- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- fatigue testing

Results for

Fatigue testing - Import export

POPPE + POTTHOFF MASCHINENBAU GMBH

Germany

The system is a self-sufficient unit and is made of a solid welded frame, contains media preparation, a hydraulic unit, and electrical engineering. The pressure test bench has a secure test chamber for burst pressure and hydrostatic pressure tests and, optionally, a climatic chamber for pressure tests with environmental simulation. Depending on the option selected, pressure change tests up to 2,000 bar and 10 Hz can be generated. With the test circuit for hydrostatic and burst pressure tests, pressure ramps up to 3,000 bar can be generated. It is operated on a support arm PC. For pressure tests according to EG79 / EU406 – Section 4.2 Pressure booster for additional supply Displacement volume max. 15cm³ Frequency up to 10Hz Pressure Load Changes as sine & trapezoidal curve (depending on the expansion volume) Impulse intensifier for small volumes up to 2,000bar Safety test chamber with automatic door Media treatment with dirt and clean tank

Request for a quote

NOVOSIM

Turkey

The development of rotating components requires intensive testing. While the primary goal may be to achieve strength and life performance, noise, vibration, temperature and other parameters can play an important role for customer expectations. Novosim therefore offers a customizable test dynamometer that can be used in the development of passenger car, commercial, truck or even military vehicle components. The software is easy to use and also highly customizable, allowing different product lines to be tested within a single system. With regenerative braking, power is recovered and returned to the test system, ensuring efficient operation. Considering that tests can last about 1 month, costs can be an important parameter to control costs. Different types of data can be collected and stored in a database for further comparisons and tracking of the development process.

Request for a quote

RUHLAMAT GMBH

Germany

The TT300-3 torsion tester is designed to perform dynamic torsion stress tests with passports, e-passports, and ID-3 inlays. The purpose of this test is to determine any adverse mechanical or functional effects in the machine readable passport arising from torsional fatigue. The test system enables to twist the passports along the long axis and to test up to 8 passports simultaneously. This method accelerates fatigue due to imposed torsion, especially in the area of the antenna and associated connections if present. The TT100-3 torsion test system is perfect for quality assurance in passport production and for passport testing in laboratories. It is helpful to ensure that the passport booklet quality meets the requirements of the ICAO. A long-lasting high quality is essential for governmental documents. Make sure your passports fulfil the requirements for global interoperability. Perfect for e-passport quality control and quality assurance in production Follows the...

Request for a quote

RUHLAMAT GMBH

Germany

The BT310-3 bending tester is designed to perform dynamic bending stress tests with passports, e-passports, and ID-3 inlays. The purpose of this test is to determine the bending fatigue resistance of the passport booklet to fully reversed loading. The test system enables to bend the passport along the short axis or the long axis. Up to 6 passports can be processed simultaneously. This method differs from the back pocket stress method by avoiding directly applied pressure. It accelerates fatigue due to imposed bending, especially in the area of the antenna and associated connections if present. The BT310-3 bending test system is perfect for quality assurance in passport production and for passport testing in laboratories. It is helpful to ensure that the passport booklet quality meets the requirements of the ICAO. A long-lasting high quality is essential for governmental documents. Make sure your passports fulfil the requirements for global interoperability. Perfect for...

Request for a quote

EP EHRLER PRÜFTECHNIK ENGINEERING GMBH

Germany

The EP endurance test benches are used to test various components over a defined cycle for durability, e.g. temperature and pressure cycle tests. A high series quality requires precision and reliability. Operational and endurance tests are necessary in order to be able to demonstrably guarantee high quality. In the form of selection or random sampling tests, components are tested for fatigue and wear by means of load tests, for example under pressure and temperature changes. The tests are used for endurance stress testing of various materials and products with different pressure curves and temperatures. We build test benches according to your requirements: e.g. for long-term or short-term tests, under static or pulsating test conditions and depending on other factors. Present us your requirements!

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ZWICKROELL GMBH & CO. KG

Germany

The HB Servo-Hydraulic Testing Machine is specifically designed to provide an excellent quality performance and functionality. It is a high quality device which is built with a testing actuator mounter on top of the cross head. The superior quality apparatus is considered as a very versatile device to be used especially in conjunction with the T-slotted platform which allows flexure tests and component testing in addition to several fatigue tests. It is also available in a wide a range of versions for test loads from 50 to 2500 kN. The standard testing actuator stroke of 100, 250 or 400 mm. It can be supplied for 210 or 280 bar system pressure. The test frame features extremely high stiffness and natural resonance. Advantages and features • testing actuator mounted on upper crosshead • hydraulic clamping and adjustment for easy positioning of upper crosshead • comprehensive range of accessories, including hydraulic grips, compression platens, flexure test kit etc.

