- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- injection applications

Results for

Injection applications - Import export

POLYNEO GMBH

Germany

PolyNeo GmbH looks back on decades of experience in polymer trading. A high level of professionalism, both customer and supplier contacts that have developed over the years, in-depth market knowledge, strong cost awareness as well as the extensive technical know-how of our employees constitute the strengths of PolyNeo GmbH. For decades now, we have supported producers and customers all over the world by raw material sourcing, marketing and distribution as well as tailor-made logistics services. Raw material and compounds for fibers, film as well as a diversity of extrusion and injection molding applications (mineral filled, glass reinforced, impact modified, UV modified, flame-retardant both halo and non-halo, elevated temperature modified). Broad range of different types e.g. GF 10, GF 15, GF 30, GF 35, GF 40, GF 50

Request for a quote

GOLDEN COMPOUND GMBH

Germany

GC green 2082 MI contains 20% natural fibers and is a biomaterial - allrounder for various injection molding applications. With GC green you get a resource-saving and home-compostable material with ground sunflower seed hulls. The fibers from sunflower seed hulls are a by-product of sunflower oil production. They are GMO-free, do not compete with food and do not require additional acreage. Often this material has already been used for various packages or even plant clips. In order to provide you with an optimal color selection, we have had 10 masterbatch colors certified by TÜV Austria. We will be happy to advise you. Further advantages of GC green: 100% recyclable Reduced cycle times No sink marks Lower energy input In addition to our allrounder compounds, we naturally have many other material formulations. Just contact us, together we will find the perfect compound for your application.

Request for a quote

GOLDEN COMPOUND GMBH

Germany

GC green 3092 MIF contains 30% natural fibers and is a biomaterial - allrounder for various injection molding and also thermoforming applications. With GC green you get a resource-saving and home-compostable material with ground sunflower seed hulls. The fibers from sunflower seed hulls are a by-product of sunflower oil production. They are GMO-free, do not compete with food and do not require additional acreage. Often this material has already been used for labels. In order to provide you with an optimal color selection, we have had 10 masterbatch colors certified by TÜV Austria. We will be happy to advise you. Further advantages of GC green: 100% recyclable Reduced cycle times Certified quality No sink marks Lower energy input In addition to our allrounder compounds, we naturally have many other material formulations. Just contact us, together we will find the perfect compound for your application.

Request for a quote

GOLDEN COMPOUND GMBH

Germany

GC green 3071 MI T6 contains 30% natural fibers and is a biomaterial - allrounder for various injection molding applications. With GC green you get a resource-saving and home-compostable material with ground sunflower seed hulls. The fibers from sunflower seed hulls are a by-product of sunflower oil production. They are GMO-free, do not compete with food and do not require additional acreage. Often this material has already been used for our thik-walled plantable plant pots or urns. In order to provide you with an optimal color selection, we have had 10 masterbatch colors certified by TÜV Austria. We will be happy to advise you. Further advantages of GC green: 100% recyclable Reduced cycle times No sink marks Lower energy input In addition to our allrounder compounds, we naturally have many other material formulations. Just contact us, together we will find the perfect compound for your application.

Request for a quote

GOLDEN COMPOUND GMBH

Germany

GC green 3082 MIF T13 contains 30% natural fibers of sunflower seed shell and is a biomaterial - allrounder for various injection molding applications. With GC green you get a resource-saving and certified-home-compostable material with ground sunflower seed hulls. The fibers from sunflower seed hulls are a by-product of sunflower oil production. They are GMO-free, do not compete with food and do not require additional land for cultivation. Frequently, this material has already been used for the HOMEcap coffee capsule and various packaging in the food sector. Further advantages of GC green: 100 % recyclable Reduced cycle times No sink marks Certified quality Reduced energy input In addition to our allrounder compounds, we naturally have many other material formulations. Just contact us, together we will find the perfect compound for your application.

Request for a quote

GOLDEN COMPOUND GMBH

Germany

GC green M2571 7G3 A contains 25% natural fibers and is a biomaterial - allrounder for various injection molding applications. With GC green you get a resource-saving and home-compostable material with ground sunflower seed hulls. The fibers from sunflower seed hulls are a by-product of sunflower oil production. They are GMO-free, do not compete with food and do not require additional acreage. Often this material has already been used for our thin-walled plantable plant pots: Natural Pot. In order to provide you with an optimal color selection, we have had 10 masterbatch colors certified by TÜV Austria. We will be happy to advise you. Further advantages of GC green: 100% recyclable Reduced cycle times No sink marks Lower energy input In addition to our allrounder compounds, we naturally have many other material formulations. Just contact us, together we will find the perfect compound for your application.

