- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- friction connections

Results for

Friction connections - Import export

NORELEM FRANCE

France

Housing steel. Clamping lever plastic. Threaded spindle grade 12.9. Version Housing nickelplated. Clamping lever, spindle black oxidised. Note Manually operated clamping elements for static clamping tasks. Manual clamping process using the freely adjustable clamping lever. The floating clamp ensure symmetrical application of force onto the rail. Up to 50,000 static clamping cycles (B10d value). In general, a friction connection is created between the clamping element and the the linear guide on the open faces of the profile guide rail so that the ball guide tracks are not damaged. The retaining force is tested on an oil smeared profile guide rail. An adapter plate, dependent on the type of carriage used, is required for height adjustment.

Request for a quote

NORELEM FRANCE

France

Angle diecast zinc. Screws and slot nuts steel. End cap polyamide, fibreglass reinforced. Version Angle painted aluminium tone. Screws and slot nuts electro zincplated. End cap black. Note Suitable for reinforcing profile constructions and for frictional connection of profiles with each other without machining. Can also be used as fastening element (e.g. bracket) for any components. The angles have centring lugs for accurate and twistproof mounting. The centring lugs can be removed if necessary by breaking off i.e. for mounting plates. The open side can be closed off with the end cap.

Request for a quote

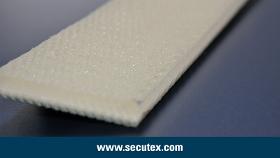

SPANSET SECUTEX GMBH

Germany

secutex has developed the new “TopDrain” structure surface for lifting wet or oily components. Most of the damages at sharp or rough edges are caused by the movement of the load across the sling. In the case of loads with a “sharp edge” or with a very rough surface, a protective sleeve or fixed coating must be used to protect the textile lifting sling. If the load moves sideways, a cutting movement on the edge is the result. Similar to a knife blade, the edge can cut through the fibers of the textile sling. The new “TopDrain” surface drainage provides good adhesion of the protective sleeves and the coated lifting slings even on wet and oily materials. The liquid can drain off into the surface hollows and the load lies securely in the lifting sling. The “TopDrain” structure works like a drainage and ensures the frictional connection of the secutex coating to the load.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Assembly lubrication of sliding points Screw lubrication at normal temperatures and low speeds Lubrication when joining parts Advantages and benefits Prevents frictional corrosion on joint connections of steel parts of all kinds subject to vibration loading under damp-room and aggressive operating conditions Low consumption thanks to thin-film lubrication Excellent water resistance Excellent lubricating and separating effect Good corrosion protection behaviour Metal-free For optimum adhesion, clean contamination and other lubricants from sliding surfaces. Best way is to clean mechanically first (for example, with a wire brush) and then with OKS 2610/OKS 2611 universal cleaner. Apply the paste evenly and thinly with a brush, spatula, etc. Remove excesses. Do not use paste instead of grease and mix only with suitable lubricants.

Request for a quote

GMN PAUL MÜLLER INDUSTRIE GMBH & CO. KG

Germany

Based on its many years of experience in the development and production of high-quality machine components, GMN has chosen to specialize in the production of efficient, long-life sprag type freewheel clutches. The standardized model series offer a large selection of feature options to furnish effective freewheel clutch solutions for almost any field of application. The functional principle of sprag type freewheel clutches is based on static friction. A certain number of sprags are in constant friction contact with the connecting parts. Sprags are components with variable height. They are uprighted when the connecting parts are rotated and clamped between the connecting parts while there is static friction between sprags and connecting parts. The static friction is guaranteed by a specific geometry (clamping angle) of the sprags to the connecting parts. GMN sprag type freewheel clutches can be used as indexing clutches, backstops or as overrunning clutches.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

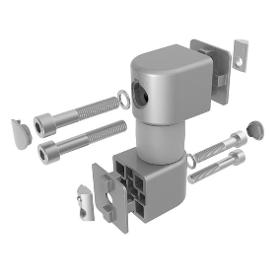

FATH GMBH

Germany

Description: Connection joint with friction for the creation of system arms using profile pieces; pivotable 360°; friction joint can be attached lateral, transverse, or on the face of the profile; if attached on the front face, the core hole of the respective profile must be M8 threaded (min. 15 mm deep) Material: Housing: Aluminum die-cast Cover ring: Plastic Inserts: Steel Friction shaft: Steel Cover caps: Plastic Screws: Steel Washers: Steel Centering plates: Aluminum die-cast T-slot nuts: Steel Surface: Housing: Laquered Centering plates: Laquered Screws: Zinc plated Washers: Zinc plated T-slot nuts: Zinc plated Color: Housing: Alu color Cover ring: Gray ≈ RAL 7042 Cover caps: Gray ≈ RAL 7042 Centering plates: Alu color Set: Various Sets available - Please contact us for Details Pack Quantity: 1 piece/set