Request for a quote

HEGEWALD & PESCHKE, MESS- UND PRÜFTECHNIK GMBH

Germany

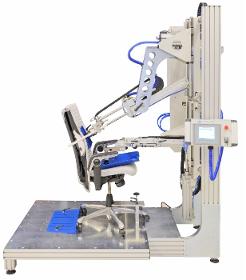

Various test rigs: - Alternating bending test rig for seating furniture: seat/back rest load acc. to BIFMA X5.1, EN 581-2, EN 1335, EN 1728, BS 5459 - Double test rig for chair testing: seat and backrest tests, side-to-side tests and armrest tests according to EN 1335, EN 581-2, EN 1728, BIFMA X5.1, BIFMA X5.4, BIFMA X6.5, BS 5459 - Test rig for alternating bending tests of arm rests according to EN 1335, EN 1728, EN 581-2, DIN 4551, BIFMA X5.1 and BSI/BS 5459 - Portal drop test rig: testing of chairs, stools, tables, beds acc. to BIFMA X5.1, BIFMA X6.1, EN 581-2, EN747-2, EN 1728, EN 1730, ISO 7173, EN 12520, EN 14072 - Test bench for determining the stability of chairs in accordance with the standards EN 1022, EN 1729-2, EN 581-2, ISO 7174-2 and BIFMA X5.1 - Test rig for tilting drop tests at chairs according to DIN 68878/1 - Swivel test rig according to DIN 4551, EN1335, NEN 1812 and BIFMA X5.1

Request for a quote

HITACHI HIGH-TECHNOLOGIES EUROPE GMBH

Germany

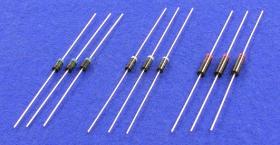

Hitachi High-Technologiees Europe GmbH is very pleased to introduce different types of Power Diodes for Automotive application. Alternator diodes and High Voltage Diodes are characterized by significantly improved quality. Alternator diodes: Quality improvement High Endurance Level: Twice better Life Time verified in Thermal Fatigue Test (vs. competitor) High Reliability: Operating Temperature -40°C to 225 °C Variety of Line up: ZSM35C22/R: Operating Junction Temperature: -40°C to 225 °C; Storage Temperature: -40°C to 225 °C; Average Forward Current:35A; Surge (Non-Repetitive) Reverse Current: 30A; Peak Forward Voltage: 1,3V; Peak Reverse Current: 0,8uA; Zener Voltage: 20-24V ZSM50C22/R: Operating Junction Temperature: -40°C to 225 °C; Storage Temperature: -40°C to 225 °C; Average Forward Current:50A; Surge (Non-Repetitive) Reverse Current: 55A; Peak Forward Voltage: 1,2V; Peak Reverse Current: 0,8uA; Zener Voltage: 20-24V ZSM70A22/R: Operating Junction Temperature:

Request for a quote

WESTLAKE EUROPE

Belgium

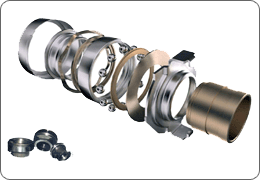

Complete range of release bearings produced in house. Produced to ensure optimum performance levels in line with OE standards. A range of Concentric Slave Cylinders, (CSC) also available. All release bearing components - Produced utilizing Japanese manufactured automatic heat treatment plant and computer tested against OE specifications. Tests include over 1, 000, 000 actuations in the fatigue test.

Request for a quote

WESTLAKE EUROPE

Belgium

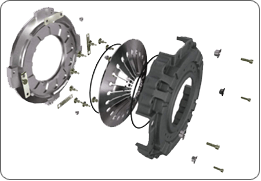

Castings for Pressure plates are produced in our own factory from high quality cast iron produced in accordance with the requirements of BS1452 and DIN1619. The material must be compact, devoid of blowholes and/or inclusions, crack free and uniform in hardness and texture. Cover pressings are produced using the most sophisticated press equipment available. Pressure Plates, Diaphragm Springs, Straps and all other components undergo strict analysis for chemical composition, tensile strength, hardness and microstructure. All components parts undergo rigorous inspection and measurement controls before entering the production areas. Diaphragm springs - Produced utilizing Japanese manufactured automatic heat treatment plant and computer tested against OE load specifications before assembly. Tests including clamp load, release load, pressure plate lift, finger height, stress and fatigue testing using the latest sophisticated test and inspection facilities.

Request for a quote

ZWICKROELL GMBH & CO. KG

Germany

The Kappa creep testing machine is a flexible and highly-precised creep testing machine used for maximum cost-effectiveness. It is fully equipped with a test frame having four steel columns for high lateral and axial stiffness. It is powered by top-quality components that includes testXpert® II testing software and test control measurement and control devices. It has attained success due to its successful installations worldwide. It features an intelligent sensor technology which recognizes and calibrates all the sensors that are connected including their projected force limits and environments. It generally focuses on the most essential requirements of creep testing which include load, temperature, strain and data security.

Request for a quoteResults for

Fatigue testing - Import exportNumber of results

12 ProductsCountries

Company type