- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- feeder

Results for

Feeder - Import export

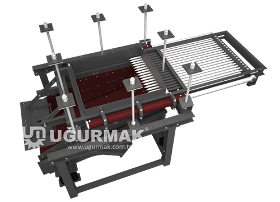

UGUR MAKINA CRUSHING & SCREENING

Turkey

In some crushing and screening processes, there may be a need to divide the process in half. In such cases, tunnel type intermediate stock center is frequently preferred. It is positioned in the middle of the stock center. Their main field of use is to ensure that the stocked material is fed to the second stage of the process. This vibrating feeder type UTF series Tunnel Feeder provides high performance in heavy conditions

Request for a quote

UGUR MAKINA CRUSHING & SCREENING

Turkey

Apron feeders can operate horizontally or at an incline. In general, an Apron Feeder consists of overlapping abrasion-resistant pallets that are fastened on the chain with bolts, working like a conveyor. These chains, to which the pallets are attached, are driven by chain gears located on both sides

Request for a quote

PARSMEGA MAKINA

Turkey

It ensures that flour and bran-like products coming out of the machines are returned to the factory.

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

This feeder consists of a completely overhauled rotary feeder from CMC, a new pressure/vacuum pump made by Becker, and a self-programmed control system. All components are mounted on a stable frame made of aluminum construction profiles, which can be placed as a compact unit autonomously at any desired position in the production. The machine can either be operated continuously or controlled by an external signal. This allows inserts to be placed with pinpoint accuracy in a collecting section or at high speed on a conveyor belt to be addressed via inkjet, for example. We offer a 6-month warranty on parts and service for this machine. Our systems can be freely configured according to your needs. Tell us your requirements so that we can present a concrete solution proposal.

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

This coin feeder enables continuous feeding of a coin sorting machine or a coin wrapping machine. Fill level controlled by detectors. Adaptation to your coin trolleys. - Robust frame made of epoxy painted steel - Hooking device for all types of trolleys - Specially designed trolley that is easily handled and adaptable to the forklift truck - Possibility of manufacturing to your dimensions depending on the quantity required - Height adjustable from 500 to 1300 mm - Dimensions can be changed on request - Speed: up to 7000 pieces/min - Speed control by variator The materials comply with the applicable EC standards.

Request for a quote

EC PLAZA

South Korea

The process of Infeed Shaker 1. Conveying 2. Dewatering 3. Grading 4. Sieving Product Features 1. Equipment that hygienically transports food, grain, and medicines using vibration. 2. Once the equipment is installed, stable and semi-permanent transportation is possible. 3. Install a feeder suitable for the customer's on-site conditions. 4. Various types of infeed shaker designs for each sample. 5. Securing equipment safety through analysis and simulation. Our Company DUK YOUNG ENGINEERING Based on powder and liquid mixing technology for the past 30 years, our company provides total engineering service of automation processes required throughout the industry, such as storage, transfer, metering and input.

Request for a quote

TOMECH SOLUTIONS

Romania

Feeders are devices used to regulate and control the flow of bulk materials from a storage container or hopper to downstream processes or equipment. They play a vital role in ensuring a steady and controlled supply of material, enhancing the efficiency and productivity of material handling systems. Vibrating feeders are a type of feeder that utilizes vibrations to move materials along a trough or tube. Vibrating feeders are commonly used in industries such as mining, aggregate processing, and pharmaceuticals due to their ability to handle a wide range of materials and feed rates while minimizing spillage and dust emissions. We specialize in feeder design services, offering tailored solutions to optimize material flow, feed rate, and system performance. Our expertise encompasses the design, selection of feeder type, and integration of feeding equipment into material handling systems to meet the specific requirements of our clients and enhance their operational efficiency.

Request for a quote

SACFORM/AGMLINE

Turkey

With SACFORM Straightener System’s Custom-Made Design and Appropriate Rollers Enables to Flatten the Bent / Distorted Sheet Materials and Coil at the Desired Tolerance.

