- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- high-resistance steels

Results for

High-resistance steels - Import export

IGUS® GMBH

Germany

DryLin® R shafts and supported shafts - Technical data DryLin® R - AWMP Precision aluminum shaft, mm DryLin® R - AWMP DryLin® R - AWMU Supported aluminum shaft, mm DryLin® R - AWMU DryLin® R - SWM/EWM An steel or stainless steel precision shaft, mm DryLin® R - SWM/EWM DryLin® R - SWUM/EWUM Supported steel shaft orstainless steel shaft, mm DryLin® R - SWUM/EWUM DryLin® R - SWUMN/EWUMN Low supported steel shaft orstainless steel shaft, mm DryLin® R - SWUMN/EWUMN DryLin® R - EWUM Partially supported stainless steel shaft, mm DryLin® R - EWUM-Ø DryLin® R - CWM Carbon-fiber shaft, mm DryLin® R - CWM DryLin® R - AWMP Precision aluminum shaft, mm DryLin® R - AWMP DryLin® R - AWMU Supported aluminum shaft, mm DryLin® R - AWMU DryLin® R - SWM/EWM An steel or stainless steel precision shaft, mm DryLin® R - SWM/EWM DryLin® R - SWUM/EWUM Supported steel shaft orstainless steel shaft, mm DryLin® R - SWUM/EWUM DryLin® R - SWUMN/EWUMN Low supported steel shaft orstainless steel shaft, mm DryLin® R - SWUMN/EWUMN DryLin® R - EWUM Partially supported stainless steel shaft, mm DryLin® R - EWUM-Ø DryLin® R - CWM Carbon-fiber shaft, mm DryLin® R - CWM Aluminum Low weight Lower wear of the plain bearing Corrosion resistant Ideal in combination with liners made of iglidur® J/J 200 Delivered off the shelf Steel Low-priced standard High load capacity Application in dry area Hard chrome-plated also available Lower coefficient of friction against plastic bearing Stainless steel High corrosion-resistance High resistance to chemicals Ideal solution for the wet area V4A for extreme chemical intensive applications Female thread, axial male thread Pins Groove cut-in Spanner flat Female thread, radial Special machining All shafts can be individually machined. Please send us your drawing. We'll submit an offer to you in a short time. Shaft request

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

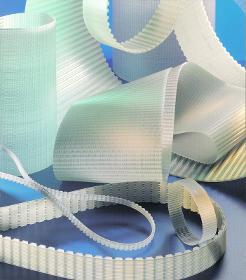

Keiper open-ended PU timing belts are made of abrasion-resistant polyurethane and high-strength steel cords or aramid cords and are available in open lengths. These timing belts are very suitable for synchronous conveying and positioning applications because they have very high flexibility and can be made with many different tooth shapes and materials; when combined with different tension cords, innumerable applications are possible. Keiper open-ended PU timing belts can be produced endless welded and by the meter in almost all lengths and widths. Based on this combination of high-quality materials and production methods, these belts exhibit outstanding mechanical, chemical and physical properties. Endless welded timing belts are available in any length. Welded PU timing belts primarily are used in conveying technology.

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

Keiper self-guiding PU track timing belts are made of abrasion-resistant polyurethane and high-strength steel cords or aramid cords and produced in open lengths. The V-guide is either integrated in the timing belt during production or welded into the belt later. These timing belts exhibit the same properties as standard timing belts. In addition, axial movements are prevented. Keiper self-guiding PU track timing belts are available as endlessly welded belts and cut goods, in almost any length and width. Properties and special features: Prevent axial movements V-profile guides can be combined with any tooth profile in all sizes Flanges are no longer required, the notched design of the V-profile guide gives rise to high flexibility Applications: Conveying and positioning applications with large center distances Applications, in which axial movement is a problem and flanges cannot be used.

