- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- braze-welding

Results for

Braze-welding - Import export

QUELLTECH GMBH

Germany

QuellTech Solution For this purpose, QuellTech offers a perfectly tailored seam tracking solution, which is based on a QuellTech 2D-Laserline Sensor of the Q4 family. The method consists in measurement of the real position and width immediately ahead of the welding process. The laser sensor captures the real dimension of the weld bead, and the software used for this process simultaneously sends the nominal position to the robot. The robot performs a correction movement in X or Z position according to this measurement. This way not only the deviation caused by tolerances, but also the warping effect can be compensated – and the weldment takes place exactly at the required position. The QuellTech 2D-Laserline Sensor is specially prepared to the highly disturbing ambient light from the weld process. It can be cooled and protected from weld spatter, so this model proves to be particularly adequate for operation in the harsh environment of the welding process.

Request for a quote

QUELLTECH GMBH

Germany

Particular challenges To correct the effect of the tolerances of the parts, the welding robots path in conventional applications is usually adjusted, by means of a time consuming manual correction (teaching). The warping effect caused by the thermal expansion however cannot be compensated this way. For this purpose, QuellTech offers a perfectly tailored seam tracking solution, which is based on a QuellTech 2D-Laserline Sensor of the Q4 family. The method consists in measurement of the real position and width immediately ahead of the welding process. The laser sensor captures the real dimension of the weld bead, and the software used for this process simultaneously sends the nominal position to the robot. The robot performs a correction movement in X or Z position according to this measurement. This way not only the deviation caused by tolerances, but also the warping effect can be compensated – and the weldment takes place exactly at the required position.

Request for a quote

FÖHRENBACH GMBH

Germany

With high demands on accuracy and dynamics, the base frame in welded construction or hard stone is also a possible and reasonable part of the scope of supply. Here, all axes are specified, assembled, aligned, measured, tested and recorded - according to desired specifications. By means of hard stone, the required accuracies can be achieved. Hard stone offers all the characteristics required - ranging from a small coefficient of expansion, high abrasion resistance, optimum vibration damping, absence of unwanted residual stresses up to the necessary accuracies regarding flatness, parallelisms and angularity.

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

Stampling device for welding work ■ positioning, centering & clamping of metal part, with integrated part scanning The individuel customized solution will be performed according to customer specification!

Request for a quote

ANTHERMO GMBH

Germany

Straight from our warehouse We have around 150 different versions of Socket Weld Outlets (ANSI B 16.11 / MSS SP 97) in our extensive warehouse in Kamen. We can deliver to you at short notice at any time. We only deliver goods of European origin. Standards and special requests We supply socket weld outlets in two pressure levels (3000 lbs and 6000 lbs) and in all common materials. We can also supply special materials on request. Furthermore, socket weld outlets differentiate between reduced and full branches. Express service We can deliver socket weld outlets in stock to the customer within Germany the next day if the order is received by 11.00 a.m. Simply specify when ordering if you would like to use this express service. Technical specifications More details, technical data and dimensions can be found in our data sheet “Socket weld outlets” in the download area. We will be happy to provide you with information on special dimensions and custom-made products on request.

Request for a quote

ANTHERMO GMBH

Germany

Numerous designs available at short notice Support-free assembly Nipple outlets (MSS SP 97) have been specially developed for support-free assembly. Nipple outlets are available with different ends. Smooth or beveled ends are used for welded connections, while the ends have an external thread for screw connections. We can deliver nipple outlets with NPT thread according to ASME B1.20.1 from our warehouse. We can deliver nipple outlets with BSP / T threads according to ISO 7-1 and BSP / P threads according to DIN ISO 228 with short delivery times. Standards and special requests We deliver nipple outlets in different wall thicknesses (STD, XS, S 160 & XXS and special wall thicknesses) as well as in all common materials. If required, we can also supply special materials. Technical specifications You can find more details, technical data and dimensions in our data sheet "Nipple outlet" in the download area.

