- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- assembling machines

Results for

Assembling machines - Import export

RALF LANG MASCHINENBAU GMBH

Germany

Axial bearing 1000 N press, locking ring assembly and testing station

Request for a quote

RALF LANG MASCHINENBAU GMBH

Germany

Fast cycling assembly machine 10 stations with O-ring assembly. Cycle time 1.7 sec.

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

UNT 6 and UNT 10 are reliable machines for the production of reusable hose assemblies, insertion of high pressure fittings or even to use with a skiving tool. Modell:UNT 6 Maximum Hex or hose diameter 0 40 mm (1,57") Maximum travel distance 0 500 mm (19,68") Industrial* 7-55 mm (0,02" - 2,16") Motor rotation (RNP) 101/207 Noise level (dBA) 70 L x W x H (mm) 1600x550x850 Weight 176.5 Kg

Request for a quote

WECKERLE MACHINES

Germany

FAL stands for Flexible Assembly Line and offers flexible solutions to automize the processing of your products to the desired level. It covers Upstream and Downstream processing modules and can be integrated to any Filling Line for Cosmetics, Food and Pharma according to your needs. Machines can be upgraded with customized modules at any time. Options for Upstreaming i.e. for base/bottle or cap/applicator feeding: - FlexFeeder with up to 200pcs/min throughput – bulk or tray delivered - Tray tower system especially for high-class and scratch-sensitive products - Plate feeding system for a cost-efficient solution for bulk-delivered products - Linmot or servodriven controlled positioning of the products A high automization will reduce the cost per piece, adds stability and reliability to the process and makes your production efficient.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

CNC machining assemblies.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These parts are used for the precision accessories,after process by 3-4 axis machining,then going for the anodize and chrome plating.

Request for a quote

SCHOCK GROUP

Germany

Our process-controlled assembly machining up to the manufacture and delivery of complex assemblies rounds off the range of production and services within SCHOCK.

Request for a quote

TECHNO-COMPOSITES DOMINE GMBH

Germany

Contract Manufacturing TC Domine is a dependable partner for the highprecision machining of components made of thermoplastics and glass fibre or carbon fibrereinforced plastic. Six modern CNC machines with up to five axes can machine components 6,140 mm long, 1,900 mm wide and up to 500 mm high. As such, we are able to design and manufacture the necessary parts inhouse. Subsequent processing steps such as gluing, painting and assembling addon components are an integral part of what we do.

Request for a quote

HOCHRAINER GMBH

Germany

Custom machine for complete assembly of keys for locking systems

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

The TEC 20 form, fill and seal machine enables the production of bags made of polyethylene film from a flat film roll. The film can be neutral or coloured, with continuous printing or centred printing with print mark. The design of the machine and the low loading height allow ergonomic adaptation to a manual feeding station or easy connection to a feeding unit, such as an automatic counter, an automatic weighing system, an automatic assembly machine, an injection moulding machine, a conveyor belt or similar.

Request for a quote

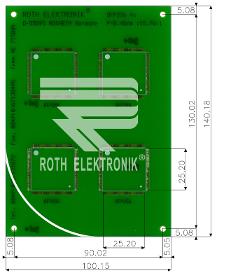

ROTH ELEKTRONIK GMBH

Germany

Epoxy fibre-glass FR4 1.50 mm Single-sided 35 µm Cu Without holes Hot air leveling (HAL-leadfree) with solder stop mask Component print PCB for machine assembly (Pick & Place) of Fine-Pitch QFP 256 QFP 256 4 x Size 100 x 140 mm

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The incremental digital displays are used in combination with our high-precision displacement sensors 8738. The digital technology of these measuring systems satisfies high demands for precision and long service life, as is required more and more nowadays — in measuring laboratories — in production — in testing laboratories — in workshops and many other areas. Typical uses: —Automatic assembly machines —Semiconductor industry —Keyboard tests —Robot controllers —Testing of shafts and planes —Measurement of differential displacement With its phenomenal resolution of 0.1 µm and the high response frequency of 20 MHz, the 9140 is a powerful display unit with a compact design. The comparator function integrated as standard allows for direct evaluation of measurements almost in real-time; these can be processed further by a higher-level controller. A rather more comprehensive acquisition method is also integrated into the system.

Request for a quote

FÖHRENBACH GMBH

Germany

Rotary tables with direct drive series RT3 The rotary tables with direct drive are available in different types: RT3A100x100, RT3A100x155, RT3A080x130, RT3A150x100, RT3A150x130, RT3A250x170, RT3A200x060 und RT3G630x225 Rotary tables RT3G630 – high dynamics, high precision, high loading capacity This direct driven rotary table RT3G630 has particularly been developed for machine tool industry and assembly machines. It is characterised by its high precision, highdynamics and its high loading capacity. The rotary table is driven by a permanently excited 3-phase synchronous motor. The rotary plate and the housing are made of gray cast iron.

