- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- industrial maintenance

Results for

Industrial maintenance - Import export

RIDZEWSKI GMBH

Germany

The automatic leakage tester used to control the tightness of CO2 inert gas packaging allows even the smallest leaks - even in the micro range - to be detected.The package is tested by simply placing it in the vacuum chamber. The automatic test cycle starts when the lid is closed. The unit generates a user-defined vacuum during this process. After the vacuum is reached, the sensor is set to the "virtual" zero point. If the CO2 concentration rises during the measuring time that now begins and was previously selected by the user, this indicates that the packaging is leaking. The measured increase of the CO2 content in ppm gives information about the size of the not tightly sealed area. The sensor demonstrably detects even the smallest leaks up to approx. 10 µm. (µm is a micrometre and corresponds to 0.001 millimetres)

Request for a quote

RIDZEWSKI GMBH

Germany

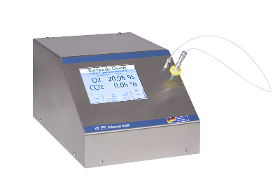

The EPC Spot is our measuring device for a random check of the gas levels of O2/CO2 in packaging or packaging machines. A sample is taken by a special needle. Due to the small amount of gas the analyser needs for the measurement, blister packs or ampoules can also be tested. As a user, you can enter several limit values for different products in the device. The result is then additionally visualised in red or green. All measurements are stored in the device and can be further processed in various ways. Advantages - Over 20 years of experience in development and optimisation - Top response time and short heat-up phase - Two different sizes for added flexibility - Long average life components - Digital measurement data logging - User-friendly filter change - 5.7 inch touch screen - Intuitive menu navigation - in many languages

Request for a quote

RIDZEWSKI GMBH

Germany

The EPC VM is our measuring device for monitoring O2/CO2 in packaging machines. In addition to continuous measurement of the gas atmosphere, spot measurement of individual packages is also possible. The functionality is the same as with our Zr-Ox EPC spot analyser. Once set, the analyser can also control the gassing of the machine. Advantages - Over 20 years of experience in development and optimisation - Top response time and short heat-up phase - Two different sizes for added flexibility - Long average life components - Digital measurement data logging - User-friendly filter change - 5.7 inch touch screen - Intuitive menu navigation - in many languages - Various RS232 protocols that can be changed in the unit for communication with different soldering, packaging soldering, packaging machines, analysers or other equipment and processes - Operation for user and administrator in different levels

Request for a quote

RIDZEWSKI GMBH

Germany

The EPC SMC is equipped with an integrated proportional valve. This allows the analyser to automatically regulate the gassing in a wide range of processes. All settings for the control can be configured on the unit or via external signals. This means that the customer is not required to control the process completely manually. This gives you the option of controlling the gassing at our analyser or at the plant. For some processes, a single adjustment is sufficient and the production runs fully automatically from then on. Advantages - Over 20 years of experience in development and optimisation - Top response time and short heat-up phase - Two different sizes for added flexibility - Long average life components - Digital measurement data logging - User-friendly filter change - 5.7 inch touch screen - Intuitive menu navigation - in many languages

Request for a quote

RIDZEWSKI GMBH

Germany

Our EPC 3GAS analyser is a more flexible variation of the basic model. The device changes the measurement automatically or externally controlled in order to monitor several processes simultaneously or consecutively. The change of the currently active measurement from process 1. to process 2. is done either by an external signal or in an adjustable time interval. Since our sensors can determine the oxygen concentration very quickly, time intervals of 30 seconds are realistically achievable. With desired concentrations of approx. 500 ppm, this is completely sufficient. Advantages - Over 20 years of experience in development and optimisation - Top response time and short heat-up phase - Two different sizes for added flexibility - Long average life components - Digital measurement data logging - User-friendly filter change - 5.7 inch touch screen - Intuitive menu navigation - in many languages