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

Keiper PU molded timing belts (form belts), which are cast in special molds, are made of abrasion-resistant polyurethane and high-strength steel cords (or aramid cords). The cast PU timing belt is an exact replica of its mold. Consequently, high pitch accuracy along the entire length of the belt is realized. They are particularly well suited for smooth running and high speeds. By combining high-quality materials and this modern production method, the resulting timing belts exhibit supreme mechanical, chemical and physical properties. Mechanical properties: Low longitudinal tolerance Longitudinal stability, negligible elongation Form-fit, synchronous running Low noise High abrasion resistance Favorable performance-weight ratio Chemical properties: Good ageing resistance Operating temperature range from -30°C to +80°C Resistant to simple oils, greases and gasoline Applications All types of drives Office machines Textile machines Wood-processing machines

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

Keiper PU Flex timing belts are extruded of abrasion-resistant polyurethane and high-strength steel cords, aramid cords or high flexible steel cords and VA steel with endless winded cords. In these belts the cords are helically spooled. These timing belts can be used for all kinds of power transmission applications because of their high power transfer, and their high flexibility make them suitable for synchronous transport and positioning applications. By using standard polyurethane and such other belt materials as polyurethane that is cold resistant, heat resistant or suitable for contact with foodstuffs a wide spectrum of applications is possible.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Braided from Carbon fiber and carbon reinforced expanded Graphite Tape Practical useful application data: max. temperature in oxidizing atmosphere: +400 °C Characteristics Universal plant wide use in static and rotating applications Wear and extrusion stability through carbon fiber corner reinforcement Non hardening, good reset capability, coefficient of thermal expansion corresponds to the coefficient of steel High temperature resistance and excellent heat and electric conductivity Self lubricating, excellent use in pumps, minimizing the need of flushwater Easy to cut, assemble and disassemble Low coefficient of friction minimizes the adjustment force in valves No shaft wear, excellent dry running characteristics Rings should be compressed in valve applications at assembly approx. 15 - 20 % in height Die formed rings are recommended Operating range Pressure [p max]: 25 bar, Velocity [v max]: 30 m/s Pressure [p max]: 100 bar, Velocity [v max]: 2 m/s Pressure [p max]: 300...

Request for a quote

EWM AG

Germany

EWM welding consumables for MMA welding Welders can choose between different stick electrodes with different coating materials to work with: — unalloyed steels — low-alloy heat resistant steels — high alloy steels — Copper-based materials — Cladding

Request for a quote

ENHA GMBH

Germany

A dexterous high cut resistance glove, glass and steel fibre free. Ideal in dry or greasy conditions.

Request for a quote

PVA INDUSTRIAL VACUUM SYSTEMS GMBH

Germany

VSG systems offer a poven and economic solution for the inductive melting of metals or alloys under vacuum or protective gas atmosphere and subsequent casting. Applications: The VSG furnaces can be universally employed for melting and casting under high vacuum or different gas atmospheres in the laboratory or production, e.g. alloying, degassing, purification melting, re-melting processing of noble metals highly pure, highly alloyed steel. • Processing of: ◦noble metals ◦ processing of highly pure, highly alloyed steel ◦ High temperature resistant materials on Fe- Ni- Co- basis ◦ Solar-silicon and other special material ◦ Special- / super alloys

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The range of application for the high-precision resistance decades models 1406 and 1407 stretches from reference standard for precision measurements up to simulation ot a host of measuring transducers. They can be used for control in complicated equipments and systems, such as equivalent circuit in resistor networks. Another application is the use in switching circuits, as reproducible variable in laboratory and test assemblies. The decade resistors meet all the requirements of these differing functions as well as the resulting demands. The high-precision resistance decades models 1406 and 1407 are designed to meet the highest demands with regard to precision, temperature and long-term consistency. Many years at experience, tried-and-tested technology and the use of fieldproven materials guarantee the high level of precision. The decade resistors consist of low-capacity and low inductance wire windings of MANGANIN®.

Request for a quoteResults for

High-resistance steels - Import exportNumber of results

12 ProductsCountries