Request for a quote

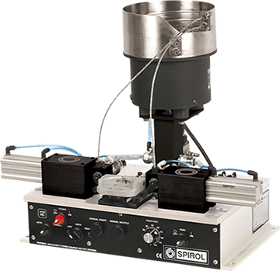

SPIROL

Germany

SPIROL's Model HC Dual Pin Inserter is a lightweight, portable, horizontal Pin Inserter designed to install SPIROL Series 550 Cosmetic Coiled Pins into plastic hinges. The cylinder/driving head modules can be moved in and out with ease, and fixture changes are simple which enables quick conversion from one assembly to another. This machine quickly and effectively delivers the pins automatically to the installation site eliminating the need for the operator to touch them during the entire assembly operation. This machine dramatically increases production efficiency with minimal operator training and effort.

Request for a quote

RALF LANG MASCHINENBAU GMBH

Germany

Pressing bearings Manually assemble anti-knock on hand lever press Automatically assemble and test retaining ring

Request for a quote

FATH GMBH

Germany

Milling connector set ; for quick and stable connection of two aluminium profiles without profile machining. different sizes: — Profile 30, 40, 45 — profile groove 8 or 10 material: — Steel, zinc plated Set contents: 1 milling connector 1 screw DIN 912 1 hammer nut

Request for a quote

FATH GMBH

Germany

Automatic connector with self-cutting thread; profile slot 5, 6, 8, 10, 12 for fast and solid connection of two aluminium profiles, assembly without machining Different versions — Cutting sleeve with assembly set for profile with screw and T-slot nut or hammer nut — Cutting sleeve without assembly set — Single or double connector — Plug-in connector, butt connector or corner connector Choice of material — Steel, zinc plated — stainless steel — ESD-compatible Other possible accessories: — Cover cap to cover the automatic connector — swivelling double slot nut different lengths with several threads in multiple threads in different sizes available on request

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WALTER STAUFFENBERG GMBH & CO. KG

Germany

The STAUFF Press Assembly Machine SPR-PRC-POC allows the pressure/position-controlled pre-assembly and final assembly of cutting rings from the Extra-Light Series (LL), the Light Series (L) and the Heavy Series (S) according to ISO 8434-1 / DIN 2353 on tube ends with outer diameters between 4 mm and 42 mm. The machine is designed as a robust table-top device for continuous operation in the workshop. It is used in connection with hardened and wear-resistant assembly studs FI-FMK and support plates FI-GP which are specially designed for the machine-assisted assembly. The combined pressure/position-control of the device allows wear on the assembly tools to be detected in time before it can have a negative influence on the assembly result. Maximum service life of the tools is achieved through careful handling of the components and practical operation of the assembly machine. Other factors are proper storage (protected against contamination and corrosion), regular cleaning and...

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

The electro-hydraulically operated STAUFF Press Assembly Machine SPR-PRC-MA allows the assembly of cutting rings in the Light Series (L) as well as in the Heavy Series (S) according to ISO 8434-1 / DIN 2353 on metric tube ends with outer diameters from 4 mm to 42 mm. Exchangeable heads allows the device to be adapted for 37° flaring of metric and imperial tube ends with outer diameters from 4 mm to 42 mm and from 1/4 in to 1 1/2 in respectively according to DIN 3949 or SAE J514 / ISO 8434-2. Short times for tool changes, setup and assembly (even when changing the assembly type from cutting ring assembly to 37° tube flaring) make it possible to carry out series production as well as the assembly of small and medium quantities with a high level of economic efficiency, reproducibility and process reliability with considerable reduction of times and cost of assembly of fittings. The adjustable return stoke of the cylinder helps the operator to further optimise the total cycle...

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The Metzner AM 1000 is a sensation among the tabletop units. The automatic cutting and stripping machine processes cables, strands and wires up to 9 mm diameter and 6mm² cable cross-section with a special cutting and pull-off force (optional 10 mm², depending on material). The presettings are conveniently made via the modern 12" touch panel, where the operator can define all processes. Thanks to the sensors for diameter and material recognition, the AM 1000 works extremely precisely. Another special feature is the tool-free replacement of guides and rollers. This means that the AM 1000 can be changed over in just one minute. With the extensive interface preparation, the machine can be optimally expanded with peripheral devices and adapts to all customer requirements. The compact design with retractable touch-screen and the low weight of only 28 kg also offer special comfort. This makes the AM 1000 especially easy to transport.

