- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machining industry

Results for

Machining industry - Import export

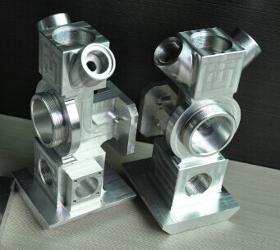

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are aluminium cnc machining parts,used in architectural industry.

Request for a quote

BERGSIEK BEHÄLTERBAU GMBH

Germany

We adapt the products to the requirements of our customers and therefore always find the optimal solution. Optimised for the specified axle load of various base vehicles, our focus is always on the quality of the products, in order to guarantee lasting use of the sweeping containers. We are happy to provide individual and detailed advice in this segment.

Request for a quote

CNC-STEP GMBH & CO. KG

Germany

Thanks to the robust steel frame, our T-Rex CNC mill enables you to produce precisely, quickly and cleanly. Even with workpieces made of hard material, you will achieve ideal results, thanks to the high stability of the CNC machine, which is guaranteed by the robust construction. On this machine, you can even process thicker plate material, as the clearance height of the Z-axis is 200 mm. Versatile application possibilities: drilling, cutting or engraving in different materials such as plastic, wood, granite, marble, stone and metal can be done with high accuracy. Basic equipment: > vacuum table with several zones > manual central lubrication > KinetiC-NC control software > ergonomic control panel with integrated CNC control > full version of the design software ConstruCAM-3D > Estlcam software CE-compliant commissioning of our CNC machines requires the attachment of the protective housing and the exhaust connection.

Request for a quote

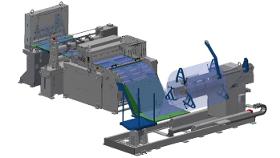

GSW SCHWABE AG

Germany

The Combination Slitting & Cut-To-Length Lines are probably the most flexible coil processing lines within the field of cutting. By combining the cutting lengthwise and across, the coil material can be processed into a variety of blanks. So, if your production features a limited number of different coils as basic materials, while the variety of widths and lengths of the blanks is high, a Combination Slitting & Cut-To-Length Line will be the right choice. The system bases on the Cut-To-Length technology while offering the additional functionality of slitting. Since the slitting technology is home-made too, we can provide a fully integrated solution. An incisive experience so to speak. As a sizable advantage, storage space and material costs per ton are both significantly reduced, and with Combination Slitting & Cut-To-Length Lines even smallest batches can be delivered immediately.

Request for a quote

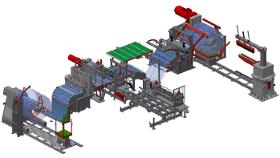

GSW SCHWABE AG

Germany

Also Slitting Lines do of course belong to the family of Cutting Lines. They are suitable especially for such customers who have to control a large portfolio of coil widths within their production. And if you build quality products you need quality even in your primary material. Finding it requires a good Steel Service Center but can be costly and unavailable at time of need. So why not cut your own coils? Our Slitting Lines are optimized for smaller batches and provide flexibility supporting your deadlines.

Request for a quote

CRYOSNOW GMBH

Germany

• For large surfaces and stubborn contaminations • Powerful round nozzles • Flat nozzles with blasting widths of up to 100 mm (4") • Available as Desktop and Trolley • No power supply, as driven pneumatically

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

ZWP is one of the leading independent manufacturer in Germany for gears, pinions and rim gears. We supply already well-known manufacturers for gear boxes. We are looking forward getting intouch with you to have a conversation about possibilities for your supply. Sectors of our (international) customers are: Mining, Oil, Offshore, rail and ship transmissions, industrial transmissions, and many more fields of applications. Overview about the capabilities for production: Gears internal and external toothed hardened and grinded Module 2 – 50 mm Diameter 100 – 2,000 mm Internal toothed rings / rim gears hardened and grinded Module up to 20 mm - more on request Diameter 100 to 1,800mm Pinions and shafts internal and external toothed hardened and grinded Module 1 – 50 mm Diameter 50 – 500 mm Length up to 1,500 mm Hardening and balancing inhouse possible Cooperation with companies for special manufacturing of gears and pinions etc We speak English.

Request for a quote

CNC-STEP GMBH & CO. KG

Germany

- made of steel - with safety housing - desktop machine or stand-alone - incl. CNC control Zero3 - incl. ConstruCAM-3D software - incl. Estlcam software - 16 different sizes available

Request for a quote

MESUTRONIC GMBH

Germany

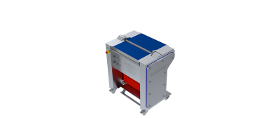

- detects and separates any type of metal, loose or encapsulated - flexible integration into existing conveying systems independent of direction, quick and cost-effective -easy to operate - high-precision metal detection, extremely reliable - uncompromising safety, thanks to mesuSafetyPack

Request for a quote

SCHOLL APPARATEBAU GMBH & CO. KG

Germany

Design: Carving station made of chrome nickel steel 18/10. Digital adjustable from 30 – 100 °C. Carving surface with retaining lip. Incl. heat resis tant carving board made of glass. Available with cough protection on guest side upon request.

