- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- piping systems

Results for

Piping systems - Import export

FRÄNKISCHE INDUSTRIAL PIPES GMBH & CO. KG

Germany

Our ducts and corrugated tubes for engine air intake can feature flexible sections, smooth sections and matching connections to meet customers specifications. This is a reliable way to connect a corrugated tube to the connecting cuff and allows for time-saving assembly. The advantages are obvious: Weight can be reduced, and great flexibility with high flow quantity and high strength in the cuff section are guaranteed. Available materials/maximum operating temperature: PP 100°C PA6 120°C PA12 120°C Application: Automotive, agricultural machinery and construction engines, in applications that require small bend radii and/or dynamic stress environments, connecting lines between various components, engine air intake

Request for a quote

FRÄNKISCHE INDUSTRIAL PIPES GMBH & CO. KG

Germany

Our fuel lines ensure the safe transport of aggressive substances and allow for easy and time-saving installation thanks to matched connectors. All lines, smooth sections, cuffs and Quick connectors are made to customers specification and guarantee a reliable connection. The flexibility of our corrugated tubes provides a key advantage especially in tanks where space is limited. Depending on the material, the systems are resistant to chemical substances and withstand temperatures up to 140°C. Available materials / maximum operating temperature: PA6 120°C PA11 120°C PA12 120°C PA612 140°C 1-, 2-, 3-, 4- or 5-layer design Other materials available upon request Application: Automotive, agricultural machinery and construction engines; in engine compartment, e. g. supply lines, return lines, jet-pump lines, compensating lines, fuel supply lines, filling channels

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Stainless steel flanges are a crucial component in various piping systems, providing ease of assembly and strength in connecting pipes, valves, pumps, and other equipment. They serve as a plate for covering or closing the end of a pipe and are commonly used in plumbing, oil and gas, petrochemical, and food industries due to their durability and corrosion resistance. Types and Specifications Stainless steel flanges come in several types to suit different applications: Weld Neck Flanges: Designed to be welded to the pipe. Suitable for high-pressure applications. Slip-On Flanges: Easily slide over the pipe and are welded in place. Socket Weld Flanges: Used for smaller, high-pressure piping. Threaded Flanges: Attached without welding, ideal for low-pressure applications or pipes with a thin wall. Blind Flanges: Used to seal the end of piping systems or pressure vessel openings. Lap Joint Flanges: Used with stub end fittings for applications requiring frequent dismantling.

Request for a quote

HS UMFORMTECHNIK GMBH

Germany

Pipe bracket with rubber inlay

Request for a quote

SPANSET SECUTEX GMBH

Germany

The noise levels in pipe and rod raising systems can be very high. A chute lined with secutex pipe modules ensures that noise levels are reduced and that surfaces are protected. The secutex material with inset perforated plates is particularly wearresistant and cushions the movement of pipes and rods very well. The cast sections are attached using drilled attachment holes. Segment sizes and joins are manufactured according to client requests.

Request for a quote

FLUX-GERÄTE GMBH

Germany

Pump F 430 PP 100/50 in polypropylene was designed for higher delivery pressure. Instead of a rotor, it is equipped with an impeller in a pump housing. In connection with the powerful FLUX motors the pump delivers a far higher pressure of over 3 bar compared to pumps with semi-axial rotors. This makes it especially convenient for conveying media out of e.g. IBCs and other containers into higher lying pipe systems or out of an IBC in the basement to a higher floor. Benefits: - The pump has a significantly higher delivery head in the range up to 40 l/min compared to pumps with half-axial rotor (Z-rotor) - Allows the conveying of media out of an IBC stock in the basement into higher floors - Ideal for pumping media into a higher lying pipe system - Can be used as a supply pump of line networks e.g. for feeding of process water

Request for a quote

RG + SCHWINGUNGSTECHNIK GMBH

Germany

Vibration dampers of the series GAB are especially used to stabilize your pipe system. You can use these elements to absorb thermal expansion of the pipes, too. These elements are often used in the field of plant engineering. Depending on the chosen series you are able to couple your system with this elements by a welding profile or a fork head. RG+ offers these suspensions in the following designs: GAB-( )-2 with one fork head on each site GAB-( )-5 with one fork head on one site and a welding profile on the other