Request for a quote

HARVEST TRADING CHAIN COMPANY

Turkey

New Holland Elevator Chain, New Holland Combine Harvester Chain, New Holland Wheat Chain New Holland CS 640 Combine Harvester Chain Orjinal No: 84441578/47483253 Model: CS 640/6080/6090 Brand: Donghua

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Loss-in-weight feeder for powders and pellets — Stainless steel hopper with stirring — agitator for consistent screw filling and mass flow of ingredient — Separate screw and agitator motors (3 phase AC gear motors), — Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates Power range - Different Versions 4-3743 dm³/h 20-3743 dm³/h

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Universal loss-in-weight feeder for virtually all flowable ingredients (powders, pellets, flakes, fibers, etc.) — Flexible polyurethane hopper agitated by amplitude adjustable paddles for consistent screw filling and mass flow of ingredient without degradation — Compact trapezoidal shape allowing up to 6 feeders to be compactly arranged around a central feed point — Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates Power range 20-7610 dm³/h

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— dustproof closed compact device — is suitable for all free-flowing, free-flowing bulk goods — compact design saves space More Options: — explosion-proof design Power range 2000 - 4000 dm³/h 3000 - 100000 dm³/h 10000 - 160000 dm³/h

Request for a quote

MAKENAS GRAIN MILLING TECHNOLOGY

Turkey

It is used to feed regularly the granular or powdery product into a conveying line or a machine at a suitable rate especially at flour mills

Request for a quote

MAKENAS GRAIN MILLING TECHNOLOGY

Turkey

It is used to feed the product regularly into pneumatic conveying pipes at the pneumatic conveying systems

Request for a quote

MAKENAS GRAIN MILLING TECHNOLOGY

Turkey

It is used to feed regularly the granular or powdery product into a conveying line or a machine at a suitable rate especially at flour mills

Request for a quote

MITA FOREIGN TRADE COMPANY

Turkey

The unit is a durable and flexible chick plate made of first-class rubber that may comfortably be used thanks to its easy mountable-demountable capability. The unit seamlessly provides feed to chicks starting from the initial day of the chick, and eliminates the need to set feed height by securing no waste of feed.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

UGUR MAKINA CRUSHING & SCREENING

Turkey

UĞURMAK UMBB Series Vibrating Feeders are positioned in the intermediate stock points, at the exit of the silo or bunker where the material is stocked, in order to ensure continuous feeding of the machines at all stages after the primary crushing stage in crushing and screening processes.

Request for a quote

ROBINSON CO.

Turkey

The cylindrical body structure is produced in a structure suitable for the product flow in one or both sides, depending on the project conditions, with supporting legs suitable for connecting to the floor deck or floor. The vibro feeding system connected to the conical structure has an adjustable flow flap and is driven by a vibromotor. In flour factories, it is used in the parts that require the adjustment of the ground grains at the appropriate flow and simple feeding, generally in the parts where the filter outlets need to feed a pneumatic line or a machine and where the dust wastes are brought into the system with pneumatics.

Request for a quote

NOVELTY STEEL

Turkey

Apron feeders come in varying widths, ranging from 0.6 to 3.0 meters, and lengths spanning from 2.4 to 30.5 meters. Lengths exceeding 4.6 meters are primarily used for material conveyance rather than being an integral part of the feeder. Apron feeders exhibit capacities ranging from 91 to 2,270 tons per hour. The power requirements for apron feeders are approximately twice as high as those for comparable belt feeders. Apron feeders are typically employed in situations involving truck dumps or other scenarios where very coarse materials are handled, such as in the feeding of primary or secondary crushers. When an apron feeder is intended for use under a truck dump hopper with an elongated hopper opening, it’s essential to design the hopper with a taper that widens in the direction of horizontal flow for belt feeders. Novelty Structures supplies various types of feeders such as; * Apron Feeders * Belt Feeders * Rotary Table Feeders * Screw Feeders

Request for a quote

NOVELTY STEEL

Turkey

A screw feeder is primarily designed for handling very low-tonnage outputs, with a critical requirement for positive and controlled material discharge. This type of feeder offers the advantage of easy enclosure, making it effective at preventing the release of dust. Consequently, it allows for a sealed hopper and chute arrangement from the hopper to the delivery point. The basic structure of a screw feeder includes a helical screw that rotates below the hopper outlet and is driven by an external power source. The screw can have a fixed pitch or a variable pitch with smaller spacings in the rear and gradual increases in pitch towards the discharge end. This design ensures that the material moves efficiently within the rear portion of the hopper. Novelty Structures supplies various type of Feeders for Mineral Processing Plants. * Belt Feeders * Screw Feeders * Apron Feeders * Rotary Table Feeders

