- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- mechanical seals

Results for

Mechanical seals - Import export

BILLI DICHTUNGSTECHNIK GMBH

Germany

Designing pumps, compressors and other equipment, the aim is to prevent leakage into that can emerge at any point by liquids or gases. To solve this problem very often are used mechanical seals. To obtain the desired sealing function and an adequate lifetime of the mechanical seal,the preconditions must be fulfilled within the permitted tolerances at any time: parallelism of the sealing surfaces perpendicularity of the seal faces to the rotation axis elastic contact of the sealing surfaces existence of a lubricating film between the two sealing surfaces Usually the sealing capability of the mechanical seal against shaft or housing is obtained with the secondary seals, as O-rings, bellows or boots In conjunction with the International Organization for Standardization (ISO) and their standards (ISO 3069), the German Industrial Standard (DIN) published proposals for standard mechanical seals with DIN EN 12756 (24960).

Request for a quote

BILLI DICHTUNGSTECHNIK GMBH

Germany

Our mechanical seals for compressors are suitable for use in: Bitzer®, Bock®, Carrier®, Carlyle®, Carrier-Sutrack®, Copeland®, Dunham Bush®, Frick®, Gram®, Grasso®, APV Halls®, Howden®, Lightfoot®, Sabroe®, Stal®, Thermo-King®, Witt®, Zanotti® etc.

Request for a quote

BILLI DICHTUNGSTECHNIK GMBH

Germany

Our mechanical seals for the shipping industry are suitable for use in: Allweiler®, Bornemann®, IMO®, Kral®, KSB®, Netzsch®, Seepex®, Thune Eureka®, Behrens®, Garbarino®, Grundfos®, Gulnard®, Hamworthy®, Heishin®, Herborner®, Iron®, JMW®, Jugoturbina®, Kikai®, Leistritz®, Merser®, Naniwa®, PCM®, Rickmeier®, Samson®, Scanpump®, Shinko®, SIHI®, Speck®, Sta-Rite®, Svanehoj®, Taiko®, Teikoku®, Worthington® etc.

Request for a quote

BILLI DICHTUNGSTECHNIK GMBH

Germany

Mechanical seals for the food industry are used in a very broad range of industry sectors, such as in breweries, wine and cider productions, beverage industry, cheese dairies, creameries, juice productions, producers of "soft drinks", etc. In this case, the various components of the seal are made of FDA approved materials. Our mechanical seals are suitable for use in: KSB ®, A.P.V. ®, Alfa Laval ®, FRISTAM ® Lowara ®, TUCHENHAGEN ®, HILGE ®, INOXPA PROLAC ®, INDAG ®, GRUNDFOS ®, JABSCO ®, JOHNSON ®, etc.

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

Heavy Duty Grease Description Castrol Molub-Alloy 3136 has been developed for use in applications with high loads, adverse environmental influences and low movement speeds. It is successfully used in all known heavy industries such as steel, mining or construction. Castrol Molub-Alloy 3136 is a mineral oil-based lithium soap grease. It has a good sealing effect against contamination if mechanical seals are damaged or missing (sealing grease collar on the bearing). Castrol Molub-Alloy 3136 provides effective protection against corrosion and is resistant to aging. It is free of heavy metals such as antimony and lead. Light-colored solid lubricants offer excellent emergency running properties in the event of a lack of lubricant.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DIERMEIER ENERGIE GMBH

Germany

Castrol Molub-Alloy 777 NG series (05/20/2021) High-duty lubricating greases Description Castrol Molub-Alloy 777 NG high-duty lubricating grease was developed for high loads in unfavorable environmental conditions . It is manufactured and additived in such a way that it can withstand shock and heavy loads such as those found in the steel industry or in the construction industry, mining and forestry. To produce Castrol Molub-Alloy 777 NG, a mixture of high viscosity mineral oils and polymers are used, which form a tough lubricating film that can withstand shock loads and vibrations. The shear-stable thickener has a very good sealing effect against contamination if mechanical seals are damaged or missing (sealing grease collar on the bearing). The grease contains solid lubricants whose structure has been selected to meet the requirements of harsh operation in heavy industry . It shows a good affinity for metallic surfaces.