Request for a quote

STRONG MAGNETS GMBH

Germany

The injected Neodymium magnets are magnetic products mixed with different plastic products. Its main advantage is the diversity of molding offered by the injection process, allowing the products to be customized to meet the needs of the customers. Advantage Injected Neodymium magnets are more resistant to corrosion than sintered Neodymium magnets, with this character, they can be used in most applications without special coatings.Produced by injection process, injected magnets are with high precision and are tailored for each application. This type of injected magnets can be used under working temperature from 100oC to 200oC with good performance. Application The scope of application of the injected magnets is very wide, our magnets are widely in different industrial sectors, such as automotive, electronics, robotics ...

Request for a quote

HEXPOL TPE GMBH

Germany

Dryflex SE is our standard TPE range. It is extremely adaptable and can be used advantageously in many applications. The compounds are easy to process and are optimised for injection moulding. We have developed endless formulations to fulfil different properties and application requirements to optimise the finished component. Grades with improved compression set properties, high temperature resistance or more cost efficient values are an essential part of today’s wide product spectrum. Key Properties Unfilled, semi-filled & filled series 30 to 90 Shore A hardnesses Translucent, black, natural or coloured compounds are available Good adhesion to PP & PE High flexibility Easy processing via injection moulding Good mechanical properties Applications with food contact are possible Service temperature range from -50°C to 125°C (unstressed) Conforms to European directives 2002/95/EC (RoHS) and 2003/11/EC 100% recyclable Processing Dryflex SE TPE compounds can be processed using con

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

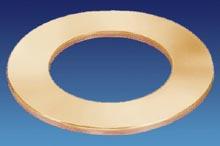

Where to use deva.bm/9P deva.bm ®/9P is a self-lubricating bi-metal sliding material. The sliding layer is applied to the stainless steel back in a combined rolling/sintering process. The lubricant in deva.bm ®/9P is microscopically distributed PTFE which leads to significantly reduced friction and wear figures. deva.bm ®/9P is the optimum material for p>25 N/mm² and has its best performance at slow speeds and intermittent service. Applications Water turbines, injection molding machines, packing machinery, food and beverage industry, printing machines, shut-off values, hydromechanical engineering, tire molds, construction equipment and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (PTFE) 4. Stainless steel backing

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm/9P deva.bm ®/9P is a self-lubricating bi-metal sliding material. The sliding layer is applied to the stainless steel back in a combined rolling/sintering process. The lubricant in deva.bm ®/9P is microscopically distributed PTFE which leads to significantly reduced friction and wear figures. deva.bm ®/9P is the optimum material for p>25 N/mm² and has its best performance at slow speeds and intermittent service. Applications Water turbines, injection molding machines, packing machinery, food and beverage industry, printing machines, shut-off values, hydromechanical engineering, tire molds, construction equipment and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (PTFE) 4. Stainless steel backing

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm/9P deva.bm ®/9P is a self-lubricating bi-metal sliding material. The sliding layer is applied to the stainless steel back in a combined rolling/sintering process. The lubricant in deva.bm ®/9P is microscopically distributed PTFE which leads to significantly reduced friction and wear figures. deva.bm ®/9P is the optimum material for p>25 N/mm² and has its best performance at slow speeds and intermittent service. Applications Water turbines, injection molding machines, packing machinery, food and beverage industry, printing machines, shut-off values, hydromechanical engineering, tire molds, construction equipment and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (PTFE) 4. Stainless steel backing

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm/9P deva.bm ®/9P is a self-lubricating bi-metal sliding material. The sliding layer is applied to the stainless steel back in a combined rolling/sintering process. The lubricant in deva.bm ®/9P is microscopically distributed PTFE which leads to significantly reduced friction and wear figures. deva.bm ®/9P is the optimum material for p>25 N/mm² and has its best performance at slow speeds and intermittent service. Applications Water turbines, injection molding machines, packing machinery, food and beverage industry, printing machines, shut-off values, hydromechanical engineering, tire molds, construction equipment and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (PTFE) 4. Stainless steel backing

