- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- plant engineering

Results for

Plant engineering - Import export

YSTRAL GMBH MASCHINENBAU + PROCESSTECHNIK

Germany

Paints and coatings, sealing and insulating materials, coatings, chocolate masses, dairy products, personal care and many other products are produced on process systems from our company. The efficiency and effectiveness of your manufacturing processes can be significantly increased with the help of individually built process plants. Customized process plants are used by our customers worldwide. Container systems, which can be used flexibly at different locations, are available as well as our skidded units, which are completely frame-mounted and automated production units. Recipe control, visualization, weighing, measurement and control technology, containers and piping, CIP systems - all plants are completely assembled in our factory. After a test run under production conditions they are accepted by you. Our technicians are available to you on site for installation, commissioning and service.

Request for a quote

SIM AUTOMATION GMBH

Germany

SIM feeding and sorting systems ensure the reliability of our assembly, testing and inspection systems. We develop, design, manufacture and adapt these systems based on customer specifications and the existing assembly system. A combination of various feeding, handling, camera and sensor systems, robots can be used in additional to individual systems. The systems are used in virtually all industrial branches, including medical engineering, pharmaceuticals, food and cosmetics, the automotive industry and electrical engineering. Feeding systems are an important part of automation technology, as are the isolation and provision of individual components. In addition to simple feeding systems, complex testing, measuring and assembly processes can be added without any problems. Different feeding systems can also be combined thanks to the use of robots and handling systems. In this way, we create a seamless transition from simple part feeding through to compact feeding and testing cells.

Request for a quote

SIM AUTOMATION GMBH

Germany

Some requirements are so specific that this is a job for our special machine construction department. Particularly complex processes can be automated with special machines. In some cases, our specialist expertise is also required to make adjustments to series-produced machines and plants. Whether feeding technology, devices and components, laser cells or support and assistance for other mechanical engineers or engineering companies, our SIM concept shows just why individuality is our strength. After all, while there are different optimization scenarios in every branch, it is special machine construction where particularly creative cross-industry expertise is required above all. With our knowledge of the branch, you have come to the right place. Products manufactured using special machines from SIM: — Pens — Food packaging machines

Request for a quote

SIM AUTOMATION GMBH

Germany

The product portfolio at SIM Automation ranges from the effective design of individual manual workstations all the way through to completely interlinked, highly automated process lines. We handle all common transfer systems and can thus offer solutions that are independent from the branches of our customers. In addition to all standardized joining, measuring, testing and inspection systems, our assembly plants can also implement the customer’s own processes, including: - Joining, screwing, bonding, riveting, welding (laser, ultrasonic, resistance) - Testing, measuring, inspecting (optical, tactile, electrical, thermal) - Robot systems - Linear systems (pneumatic, electrical, mechanical) - Cam-controlled drives, linear and handling systems Testing and inspection lines we have been involved in: - Electric high-performance gear components (up to 6 kV) - Electric central locking systems (vehicles)

Request for a quote

HILGEFORT GMBH

Germany

At home in every sector Hilgefort produces and assembles all steel, special steel, copper and aluminium components imaginable, ranging from simple individual components through to complex systems, for customers in a wide range of industries. The maximum possible dimensions for one-piece components are a diameter of up to 7 m and a length of up to 100 m. Larger assemblies are manufactured in segmented designs. This facilitates movement of unit weights up to 300 tons on the rotary devices (hydraulic lift for loading the trailer). The capacity of each of the hall cranes is around 100 tons of unit weight. Multiple modern and well-equipped production halls provide “play” for extensive and oversized productions You can find an overview of the machine and production capacities here. More information about our experience and services for a wide variety of industries can be found here. The skill and diligence of all our employees guarantee reliable production quality In addition to...