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

Your expert in welding technics like MIG, MAG, WIG, resistance spot & stud welding, e-welding, welding robots For the returning serial welding tasks, 2 gantry welding robot system are available. With a machining length of up to 8 meters (26,2 ft), we can lealize complex customer requests thanks to 10 treatment axis performance. We are authorized to weld structural steelwork in accordance to EN1090

Request for a quote

ANTHERMO GMBH

Germany

Swept outlet similar to ANSI B 16.19 / ANSI B 36.10 Swept outlets in pipeline construction A swept outlet is used in pipeline construction just like a welding outlet, a socket welded outlet or a threaded outlet for a 90 ° branch. A swept outlet is an alternative to the T-piece / red. In comparison to the T-piece / Red.Tee, the installation effort for a swept outlet is lower because only one hole has to be drilled into a pipe. The swept outlet can then be welded into this hole. A swept outlet differs from a welding outlet in the type of welding. While a welding outlet is only placed on the run pipe and then welded, a swept outlet is welded directly into the run pipe. Ideal stress distribution Swept outlets were developed in order to achieve the best possible stress distribution for internal pressure and pipe forces. Due to the favorable voltage level, swept outlets are often used in highly stressed pipes in the oil and gas industry.

Request for a quote

ANTHERMO GMBH

Germany

Numerous designs available at short notice Branch connections on straight pipe sections Lateral outlets are used for 45 ° branches on straight pipe sections. Other departure angles are possible on request. Standards and special requests We deliver lateral outlets in two pressure levels (3,000 lbs and 6,000 lbs) and in all common materials. If required, we can also supply special materials. Technical specifications You can find more details, technical data and dimensions in our data sheet “Lateral outlets” in the download area. We will be happy to provide you with information on special dimensions and custom-made products on request.

Request for a quote

ANTHERMO GMBH

Germany

Elbow outlets for 90 ° bends 1.5 D Up to 2 “elbow outlets fit on elbows of all diameters mentioned in our data sheet (see download area). Larger branches are manufactured precisely for the respective arch diameter. Standards and special requests We deliver elbow outlets in two pressure levels (3000 lbs and 6000 lbs) and in all common materials. If required, we can also supply special materials. Technical specifications More details, technical data and dimensions can be found in our data sheet "elbow outlets" in the download area. We will be happy to provide you with information on special dimensions and custom-made products on request.

Request for a quote

ANTHERMO GMBH

Germany

Straight from our warehouse Approx. We always have 150 different versions of threaded outlets (ANSI B 16.11 / MSS SP 97) available in our extensive warehouse in Kamen. In our warehouse we have threaded outlets with NPT threads according to ASME B1.20.1 in stock. Threaded outlets with BSP / T threads according to ISO 7-1 and with BSP / P according to DIN ISO 228 are available with short delivery times. We only deliver goods of European origin. Standards and special requests Threaded outlets are available in two pressure levels (3,000 lbs and 6,000 lbs) and in all common materials. If required, we can also supply special materials. In the case of threaded outlets, a distinction is also made between reduced and full branches. Express service We can deliver threaded outlets in stock within Germany the next day to the customer if the order is received by 11.00 a.m. Simply specify when ordering if you would like to use this express service.

Request for a quote

ANTHERMO GMBH

Germany

Straight from our warehouse Approx. We keep 300 different versions of welding outlets (ANSI B 16.9 / MSS SP 97) in our extensive warehouse in Dortmund. We can also supply you at short notice. We only deliver goods of European origin. Standards and special requests We deliver welding outlets in different wall thicknesses (STD, XS, S 160 & XXS and special wall thicknesses) and in all common materials. If required, we can also supply special materials. In the case of welding outlets, a distinction is also made between reduced and full waste. Express service We can deliver welding outlets in stock within Germany to the customer the next day if the order is received by 11.00 a.m. Simply specify when ordering if you would like to use this express service.

Request for a quote

SCHNELLDORFER MASCHINENBAU GMBH

Germany

ROTAWELD is our platform to cover a wide range of applications requiring circumferential seam welding. The precision servomotor rotation axis combined with our advanced control system form the basis for the production of accurate and repeatable circumferential seam welds. Machine sizes, part holders, welding equipment, torch holders and any additional positional axes are designed specific to the customer and their products.

