- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- non-ferrous metals

Results for

Non-ferrous metals - Import export

HFP BANDSTAHL GMBH & CO KG

Germany

In coil coating, an organic coating is applied to the surface of a metal strip in a continuous process. The HUEHOCO portfolio includes both decorative and weather-resistant coatings as well as system solutions for a firm bonding of the metal strip with various rubber compounds and/or various plastics. For technical applications, there are also high-temperature resistant and non-stick as well as anti-friction systems, directly rubber- or plastic-coated metal strips. Since 1989 we have been the first company in the world to offer our customers the opportunity to have their goods delivered "endlessly" wound with more than 200,000 metres in a single strip on metal or plastic spools. Depending on our customers' requirements, we can process all wrought aluminium alloys, stainless steels, steel grades and non-ferrous metals available on the market in various degrees of hardness.

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

The VA-L series aluminium saws define a whole new performance class with their design. Servo-driven axes and a harmonic drive gear guarantee high-performance and process-reliable operation from aluminium alloys to copper and brass alloys. Due to the technical features and the associated sawing performance, the sawing results meet requirements regarding the surface of Rz < 8 µm and cutting tolerances < 0.1 mm. In many cases, further processing of the surface is therefore no longer necessary. All components of the aluminum circular saws and their processes are designed with this in mind. On the one hand, this includes material processing in terms of chip flow and minimum rest piece length, but also machine components of the latest generation. The VA-L aluminium saws are equipped as standard with pneumatic short-stroke cylinders for material clamping and do not use any hydraulics.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Golden anodizing specifically refers to creating a layer of golden oxide on the metal surface through the anodizing process. Golden anodized surfaces have a beautiful, metallic gold hue. The color is not only aesthetically pleasing but also provides additional durability and corrosion resistance to the metal.Decorative Purposes: Golden anodizing is often used for decorative purposes, such as architectural elements, jewelry, and consumer electronics. Functional Uses: Beyond aesthetics, it also serves functional purposes, such as preventing galling of threaded components and creating dielectric films for electrolytic capacitors. golden anodizing combines both functionality and aesthetics, making it a popular choice for various applications. Whether you’re looking to enhance the appearance of a product or improve its durability, golden anodizing is a versatile process that delivers impressive results.

Request for a quote

SCHOCK GROUP

Germany

SCHOCK offers complete metal assembly systems with integrated functional components such as soft-close mechanisms, adjustment mechanisms, and mounting systems. The SCHOCK High Cabinet Full Extension, measuring 600mm in length and designed for installation in wooden cabinets with a load capacity of up to 120 kg, is available as a ready-to-install assembly: Full extension, length 600 mm Load capacity of up to 120 kg Guided both at the bottom and top Mounting brackets with front adjustment Soft-closing self-retraction with a 50 mm movement in the lower and upper guides Set packaging – pre-assembled and includes installation instructions We are also happy to manufacture other assemblies upon request according to your specifications. Length: 600 mm Load capacity: up to 120 kg Comfort features: Soft-closing self-retraction

Request for a quote

ERDWICH ZERKLEINERUNGS-SYSTEME GMBH

Germany

ERDWICH hammer mills are the answer to the challenge of selectively shredding hard and brittle materials. Then again, ERDWICH hammer mills also take the pelletisation of rubbery materials – as preparation for downstream separation systems – in their stride. A tough customer? Just so. ERDWICH hammer mills are especially suited to metal, electrical and electronic scrap or swarf from steel or aluminium – and many other materials besides. Simple adjustability during operation also makes short work of the pelletisation of non-ferrous metals. The final fragment size is variable and can be changed during operation. That’s also a great example of the product’s flexibility in catering to a wide range of applications. For the selective challenges in life. ERDWICH hammer mills.

Request for a quote

SCHWEIZER GMBH & CO. KG

Germany

Hose cover against radiant heat maximum 450 ° C. Outside with aluminum foil and inside with glass silk or Kevlar fabric. Closed or with Velcro for quick installation and removal.