Request for a quote

HERBERHOLZ GMBH

Germany

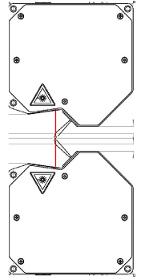

Applications: Mechanical and Plant Engineering / Renewable Energy Technology / Shipbuilding One-piece body, centric disc Operating temperatures up to 800°C, depending on material selection Wafer type body for flanges according to DIN EN 1092-1 or ASME B16.5 / ASME B16.47 Face-to-face length according to manufacturer’s standard or individual customer specifications Mounting flange for actuators according to DIN EN ISO 5211 Inspection according to DIN EN 12266

Request for a quote

HERBERHOLZ GMBH

Germany

Applications: Environmental Technology / Mechanical and Plant Engineering / Renewable Energy Technology One-piece body, centric disc Also available as multi-blade version Operating temperatures up to 900°C, depending on material selection Flanged body according to DIN 24193 or customer specification Face-to-face length according to manufacturer’s standard or individual customer specifications Mounting flange for actuators according to DIN EN ISO 5211 Inspection according to DIN EN 12266

Request for a quote

HERBERHOLZ GMBH

Germany

Applications: Shipbuilding / Mechanical and Plant Engineering One-piece body, centric disc Operating temperatures up to 800°C, depending on material selection Wafer type body for flanges according to DIN EN 1092-1 or ASME B16.5 / ASME B16.47 Face-to-face length acc. to DIN EN 558-1 R20, from DN400 acc. to manufacturer’s standard Mounting flange for actuators according to DIN EN ISO 5211 Inspection according to DIN EN 12266 SIL certification according IEC 61508 and IEC 61511

Request for a quote

HERBERHOLZ GMBH

Germany

Applications: Mechanical and Plant Engineering / Industrial Combustion Technology / HVAC One-piece body, tight-closing, centric discs With blow-out proof shaft Wafer type and lug type for flanges according to DIN EN 1092-1 and ASME B16.5 / B16.47 Exchangeable liner in various elastomer materials Maximum operating pressure: 20 bar, depending on configuration Insulatable according to EnEV Face-to-face length according to DIN EN 558-1-R20 Mounting flange for actuators according to DIN EN ISO 5211 Inspection according to DIN EN 12266

Request for a quote

QUELLTECH GMBH

Germany

Many materials cannot be measured tactilely, therefore non-contact thickness measurements become necessary. Especially e.g. with glowing materials, or wet processes, a continuous tactile measurement is nearly impossible. Furthermore, web speeds in plant engineering and production have increased, requiring a corresponding fast sampling rate of the measuring systems. In addition, high measuring widths are often required. Why is contact free measurement technology so perfect for this application? Can be used in any web width, Scalable measurement thicknesses from a few millimetres to several meters, Thickness and coating thickness can be measured for different materials, Vibrations of the web materials, can be compensated, Turnkey solution for mechanical engineering, Non-contact and non-destructive measurement method, Large distances to the measured object are possible, Measurement of free forms,

Request for a quote

ERDWICH ZERKLEINERUNGS-SYSTEME GMBH

Germany

The reclamation of valuable resources from electrical and electronic scrap – a global volume in excess of 40 million tonnes/year – is one of the greatest challenges facing our society. With additional support from WEEE Directive legislation, this represents enormous growth potential for recycling companies in all consumer-oriented markets. For many years now, ERDWICH has specialised in the reclamation of valuable primary materials from electronic waste with its turnkey system solutions. ERDWICH pre-processing: All process execution is fully compliant with the new DIN EN 50625/1 rules. Whether you need to handle electrics/electronics, small/large household appliances or specialist items such as fluorescent lamps, PCBs, LCD monitors and PV modules, whether as a mobile or stationary solution: create new value from electronic waste with ERDWICH. To get an idea of what we’re capable of, please see the following Case Studies. Now it’s your turn: we look forward to receiving your...

Request for a quote

ERDWICH ZERKLEINERUNGS-SYSTEME GMBH

Germany

The shredding and sorting of rubbish and refuse is one of the key challenges within the waste management cycle. And with ERDWICH systems, there is a perfect set of solutions for meeting any of these application scenarios: System solutions range from simple shredding machinery through waste volume reduction plant to complete turnkey facilities for shredding and sorting. Deployed in waste sorting facilities, waste incineration plant, hospitals, major catering businesses, light and heavy industry, composting firms or waste reclamation units, ERDWICH wastes no time with waste. With hundreds of machines and systems deployed worldwide, use market-leading ERDWICH technology to ensure your success in special waste recycling. To get an idea of what we’re capable of, please see the following Case Studies. Now it’s your turn: we look forward to receiving your project enquiry!