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

We manufacture gears, gear rings and toothed shafts for various applications in industry with a focus on mechanical engineering and heavy machinery. Our customers come from a wide range of industries: railway, wind power, marine, industrial gearboxes, oil and gas extraction, crane construction or construction machinery as well as special machines. We also supply the retrofit industry and manufacture the parts in small series or individual production. Depending on the dimension a quality of 4 can often be achieved. We examine the possibilities without obligation and without charge. Our customers include renowned and well-known companies. References to your industry on request. We manufacture according to customer drawings and have our own hardening plant. This saves time and costs during production. Cooperation exists for gas nitration and single-tooth induction hardening with experts in their field. ZWP supports you in the overhaul of plants and machines (Retrofit).

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

We manufacture toothed wheels, cog wheels, gear rings and toothed shafts for various applications in industry with a focus on mechanical engineering and heavy machinery. Our customers come from a wide range of industries: railway, wind power, marine, industrial gearboxes, oil and gas extraction, crane construction or construction machinery as well as special machines. We also supply the retrofit industry and manufacture the parts in small series or individual production. Depending on the dimension a quality of 4 can often be achieved. We examine the possibilities without obligation and without charge. Our customers include renowned and well-known companies. References to your industry on request. We manufacture according to customer drawings and have our own hardening plant. This saves time and costs during production. Cooperation exists for gas nitration and single-tooth induction hardening with experts in their field. ZWP supports you in the modernisation of plants and machines.

Request for a quote

MESUTRONIC GMBH

Germany

metal separator was developed for the examination of plastic granulates, ground material and powders for metallic foreign bodies. It is used in the injection molding and extrusion areas for slow-flowing material columns. Both the detector and the ejection unit have been specially developed for this area of use. This results in top performance data for precision, operating reliability and ease of cleaning. Failsafe storage of all system parameters Digital signal processing for best detection Process- and condition monitoring Standardised system for a wide area of use Robust construction for maximum lifetime Highest precision in long-term operation Fast ejector for minimized material loss Dismantle without tools All components are easily accessible

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

Get the most out of your slicer blades! With the weSHARP 7000 sharpening center, you can quickly and easily get back the ideal slicing properties of your blades, even after intensive use in the slicer. The weSHARP 7000 is suitable for the refurbishment of all Weber Durablade Performance, involute and circular blades, and guarantees a precise and reproducible sharpening result with minimal material loss of the cutting edge. Thanks to program recognition and data storage, the sharpening process can be completed in the shortest possible time, and the use of tool-free fast-change systems also ensures that setup times are kept to a minimum. Advantages Simple operation with RFID technology Sharpening of all Durablade circular and involute blades Precise and reproducible sharpening result Precise sharpening process thanks to servo drive Convenient handling via touchscreen

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

Sharpener SSG is suitable for gentle processing of all Durablade® involute blades with low material abrasion. The compact unit for various sharpening angles ensures constant sharpening of the cutting edge thanks to the rotating contour tracking. A counter is integrated for individual specification of sharpening cycles. A water bath improves the sharpening result. Advantages Gentle blade processing Low level of material removal Non-actively driven sharpening discs Compact device for different sharpening angles Constant sharpening of cutting edge thanks to all-round contour tracing Counter for the individual specification of sharpening cycles Water bath for improved sharpening Simple operation Very quiet running Long blade service life

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

Sharpener KSG processes the blades gently with short setup times thanks to its intelligent sharpening technology. The sharpening unit is positioned via a visor. Sharpener KSG guarantees rapid, reproducible sharpening and has a long service life thanks to the sharpening disks which are not actively driven. A counter is integrated for individual specification of sharpening cycles. Advantages Long service life thanks to non-actively driven sharpening discs Sharpening unit positioning via sighting tool Gentle processing due to clever sharpening technology Quick, reproducible sharpening Counter for the individual specification of sharpening cycles Short set-up times Simple operation Clear, robust technology