Request for a quote

SCHWEIZER GMBH & CO. KG

Germany

Protective hose, flame retardant and insulating against heat and flying sparks for cables

Request for a quote

SCHWEIZER GMBH & CO. KG

Germany

Protection against heat and flames up to approx. 1100 ° C for approx. 15 minutes and can withstand ambient temperatures of 73 ° C 260 ° C without limit. Inner life made of calcium silicate yarns, textured and twisted, good insulation properties.

Request for a quote

MICRO-EPSILON

Germany

Iron and steel represent a fundamental pillar in industrial production. Precision in the production process of metal plates, sheets and coils is crucial to the efficient use of scarce resources and economic success. As a manufacturer of measuring systems for the steel industry based on optical sensors, Micro-Epsilon offers a comprehensive portfolio without radioactivity that ensures More Precision in all applications regardless of complexity and material properties. With optimized sensor technology tailored to the respective application, innovative mechanical design, as well as cooling and protective devices, the systems meet the challenges of the processes. The high-performance signal processing and analysis software makes the systems the leading optical measuring systems on the market which detect the following parameters

Request for a quote

ALUMINIUMWERK UNNA AG

Germany

On request, we can supply aluminium alloys in the form of rod or bar. These are available in most of the commercially available aluminium alloys. The tolerances of extruded aluminium rods and bars can also be further improved by subsequent drawing. In recent years, ALUnna has specialised in the production of rod and bar meeting the highest quality standards. If you require a specific delivery option for rod or bar such as special testing then we will definitely find a solution for you.

Request for a quote

ANTHERMO GMBH

Germany

(Socked-Weld-Fittings) Straight from our warehouse We always have numerous versions of weld-in fittings (ANSI B 16.11) available in our extensive warehouse in Kamen. We can also supply you at short notice. We only deliver goods of European origin. 3 types of reducing inserts Insert reducers are available in three different types (see technical data sheet in the download area). Standards and special requests We supply weld-in fittings as standard in two pressure levels (3000 lbs and 6000 lbs) and in all common materials. We can also supply 9000 lbs and special materials if required. Technical specifications You can find more details, technical data and dimensions in our data sheet "Weld-in fittings" in the download area. We will be happy to provide you with information on special dimensions and custom-made products on request.

Request for a quote

ANTHERMO GMBH

Germany

Buttweld fittings according to ANSI B 16.9 Extensive stock range in special materials We can deliver Buttweld Fittings in numerous dimensions and materials directly from stock at short notice. Pipe bends with different radii (seamless and welded), T-pieces, reducers and caps essentially make up the product groups Buttweld Fittings (buttweld fittings). We only deliver goods of European origin. Special materials In particular, we supply special materials, which are generally only rarely requested, at short notice from our extensive range in stock. The following special materials are available at short notice: Low Temp Steel A 420 WPL6 / WPHY52 Chrome-Moly A234 Alloy WP5 Chrome-Moly A234 Alloy WP11 Chrome-Moly A234 Alloy WP22

Request for a quote

KOREMA® GMBH & CO.KG

Germany

Each expansion joint is tailor made. Layers of material are assembled on a frame which conforms exactly to the required profile. Bellows type expansion joints incl. or without reinforcing rings/frames. Diaphragms Expansion joints for varying cross sections and transitions. Construction from round to rectangular Construction according to drawings Non-standard high temperature seals Compound movement

Request for a quote

KOREMA® GMBH & CO.KG

Germany

The number of patents awarded to KOREMA® such as SIMIFLON® reflects an ongoing commitment to long term development of specialty materials which have opened new horizons and perspectives for the future. SIMIFLON®, (light colored material) is designated foodstuff quality and certified according to § 177.2600/177.1550 CFR of US Food and Drug Administration (FDA) as well as to EU Regulations EU 2002/72/EG and EU 10/2011.

Request for a quote

KOREMA® GMBH & CO.KG

Germany

This is the most installed version of the fabric expansion joints (KOREMA® type A3 or AC3 as well as B3 or BC3). The name »flange-type« is used for expansion joints located between pipe or duct end flanges. For existing plants, the flange design varies according to customers’ requirements or depending on the constructed steel design. For innovative designs KOREMA® will identify the suitable technical and economical solution. Special design: supplied as »open« multilayer expansion joint. On-site service available exclusively from the KOREMA® service team. Insulation is incorporated to protect the expansion joint against abrasion as well as for thermal insulation. The choice of insulating material, either mineral wool or ceramic felt, depends on the design temperature. For operation at or below dew point, a vulcanized elastomeric layer is available. Pre-assembled units, complete with liners and clamp bars, are available.