Request for a quote

RIDZEWSKI GMBH

Germany

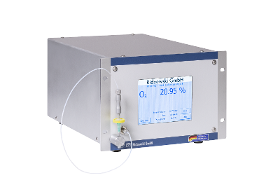

The Zr-Ox EPC is our standard model for continuous monitoring of residual oxygen. Advantages - Over 20 years of experience in development and optimisation - Top response time and short heat-up phase - Two different sizes for added flexibility - Long average life components - Digital measurement data logging - User-friendly filter change - 5.7 inch touch screen - Intuitive menu navigation - in many languages - Various RS232 protocols that can be changed in the unit for communication with different soldering, packaging soldering, packaging machines, analysers or other equipment and processes - Operation for user and administrator in different levels - Standardised 0/2-5/10 VDC or 00/04-20 mA analogue signal adjustable - 3 backups for storing different unit functions and settings - Display of all alarms and errors

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

Long-term system reliability at the lowest cost Service technology Lödige Industries provides bespoke maintenance services for equipment ranging from single machines up to complete automated systems, which guarantee your assets operate reliably and at the lowest possible cost. At the same time, our international service network ensures a fast response in the event of random faults even for equipment not delivered by Lödige. As your needs change over time, Lödige can also support the expansion of your facility, or the transition to new technologies. Lödige have a strong track record for delivering system enhancements or modernisations whilst Clients continue to run their day to day business. MAINTENANCE The modular configuration of our maintenance agreements provides you with long-term reliability at the lowest cost. CONSULTING We provide expert advice on the current condition of your systems and potential for improvement with regard to technology, throughput and operation. ...

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

You will only get the best results in terms of accuracy with clamping devices that are in top condition. Our new care set will help you here. This includes: 1 x Cleaning spray to degrease 1 x Penetrating lubricant to oil 1 x Grease gun to lubricate / grease 1 x Microfiber cloth to remove chips 2 x Grinding pad to remove rust film 2 x Pairs of safety gloves

Request for a quote

GEDA GMBH

Germany

Wherever heavy loads have to be transported to great heights, the new GEDA BL 2000 P ensures the required efficiency in the industry. With a load capacity of 2000 kg or 23 persons and a max. lifting speed of 40 m/min, this permanent passenger and material hoist is the new powerhouse from GEDA. The fixed platform size of 3.20 x 1.45 x 2.10 m also allows transport of bulky goods up to a height of 250 m. For added comfort and operating convenience, the hoist is equipped with comprehensive state-of-the-art control variants. The GEDA BL 2000 P is perfectly tailored to the requirements in rough industrial environments. Maintenance and repair work can be conducted efficiently with the permanent passenger and material hoist.

Request for a quote

CL MACHINERY GMBH

Germany

With its full stainless steal and modular construction, Closure Systems International's Series 5000 Combi Capping Machine is recognized in the industry for its reliability, low maintenance, and flexibility. This durable and versatile capper allows bottlers to effectively apply a wide variety of closures, especially aluminum caps, including: TSROPP, ROPP, screw caps, lug caps, Ring Pulls, and T-Corks for glass, aluminum, and PET bottles. In fact, Series 5000 Combi, allows plastic closures (CIH) and metal roll-on caps to be applied on the same capper using the same spindle. Reliable & Robust Robust, durable construction for long-lasting performance Full stainless steel construction to prevent corrosion Stainless steel turret Stainless steel spindles with wear-resistant plastics Stainless steel headsets New modular spindle assembly Proven headset designs for highly consistent closure application and torque control High throughput Plastic: 42 BPM / 2,520 BPH per head Roll On: 50 BPM.

CL MACHINERY GMBH

Germany

Closure Systems International’s Series 200 bottle cappers are the ultimate for aluminum roll-on applications. CSI's custom-engineered and precision built Series 200 cappers have been the preferred choice of the beverage and beer industry for decades. Industry’s Best TSROPP Performance Two cams provide independent control of top seal and thread forming, allowing precise control for specialty aluminum / roll-on packaging Perfect for roll-on closures requiring top/side sealing Robust, durable construction for long-lasting performance Corrosion-resistant materials in product zone; full stainless steel option Direct integration with any filler: various custom drive systems and pitch diameters to match filler, sorter and other bottling line equipment choices Open design for ease of cleaning Easy removal spindle assembles for quick maintenance Industry leader in Alumitec Application High-Speed, Consistent Application Industry-leading throughput at 50 BPM / 3,000 BPH per head Proven...