Request for a quote

SCHNELLDORFER MASCHINENBAU GMBH

Germany

Schnelldorfer CORNERWELD seam welding machines have been designed to weld sheet metal plates in a 90° joint. The precision clamping system with inert gas coverage and advanced OEM control package precisely controls the welding sequence and weld parameters, resulting in the perfect weld for your corners. CORNERWELD applications include welded corners for food, medical equipment, HVAC drip pans, electrical enclosures, and laboratory furniture. Complex inward and outward flanges can be accommodated with custom made tooling pieces. A wide range of materials can be welded, including Stainless Steel, Carbon Steel and Aluminium. Complete welded parts do not require any costly grinding, polishing or blending thus greatly saving on manufacturing costs.

Request for a quote

SCHNELLDORFER MASCHINENBAU GMBH

Germany

High quality, productive longitudinal seam welding calls for the utilisation of advanced, superior technology. This enables us to us to protect and expand our market position despite increasingly fierce competition. Our ELENA® longitudinal seam welders provide unsurpassed technology for welding of longitudinal metallic seams.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CARBO-WELD SCHWEISSMATERIALIEN GMBH

Germany

keine englischen Dateien angezeigt/ Bezeichnung aus der deutschen Version Carbolot 1 Carbolot 2 Carbolot 1 F Carbolot 2 F

Request for a quote

AAAGILER GMBH

Germany

Discover our highly effective mobile welding protection wall made of cardboard - the perfect solution to protect your working environment from flying sparks and fire hazards during welding and grinding. This cut-to-size cardboard combines welding protection with environmental protection.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

The consistent high quality of B57S makes it an excellent choice of anodising quality aluminum. It is designed for many different applications including electronic covers, in the transport and automotive industries, road and advertising signs and equipment housings. Your selection of material is of utmost importance. Finding a high quality product, with a good price/performance ratio, B57S will meet your needs. B57S can easily be cut, drilled, punched, edge-flanged and formed. Welding and brazing should be avoided in visible areas, because the localized heating of the metal will change its structure and affect the anodized finish.

Request for a quote

ORBITEC GMBH

Germany

Tube squaring machines are necessary to achieve burr-free and right-angled seam preparation for orbital welding. That‘s why Orbitec offers two machines, from the small handy Planfix 40 S to the large Planfix 115 S. The Planfix 115 S is a high-performance tube squaring and chamfering device with angle gear for mobile or stationary use with a mains drive. It has a large viewing window, a chip collector and a feed with 0.1mm scale graduation. Optionally, the device can be equipped with a tool carrier and a double-sided indexable insert holder or the well-known Orbitec L facing tool bits. Package includes exemplary for Planfix 115 S Power 230 V: — Tube clamping attachment — Drive — Tool set — Transport box

Request for a quote

ORBITEC GMBH

Germany

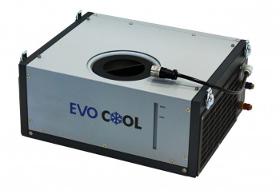

Water cooling unit for use with the EVO 200 WP or LITE controller and Tetrix 200 in conjunction with water-cooled welding tools.ols. — Standalone or continuous operation possible — Temperature-regulated fan control — Water flow feedback through in-built flowmeter Package includes: — Water cooling unit — Inverter / cooling unit (permanently mounted) connection cable — Fasteners for EVO series — 4 l blueCool 10i-5 coolant

Request for a quote

ORBITEC GMBH

Germany

The RBK 60 S is an extremely robust water-cooled weld head for a standard heat exchanger application up to an ID of 60 mm, modified to an ID of 99 mm or 120 mm. The head is pneumatically centred and is available with a rotating wire device and/ or arc voltage control (AVC) as an option. The head can also be used with a pneumatic positioner instead of a balancer. Versions: — RBK 60 S weld head with pneumatic centring, including hose package, 8m, water-cooled — RBK 60 S weld head with pneumatic centring and wire feeder incl. hose package, 8m, water-cooled — RBK 60 S weld head with pneumatic centring, wire feeder and AVC incl. hose package, 8m, water-cooled Package includes: — Weld head — Small torch incl. torch consumables and tungsten electrode Ø 2.4 mm — Water-cooled hose package, 8 m — Pull bar B — Transport case Optional: — Div. spring sleeves and pull bar sets for RBK 60 S — Torches, Balancer, Tube-to-tubesheet positioner...