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

Every Weber slicer contains a Weber blade. The involute or circular blades are manufactured in Weber's own blade factory in Mecklenburg-Lower Pomerania and marketed worldwide under the Durablade brand. Weber Durablade involute and circular blades let you make the best cut at all times: with maximum hygiene, slicing quality, resilience and durability. Durablade blades are now also available to fit other manufacturers' slicers. Price advantage thanks to new manufacturing technology We are continuously investing in research, progress and manufacturing technology. We recently supplemented our blade production with a robot-controlled and high-performance production system, which combines quality assurance with maximum profitability. Weber Durablade involute and circular blades let you make the best cut at all times: with maximum hygiene, cut quality, resilience, durability and reduced prices.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WEBER FOOD TECHNOLOGY GMBH

Germany

The products to be recorded can be fed on multiple tracks into a LED camera system, which individually measures and then weighs them at a weighing station. Based on the captured data, the highest yield and minimal give-away is guaranteed during slicing of pieces/chunks and slices. Advantages Open design, simple handling High fault tolerance Excellent detection of products with extremely fluctuating color contrasts Precise measurement even in extraneous light The laser scanner is available in various sizes to fit your product.

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

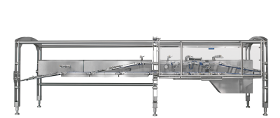

The Log Peeler CCP fully automatically and hygienically removes the casing from lunch meat and cheese products. The machine can be put together individually. A clear distinction between grey zones and hygiene zones allows the product casing to remain in the grey area, which increases the safety of the peeled product. With continuous production, the buffer can be inserted both upstream and downstream of peeling. The flexible system permits simple and rapid conversion when changing calibers. Advantages Continuous production: buffering possible before and after the peeling process Casing remains in non-high risk area, increased safety for the peeled product Safe: constant control of the peeling process Optional hygiene kit Optional hygiene kit: UVC irradiation from underneath of conveyors in the product contact area UVC air disinfection within the peeling area

Request for a quote

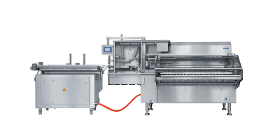

WEBER FOOD TECHNOLOGY GMBH

Germany

The CompactLoader is an especially compact infeeder which transports sliced portions fully automatically and feeds them into a packaging machine – all at a very modest footprint. Human touch of groceries is practically reduced to zero. Cleaning times of the CompactLoader are short and efficient. Advantages Compact, small footprint Modular adjustable system Weber hygienic design Arranges portions in die fomats, buffers them and places them in the packaging machine One design in different configurations – from base to top Space saving due to integrated rocker Optimal access to packaging machine by raising the buffer conveyors Infeeding belt foldable and swivable side-wise Easy cleaning, maintenance and service Options: Upper reject conveyor Buffer conveyor (2, 3, 4) Grouping conveyor (3, 4) Line divider – 2 axis 1 > n or 2 > 2 n Line divider – 3 axis 1 > n, 2 > 2 n, 2 > 3

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

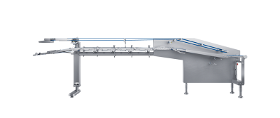

The infeeder CCA600/800 offers a high output with great flexibility. With a foil width of up to 830 mm, portions can be fed to up to six tracks of the packing machine in a wide variety of distribution variants. By adding various features such as diverse distribution variants, e.g. from four to six portions, or row completion, which supplements incomplete rows and inserts them again, infeeder CCA offers maximum flexibility and efficiency for many applications. Optionally, the infeeder can also complete rows and insert portions again. Advantages Automatic feeding of all commonly existing portion shapes and die formats Sets new hygiene standards Modular construction enables flexible design of the line length Optional: Automatic grouping of incomplete rows including automatic reintroducing UVC disinfection

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

Powerful derinding machine for large and small pieces of cheese. In addition to an ideal cutting width, the Weber Cheese Skinner offers product-specific height adjustment of the blade, meaning that natural and plastic rinds can be optimally removed. Maximum product yield is guaranteed. Advantages Powerful and with a compact footprint A special cheese transport roller and perfectly adjusted blades for optimal processing results Ideal cutting width for powerful derinding of large and small pieces of cheese Bolted blade with blade protection in cleaning position Unique geared brake motor with quick stop Options: special voltages

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

The Weber Slicer 305 is the entry-level model for state-of-the-art slicing technology. Thanks to the intuitive Weber Power Control, Slicer 305 is easy to operate. The programmable touch screen assures rapid product changeovers, and the shear bar and side limit stop can be configured for the product width. Weber hygienic design ensures that the system is easy to clean. Option: Stack lowering device Interleaver, Interleaver Speed Plus Pivotable blade safety cover Further options available. We will happily provide you with more information.