CL MACHINERY GMBH

Germany

With its full stainless steel and modular construction, Closure Systems International’s Series 5000 capping machine is recognized in the industry for its reliability, low maintenance and flexibility. This durable and versatile capper allows bottlers to effectively apply a wide variety of closures, especially aluminum caps, including: TSROPP, ROPP, screw caps, lug caps, Ring Pulls, and T-Corks for glass, aluminum and PET bottles. Reliable & Robust Robust, durable construction for long-lasting performance Full stainless steel construction to prevent corrosion Stainless steel turret Stainless steel spindles with wear-resistant plastics Stainless steel headsets New modular spindle assembly Proven headset designs for highly consistent closure application and torque control High throughput Plastic: 42 BPM / 2,520 BPH per head Roll On: 50 BPM / 3,000 BPH per head CSI Cap-in-Head technology assures proper closure placement at high speeds for optimized cap application Direct integration.

ABS SAFETY GMBH

Germany

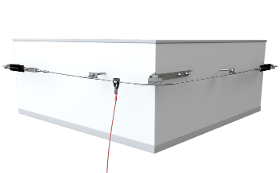

These traversable, stainless steel lifeline systems (8 or 6 mm) are designed for flexible installation on a facade or wall. A variety of curve and corner elements can be used to run the system over an edge or around an obstacle. Both systems have been awarded national technical approval and provide reliable fall protection for up to 4 individuals. National technical approval ("abZ"): Z-14.9-786 (pls. observe the installation instructions provided in the "abZ") EN 795:2012, C & CEN/TS 16415:2013 Compatible with most ABS Safety system supports Suitable for Installation on virtually any surface 8 or 6 mm stainless steel cable (V4A) Designed for facades, crane ways, filling plants, industrial, bus, plane and maintenance halls etc. Simultaneous protection for up to 4 individuals

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Formstable biaxially expanded ePTFE sheets or die cutted gaskets Characteristics Excellent adaption High blow-out resistance No cold flow Chemically inert Technical parameters pH 0 - 14 Temperature: t = -200 … +280 °C Pressure: p = Vacuum … 200 bar Density: 0,95 g/cm 3 (D11 - 0,7 g/cm 3) Minimum Surface pressure: VU (40 bar; 0,01) = 26 Mpa Maximum Surface Pressure: VO = 150 Mpa Minimum surface pressure in operation: BU < 5 Mpa Cold upset compression value: KSW = 40 % Remaining Thickness after compression approx. 15 % higher than values of D11. Main application Flanges Vessels Lids Joints Narrow flanges Bigger uneveness Tension sensitive components (e.g. sight glasses) Suitable for Chemical industry Food industry Maintenance Approvals DIN 28090-2 TA Luft 1,5 · 10 -8 mbar · l/(s·m) @ 250 °C FDA conformity EG 1935:2004 EU 10/2011 Form of delivery Sheet dimension: 1,000 x 1,100 mm and 1,500 x 1,500 mm Sheet gaskets thicknesses: 0.5 / 1.0 / 1.5 / 2.0 / 3.0 / 4.0 / 5.0...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

100 % PTFE Tape packing with cover braid and additional outside PTFE Tape Wrap Practical useful application data: max. temperature: +200 °C Characteristics Low coefficient of friction Good adaption to any kind of surface Non ageing or hardening Used as spiral guarantees simple assembly and disassembly in one piece Available in 2-15 mm Operating range Pressure [p max]: 20 bar, Velocity [v max]: 1 m/s Pressure [p max]: 20 bar, Velocity [v max]: 1 m/s Pressure [p max]: 100 bar Temperature: t = -200… +280 °C pH: 0 - 14 Density: 1.45 g/cm³ Practical useful application data: max. temperature: +200 °C Main application Valve Packing, easy to use Suitable for Chemical industry Universal use Installation and maintenance shops