Request for a quote

ERDWICH ZERKLEINERUNGS-SYSTEME GMBH

Germany

Analytical shredding systems for QA work are a fundamental preliminary component in the production of substitute fuels. Businesses that buy in their substitute fuel from external suppliers are faced with two key analytical requirements before putting it to use: pollutant analysis and calorific analysis. To ensure the proper handling of these analyses, a sophisticated sampling system is required, meeting the following criteria. Combining over 30 years of experience and the deployment of our proven single-shaft shredder, ERDWICH has developed an automated, integrated system that sets new standards in the areas of sampling and process reliability. Utilise market-leading ERDWICH technology to ensure your success in the substitute fuels sector. To get an idea of what we’re capable of, please see the following Case Studies. Now it’s your turn: we look forward to receiving your project enquiry!

Request for a quote

ERDWICH ZERKLEINERUNGS-SYSTEME GMBH

Germany

In metal-working shops utilising swarf-producing manufacturing techniques, the generated swarf is often an underestimated cost factor that influences the service life and productivity of the expensive machine tools: The key challenge here is therefore process reliability. For efficient swarf management, ERDWICH offers proven centralised and decentralised solutions with the following benefits: Whether centralised or decentralised, Erdwich lets you handle swarf management in double-quick time. To get an idea of what we’re capable of, please see the following Case Studies. Now it’s your turn: we look forward to receiving your project enquiry!

Request for a quote

ERDWICH ZERKLEINERUNGS-SYSTEME GMBH

Germany

One particular challenge in the refrigerator recycling process is presented by chlorofluorocarbons such as R 11, R 12 or R 141b, which were used for decades as foaming agents for insulation materials. Since these substances damage the Earth’s ozone layer when released, they must be removed and collected securely in a closed-system pre-processing plant. With ERDWICH, you are assured of the latest, technologically advanced solutions: Whether you’re handling small-scale units or complex refrigeration plant: utilise the expertise we’ve gained in processing over 30 million refrigerator units. To get an idea of what we’re capable of, please see the following Case Studies. Now it’s your turn: we look forward to receiving your project enquiry!

Request for a quote

IGUS® GMBH

Germany

Removable ball pins Replaceable Customer specific dimensions and configurations can be removed and exchanged from both sides. maintenance-free Ball pins made from steel, stainless steel, plastic Easy assembly and disassembly of the ball pins by defined forces Configuration online Light weight Application areas:Automobile industry, automation, agricultural engineering, plant engineering, vehicle engineering igubal® double spherical bearing WDGM igubal® variable double spherical bearing igubal® double spherical bearing WDGM igubal® removable angle joints Easy assembly and disassembly of the ball pins by defined forces igubal® removable angle joints not removable igubal® coupling bars configurator - not removable One side removable igubal® coupling bars configurator - removable from one side Both sides removable igubal® coupling bars configurator - Removable from both sides Removable ball pins Replaceable Customer specific dimensions and configurations can be removed and exchanged from both sides. maintenance-free Ball pins made from steel, stainless steel, plastic Easy assembly and disassembly of the ball pins by defined forces Configuration online Light weight Application areas:Automobile industry, automation, agricultural engineering, plant engineering, vehicle engineering igubal® double spherical bearing WDGM igubal® variable double spherical bearing igubal® double spherical bearing WDGM igubal® removable angle joints Easy assembly and disassembly of the ball pins by defined forces igubal® removable angle joints