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm/9P deva.bm ®/9P is a self-lubricating bi-metal sliding material. The sliding layer is applied to the stainless steel back in a combined rolling/sintering process. The lubricant in deva.bm ®/9P is microscopically distributed PTFE which leads to significantly reduced friction and wear figures. deva.bm ®/9P is the optimum material for p>25 N/mm² and has its best performance at slow speeds and intermittent service. Applications Water turbines, injection molding machines, packing machinery, food and beverage industry, printing machines, shut-off values, hydromechanical engineering, tire molds, construction equipment and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (PTFE) 4. Stainless steel backing

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm/9P deva.bm ®/9P is a self-lubricating bi-metal sliding material. The sliding layer is applied to the stainless steel back in a combined rolling/sintering process. The lubricant in deva.bm ®/9P is microscopically distributed PTFE which leads to significantly reduced friction and wear figures. deva.bm ®/9P is the optimum material for p>25 N/mm² and has its best performance at slow speeds and intermittent service. Applications Water turbines, injection molding machines, packing machinery, food and beverage industry, printing machines, shut-off values, hydromechanical engineering, tire molds, construction equipment and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (PTFE) 4. Stainless steel backing

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

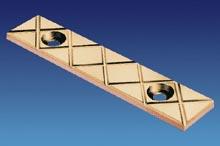

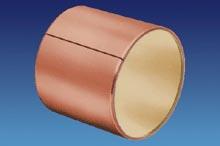

Where to use deva.bm ® deva.bm ® is a thin-wall, self-lubricating bearing material suitable for hostile environments, high or dynamically loaded applications or where lubrication is difficult, unreliable or impossible. It consists of a steel backing with a deva.metal ® bearing layer. deva.bm ® offers basically the same bearing characteristics as deva.metal ®: but is capable of even higher loads and offers an economic solution to many bearing problems Applications Water turbines, injection moulding machinery, packing machinery, printing machines, construction equipment, shut-off valves, tire moulds and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (graphite) 4. Steel backing

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm ® deva.bm ® is a thin-wall, self-lubricating bearing material suitable for hostile environments, high or dynamically loaded applications or where lubrication is difficult, unreliable or impossible. It consists of a steel backing with a deva.metal ® bearing layer. deva.bm ® offers basically the same bearing characteristics as deva.metal ®: but is capable of even higher loads and offers an economic solution to many bearing problems Applications Water turbines, injection moulding machinery, packing machinery, printing machines, construction equipment, shut-off valves, tire moulds and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (graphite) 4. Steel backing

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm ® deva.bm ® is a thin-wall, self-lubricating bearing material suitable for hostile environments, high or dynamically loaded applications or where lubrication is difficult, unreliable or impossible. It consists of a steel backing with a deva.metal ® bearing layer. deva.bm ® offers basically the same bearing characteristics as deva.metal ®: but is capable of even higher loads and offers an economic solution to many bearing problems Applications Water turbines, injection moulding machinery, packing machinery, printing machines, construction equipment, shut-off valves, tire moulds and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (graphite) 4. Steel backing

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm ® deva.bm ® is a thin-wall, self-lubricating bearing material suitable for hostile environments, high or dynamically loaded applications or where lubrication is difficult, unreliable or impossible. It consists of a steel backing with a deva.metal ® bearing layer. deva.bm ® offers basically the same bearing characteristics as deva.metal ®: but is capable of even higher loads and offers an economic solution to many bearing problems Applications Water turbines, injection moulding machinery, packing machinery, printing machines, construction equipment, shut-off valves, tire moulds and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (graphite) 4. Steel backing

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm ® deva.bm ® is a thin-wall, self-lubricating bearing material suitable for hostile environments, high or dynamically loaded applications or where lubrication is difficult, unreliable or impossible. It consists of a steel backing with a deva.metal ® bearing layer. deva.bm ® offers basically the same bearing characteristics as deva.metal ®: but is capable of even higher loads and offers an economic solution to many bearing problems Applications Water turbines, injection moulding machinery, packing machinery, printing machines, construction equipment, shut-off valves, tire moulds and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (graphite) 4. Steel backing

Request for a quoteResults for

Injection applications - Import exportNumber of results

20 ProductsCountries

Company type