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Carbonized synthetic fiber with PTFE impregnation and run in lubricant Practical useful application data: max. temperature: +140 °C Characteristics Good flexibility Rot proof Form stable packing Good value for the money Recommended surface hardness HRC50 Operating range Pressure [p max]: 15 bar, Velocity [v max]: 15 m/s Pressure [p max]: 100 bar, Velocity [v max]: 2 m/s Pressure [p max]: 100 bar Temperature: t = -50… +200 °C pH: 3 - 12 Density: 1.30 g/cm³ Practical useful application data: max. temperature: +140 °C Main application Centrifugal pumps Mixer Kneader Agitators Refiner Autoclave Gate valves Filter Suitable for Pulp and paper industry Sugar industry Waste water technology General maintenance Form of delivery This packing can be manufactured from 4 to 40 mm square as well as in intermediate, inch sizes and special measurements. 04 - 09 mm on 1 kg spool 10 - 15 mm on 2,5 kg spool 16 - 25 mm on 5 kg spool Special length, pre-cut or die formed rings on request. 1 kg...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KLN ULTRASCHALL AG

Germany

The machine of series KT can be applied universally. It is designed for the industrial part cleaning. Application fields: metal degreasing, electrical industry, optical industry, medical technology, maintenance and service etc. The compact design of the machine as 3-tank system guarantees a high cleaning quality together with space-saving location. The basic version consists of a heated ultrasonic tank (tank 1) and heated cascade rinsing (tank 2 and 3). Additionally a separate dryer corresponding to the size of the compact unit can be made available. The tanks are incorporated in a solid frame. Optionally a stainless steel base frame can be delivered. Armatures, tank and frame are made of stainless steel. All valves can be easily operated at front of the machine. All electrical operating elements are on the front of the machine. They are each assigned to the tanks.

Request for a quote

CBG COMPOSITES GMBH

Germany

With fako® Polishing paste No.9311 a care product is available, which is specially developed for the properties of Plexiglas, other acrylic glass and plastics. Polishes deep scratches and scrapes. Matt surfaces become clear again, scratches and scrapes are removed. Unsightly panes become flawless again! The treatment process is quite simple. Clean dirty surfaces with clear lukewarm water and a clean, soft viscose sponge until adhering dirt is removed. Put some fako® Polishing paste No. 9311 with lint-free fako® special polishing cloth on the moistened surface and polish under pressure in circular movements until the surface is dry. Polish to a gloss with another dry fako® special polishing cloth until the residues are removed and the surface is dry and clear. When removing deep scratches, the polishing process may cause matt spots. In this case we recommend an after-treatment with fako® Polishing milk No.9322.

Request for a quote

CBG COMPOSITES GMBH

Germany

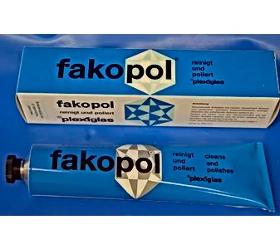

Our care products specially developed for Plexiglas help you to maintain the beauty and value of the material for years and decades. In comparison to silicate glass, two properties must be taken into particular consideration when caring for and cleaning acrylic glass. On the one hand the lower surface hardness and therefore higher susceptibility to scratches of acrylic glass, on the other hand the susceptibility of acrylic glass to solvents, especially organic ones. The use of incompatible polishing materials can cause stress cracks and matt surfaces. With fakopol® a care product is available, which is specially developed for the properties of Plexiglas, other acrylic glass and plastics. It has both cleaning and polishing action, removes wipe scratches and marks and is ideal for finishing of industrially manufactured parts. Gives long-lasting protection and glossy deep shine. The treatment process is quite simple.

Request for a quote

CBG COMPOSITES GMBH

Germany

fako® cleaning and polishing milk no. 9322 is a maintenance agent at your disposal that especially meets the demands of Plexiglass and other acrylic glasses, plastics as well as gel coat finish and fiberglass. It is used for regular care, removal of marks, dirt and minor scratches, oxidation, yellowing and chalking, gives plastics optimum protection with dust-repellent properties and preserves their natural brilliance. Matt panes become radiantly clear again. Maintenance is simple and straight forward with excellent results. The use of fako® Polishing milk does not lead to stress-corrosion cracking.

