- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- fume extraction systems

Results for

Fume extraction systems - Import export

STAHLMED LABORATORY SYSTEMS

Turkey

Fume hood exhaust fans and Air extraction fume hoods are used as lab air ventilation systems that extract dangerous chemical fumes which is harmful to the health from the air inside laboratories. These air ventilation systems pull and filter the air from the laboratories using fume hood exhaust fans to protect and maintain lab air quality and safety standards for the workers during their working. 304 Quality Stainless Steel Construction With/out Duct Models WxDxH: 1000x620x770 ( without internal Fan unit ) Perforated Working Area Led Light with Light Intensity Controller Fan with Fan Speed Controller Custom Built Availability

Request for a quote

THE FUME CUPBOARD COMPANY LTD

United Kingdom

Educational & Commercial - Fume Extraction Systems Our COSHH Test engineers are fully qualified to BOHS P601 (Commissioning and Thorough Examination of LEV Systems). We ensure all surveys are carried out in accordance with the COSHH regulations 7 & 9, following Health & Safety guidance (HSG258). The Local Exhaust Ventilation test is designed to determine the efficiency and integrity of an extraction system. It requires the engineer to gain quantitative measurements by using airflow instruments and qualitative assessments with smoke tests and a dust lamp. Engineers analyse these results and use invaluable expertise to identify design flaws, defects and maintenance issues that might affect the performance of an LEV system following completion of LEV Testing. Upon completion of an onsite COSHH Safety test a detailed report is produced that contains the findings of the survey and any comments and recommendations that are relevant, including remedial work required.

Request for a quote

INTEGRATEDAIR SYSTEMS

United Kingdom

From paint spraying to welding, many processes within industrial settings can create extremely harmful fumes – including chemical and acid fumes. When breathed in by those in the workplace, these fumes can cause breathing problems such as asthma and even more serious long-term conditions such as cancer. Alongside directly risking the health of employees, fume particles that are not extracted from the workplace also pose a risk to health through contamination of food, drink and pharmaceuticals – as well as possibly damaging the finish of products. In all these instances, a fume extraction system is essential to removing airborne particles and returning clean air to the workspace. By making integratedAIR Systems your fume extraction partner, you can rest assured that your workplace is safe, protected by years of experience, dedication and high quality.

Request for a quote

THE FUME CUPBOARD COMPANY LTD

United Kingdom

Fire Suppression in Fume Cupboards. Add Layer of Protection Fume Cupboards control the risk of fume inhalation, those same contaminants that a Fume Cupboard is protecting the operator, environment, and equipment from, can also contribute to the risk of a fire. Fume Extractions Systems should ideally protect both. Fire suppression systems, can be retrofitted as an option for all types of Fume extraction systems This unit is not recommended for preparation rooms where the Fume Cupboards are used for long periods of time as this will degrade the carbon filter faster than expected.

Request for a quote

THE FUME CUPBOARD COMPANY LTD

United Kingdom

Ductwork Design & Installation - Onsite Ductwork Fabrication A Fume Cupboard Extraction System. should be designed, installed to run efficiently, safely and with the minimum of noise levels. To achieve these requirements all our extract and duct work systems are designed, installed, and commissioned to meet the requirements of H.V.A.C. DW154 (Plastic duct work specification), and B.S. E.N. 14175. Extract systems to serve educational style fume cupboards will meet standards set out in Building Bulletin 88 or B.S. E.N. 14175. At the fume cupboard company, we try and hot air weld as much of the ductwork as possible this prevents leakage and sustains the integrity of the joints for the duration of its life. We provide a variety of different duct materials these consist of: Chemically resistant P.V.C | Polypropylene | Galvanized Metal. For extra protection we can also make glass reinforced plastic (GRP) and fire retardant coating for this duct work.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

UNITED PROARC CORPORATION

Taiwan R.O.C.

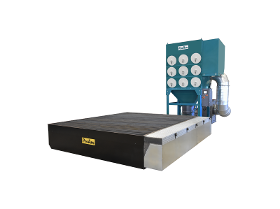

Metal fume and dust come from CNC plasma cutting is always harmful to our healthy, how to efficiently collect these pollution is always a headache to customer. 1.We offer "One-Shop service" for CNC cutting machine / Fume collection table / H-beam foundation / Dust collector for customer. 2.ProArc special design high efficiency fume collection cutting table and fume collection duct will help customer solve these issue and provide a healthy working environment in cost saving way. *CE Conformity

Request for a quote

INTEGRATEAIR FILTRATION

United Kingdom

Introducing integratedAIR Filtration’s BlueClean® VCP range of self-cleaning pulse jet cartridge filter units. A versatile range of high efficiency filter units incorporating conical filter elements providing highly effective filter cleaning even when dust loadings are high. Our VCP Square unit can be supplied as an insertable, flanged open base or complete free standing filter unit with each design being able to be supplied with or without inlet mounted fan sets. The VCP Square, a range of high quality pulse jet filter units designed for use within processing and dust control applications and part of the Industrial Air Filtration range, dust control filter units built without compromise.

Request for a quote

INTEGRATEAIR FILTRATION

United Kingdom

Our BlueClean® HC PRO Lite is designed as a compact and cost-effective solution to your dust and fume extraction needs which can be supplied as a true ‘plug and play’ filter unit. All key elements of the unit are integral; therefore, easy to install and commission. The HC PRO Lite can house between 2 and 8 filter elements. This range is suitable for a wide range of dry dust process requirements.

Request for a quote

INTEGRATEAIR FILTRATION

United Kingdom

Our BlueClean® HC PRO range of horizontally mounted cartridges are designed with maintenance and ease of use in mind. With multiple configurations available, this versatile range is suitable for a wide range of process requirements. True downflow cleaning technology with the dust laden air entering the unit at high level flowing downwards through the filter unit chamber using gravity and downwards air flow to aid dust release We install a single filter cartridge in each aperture reducing the number of filter seals present within the filter unit substantially reducing the risk of filter seal failure and dust by pass. With using a single filter element this provides a more active filter cleaning area improving the filter cleaning action. Our single filter cartridge design per access door reduces the risk of dust exposure when withdrawing filter elements. Ease of maintenance with tool less filter cartridge change.

Request for a quoteResults for

Fume extraction systems - Import exportNumber of results

10 ProductsCountries

Company type