Request for a quote

ORBITEC GMBH

Germany

Our latest series of 2 gas-cooled and compact weld heads. They are for smaller outside diameters with a narrow handle for tighter access conditions. Weld head type | Field of application mm | inch | weight | item number OSK 21 CS | OD 3.17 - 21.3mm | 0.125" - 0.839" | 0.8kg | 1.0.2820 OSK 38 CS | OD 3.17 - 38.1mm | 0.125" - 1.500" | 1.2kg | 1.0.2920 Our new generation of compact weld heads for high duty cycle requirements have watercooled clamp housings and clamping levers. Both OSK CW weld heads are operated using a sharable handle and cable assembly. Weld head type | Field of application mm | inch | weight | item number OSK 21 CW | OD 3.17 - 21.3mm | 0.125" - 0.839" | 1.0kg | 1.0.2820W OSK 38 CW | OD 3.17 - 38.1mm | 0.125" - 1.500" | 1.4kg | 1.0.2920W Only one drive unit is needed for all C and CW weld heads.

Request for a quote

ORBITEC GMBH

Germany

Our latest series of 3 gas-cooled weld heads, technically optimized and in a new design, covers the tube size ranges from 6mm - 114.3mm / 0.250" - 4.500". Unique construction and material selection allows a high duty cycle even without water cooling. The weld heads are one of the narrowest on the market and have a 'quick latch' system for retaining the collets. Our latest series of 3 OSK SW-weld heads, even narrower, technically optimized and in a new design. For high duty cycles we also offer the gas-cooled S-series weld heads in a water-cooled SW-version (the overall width remains unchanged). The water-cooling circulation covers the lower clamp housing. OSK 53 S (SW) | OD 6 - 53mm | 0.250" - 2.087" | 2.1kg | 1.0.2520 (1.0.2520W) OSK 76 S (SW) | OD 6 - 76.2mm | 0.250" - 3.000" | 2.6kg | 1.0.2620 (1.0.2620W) OSK 115 S (SW) | OD 9.53 - 114.3mm | 0.375" - 4.500" | 3.4kg | 1.1.2720 (1.1.2720W)

Request for a quote

ORBITEC GMBH

Germany

Turn table, especially suitable for orbital components with higher quantities and can be connected to all Orbitec controllers. Package includes: — Turning device — 3-jaw chuck — Interchangeable jaws — Chuck key — Durable multi-positional torch arm with central mechanical clamping — Ground cable — Interconnection cable with wire and AVC outlet Special versions available on request.

Request for a quote

ORBITEC GMBH

Germany

The EVO Industry 4.0 series is new to the market. Several systems, initially compact as the 200 A Autorange and now also modular in connection with the Tetrix inverters. The systems are small, lightweight and handy and offer a high-resolution colour display, multilingual intuitive user guidance due to a colour touch interface, or alternatively operation using a membrane keyboard, a stable operating system (without data loss during power outages and quickly ready for use again), full access through tablet with QR-code scanner, data transfer via USB, LAN and WLAN, fault analysis program, manufacturer support via remote maintenance, a mountable cooling unit as an option, and many other functions... Connection to Tetrix 200 or Tetrix 351. Compact and light with the external dimensions (L x W x H) 405 x 325 x 170 mm and weighing only 9.7 kg. Optional: — Water Cooling Unit COOL 50 or EVO COOL — EVO Remote Control — Gas Controller Box

Request for a quote

ORBITEC GMBH

Germany

Mobile inverter power source for TIG manual or orbital welding with built-in cooling system and gas sensor. Can be used with all Orbitec controllers, particular in high-demand applications such as tube-to-tube-sheet. Technical Data: Output: DC Mains voltage: AC 3 x 400V Mains frequency: 50 / 60Hz Power rating: 15 kVA Generator output: 20.3 kVA Current range: 5A – 350A Welding current: - 60% TIG / MMA: 350A - 100% TIG / MMA: 300A Cooling efficiency: 1500W Water column: 35m / 5l / min. Tank capacity: 12l Weight: 131kg Dimensions (L x W x H): 1100 x 455 x 1000 mm Package includes: - Inverter - Power cable - 10l coolant

Request for a quoteResults for

Braze-welding - Import exportNumber of results

72 ProductsCountries

Company type