600×200 mm, spindle ER-25 with power of 2.2 kW, water cooling system. The portal is moved by step engine controlled by driver Yako 2405. Operator controls the machine with control system NC-Studio. Frame of the machine is welded from steel profiles construction; weight of the machine is 500kg. Max speed of spindle movement along axis is up to 25 000 mm/min, max working speed is 15 000 mm/min. Spindle rotation speed can reach 24 000 rpm. The working table has a T-slot grid plate. We can modernize the machine with the following: vacuum table, DSP controller, chip removal system, automatic lubrication, more powerful spindle or additional cutting heads, rotator for cylinder shaped parts, tool sensor.

Request for a quote

VIRMER

Netherlands

WATTSAN М1 1313 has a grid type working table of 1300×1300×200 mm, but additionally we can install a vacuum table, that holds the sheet material in place and significantly ease the process. The construction includes a spindle ER-25 with collet and power of 2.2 kW, water cooling system. The portal moved by step engine driver Leadshine 860. Operator controls the machine with control system NC-Studio. Frame of the machine is welded from steel profiles construction; weight of the machine is 700kg. Max speed of spindle movement along axis is up to 25 000mm/min, max working speed is 15 000mm/min. Spindle rotation speed can reach 24 000 rpm. We can modernize the machine with the following: vacuum table, DSP controller, chip removal system, automatic lubrication, more powerful spindle or additional cutting heads, rotator for cylinder shaped parts, tool sensor.

Request for a quote

VIRMER

Netherlands

WATTSAN A1 1313 machine has a working field of 1300×1300×200 mm, an ER-20 spindle with a power of 2.2 kW, and a water cooling system. A stepper motor controlled by the Yako 2405 driver is responsible for moving the portal. The body of the machine is a welded structure made of steel profile, the weight of the machine is 500 kg. The maximum travel speed along the axes is 25,000 mm/min, the maximum speed in operation is 15 000 mm/min. Spindle speed can reach 24000 rpm. The table has a slatted T-slot cover. The machine is controlled by NcStudio software. To upgrade this machine, we can install: vacuum table. DSP controller. Chip removal system. Manual auto lubrication. More powerful spindle or additional cutting heads. Rotary device for processing cylindrical products. Tool sensor.

Request for a quote

SELMACH MACHINERY LTD

United Kingdom

The Morgan Rushworth HSW 45 and HSW 60 are compact universal hydraulic steelworkers with 5 work stations and have been designed for volume production with maximum efficiency. Punching, shearing, cropping, notching can be instantly carried out by pressing the movable foot pedal. The low power inch mode on each work station enables correct workpiece positioning and tool alignment. The machines are supplied with a centralised lubrication system ensuring a easy, simple maintenance programme. Adjustable hold downs are situated on all work stations to ensure safe accurate processing of material. A 1m ruled length stop is supplied as standard equipment. Selmach Machinery has two models of steelworkers which range from 60 to 175 tonnes. Our HST machines are twin operated machines providing power and accuracy whilst our HSW provide single food pedal operation and are designed with volume, production and efficiency in mind.

Request for a quote

PROSAW LIMITED

United Kingdom

Automatic upstroking circular saw with NC Programmable Controls. Yilmaz SK450 Standard Details Designed for high-volume straight cutting of non-ferrous profiles 4 – 6 second cycle time* High precision servo motors accurate to ±0.05mm* 450mm TCT blade with 4 kW motor Servo-controlled infeed speed and saw blade stroke adjustment Horizontal and vertical pneumatic clamping of the workpiece for precise cutting Automatic retraction of stock material at end of cut to protect the surface from scratches Single or multi-bar** (bundle) cutting Computer-controlled blade lubrication system System shuts down automatically after cutting the required quantity Interlocked safety guards Windows-based industrial PC with 7’’ LCD colour touch screen HMI & USB cutting job input Internet connection possible for technical support Automatic feeder stroke from 5 – 600mm. Maximum cutting length 9990mm Automatic end of bar sensor *Depending on material **Extra-cost option

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

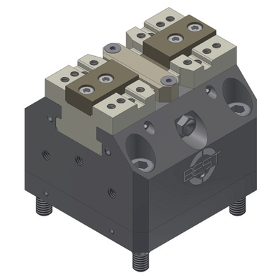

Repetition Accuracy of 5 micron Extremely High Clamp Forces Low wear due to Nitrogen Hardened Surfaces Suitable for Internal or External Clamping BEST hydraulic centric vices are a no compromise solution to repeating and long running 4th and 5th axis workholding. BEST have focused on the production of high accuracy, high rigidity vices. These vices are suitable for both internal and external clamping. They offer very high clamping forces and repeatability of 0.005mm and a centring accuracy of 0.01mm. The Hydraulic vices also have the following options: Clamp Path Monitoring, Fixed Jaw, Central Lubrication System and Positive Air Pressure to prevent swarf ingress.

Request for a quote

GLOBAL INDUSTRIAL SEWING MACHINES

Netherlands

WF 9245-35 – Single needle, flatbed, walking foot machine with 35 cm working space. This is a high quality machine suitable to sew on leather, furniture and upholstery. This machine is equipped with a large hook, safety clutch and semi-automatic lubrication system.

Request for a quote

GLOBAL INDUSTRIAL SEWING MACHINES

Netherlands

WF 9245 – Single needle, fl atbed, walking foot machine. This is a high quality machine suitable to sew on leather, furniture and upholstery. This machine is equipped with a large hook, safety clutch and semi-automatic lubrication system. WF 9245 B – Same as WF 9245, but equipped for binding work (binder not included). Products WF 9245, WF 9245 B Table Top No Table Top, Table grey C WF 9245 (120x55x4 cm), Table Top D 105x55x4 cm Stands No Stand, Stand C (China), Stand K (912 mm), Stand K short (667 mm), Stand Z Motor Set External synchroniser SY0129 (600-29), G 60 Servomotor (optional: external synchroniser G series), i60-4-GL-220, MT0175 – 750 Watt mini motor, No Motor Set, NS clutchmotor 1400 RPM 220 V, NS clutchmotor 1400 RPM 380 V Option External synchroniser for G-series, No option, Thermical switch 220 V, Thermical switch 380 V Option for i60-4-GL-220 pneumatic presser foot lifter WF 1335, 9245, ZZ 1266, Pneumatic backtack WF 1335, 9245, Set PFL + BT WF 1335, 9245,...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MARINE FUEL MILOS

Greece

Engine oils, driveline fluids, automotive specialties, coolants, lubricants, hydraulic oils, industrial products, greases and cleaners. Lubricants Milos Livanios distrbution Ports of Adamas and Pollonia Lubricants Milos Livanios and Eko. Lubricants have been developed to meet all the requirements of the REACH regulation on the safe use of chemicals and the CLP regulation on the classification, labeling and packaging, which aligns existing EU legislation to the United Nations Globally Harmonized System (GHS). EKO lubricants applications are supported by special technical advisors, either on the field or through any other communication, always upon request. The specifications of the products may change at any time, without prior notice, due to the continuous product development procedures and the technical evolutions of the equipment. Always consult the Product Data Sheet. For the safe use of the product, consult its Safety Data Sheet.

Request for a quote

BRITISH METRICS

United States

British Metrics is a proud distributor or quality German made grease fittings in the USA. We carry all metric sizes and British sizes in steel Rohs and Reach zinc plated and in stainless on request.

Request for a quoteResults for

Lubricating system - Import exportNumber of results

20 ProductsCountries

Company type