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

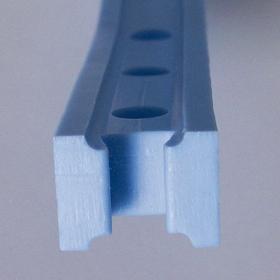

Economical storage independent from shaft diameter, follow the packing diameter by 1.2 m-pieces Replacement for machined lantern rings Universal use, excellent chemical and thermal resistance Easy to remove with packing extractor No corrosion and wear of shafts, no canting during use Technical parameters Temperature: t = -100 … +250 °C pH 0 - 14 Main application Pumps with mechanical seals with flush port Stuffing box packings with lantern rings Suitable for All Industries Approvals FDA conformity Form of delivery 1.2 m per roll, special length 2 m on request Special sizes on request Packing dimension The hight of the lantern ring depends on the size of packing (see chart). Article (Lanternring) Height x width [mm] Height x width [imp.] STAR-AQUA BLUE 8 mm 7.6 x 11.4 0.30 x 0.45 STAR-AQUA BLUE 3/8" 9.0 x 13.2 0.35 x 0.52 STAR-AQUA BLUE 10 mm 9.4 x 13.2 0.37 x 0.52 STAR-AQUA BLUE 7/16" 10.5 x 14.3 0.41 x 0.56 STAR-AQUA BLUE 12 mm 11.1 x...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

PROCONTROL Precise metering and constant pressure of sealing water (p = 1 bar above media pressure) - environmental protection and cost reduction in fact of reduced seal water consumption Flow and pressure monitoring - protects the aggregate from failing (inductive alarm system) Stable and compact construction guarantees safety and simple handling Corrosion and temperature resistant Displays are easy to read and clean With an inductive switch (special component) alarm system can be used. Technical parameters Flow range 0.5 up to 1.5 ltr/min 0.5 up to 3.0 ltr/min 1.0 up to 8.0 ltr/min 2.0 up to 15.0 ltr/min Temperature: t = … +80 °C Pressure: p = 10 bar (Option 25) Main application Pumps with mechanical seals with flush port Stuffing box packings with lantern rings Suitable for All Industries Accessories and options Pressure valve for creating blocking pressure Pressure Gauge Stand Inductive switch Hoses, connecting...

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

120 - 5300 CFM / 195 to 9,000 m³/h The NASH Vectra was designed around a modular platform using the most advanced computer aided design techniques, such as 3D solid modeling and finite element analysis (FEA). The modular platform offers the advantage of two versions with numerous common parts. The Vectra GL model, available from 120 to 830 CFM (200 to 1,500 m³/hr), is ideal for general industrial applications. It comes standard with internal mechanical seals and many Nash patented innovations including gas scavenging. The Vectra XL model was designed to meet the stringent requirements of many CPI applications. Whether operating as a vacuum pump or compressor, it features a 30 PSI (2 bar) differential capability. It is available in ductile iron or 316L stainless steel with a variety of shaft sealing options. Sizes range from 120 to 5,300 CFM (200 to 9,000 m³/hr). The NASH Vectra can be operated within a wide range of operating speeds, with numerous 50 and 60 HZ direct drive speeds. This increased turndown capability makes them ideal for varying load applications when driven by VFD's.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

3000 - 16000 CFM / 5,100 to 27,200 m³/h The NASH 905 is a redesign and upgrade of the NASH 904. Capacities of the 904 pumps range upward from about 3,000 CFM at vacuum. These durable compressors can handle excess liquid carryover without any difficulty, even if it arrives as massive slugs. 904 compressors are found in many industries, including Paper, Chemical, and Mining. The 905 series has been designed to provide superior reliability and performance in harsh applications such as chemical processing or geothermal power generation. Constructed of 316L stainless steel, the 905 series offers excellent corrosion resistance and can be outfitted with a variety of mechanical seals. It also includes a patented gas scavenging feature.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