Request for a quote

NOVELTY STEEL

Turkey

A belt feeder is comprised of an uninterrupted rubber belt that is supported by closely spaced idlers and propelled by end pulleys, commonly known as the head and tail pulleys. This entire assembly is enclosed within a single framework. The motor can be installed on the ground or on a separate frame and drive the feeder through the use of V-belts. Typically, the belt feeder is positioned beneath a hopper with a long, narrow slot-like opening. It allows the material to be fed along the length of the hopper. Belt feeders typically come in a range of widths from 0.6 to 1.8 meters and lengths spanning from 1.5 to 4.6 meters. The capacity of a belt feeder is determined by the width of the belt and the speed at which it moves. In practice, the capacity of belt feeders generally falls within the range of 4.5 to 2,270 tons per hour. Novelty Structures supplies various type of Feeders for Mineral Processing Plants.

Request for a quote

SACFORM/AGMLINE

Turkey

Our Servo Feeder Models are Being Produced at desired Coil Widths According to the Project Requirements, alongside to be used as Sheet/Plate Feeder by adding Auxiliary Equipment.

Request for a quote

SACFORM/AGMLINE

Turkey

Decoiler-Straightener & Servo Feeder Systems are Designed on a Single Chassis to Minimize Space Need at Our Customers Production Facility. These Systems are Convenient for Various Purpose of Work and Desired Projects for The Metal Industry.

Request for a quote

SACFORM/AGMLINE

Turkey

With Our Mini-Servo Feeders’ Feasible Design to Mount On Press Chassis Provides an Opportunity to Minimize the Mold Distance and Eliminates the Need for Extra Guiding Unit.

Request for a quote

HARVEST TRADING CHAIN COMPANY

Turkey

John Deere Grain Elevator Chain, John Deere Lexion Grain Elevator Chain, John Deere Harvester Combine Chain, John Deere Wheat Chain John Deere Conveyor Chain John Deere Elevator Chain John Deere Feeder Chain Orjinal No: AZ46327 Model: 2054/2056/2058/2064/2066 2254/2256/2258/2264/2266

Request for a quote

HARVEST TRADING CHAIN COMPANY

Turkey

John Deere Grain Elevator Chain, John Deere Lexion Grain Elevator Chain, John Deere Harvester Combine Chain, John Deere Wheat Chain John Deere Conveyor Chain John Deere Elevator Chain John Deere Feeder Chain

Request for a quote

HARVEST TRADING CHAIN COMPANY

Turkey

Claas Feeder Chain, Claas Lexion Feeder Chain, Claas Combine Harvester Chain, Claas Wheat Chain Orjinal No: 520069 Model: Lexion 400/500 Serisi Brand: Donghua

Request for a quote

HARVEST TRADING CHAIN COMPANY

Turkey

Claas Feeder Chain Claas Dom Chisel Chain Claas Combine Chain Claas Wheat Chain Claas Medion Combine Chain Claas Feeder Chain Orjinal No: 520196 Model: Dom 88/98/108/118 Mega 200/300 Serisi Medion 300 Serisi Brand: Donghua

Request for a quoteResults for

Feeder - Import exportNumber of results

350 ProductsCountries

Company type

Category

- Troughs and feeders (60)

- Greasing equipment (49)

- Harvesting machinery and equipment (38)

- Weighing and dosing equipment (18)

- Lubrication equipment and machinery (17)

- Poultry farming - machinery and equipment (17)

- Metal straightening machines (10)

- Cables - accessories (9)

- Conveyor systems (9)

- Bird cages and aviaries (8)

- Metals - Machines & Equipment (8)

- Horse riding - equipment and accessories (7)

- Cutting - machine tools (6)

- Dosing - machines and equipment (6)

- Mechanical surface treatment - machinery (6)

- Valves for pneumatic equipment (6)

- Bakery and confectionery industry - machinery and equipment (5)

- Crushing and grinding machinery (5)

- Automation - systems and equipment (4)

- Machine tools, metal machining - parts and accessories (4)