Request for a quote

IGUS® GMBH

Germany

Overview of E4.1 benefits Additional information Series E4.21 Inner height hi: 21 mm Inner widths Bi: 30 - 120 mm bending radii R: 38 - 200 mm Pitch: 30.5 mm E-Chain® with crossbars at every link Series E4.28 Inner height hi: 28 mm Inner widths Bi: 40 - 300 mm bending radii R: 55 - 250 mm Pitch: 46 mm E-Chain® with crossbars at every link Series E4.32 Inner height hi: 32 mm Inner widths Bi: 50 - 400 mm bending radii R: 63 - 300 mm Pitch: 56 mm E-Chain® with crossbars at every link Series E4.42 Inner height hi: 42 mm Inner widths Bi: 50 - 400 mm bending radii R: 75 - 350 mm Pitch: 67 mm E-Chain® with crossbars at every link Series E4.56 Inner height hi: 56 mm Inner widths Bi: 50 - 600 mm bending radii R: 135 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every link Series E4.80 Inner height hi: 80 mm Inner widths Bi: 50 - 600 mm bending radii R: 150 - 1000 mm Pitch: 111 mm E-Chain® with crossbars at every link Series 1640 Inner height hi: 112 mm Inner widths Bi: 50 - 600 mm bending radii R: 200 - 600 mm Pitch: 143 mm E-Chain® with crossbars at every link E4.112 series Inner height hi: 112 mm Inner widths Bi: 50 - 600 mm bending radii R: 200 - 1000 mm Pitch: 143 mm E-Chain® with crossbars at every link E4.162 series Inner height hi: 162 mm Inner widths Bi: 200 - 600 mm bending radii R: 250 - 1000 mm Pitch: 200 mm E-Chain® with crossbars at every link Series 800 Inner height hi: 200 mm Inner widths Bi: 200 - 600 mm bending radii R: 325 - 1000 mm Pitch: 250 mm E-Chain® with crossbars at every link Series 840 Inner height hi: 204 mm Inner widths Bi: 100 - 563 mm bending radii R: 325 - 1000 mm Pitch: 250 mm E-Chain® with crossbars at every link Series E4.350 Inner height hi: 350 mm Inner widths Bi: 400 - 800 mm bending radii R: 500 - 1000 mm Pitch: 470 mm E-Chain® with crossbars at every link Series H4.32 Inner height hi: 32 mm Inner widths Bi: 50 - 400 mm bending radii R: 63 - 300 mm Pitch: 56 mm E-Chain® with crossbars at every other link Series H4.42 Inner height hi: 42 mm Inner widths Bi: 50 - 400 mm bending radii R: 75 - 350 mm Pitch: 67 mm E-Chain® with crossbars at every other link Series H4.56 Inner height hi: 56 mm Inner widths Bi: 50 - 600 mm bending radii R: 135 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every other link Series H4.80 Inner height hi: 80 mm Inner widths Bi: 50 - 600 mm bending radii R: 150 - 1000 mm Pitch: 111 mm E-Chain® with crossbars at every other link Series H4.112 Inner height hi: 112 mm Inner widths Bi: 50 - 600 mm bending radii R: 200 - 1000 mm Pitch: 143 mm E-Chain® with crossbars at every other link Series R4.28 Inner height hi: 28 mm Inner widths Bi: 50 - 300 mm bending radii R: 63 - 250 mm Pitch: 46 mm E-Tube, swivel lid Series R4.32 Inner height hi: 32 mm Inner widths Bi: 50 - 300 mm bending radii R: 125 - 300 mm Pitch: 56 mm E-Tube, swivel lid Series R4.42 Inner height hi: 42 mm Inner widths Bi: 50 - 300 mm bending radii R: 125 - 350 mm Pitch: 67 mm E-Tube, swivel lid Series R4.56 Inner height hi: 56 mm Inner widths Bi: 75 - 462 mm bending radii R: 150 - 500 mm Pitch: 91 mm E-Tube, swivel lid Series R4.80 Inner height hi: 80 mm Inner widths Bi: 150 - 460 mm bending radii R: 200 - 1000 mm Pitch: 111 mm E-Tube, swivel lid Series R1608 Inner height hi: 112 mm Inner widths Bi: 200 - 400 mm bending radii R: 250 - 600 mm Pitch: 143 mm E-Tube, swivel lid R4.112 series Inner height hi: 112 mm Inner widths Bi: 200 - 400 mm bending radii R: 250 - 1000 mm Pitch: 143 mm E-Tube, swivel lid Assembly tool for E4-series For the practical opening and closing of the E4 series. Big savings in assembly time Assembly tool for E4-series IPA classification -Report IG 1303-640, tested E4.32.10.063.0 41 dB(A) determined at the igus® laboratory, v = 1.8 m/s unsupported ESD classification: Electrically conductive ESD/Atex versions on request System E4.1 proven in long travels e-tubes available as special design with HT