Request for a quote

F.E.S. GMBH

Germany

Vacuumfilters are used for the cleaning of contaminated cutting fluids in metal processing and rolling mill applications. Clean cutting fluids lead to longer tool life, improved surface quality of workpieces or rolled goods, and efficient heat dissipation at the processing or forming point. Advantages: Compact size Excellent filtration results Low installation effort Low maintenance requirements Affordable price Optional configuration without consumable filter fleece, with continuous filter belt, and washing device Significantly lower consumption of filter fleece compared to gravity filter systems during challenging filtration tasks and fleece operation Operating Principle: The contaminated cutting fluid flows through a piping system (1) and an inlet distributor (11) into the dirt chamber (2) of the underpressure filter tank.

Request for a quote

KB SCHMIEDETECHNIK GMBH - A GERMAN DROP FORGE - CLOSED DIE FORGINGS - ALL STEEL GRADES

Germany

Forged components for nuclear reactors, boiler systems, piping Valves are pivotal in various industrial contexts. Forged parts designed for nuclear reactors, boiler assemblies, pipeline construction, and safety valves are crucial elements in various industrial applications. Safety valves, typically pressure relief valves, stand out as paramount safety features within most systems. Their primary function is to safeguard pressurized vessels like steam boilers, reactor vessels, and pipelines from potentially hazardous pressure surges. In the event, that pressure exceeds safe limits, these valves release trapped gases, vapors, or liquids either into the atmosphere or into designated manifold systems. The West German drop forge KB Schmiedetechnik GmbH in Hagen (NRW) boasts decades of proficiency in crafting drop-forged components tailored for pressure applications compliant with the Pressure Equipment Directive (PED) and for nuclear facilities adhering to KTA, AVSD, and RCCM standards.

Request for a quote

GEMÜ GEBRÜDER MÜLLER APPARATEBAU GMBH & CO. KG

Germany

The pressure relief valves GEMÜ N085 and N185 protect the plant and the piping system against gauge pressure and reduces pressure peaks. The third pipe spigot enables the valve to be installed in the main pipe. If the pressure increases, the spring is raised and the valve opens. The pressure is reduced to the preset value and can escape via the third pipe spigot into an adjacent pipe. If the pressure falls, the spring force presses the diaphragm in the direction of the seal seat and it is closed. The spring force can be adjusted as required using a set screw. - Valve adjustments can also be made under working pressure. - The optimization of piston, springs and control face ensures good control characteristics - The actuator is hermetically separated from the medium

Request for a quote

ROLEC GEHÄUSE-SYSTEME GMBH

Germany

aluDISC is the first round aluminium enclosure for industrial electronics and electronic components. The unique shape integrates perfectly into industrial machinery and piping systems. Whether fitted to the wall, integrated into a pipe system or a machine body – the round shape always makes a good impression. The lid already has a recess to accommodate membrane keypads or a front plate. A version with a fold-out, transparent lid with ingress protection IP 65 is also available. The snap-on design covers hide the screw channels. The enclosure can be mounted while closed. Practical lid supports are also available. Fastening domes in the bottom and the lid to accommodate e.g. circuit boards or mounting plates are also integrated as standard. Matching cable glands and more can also be supplied by us.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

These consists of a multitude of individual components, such as Our piping and duct systems are dimensioned and designed taking into account aspects of flow dynamics and energy. Depending on the intended purpose of use, they are manufactured from galvanised sheet steel, from thick-walled sheet steel (painted or hot-dip galvanised), from stainless steel or from plastic.

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

The STAUFF Clean System comprises of a pneumatic launcher and a range of specially designed nozzles and projectiles. The launcher uses standard industrial compressed air pressure between 6 and 8 bar / 87 and 116 PSI to propel a foam projectile through the nozzle and into the pipe, tube or hose bore to have their inside surface cleanedfrom any unwanted contamination. This provides a safe and environmentally friendly tool that requires little formal expertise to operate and apply. The launcher is the part of the system that controls the air supply to propel the projectile from start to finish of the cleaning job. The nozzles are specially designed to affect an airtight seal on any pipe, tube or hose with or without end fittings. Its main purpose is to compress the foam projectile allowing it to enter the internal diameter of the pipe, tube or hose to be cleaned. The projectile is the part of the system that does the cleaning: The foam projectile is sized to be approximately 15 %...

