- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- industrial%20mixers

Results for

Industrial%20mixers - Import export

MIXACO MASCHINENBAU

Germany

The Robust Workhorse: The high-performance MIXACO universal mixer is ideal for many different applications. Whether slow, gentle homogenization or thorough mixing is required, consistently high quality is guaranteed for every mixing process. In particular, the universal mixer’s highly flexible design possibilities enable it to be adapted easily to suit the required mixing task and individual on-site requirements. The MIXACO universal mixer is available in sizes from 20 to 6,000 liters. All Benefits at a Glance •Can be used for a wide variety of applications, such as homogenization, dispersion, coating or granulation •Mixer tools optimized for the individual mixing task •Performance-optimized selection of mixing drives ensures high energy efficiency •Rapid cleaning possible when pivoting mixer lid is open •Double-walled mixing vessel enables ideal temperature control of product during mixing •ATEX version possible

Request for a quote

MIXACO MASCHINENBAU

Germany

MIXACO Container Mixer Vortex™ It is suitable for any industry where different recipes need to be mixed in quick succession, resulting in frequent mixer cleaning. As the transport container and mixer head are separate units, products can be conveyed to the next processing station without loss of time. The design of the MIXACO Vortex™ mixer, which was robust from the outset, is continuously being improved and updated. The system and its individual components are also configured for multi-level operation, with corresponding connectors to allow dust-free, airtight discharging of the transport container directly into extrusion, kneading, weighing and bagging machines. The MIXACO Vortex™ is more than simply a classic among container mixers; it also offers modern technology with numerous advantages for your in-house material logistics and work processes.

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The laboratory model supplements the well-established Lödige mixing granulator range. The laboratory mixing granulator permits the same process steps as the production machines: — Mixing — Moistening — Granulation — Temperature control (using double jacket) The laboratory mixing granulator is delivered operation-ready with a CE conformity declaration. For the sizes, please refer to the machine flyer. A three-bladed impeller rotates at the bottom of the vertical, cylindrical mixing vessel, to create a vortex type of circulation for the material to be mixed. Very short mixing times and excellent mixing quality are achieved, even if the product components are extremely different. The separately driven chopper (only for the 5, 10 and 15 l vessel) is designed for breaking up of agglomerated material, for uniform moistening, wet granulation and streak-free mixing of dyes, as required.

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The CoriMix® is a high-speed, continuous mixer for high throughputs, especially developed for homogeneous mixing of liquid and pasty components into dry substances. The system is based on the high peripheral speed of the mixing shaft tools of up to 50 m/s. The product is moved through the mixing chamber in a plug-flow manner. The retention time is extremely short compared with a continuous ploughshare mixer. The mixing chamber is divided into zones with different mixing tools enabling different shear intensity by selecting and adjusting the mixing tools according to each application. Liquid components are introduced directly into the product ring layer – either via tangentially placed liquid pipes through the drum wall or via a hollow mixing shaft with specially perforated tools. However, moistening of the mixer wall and shaft is largely prevented. The liquid distribution is similar to a nozzle but avoiding any risk of clogging or disturbance of the spray.

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

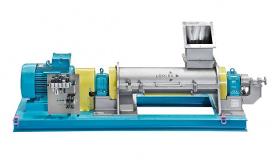

The continuous ploughshare mixer uses the mixing and fluid process introduced to mixing technology by Lödige. The ploughshare shovels in special arrangement on a mixing shaft in a horizontal, cylindrical drum rotate. Their peripheral speed and geometric form are coordinated in such a way that the mix is moved out of the product bed against the centrifugal force and in axial direction at the same time. The mixing elements having a defined shape and a special arrangement on the shaft, they ensure not only a reliable product conveyance but also a sufficient back-mixing of the product. All the product is constantly involved in the process, ensures a maximum mixing intensity at even the highest throughputs and shortest residence times until the product is discharged out of the mixer via an outlet. The continuous process can be run at filling levels between 20 % and 50 % without influencing the mixing quality. Choppers can be additionally installed in the mixing drum.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The ploughshare mixer for batch operation uses the mixing and fluid process introduced to mixing technology by Lödige. The ploughshare shovels on the mixing shaft in a horizontal, cylindrical drum rotate to the wall. Their peripheral speed and geometric form are coordinated in such a way that the mix is moved out of the product bed against the centrifugal force and in axial direction at the same time. All the product is constantly involved in the process, ensures a maximum mixing intensity at even the highest throughputs and shortest residence times until the product is discharged out of the mixer via an outlet. Thanks to their form adapted to individual application and the speed adjustment, Lödige ploughshare mixers can be used for a wide range of applications. Choppers can be additionally installed in the mixing drum to increase the turbulence in the mixing process. This ensures the mixing of fine particles in small quantity and enables the dispersion of these products .

Request for a quote

WESTMARK GMBH

Germany

• with storage section • the self-adjusting spring-loaded mechanism holds the nutmeg against the blade with consistent force

Request for a quote

FRANZ EISELE & SÖHNE GMBH & CO KG

Germany

Application options for the Eisele PTO mixers can be found in industrial businesses and in the agricultural sector. More detailed key data here: Double-start worm forced circulation (sucking) With PTO-drive 30/48 kW or with electric motor 11/15/18.5 kW Threaded spindle with crank Three-point mounting, can be tipped Stable design, highly wear resisting mechanical seal, shaft in an oil bath Agitation shaft length 3,50 – 6,00 m Application possibilities of the Eisele PTO mixers are in industrial business and agricultural sectors. They are the perfect solution for the effortless mixing in slurry tanks or similar using a tractor or other towing vehicle.

Request for a quoteResults for

Industrial%20mixers - Import exportNumber of results

9 ProductsCountries

Company type