Request for a quote

KOREMA® GMBH & CO.KG

Germany

The belt type is the preferred choice for large diameter ducts. Delivery available with insulation pre-installed for high temperature applications. Insulation depends on temperature level of the medium. Insulation is necessary to protect the expansion joint from abrasive media. Corners of rectangular expansion joint frames should be radiused. Delivered as open-end construction for site completion. The final splice will be made on site. The storage and installation instructions as well as the necessary adhesives are included with each shipment. Pre-assembled endless units are complete with appropriate steel components which may be in several parts depending on the size. KOREMA®’s “on-site service” is available for site supervision.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Fewer steps to the finished workpiece With t project you can see all the variables of the bending process before you start the production. Adapted to the material and collisionfree, it makes it possible to plan and execute complex bending geometries. The virtual bending simulation determines exact bending timings and cutting lengths; it also tests tube geometries in advance for feasibility. Tube data and bending results are documented with accuracy and they can then be replicated 100% . All the most common interfaces are available for the import and export of data and connection to BDE or ERP over the network.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TRANSFLUID® MASCHINENBAU GMBH

Germany

The right system for every need There is a great variety of handling systems available, dependent on the length of the workpiece. For short tubes there are systems gripping from below with insertion axis and for long tubes there are systems handling from above. Both options can be used in our combination systems. They guarantee ideal access for the operator, so they can complete the setup and any maintenance operations in the best possible way. Transfer stations, turning modules for processing the tube in both directions within an installation and multiple grippers are available for optimized processes. Handling robots from many different manufacturers can also be integrated. The robots are used to move tubes/workpieces. A preassembly of different workpieces is also feasible in this case. The various components can be sorted using sensors and robots.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

We offer a great variety of loading systems for all the machines, dependent on the material, tube diameter and tube length. Tubes that have already been formed and with added components can also be loaded without any issues. The appropriate orientation is therefore very important, when loading the tube into the production cell. External workpieces, such as nuts, flanges, supporting sleeves can be added to the system in a controlled manner and included in any subsequent processing steps. A great variety of loading volumes is possible. Step feeder, Conveyor feeder, Chain feeder, Swivel arm feeder, Loading tables, Bowl feeder, Alignment station

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Clean, efficient, versatile. transfluid's knife cutting method is ideal for postbending cuts. Even with extreme geometries it is possible to have perpendicular cuts with sharp edges. In both cases both chips can easily be detected in the process. Extreme requirements are also not a problem, as up to two blades can be used. An internal mandrel can also optimise the process.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Created for precision. Our chipless orbital cutting machines make precise cutting results possible. Your tubes can then be directly processed further and for instance be formed straight afterwards. That saves time and money.

Request for a quote

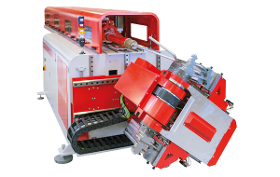

TRANSFLUID® MASCHINENBAU GMBH

Germany

In form, double strength. For the optimum processing of your individual requirements we simply combine our transfluid forming techniques, as simple as that, in particular the axial forming and the rollforming. The additional clamping unit makes even extreme forming feasible in one work sequence. The cutting before the axial tube forming is also possible, as well as the rollforming of a preformed geometry. That saves you valuable time. A strong partnership axial forming and rollforming. Our t form combination machines is the perfect union of axial and rolling tube processing, with up to 6 axial forming steps, two rollforming stations, two powered tool holders for flange orientation and an additional clamping unit. The horizontal clamping system makes the processing of bent tube geometries possible.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Powerful and fast forming. The type UMR tube forming machine uses smart operating technology with many preset settings that can be retrieved automatically to achieve perfect mirrorlike surfaces. When producing flaring with 20°90° angles, with a clamping length of 1 x D, the machine achieves perfect sealing surfaces. Flaring up to 90° can be produced in a single cycle. Tools can be changed extremely quickly. With the appropriate tools the machine can also close tube ends.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

All the options in one single machine forming, cutting, postbending cutting, threading. Our rotational technology increase the possibilities of forming on tubes with minimal expenditure on tools. All the drives are servoelectric by design and, if needed, CNCoperated. In our SRM typeforming machines, all the settings are preloaded, so there is no longer any need for costly adjustments. Different tool variants further expand the processing possibilities for chipless cutting or postbending cutting. The machines can produce internal and external profiles and can also roll in synchronicity thanks to a special tool head (inside/outside).