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

For the conveying of filtered-out materials to silos or containers. Pneumatic low-pressure conveyor systems For the conveying of filtered-out materials to silos or containers and for conveying distances of up to 200 m. The conveying air stream is generated by one or more fans. Product description Pneumatic low-pressure conveyor systems can be implemented as a single-pipe system or a ring system. In the case of the single-pipe system, a final separator in the form of a filter or a cyclone is always necessary. In a ring system the conveying air is driven in the ring. In this case the silo or container acts as the separator. Light dust particles that are not separated in the silo or container initially remain in the circulation. With most materials the fine dust particles tend to attach themselves to the coarser ones and are thus separated with them. Hence, a concentration of the fine dust particles in the conveying stream is avoided as far as possible. The loading of the conveying stream essentially depends on the grain size, density and form of the material to be conveyed. As a guiding value, one may assume 250 - 300 g/m³. Higher loads are possible under certain conditions. In cases where there is a high amount of material, e.g. in planing works, where the splinters are directly removed and transported away for further use, this can also be realised with a ring system and several containers. Switchover takes place automatically when the container signals that it is full. Containers are exchanged during operation.

Request for a quote

INOEX GMBH

Germany

The WARP CP is an inline measuring system with radar-based wall thickness sensors for detecting the various structures of a corrugated pipe. Outer and inner diameters, as well as the wall thicknesses of the bell, crest, liner, and valley can be resolved. The system is available for large, corrugated pipes with diameters from 300 mm. Since the corrugated tube has different structures, it is therefore necessary to assign the measurement data to the corresponding position on or in the tube. The WARP-CP algorithms do this automatically and prepare the data for the user in such a way that he receives different graphics and corresponding measurement data for each structure. Other advantages/features: — Non-destructive, contactless, and automated inline measurement of all relevant structures of the corrugated tube — No waste due to destructive measurement — Repair of critical thick and thin spots — Saving of material overweight in the end product

Request for a quote

INOEX GMBH

Germany

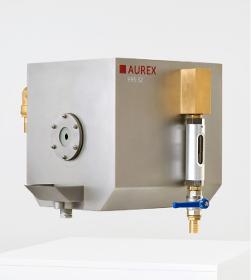

The AUREX ERS uses the measuring technique of the Electronic Rotating Scanner (ERS) principle. With this active-passive measurement, every point of the measured object is detected 100% in longitudinal and circumferential direction, so that even minimal tolerance deviations are detected. Coextruded layers can also be detected as soon as they are physically detectable by ultrasound. The AUREX ERS is complemented by the optional "Quality Check", a wall thickness error check. The "Quality Check" detects anomalies on the surface, in the material and on the inner surface of the pipe. Further advantages/features: — 100 % wall thickness measurement for pipe dimensions up to 630 mm in diameter — Electronic rotation up to 16,000 rpm — Evaluation of vertical and angular signals reflected from the tube by activating adjacent sensors — Highest measuring resolution and identification of smallest production variations

Request for a quote

INOEX GMBH

Germany

WARP 100 is an inline pipe measuring system for wall thickness and diameter measurement at up to 38 measuring points and 19 axes. More than 1100 measurements per second guarantee a gapless measurement. This is particularly important for pipes with high quality requirements, such as pressure or gas pipes. The maximum line speed for 100% coverage is up to 11.8 m/min. WARP 100 is available in three sizes and can be used for measurement in the diameter range from 25 to 630 mm. Measured variables such as wall thickness, diameter, ovality, eccentricity as well as process conditions (e.g. sagging) are precisely recorded, documented, and further used for automatic process control. Other advantages/features: — Measurement with 100% pipe coverage in diameter range from 25 to 630 mm (three sizes) — Wall thickness range from 2 up to 125 mm (depending on material) — Detection of thin sections within the tube — 100% documentation of production according to specifications

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

INOEX GMBH

Germany

The QUANTUM 360 has a terahertz sensor that reverses along the pipe to be measured. The coverage corresponds to a full 360° over the entire circumference of the pipe. This allows a very accurate overview of all process parameters. After selecting the pipe recipe, the QUANTUM 360 detects the pipe position, centers itself automatically to the pipe via a cross table and the sensor is automatically moved into focus. When changing dimensions, only a change of the pipe recipe is required. Due to the high measuring frequency, wall thickness, diameter and multi-layer measurements are possible with layer thicknesses from 100 μm. Other advantages/features: — Detailed product information (wall thickness, diameter, eccentricity, ovality) — Process automation through proven control principles — Non-contact measurement, no seals required — Material savings of up to 5% — Coextrusion measurement

