- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- dose packaging

Results for

Dose packaging - Import export

MONGIN

France

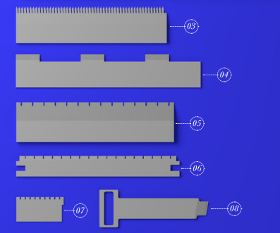

Unit dose pipettes precutting N°3 - Lengthwise precutting knife N°4 - Cross-cutting knife Precutting of unit dose pre-filled syringes N°5 - Precutting blade N°6 - Precutting knife for sealing machine Precutting for blister pack N°7 - Cross-cutting blade Precutting for blister packof medical reagents N°8 - Precutting knife

Request for a quote

MONGIN

France

PRECUTTING KNIVES FOR BLISTER PACK, PACKAGES OF UNIT DOSE PRE-FILLED SYRINGES, UNIT DOSE PIPETTES

Request for a quote

KRZ

Spain

Technical data Dimensions1169x442x696mm ( LxAxAlt) Approximate weight75 Kgr Electrical power supply220V AC50Hz/60Hz Electrical consumptionMin :400WMáx: 1KW StructureAluminio Packaging speed2200 blísters / hour Horizontal packaging of solid medication Yes Blister repackagingYes Out of blister packagingYes Split medication packagingYes, mentioned on blister and statistics, Maximum size of medication to be packed25x25x5mm ( LxWxH ) Size of blister obtained57mm(wide)x52mm Precut blistersYes, allowing to make rolls Airtight sealingYes Internal computer with integrated keyboardYes Bar code readerYes. All EAN formats (series) Data MatrixYes (New regulation February 2019) Emergency stopYes Digital temperatura controlYes Sealing temperatura114ºC Heating time as from Room temperature75 sec ConsumablesTwo rolls: One thermal (without ink) and the other colored ( Photoprotective)

Request for a quote

PERSALUTE - GINSENG COREANO

Italy

DESCRIPTION Original product concentrated by carefully processing only the red ginseng manufactured with raw ginseng cultivated by gathering the soil energy for 6 years. It is distinctive in that it was manufactured in deep extract form by extracting the active ingredients of red ginseng CONTENT / PACK 120g / n. 1 glass 120g Measuring spoon included in each bottle INGREDIENTS Panax Ginseng Root Extract: 100.00%; Content of saponin (Ginsenosides) Rg1 +Rb1 + Rg3: 6.0 mg/g DIRECTIONS Frequency of use: 2 times a day, preferably in the morning and in the afternoon an hour after meals Recommended intake: a measuring spoon at a time (1 day) Instructions for administration: dissolve in hot water, milk, tea Note: under 15 years halve the dose MANUFACTURER Produced and packaged in South Korea by the Producers Cooperative NH Nonghyup Imported by PT Srl – Via Marchesina 31 – 20090 Trezzano sul Naviglio (Milan) Italy www.persalute.it

Request for a quote

PERSALUTE - GINSENG COREANO

Italy

DESCRIPTION Original product concentrated by carefully processing only the red ginseng manufactured with raw ginseng cultivated by gathering the soil energy for 6 years. It is distinctive in that it was manufactured in deep extract form by extracting the active ingredients of red ginseng CONTENT / PACK 240g / n. 1 glass 240g Measuring spoon included in each bottle INGREDIENTS Panax Ginseng Root Extract: 100.00%; Content of saponin (Ginsenosides) Rg1 +Rb1 + Rg3: 9.0 mg/g DIRECTIONS Frequency of use: 2 times a day, preferably in the morning and in the afternoon an hour after meals Recommended intake: a measuring spoon at a time (1 day) Instructions for administration: dissolve in hot water, milk, tea Note: under 15 years halve the dose MANUFACTURER Produced and packaged in South Korea by Dajung Co.,Ltd Imported by PT Srl – Via Marchesina 31 – 20090 Trezzano sul Naviglio (Milan) Italy www.persalute.it