15 - 5300 CFM / 195 to 9,100 m³/h The NASH Vectra was designed around a modular platform using the most advanced computer aided design techniques, such as 3D solid modeling and finite element analysis (FEA). The modular platform offers the advantage of two versions with numerous common parts. The Vectra GL model, available from 120 to 830 CFM (200 to 1,500 m³/hr), is ideal for general industrial applications. It comes standard with internal mechanical seals and many Nash patented innovations including gas scavenging. The Vectra XL model was designed to meet the stringent requirements of many CPI applications. Whether operating as a vacuum pump or compressor, it features a 30 PSI (2 bar) differential capability. It is available in ductile iron or 316L stainless steel with a variety of shaft sealing options. Sizes range from 120 to 5,300 CFM (200 to 9,000 m³/hr). The NASH Vectra can be operated within a wide range of operating speeds, with numerous 50 and 60 HZ direct drive speeds. This increased turndown capability makes them ideal for varying load applications when driven by VFD's.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

3000 - 16000 CFM / 5,100 to 27,200 m³/h The NASH 905 series has been designed to provide superior reliability and performance in harsh applications such as chemical processing or geothermal power generation. Constructed of 316L stainless steel, the 905 series offers excellent corrosion resistance and can be outfitted with a variety of mechanical seals. It also includes a patented gas scavenging feature. All 904 models are still available from Gardner Denver Nash, the original designer and manufacturer. Whether you have an existing 904 pump running in your plant that is in need of service, repair, or replacement with a new or remanufactured duplicate 904/905 pump, Gardner Denver Nash is there for all of the above.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

Available in both cast iron and stainless steel construction, the 2AV2 family provides up the 600 m³/hr (360 CFM) in a compact design, while giving you the flexibility of choosing the right motor for your needs. The pedestal design of the 2AV2 provides the benefit of flange mounting the motor to a self-supporting pump. No coupling guards, base plates or cumbersome shaft alignment is needed. The 2AV2 is an ideal choice when you need a compact and economical pump for an explosion proof or severe duty application. We focused on durability and dependability when we developed these liquid-ring pumps. With a reinforced stainless steel shaft and sealed bearings, the 2AV2 can provide up to 20,000 hours of maintenance-free operation. The 2AV2 is expertly designed and manufactured to be quiet and vibration free. With sound pressure levels of less that 75 dBA, it complies with the strictest noise standards, eliminating the need for additional sound attenuating devices. Advantages at a glance Compact Rugged design for reliable operation and long service life Precision-balanced rotor Suitable for NEMA C flange motor frames Low installation costs Easy to service Standard mechanical seal Main Applications Plastics Industry Chemical Industry Medical Technology Food and Beverage Industry General Industry

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

High Capacity Monoblock Pumps Available in cast iron construction, the 2AV1 family provides capacities up to 600 m 3/h (360 CFM) in a compact monoblock design. When compared to conventional pumps, the 2AV1's monoblock design delivers the benefits of a simple, compact and economical installation. Since the pump and motor are integral and self supporting, there is no need for additional baseplates, couplings or guards, which add to the cost, complexity and overall size of the installation. We focused on durability and dependability when we developed these liquid-ring pumps. With a reinforced stainless steel shaft and sealed bearings, the 2AV1 can provide up to 20,000 hours of maintenance-free operation. The 2AV1 is expertly designed and manufactured to be quiet and vibration free. With sound pressure levels of less than 75 dBA, it complies with the strictest noise standards, eliminating the need for additional sound attenuating devices. Advantages at a glance Compact Rugged design for reliable operation and long service life Precision-balanced rotor 60hz Motors, UL recognized components Available from stock Low installation costs Easy to service Standard mechanical seal Reinforced stainless-steel shaft in the pump body Main Applications Plastics industry Chemical industry Medical technology Food and beverage industry General industry

Request for a quoteResults for

Mechanical seals - Import exportNumber of results

15 ProductsCompany type