Request for a quote

INOEX GMBH

Germany

The AUREX MK is the complete solution for pipe dimensions from 0.5 - 400 mm. It enables compliance with the specified tolerances for wall thickness, eccentricity, diameter and ovality. Thanks to the combination of high-quality electronics with innovative measuring methods, up to 7 layers from 0.02 mm wall thickness can be evaluated. In addition to the standard measurement for control and visualization of the product, the "Fast Specification Check MK/AFM" is optionally available, which allows a fast wall thickness check. Since the AUREX MK does not completely cover the pipe at the circumference, this wall thickness check can be used, for example, to detect typical thin section rings caused by jerking of the produced pipe at the entire circumference.

Request for a quote

INOEX GMBH

Germany

The AUREX AFM measuring chambers are flanged directly to the outlet of the vacuum tank. With up to 24 sensors a reliable and precise ultrasonic measurement with a centric pipe guidance is guaranteed. The measuring chambers are available for a diameter range of 63 - 630 mm. The AUREX AFM performs wall thickness and diameter measurement in parallel according to the number of sensors. Optionally, the AUREX AFM can be equipped with the "Fast Specification Check MK/AFM", which enables a fast wall thickness check. Since the AUREX AFM does not completely cover the tube at the circumference, this wall thickness check can, for example, detect typical thin section rings, which are caused by jerks of the produced tube at the entire circumference. Further advantages/features: — Large measuring range with measuring range extension — Parallel measurement of wall thickness and diameter — Very robust mechanics — Separable adapter for easier seal change

Request for a quote

FRÄNKISCHE INDUSTRIAL PIPES GMBH & CO. KG

Germany

Our duct systems can feature flexible sections, smooth sections and tailored connections to meet customers specifications. This is a reliable way to connect a corrugated tube to the connecting cuff and allows for time-saving assembly. The advantages are obvious: Weight can be reduced, and great flexibility and high strength in the cuff section are guaranteed Available materials / maximum operating temperature: PA12 120°C PA6.10 120°C PA6.12 140°C PPA 180°C

Request for a quote

Z.I.S. KUNSTSTOFF GMBH

Germany

Split pipes made of PE-HD with snap-on system For the subsequent protection of cables, which have already been laid, or for repairing damaged pipe systems - Sealed against fine sand - Reusable - No sleeve required - Extendable to any length - The joining of the split pipes does not require any tools - A continuous pipeline is achieved by offsetting the top split pipe (no sleeves required) Use as a repair split pipe: Our 120 mm x 5,0 mm split pipe is constructed in a way that the locking mechanism is on the outside of the pipe, which means that the inner diameter of 110mm is fully usable without dimensional limitations. Therefore, the split pipe can be clamped over the defective cable conduit like a plaster over a wound. You don’t need to saw off the damaged pipe section! Standard design: Material: PE-HD Locking system: snap-on locking Colour: black Length: 3 m

Request for a quote

PERKUTE MASCHINENBAU GMBH

Germany

Cleaning of valve housings with Clean-o-mat PF 150 Frontloading system with high basket load for cleaning of valve housings. The internal cleaning is ensured by an adaptive nozzle pipe system.

Request for a quote

PERKUTE MASCHINENBAU GMBH

Germany

The extensive power spectrum of this solid production series in combination with the standard equipment coordinated optimally sets new standards in cleaning technology. The solid interpretation of the machine components connected with the modern design of the easy-care machine case completes the innovative machine concept. By the choice of specific accessory articles many possible applications open up. The PERKUTE-system: economically - environmental – effektive Basic equipment Made of stainless steel Compact and sturdy construction Modern design Powerful washing pump High permissible basket load Low water pressure switch as dry-run protection Tank cover in the return flow, filterbasket incl. Programmable operation operating counter incl. Housing insulation Loading carriage incl. Grate bearing Digital temperature indication Electronic basket drive (PF 100; PF 150) Square blast pipe system (PF 200) Rotation blast pipe system (PF 300) Adjustable feed