Request for a quote

PASCHAL-WERK G. MAIER GMBH

Germany

Due to the low weight (30 kg/m²), the NeoR can be moved easily by hand – ideal for construction sites, even without a crane. - Universal fields of application: Foundations, columns, beams, walls - Height offset of the panels can be performed via oblong holes in the panel frame - Well-balanced range of panels - Keybolts as lightweight, friction-locked and cost-effective connecting pieces - Easy attachment of accessories using the hook head principle - The structural height is just 7.5 cm → low storage and transport volume - The flat steel frame guarantees robustness and durability - Fresh concrete pressure capacity of 50 kN/m² - Compatible with all PASCHAL systems Technical Data Panel widths: 90/75/60/45/30/15 cm Panel heights: 150/90 cm Large-size panel: 180 x 300 cm Frame depth: 7,5 cm Plywood: 12 mm birch plywood Max. concrete pressure: 50 kN/m² according DIN 18218 Tolerances of deflection: According DIN 18202, table 3, line 6

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

Locking Elements consist of an internal and external tapered ring. When axial force is exerted on a set of Locking Elements, radial clamping pressures are generated on the shaft and in the hub bore providing a frictional connection. Units may be stacked up to three elements deep for greater torques. For light to medium duty applications. Characteristics Customized application – by varying the number of Locking Elements, size and quantity of clamping screws, the connection can be adapted to fit most applications concerning surface pressures, materials, hub/shaft dimensions and available mounting space. Transmission of high loads – to increase the transmissible torque and axial forces up to 4 Locking Elements can be used in series. Maximum reliability – no matter whether the connection is subjected to static, pulsating, dynamic or intermittent loads. Simple manufacture – shaft and hub are designed without keyway. Apart from this, relatively large tolerances are admissible. Easy...

Request for a quote

EM-TECHNIK GMBH

Germany

For the 2N pipe connector, the pipe is placed against the inner edge of the connector and a sealing ring seals off the connection. A cutting ring wedges into the flexible tube or pipe as far as the knurled nut is screwed onto the connector body, thereby fixing the connection in place. This creates a friction-locked and tight pipe connection that can be released at any time, that eliminates dead volume in the design concept and also has no effect on the flow. The inside diameter of the connector does not correspond to the inside diameter of the pipe.

Request for a quote

EM-TECHNIK GMBH

Germany

The firm flexible tube or plastic pipe is pushed onto the integrated connecting sleeve of the 1C connector. The sealing ring forms a tightness for the connection, while it is secured in place by a cutting ring. Due to the knurled nut, this also affects the flexible tube. The cutting ring wedges into the flexible tube or pipe as far as the knurled nut is screwed onto the connector body. A shear force is applied here that intensifies the contact pressure. This creates a friction-locked and tight connection that can be released at any time and minimises the dead volume.

Request for a quote

IBK WIESEHAHN GMBH

Germany

Developed by IBK Wiesehahn, the secondary friction connection seal with H-profile has created an area of application in the industrial branch. The successfull conzept of “secondary friction connection” is based on the separation of bracing and sealing. Every functionary of the seal meet only one function. The seal is made of hard metal-profile and elastic sealing-material. The sealing-material is measured, that after reaching the block storage, the recovery behavior fully exists. A overpress of the sealing-material is basically excluded. Benfits of IBK SAFE-H® Seal: Secondary friction connection (block storage) Seal is chambered (secured against exhaust) High resilience of the flange connection Indenpendently pressure stage dimensions Easier to install regarding centring gauges Simplified warehousing High temperature resistance (up to 1000°C) High pressure resistance (up to 525 bar) Possibility of redefinition of the sealing zone with repair set

Request for a quote

CLIPPARD EUROPE SA

Belgium

EVP Series Proportional Valves The EVP series Proportional Control Valves combine the features of the existing EV series valve - long life, low power, and Clippard's reputation for high quality components - with the additional capability for proportional control. The EVP series valve provides air or gas flow control, and varies the output flow based on the current input to the solenoid. The consistent gain of this valve provides a high degree of control for many applications. Controllability and overall value are the main features of the EVP Proportional Valve series. The valve may be controlled using DC current, open or closed-loop control, and even PWM (Pulse Width Modulation) to cover a broad range of applications. Optional Valve Driver below. Read More about the EVP Series View Tips for Selecting the Right EVP Valve View Products • Flow proportional to input current • Fast response • Long life • Single moving part • Low friction and wear • Three connection styles • Two...

Request for a quoteResults for

Friction connections - Import exportNumber of results

13 ProductsCountries

Company type