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

The wide product throat in Weber Slicer 405 guarantees a high output, and the shear bar and side limit stop can be configured individually for the product width. Product change is manual and rapid, even with short products. Manual and automatic loading are available as options, and end pieces are ejected automatically. Thanks to Weber Hygiene Design, Slicer 405 is simple to clean. Options: Automatic loading Idle cut blade head Separate blade drive Clearance height infinitely adjustable Interleaver, Interleaver Speed Plus Portion designer

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

An idle cut blade head with automatic cutting gap adjustment ensures that the Weber Slicer 604 has a high yield with minimum giveaway. The product throat can be adjusted automatically in height and width, and the fully automatic central loading unit ensures rapid product changes. Products up to 1,700 mm in length are fed in automatically and processed at up to 600 slices per minute. The shear bar and side limit stop can be configured by motor and with programme control. That allows the Weber Slicer 604 to guarantee a precise cut and placement of perfect slices continuously. Options: Slice folder Variogripper Idle cut blade head Separate blade drive Interleaver Portion designer

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

Short loading times are a key feature of the Weber Slicer 702. It masters the special challenges when slicing short products with short cycle times and an endless product flow. The involute blade system reaches performances of up to 1,500 slices per minute in idle cut operation. Options: Loading arm feeder Trimmer End piece management

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

Weber Slicer 804 is among the most efficient systems in its class. The involute blade system cuts products up to 1,700 mm in length at a maximum speed of 2,000 slices per minute. The automatic central operation ensures quick product changes. Slicer 804 uses a blade head with an idle cut function, which positions slice thicknesses between 0.1 millimetres and 50 millimetres precisely in various presentation forms. The 400 mm wide and 180 mm high product throat permits four 90 calibre products or three 100 x 100 products to be processed simultaneously. The system includes a programme-controlled, automatically configurable product clearance height and width. Weber Hygiene Design ensures that the system is easy to clean. Options: Slice folder Variogripper Idle cut blade head

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

The Weber Slicer 905 combines innovative slicing technology with versatility, efficiency and ease of operation. The extremely wide cutting throat and blade speeds of up to 2000 rpm allows the industry’s highest throughputs. The improved product control system provides perfect slicing results. Delicate and odd shaped products are easily loaded and sliced. The open frame design of the 905 allows easy access for operation, maintenance, and cleaning functions. The product control system has been upgraded to allow for more hygienic operation and quicker disassembly for cleaning. The Weber 905 has been designed and constructed to meet the world’s highest sanitation standards. The modular design allows the Weber 905 to be used in conjunction with all Weber up and down stream accessories such as stacking, party tray, automatic infeeding unit, etc.

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

The Weber Slicer weSLICE 9500 is the new high-performance machine in the slicer portfolio, which once again set the standard with regards to quality and performance. On the one hand, the uncompromising slicing quality and performance is achieved using the new Weber DirectDrive technology. The product is precisely guided by the direct drive of all components, so that in addition to perfectly sliced, visually appealing slices, the highest portion weight accuracy is achieved while at the same time providing maximum protection for the product. On the other hand, equipment highlights such as the Weber Durablade Performance involute blade ensures the best slicing quality. Moreover, the Vario technology of the new slicer-flagship weSLICE 9500 contributes to this unique performance. If Weber vacuum gripper technology is used, the product yield is increased even further, as remaining end pieces are reduced by more than half.

Request for a quoteResults for

Machining industry - Import exportNumber of results

284 ProductsCountries

- Germany (284)

- Berlin and region (5)

- Bonn, Düsseldorf and North Rhine and Westphalia (44)

- Frankfurt am Main and Hesse (71)

- Hannover and Lower Saxony (2)

- Magdeburg and Saxony-Anhalt (2)

- Mainz and Rheinland-Pfalz (64)

- Munich, Nuremberg and Bavaria (52)

- Potsdam and Brandenburg (5)

- Stuttgart, Freiburg and Baden-Wurtemberg (37)

- Weimar and Thuringia (2)

Company type

Category

- Food Industry - Machines & Equipment (91)

- Plastics - machines and material for industry (75)

- Cleaning machines, industrial (47)

- Industrial cutting machine tools (30)

- Packing and packaging - machinery and equipment (4)

- Machine tools - metal machining (2)

- Milling - machine tools (2)

- Gears (2)

- Mechanical engineering - custom work (2)

- Cleaning and maintenance products, household (2)

- Industrial robots (2)

- Lapping - machine tools (2)

- Metal straightening machines (2)

- Toothed wheels (2)

- Sweeping machines, industrial (1)

- Abrasive discs (1)

- Bearings, roller (1)

- Connectors, electronic (1)

- Engraving, industrial - steels and metals (1)

- Fasteners, metal (1)