Request for a quote

KAMPMANN GMBH & CO. KG

Germany

AtmosFeel The side air outlet eliminates draughts and creates a comfortable atmosphere of well-being – introducing AtmosFeel. Cooling and heating Select a visually restrained room cooling and heating unit with the chilled water cassette. Optionally introduce fresh air. Do you notice anything? No? You shouldn´t. The cassette design on the ceiling is just as discreet as its low noise levels. With a matching frame The product range gives you complete freedom of choice: multi-stage or 0 – 100 % EC fans, 2-pipe or 4-pipe systems, five different sizes and more. Everything under control The chilled water cassette comes complete with the fully automatic KaControl. Or you connect it to an existing external BMS.

Request for a quote

FRÄNKISCHE INDUSTRIAL PIPES GMBH & CO. KG

Germany

Cable protection tubes for industry with different properties: With our corrugated tubes, threaded tubes, protective hoses and connection fittings, you are well equipped for all eventualities. They easily withstand both low and high temperatures and also have excellent fire protection and flame properties. Many of our products for industrial cable protection systems are also distinguished by the following features: self-extinguishing halogen-free cadmium-free low flue gas emission weatherproof chemical permanence antistatic Accessories for your industrial cable protection: Of course FRÄNKISCHE Rohrwerke also supplies the appropriate accessories for your industrial cable protection. Mounting clips (with and without base) Mounting rails System holder (Corrugated) pipe clamps PETP - pipe edge protection v.m. Our products for industrial cable protection systems are suitable for all industrial pipe systems from our range.

Request for a quote

SANHA GMBH & CO. KG

Germany

The innovative SANHA installation system NiroTherm® combines high-quality NiroTherm® press fittings with a black sealing ring made from EPDM (=ethylene propylene diem rubber) and NiroTherm® stainless steel system tubes. The system is produced from the material 1.4301 (AISI 304). Due to the well-known corrosion resistance of stainless steel, NiroTherm® offers installers therefore a real alternative compared to conventional steels when it comes to closed systems in humid atmospheres such as screed. Since it needs considerably less isolation against humidity*, the installation is faster and labour costs accordingly lower. In addition to the system description, NiroTherm® system press fittings are marked on the outside with a red dot. * This does not affect thermal insulation necessitated by national energy efficiency laws.

Request for a quote

SANHA GMBH & CO. KG

Germany

The innovative SANHA installation system NiroTherm® combines high-quality NiroTherm® press fittings with a black sealing ring made from EPDM (=ethylene propylene diem rubber) and NiroTherm® stainless steel system tubes. The system is produced from the material 1.4301 (AISI 304). Due to the well-known corrosion resistance of stainless steel, NiroTherm® offers installers therefore a real alternative compared to conventional steels when it comes to closed systems in humid atmospheres such as screed. Since it needs considerably less isolation against humidity*, the installation is faster and labour costs accordingly lower. In addition to the system description, NiroTherm® system press fittings are marked on the outside with a red dot. * This does not affect thermal insulation necessitated by national energy efficiency laws.

Request for a quote

SANHA GMBH & CO. KG

Germany

The SANHA®-Therm Industry installation system consists of tried and trusted SANHA®-Therm Industry system press fittings with a red moulded FKM (fluoro and perfluoro elastomer) sealing ring for high temperature applications and SANHA®-Therm carbon steel system pipes.

Request for a quoteResults for

Piping systems - Import exportNumber of results

164 ProductsCountries

Company type

Category

- Pipe and tube fittings - ferrous metal (105)

- Precision measuring instruments (7)

- Hoses, pipes and tubes - plastic (4)

- Copper and copper alloys (3)

- Gas fittings (2)

- Industrial piping (1)

- Fittings, pipe, tube and hose - plastic (1)

- Air conditioning equipment (1)

- Air purification - equipment and systems (1)

- Air-conditioning systems, vehicles (1)

- Clamp collars, plastic (1)

- Cleaning of stables and stalls - machinery and equipment (1)

- Cooling towers (1)

- Detergents and soaps - professional (1)

- Drainage systems and equipment (1)

- Forming - steels and metals (1)

- Industrial equipment hire (1)

- Industrial hardware (1)

- Nuclear power stations (1)

- Pipes and tubes, aluminium (1)