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

PARTS CLEANING FOR REPAIR AND MAINTENANCEImportant components require thorough and regular cleaning and maintenance, especially in industry, mechanical engineering and the automotive sector. Our TRT 83 x 37 cleaning trough removes grease, lubricants and other residues thoroughly and reliably, before the components are reinstalled. WHICH WORKPIECES CAN BE CLEANED? You can use the TRT 83 x 37 cleaning trough to effortlessly clean workpieces measuring up to 80 cm in length and 30 cm in diameter. Here are some examples: Bearing shells and covers Engine components Gearbox components Shafts and axles Labyrinth rings Bearings, bearing units and bearing housings

Request for a quote

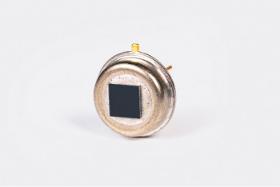

MICRO-HYBRID ELECTRONIC GMBH

Germany

The MTS1HIGHTEMP is a high-sensitivity, single-channel thermopile detector for precise, non-contact temperature measurement. Tanks to the housing with a soldered filter the detector is resistant to humidity, aggressive gases and other environmental influences. The high detectivity of up to 12.2*10^8 cm√Hz/W and the high sensitivity of up to 501 V/W are achieved by back gassing with krypton and the special chip design. Influences by humidity in the measuring environment are eliminated by a filter used in the transmission range from 8 to 14 µm. These properties allow the use in applications with high requirements, such as temperature monitoring of thermally indexed process parameters in the metal industry or testing of maintenance-relevant properties in the solar semiconductor industry. The detector can be used at ambient temperatures between -20 and 180 °C. An integrated thermistor for intrinsic temperature monitoring can compensate external temperature influences.

Request for a quote

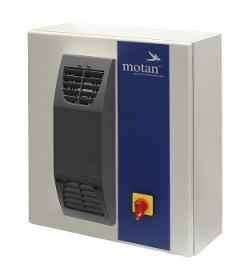

MOTAN-COLORTRONIC GMBH

Germany

motan offers a compact maintenance box for remote access via internet or company-internal intranet. The box is available as a standardised, ready-to-use system and includes a comprehensive software package for finding and analysing errors within system components as well as for monitoring and documenting system statuses. — Provides remote access to all motan CONTROLnet controls — Prevents unnecessary on-site service operations — Easy installation and compact design — Maintenance-free setup — Easy access via the Internet

Request for a quote

SCHÖNWOLF HAMBURG BY 7 SOLUTIONS GMBH

Germany

Specification of Protec Kleen: Rubber linkages at sleeves, hood, legs and waist Cover above zipper up to chin green, outside lying overlock-stitch Cat. III Type 5 +6 Available sizes for Protec Kleen: L XL XXL Application examples: Disposal of toxic waste (landfill, asbestos-, building- and roof refurbishment Dealing with solids hazardous material (agriculture, livestock breeding Chemical industry (solids) Food industry Pharmaceutical industry Cleaning and maintenance working (canal-, tank cleaning and resin coating Police investigations

Request for a quote

SCHÖNWOLF HAMBURG BY 7 SOLUTIONS GMBH

Germany

Specifications: This breathable overall protects user in working area, where protection against powdered and pulverized substances, aerosols or mist is necessary. The ventilated back ensures comfortable working and high comfort. Besides, sensitive products and workflows at contamination are protected by the carrier. Protective clothing according to CE Category III, typ 5 + 6, anti-statics according to EN 1149-1 Application ranges: Asbestos, pharmacy, nuclear, varnish and coating, tank-, canal- and industrial cleaning, maintenance work, dealing with hazardous substance etc. Material: Microporous laminate layer Version: Integrated rubber linkages at sleeves, hood, legs and back. Heightened cover above zipper, inside lying stitches, 3-part hood Datenblatt

Request for a quoteResults for

Industrial maintenance - Import exportNumber of results

27 ProductsCountries

Company type