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Accurate forming with fast tool change. Our type REB axial t form forming machines, with their compression power of up to 1,300 kN are particularly wellsuited to effortlessly master complex geometries. With up to 6 forming steps in combination with an additional clamping unit they will satisfy almost all requirements. The operation is simple and intuitive with a touch panel. The sequence control makes each separate movement of the respective forming step userfriendly and fully programmable individually. We offer the option to equip our systems with electric or hydraulicnumerical drives. These forming processes can be completed stepwise in transfer system to achieve very short cycle times. Simultaneous axis movements ensure fast production processes and an efficient and highly dynamic production.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Maximum bending freedom. The robotic bending technology combines the greatest versatility in manufacturing steps and simple handling. The robotic head is equipped with a clockwise and counterclockwise bending head, so that bending can happen in both direction once clamped. The eight synchronized and fully electric axes give maximum versatility when processing tubes. The bending process on tubes, including the processing at the ends and addon component can be done without any problems. The addon components can be positioned automatically, if needed. A radii/plane changer with up to 6 tools per bending system is integrated to give maximum flexibility..

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

We have developed these t bend machine solutions strong> for fast and efficient processing times. They are specifically tailored to the challenges of individual bends. Whether the system is manual or automated, they will deliver the best possible results. Highly efficient This manufacturing accelerator offers the profitable efficiency of our high performance bending machines for the manufacturing of hydraulics fittings together with Top Speed that is what the "AB" series stands for. For individual bends from 1xD to 1,500 mm bending radius for small and large radii, for demanding materials with thin walls, the high performance (HP) machine series guarantees the perfect bending result.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Stable, flexible and economical. This series will win you over with its special stability and performance. Individual pieces and small series can be produced in an extremely economical manner with this machine concept. The use of highvalue components ensure the machine's durability.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

For better efficiency. The electric axes can be programmed in synchronicity to give optimum cycle times.Tools for bending on multiple levels with automated tool change makes it possible to achieve various radii and the most extreme geometries on tubes. With our clockwise/counterclockwise bending machines – also available with push bending function – the most complex bends become reality with great accuracy.

Request for a quoteResults for

Non-ferrous metals - Import exportNumber of results

319 ProductsCountries

- Germany (319)

- Berlin and region (2)

- Bonn, Düsseldorf and North Rhine and Westphalia (218)

- Bremen and region (1)

- Frankfurt am Main and Hesse (13)

- Hamburg and region (1)

- Hannover and Lower Saxony (15)

- Leipzig and Saxony (1)

- Mainz and Rheinland-Pfalz (6)

- Munich, Nuremberg and Bavaria (32)

- Potsdam and Brandenburg (1)

- Stuttgart, Freiburg and Baden-Wurtemberg (28)

- Weimar and Thuringia (1)

Company type

Category

- Pipe and tube fittings - ferrous metal (158)

- Pipes and tubes - ferrous metal (16)

- Wires and cables - ferrous metal (14)

- Profiled sheets - ferrous metal (12)

- Wires and cables - non-ferrous metal (12)

- Nozzles - ferrous metal (8)

- Hand tools, non-power (8)

- Pipe and tube fittings - non-ferrous metal (7)

- Silicones (7)

- Boarding - non-ferrous metal (6)

- Expansion joints - non-ferrous metal (4)

- Machine tools, metal machining - parts and accessories (4)

- Metal detectors (4)

- Bars - non-ferrous metal (3)

- Sections - non-ferrous metal (3)

- Flexible tubes - non-ferrous metal (3)

- Pipes, bent - ferrous metal (3)

- Anti-corrosion products, chemical (3)

- Cements, special (3)

- Sawing machine tools (3)