Request for a quote

OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

Specifications Stroke rate: continuously variable from 5 to max. 250 1/min. Press: nominal punching capacity 400 kN, stroke 20 mm Slide units: max. nominal forming capacity 90 kN, max. stroke 95 mm Feed pitch: servo feed: any feed pitch, mech. feed: max. 500 mm, with feed cycle reduction Material: max. strip width 80 mm, max. wire diameter 6 mm Dimensions: width 3,930 mm, depth 1,595 mm, height 2,220 mm Weight: approx. 4,500 kg (without tooling)

Request for a quote

EISELE GMBH

Germany

- One interface for compressed air, gases, fluids, vacuum, electrical and electronic signals - Maximum modularity due to freely configurable connections - Integrated coding in the housings prevents incorrect connections - Easy, tool-free mounting and dismounting - Locking lever reduces the force needed for assembly - Machine set-up times are reduced - Fits to Eisele adaptive inserts - Coupling and slotted nut material: Chemical nickel-plated aluminum - Lever materials: anodized aluminum / 1.4301 (304) stainless steel - Other materials: 1.4404 (316L) stainless steel / A2 / POM - Knurled screw with retaining cable

Request for a quote

SIM AUTOMATION GMBH

Germany

Some requirements are so specific that this is a job for our special machine construction department. Particularly complex processes can be automated with special machines. In some cases, our specialist expertise is also required to make adjustments to series-produced machines and plants. Whether feeding technology, devices and components, laser cells or support and assistance for other mechanical engineers or engineering companies, our SIM concept shows just why individuality is our strength. After all, while there are different optimization scenarios in every branch, it is special machine construction where particularly creative cross-industry expertise is required above all. With our knowledge of the branch, you have come to the right place. Products manufactured using special machines from SIM: — Pens — Food packaging machines

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Assembly of plant components and machines We assemble plant components and complete machines including electrical wiring, pneumatics and hydraulics in our factory buildings. Our 55 specialists in the assembly departments are waiting for your challenge. Key features own production of large diameter pipelines Performance of surface coatings Complete systems or components Series or individual assembly Electric, pneumatic and hydraulic function test on test bench Advantages all from one supplier installation-ready dispatch Handling of large components up to 400t total weight Factory commissioning personal contacts

Request for a quote

SANHA GMBH & CO. KG

Germany

Washing machine assembly box for masonry, with thermally insulated and condensation-proof body, with plasterable surface, with 1 internal thread Rp 1/2 and 1 MultiFit-Flex system pipe connection 16 mm and drain connection 50 mm, dimension 270 x 200 x 70 mm

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

Exposed linear encoders are designed for use on machines and installations that require high accuracy of the measured value. Typical applications include: Measuring and production equipment in the semiconductor industry PCB assembly machines Ultra-precision machines High-accuracy machine tools Measuring machines and comparators, measuring microscopes, and other precision measuring devices Direct drives Our standard encoders are suitable for use in a low or medium vacuum. Encoders used for applications in a high or ultrahigh vacuum need to fulfill special requirements. Design and materials used have to be specially adapted for it. For more information, refer to the Technical Information document Linear Encoders for Vacuum Technology. The following exposed linear encoders are specially adapted for use in high and ultrahigh vacuum environments. • High vacuum: LIP 481 V and LIF 481 V • High vacuum: LIC 4113 V and LIC 4193 V • Ultrahigh vacuum: LIP 481 U

Request for a quote

OPTIMA CONSUMER GMBH

Germany

Containers: - Container classification using a rotary feeder - Container classification via the infeed screw - Container transport using pucks for flexible production and fast conversion - Cycled container transport Shapes: - User-friendly, fast and primarily tool-free format change Design: - Simple assembly (plug and play) - low installation costs - Good visibility and accessibility - Compact design with low space requirement - Compact design with integrated control cabinet - Glue gap or tuck-in gap closure is possible - Modular machine design for maximum flexibility for future adaptations of products, packaging or functions - Few moving parts resulting in minimized sealing and maintenance costs

OPTIMA PHARMA GMBH

Germany

All commercially available ready-to-use syringes (glass and plastic) All commercially available safety devices Gently objective handling Simple operation Continuously working Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

All commercially available ready-to-use syringes (glass and plastic) All commercially available safety devices Gently objective handling Simple operation Compact design Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

Results for

Assembling machines - Import exportNumber of results

33 ProductsCountries

Category

- Laser - cutting and welding machines (4)

- Automation - systems and equipment (2)

- Assembly robots (2)

- Pharmaceutical industry - machinery and equipment (2)

- Cutting - steels and metals (1)

- Electric and electronic components - machines for manufacturing (1)

- Mechanical engineering - custom work (1)

- Assemblies, hydraulic (1)

- Bearings, roller (1)

- Connectors, pneumatic (1)

- Custom packaging (1)

- Electrical & Electronic Components (1)

- Fasteners, metal (1)

- Industrial robots (1)

- Measurement - Equipment & Instruments (1)

- Measurement and control instruments (1)

- Mechanical transmission - components (1)

- Metallurgy - machinery and installations (1)

- Packing and packaging - machinery and equipment (1)

- Plumbing installations (1)