- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pellet granulators

Results for

Pellet granulators - Import export

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

A ViTEQ Loss-in-Weight Feeders are designed to ensure a continuous, gravimetric and high tolerance batch dosing of flowable bulk materials that are not hygroscopic, adhesive or interleaving features. The feeders are sSuitable for many bulk materials including those with the following characteristics: fragile (food products) abrasive (coarse powder, pellets, granulate) difficult to handle (like fibres, glass fibres, pharmaceutical powders) Suitable for wherever precise dosing and weighing of the main components and additives is necessary. Ideal in the following industries: Food & Animal Feed Plastics / Chemicals Pharmaceuticals Advantages & benefits less shear and pressure forces Troughs have a dead space-free design quick and easy cleaning, maintenance-free vibration discharge very gentle weighing (volumetric and gravimetric) highly precise dosing high throughputs Construction Technical data WLW-L WLW-M WLW-H Trough length (mm) 275 - 1.100 275 - 1.100 275 - 1.100 Trough wi

Request for a quote

TRIBO-CHEMIE GMBH

Germany

Dry, round, dust-free and free flowing shot sleeve- and plunger lubricant Type Wax with a micro-milled graphite content of 18 - 20 % Appearence black, round Sizes 0,5 - 1,0 mm 1,0 - 1,6 mm 1,6 - 2,0 mm Properties and Advantages • approved on all sizes of plungers • anti-static and dust-free • instant melting • capillary action guarantees optimal lubrication • minimal dosing is highly recommended • reliable and precise dosing is guaranteed when using Tribo-Chemie Beads Dispenser 3D

Request for a quote

TRADIUM GMBH

Germany

At TRADIUM, selenium is available in the following forms for industrial use: - Selen powder - Selen pellets - Selenium granules Your point of contact for selenium is: Frank Meier Phone: +49 (0)69 50 50 250 - 234 We are looking forward to hearing from you!

Request for a quote

PROTEC POLYMER PROCESSING GMBH

Germany

The SOMOS® RDF dryer is used for drying hygroscopic polymer pellets. It consists of compact RDF modules which can be flexibly combined, are capable of autonomous operation and have drying capacities of 10 kg/h to 250 kg/h per module. The modules are available in 7 sizes with a volume of between 30 l and 600 l and a drying are volume between 10 m3 and 180 m3, each one being individually controllable by its own controller. Alternatively, when interconnected, they can be controlled using a common operator control unit. Each module has an integrated air generator, so ruling out complete failure, as may occur with a centrally supplied drying system.

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

SPECTROFLEX G is ideally suited for dosing powders, pellets, regrind, granulates, flakes and fibers in continuous processes. motan's unique interchangeable system provides two huge advantages over common dosing units. Firstly, the user can swap the quick exchange modules in less than one minute easily without any tools. Furthermore, the single and twin screw exchange modules are also interchangeable, allowing the user to configure the feeder for nearly any type of material in a matter of minutes.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Compaction Custom-made solutions With our variety of granulating systems we produce granulates or compacts in every shape and size for our customers in contract work. Our modern granulating systems consist of roller compacters, pelletizing systems, drum granulators and extruders. Supplementing these are our granulating systems for vacuum packing, in addition equipped with a fully automatic compression force regulation. Through high-tech to the perfect product Our compactor plants made from stainless steel usually consist of the product feed to the roller, a vent unit by vacuuming as well as counter-rotating rollers with continuously adjustable compression force and speed regulation. Here a pre-granulation of pressed slugs, then the fine granulation of pre-granulated goods and the screening of the fine particles under continuous feedback of the screened fine grain are carried out. Our process engineers have multiple ways to customize both the shape and the properties of the final pr

Request for a quote

STEINER GMBH & CO. KG

Germany

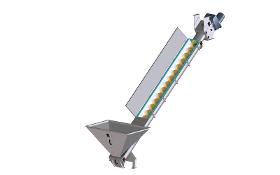

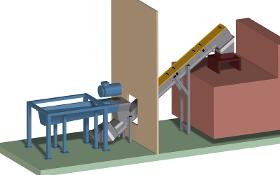

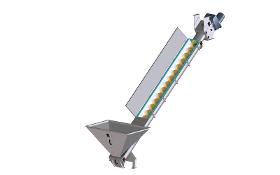

Transporting recycling materials presents particular challenges for conveyor technology. The spiral conveyors for recycling materials need to be able to withstand materials with very different properties, unlike when transporting raw materials in industrial production processes or homogenous material such as granulates or pellets. In addition, the sturdiness in regards to environmental influences cannot be underestimated as a decisive factor for the longevity of the conveyor system as a whole.

Request for a quote

STEINER GMBH & CO. KG

Germany

Transporting recycling materials presents particular challenges for conveyor technology. The spiral conveyors for recycling materials need to be able to withstand materials with very different properties, unlike when transporting raw materials in industrial production processes or homogenous material such as granulates or pellets. In addition, the sturdiness in regards to environmental influences cannot be underestimated as a decisive factor for the longevity of the conveyor system as a whole.

Request for a quote

STEINER GMBH & CO. KG

Germany

Transporting recycling materials presents particular challenges for conveyor technology. The spiral conveyors for recycling materials need to be able to withstand materials with very different properties, unlike when transporting raw materials in industrial production processes or homogenous material such as granulates or pellets. In addition, the sturdiness in regards to environmental influences cannot be underestimated as a decisive factor for the longevity of the conveyor system as a whole.

Request for a quote

STEINER GMBH & CO. KG

Germany

Transporting recycling materials presents particular challenges for conveyor technology. The spiral conveyors for recycling materials need to be able to withstand materials with very different properties, unlike when transporting raw materials in industrial production processes or homogenous material such as granulates or pellets. In addition, the sturdiness in regards to environmental influences cannot be underestimated as a decisive factor for the longevity of the conveyor system as a whole.

Request for a quote

STEINER GMBH & CO. KG

Germany

Transporting recycling materials presents particular challenges for conveyor technology. The spiral conveyors for recycling materials need to be able to withstand materials with very different properties, unlike when transporting raw materials in industrial production processes or homogenous material such as granulates or pellets. In addition, the sturdiness in regards to environmental influences cannot be underestimated as a decisive factor for the longevity of the conveyor system as a whole.

Request for a quote

STEINER GMBH & CO. KG

Germany

Transporting recycling materials presents particular challenges for conveyor technology. The spiral conveyors for recycling materials need to be able to withstand materials with very different properties, unlike when transporting raw materials in industrial production processes or homogenous material such as granulates or pellets. In addition, the sturdiness in regards to environmental influences cannot be underestimated as a decisive factor for the longevity of the conveyor system as a whole.

Request for a quoteResults for

Pellet granulators - Import exportNumber of results

13 Products