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ELMOR

Switzerland

The elmor CX counter module is mostly used as dosing unit on packaging machines. The open constructed counting head has a narrow width. Thus, multihead dosing systems can be realized easily also in tight spaces. The CX counter module consists of two parts: the counting head with conveying unit and sensor and the control unit. The control unit of the CX counting module is completely remote controlled via a PLC. The technical data of the CX counter module are quite similar to the data of our C1 seed counter. Example: Dosing module with 4 counter heads Multihead seed counter using the elmor CX With courtesy of: Tempel Verpakkingstechniek (NL) For more information please contact: info@vandertempel.nl Technical data Countable parts: 0.2 to 18 mm in diameter Cylindrical parts up to 20 mm length All sizes are counted with the same adjustable conveyor bowl; for parts with extreme shapes or sizes the sorting element can be customized The conveying speed can slow down automatically shortly before reaching the desired amount to achieve a high dosing accuracy. Spherical parts of 2 mm diameter have the following performance values: Counting speed around 50,000 pieces per hour Counting error: 1 per thousand or less The counting range and the count modes are determined by the PLC Conveyor bowls The parts to be counted are transported in a vibrating conveyor and are singularised by means of a sorting element. Both the conveyor bowl as well as the sorting element can be selected among different variants , depending on the properties of the product to be counted. A) Standard conveyor bowl made of anodised Aluminium with universal – sorting element FS0. FS0 is manually adjustable for all part sizes from 0.1 to 18 mm in diameter. B) Special sorting elements instead of FS0: FS1, manually adjustable, optimised for cereals, rice, paddy and products of similar shape and size FS2: manually adjustable, optimised for corn, soybeans, peas, beans and products with similar shape and size FS3: fine-drive adjustable in height and width, for very flat seeds or flat mechanical parts with the following dimensions: width: 0.5 to 10 mm, height: 0.5 – 8 mm, maximum length: 20 mm C) Special conveyor bowl with additional lateral opening for mechanically eliminating of accompanying substances, suitable for corn, cereals, soybean, paddy, etc. The height of this opening can be adjusted from 0 to 5 mm and allows unwanted accompanying substances laterally be sorted out. Not suitable for parts smaller than 1 mm in diameter. Can be used with sorting elements FS0, FS1, FS2, or FS3 combined. D) To meet the needs of various industries, the conveyor bowls can be made of other materials . These bowls are for example extremely impact resistant or correspond to the rules of the FDA, etc. Such trays can be made from various basic materials like Titanium, PEEK, Polyamide and others. E) The standard aluminum bowls can be treated or coated in order to satisfy specific requirements. With increased mechanical stress or when in contact with food, the surface can be hard anodized. A hard coating of nickel has a high surface hardness and is FDA approved, Polyurethane (PU) coating permits rapid transport of heavy mechanical parts and prevents noise and wear. Again, FDA approved materials can be used. F) Feeder Bowl with vertical outlet: Short cycle times are possible, as the seeds leave the bowl after a short run time. Advantageous when many different lots must be processed, often used for the fast 1000 grain weight measurement. Used for seeds which can be easily singularised like Crop, Soy, Corn, Canola etc. The seeds should have a diameter of 2 mm or more. Volume 0.8 litres, or about 2500 kernels of Corn. Feeding Conveyor elmor 610 Feeding conveyor and storage hopper for automatic refilling of the conveyor bowl of the counting machine elmor CX elmor Green Design Our label for: high energy efficiency longevity no standby power loss most components may be recycled production without solvents, ROHS conformity

Request for a quote

GAPLAST GMBH

Germany

LIQUID, SEMISOLID Nasal, Ophthalmic, Topical, Oral Use The AirlessMotion products can be combined with numerous dispensing units for: horizontical or vertical outlets spray, dropper or lotion pumps snap, crimp or screw neck design push button or trigger activation Airless container for pump & squeeze application AirlessMotion Reaching the utmost level of integrity sterility without preservative agents also during multiple use of a dosing system, requires highly engineered packaging. First of all, the container itself has to match these needs. A multilayer bottle has been evolved into a hybrid packaging consisting of a rigid bottle layer and a flexible, contracting integrated bag. The resulting system allows an airless pump not to vent the container with contaminated air during multiple applications, also if there are longer pauses in-between. Numerous patents are protecting the IP of product, function and process. Benefits of the system (B2B) Formula without preservative...

Request for a quote

TECHNOWAGY LTD

Ukraine

The automatic machine for packing washing powders in packages with fingers handle made of polyethylene tape is equipped with a double-flow weighing dozer and independently forms a 3-seam package of polyethylene tape and pour in it ready dose of washing powder, the package is sealed, cut off and step-by-step conveyed by the receiving transporter. The machine is equipped with a high-quality control system, which consists of the best components from Europe and is based on PLC Siemens. The machine is controlled using a touch-screen installed on the front of the control panel. From this display, you can monitor and configure the operation of the machine. All the parameters (like dose mass, dosing mode etc) are set at one terminal.

Request for a quote

TECHNOWAGY LTD

Ukraine

Device components and operation principle The automatic machine for packing pellets in packages of polyethylene tape is equipped with a double-flow weighing dozer and independently forms a 3-seam package of polyethylene tape and pour in it ready dose of pellets, the package is sealed, cut off and step-by-step conveyed by the receiving transporter. The machine is equipped with a high-quality control system, which consists of the best components from Europe and is based on PLC Siemens. The machine is controlled using a touch-screen installed on the front of the control panel. From this display, you can monitor and configure the operation of the machine. All the parameters (like dose mass, dosing mode etc) are set at one terminal.

Request for a quoteResults for

Dose packaging - Import exportNumber of results

10 ProductsCompany type