material for 850°C hot chips Overview of E4.1 benefits Additional information Series E4.21 Inner height hi: 21 mm Inner widths Bi: 30 - 120 mm bending radii R: 38 - 200 mm Pitch: 30.5 mm E-Chain® with crossbars at every link Series E4.28 Inner height hi: 28 mm Inner widths Bi: 40 - 300 mm bending radii R: 55 - 250 mm Pitch: 46 mm E-Chain® with crossbars at every link Series E4.32 Inner height hi: 32 mm Inner widths Bi: 50 - 400 mm bending radii R: 63 - 300 mm Pitch: 56 mm E-Chain® with crossbars at every link Series E4.42 Inner height hi: 42 mm Inner widths Bi: 50 - 400 mm bending radii R: 75 - 350 mm Pitch: 67 mm E-Chain® with crossbars at every link Series E4.56 Inner height hi: 56 mm Inner widths Bi: 50 - 600 mm bending radii R: 135 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every link Series E4.80 Inner height hi: 80 mm Inner widths Bi: 50 - 600 mm bending radii R: 150 - 1000 mm Pitch: 111 mm E-Chain® with crossbars at every link Series 1640 Inner height hi: 112 mm Inner widths Bi: 50 - 600 mm bending radii R: 200 - 600 mm Pitch: 143 mm E-Chain® with crossbars at every link E4.112 series Inner height hi: 112 mm Inner widths Bi: 50 - 600 mm bending radii R: 200 - 1000 mm Pitch: 143 mm E-Chain® with crossbars at every link E4.162 series Inner height hi: 162 mm Inner widths Bi: 200 - 600 mm bending radii R: 250 - 1000 mm Pitch: 200 mm E-Chain® with crossbars at every link Series 800 Inner height hi: 200 mm Inner widths Bi: 200 - 600 mm bending radii R: 325 - 1000 mm Pitch: 250 mm E-Chain® with crossbars at every link Series 840 Inner height hi: 204 mm Inner widths Bi: 100 - 563 mm bending radii R: 325 - 1000 mm Pitch: 250 mm E-Chain® with crossbars at every link Series E4.350 Inner height hi: 350 mm Inner widths Bi: 400 - 800 mm bending radii R: 500 - 1000 mm Pitch: 470 mm E-Chain® with crossbars at every link Series H4.32 Inner height hi: 32 mm Inner widths Bi: 50 - 400 mm bending radii R: 63 - 300 mm Pitch: 56 mm E-Chain® with crossbars at every other link Series H4.42 Inner height hi: 42 mm Inner widths Bi: 50 - 400 mm bending radii R: 75 - 350 mm Pitch: 67 mm E-Chain® with crossbars at every other link Series H4.56 Inner height hi: 56 mm Inner widths Bi: 50 - 600 mm bending radii R: 135 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every other link Series H4.80 Inner height hi: 80 mm Inner widths Bi: 50 - 600 mm bending radii R: 150 - 1000 mm Pitch: 111 mm E-Chain® with crossbars at every other link Series H4.112 Inner height hi: 112 mm Inner widths Bi: 50 - 600 mm bending radii R: 200 - 1000 mm Pitch: 143 mm E-Chain® with crossbars at every other link Series R4.28 Inner height hi: 28 mm Inner widths Bi: 50 - 300 mm bending radii R: 63 - 250 mm Pitch: 46 mm E-Tube, swivel lid Series R4.32 Inner height hi: 32 mm Inner widths Bi: 50 - 300 mm bending radii R: 125 - 300 mm Pitch: 56 mm E-Tube, swivel lid Series R4.42 Inner height hi: 42 mm Inner widths Bi: 50 - 300 mm bending radii R: 125 - 350 mm Pitch: 67 mm E-Tube, swivel lid Series R4.56 Inner height hi: 56 mm Inner widths Bi: 75 - 462 mm bending radii R: 150 - 500 mm Pitch: 91 mm E-Tube, swivel lid Series R4.80 Inner height hi: 80 mm Inner widths Bi: 150 - 460 mm bending radii R: 200 - 1000 mm Pitch: 111 mm E-Tube, swivel lid Series R1608 Inner height hi: 112 mm Inner widths Bi: 200 - 400 mm bending radii R: 250 - 600 mm Pitch: 143 mm E-Tube, swivel lid R4.112 series Inner height hi: 112 mm Inner widths Bi: 200 - 400 mm bending radii R: 250 - 1000 mm Pitch: 143 mm E-Tube, swivel lid Assembly tool for E4-series For the practical opening and closing of the E4 series. Big savings in assembly time Assembly tool for E4-series IPA Classification Report IG 1303-640, tested series E4.32.10.063.0 E-Chain® selection aids You can find the right E-Chain® quickly by entering concrete parameters and with the aid of a comparison table. Selection aids Assembly instruction video Assembly video with accurate description for joining, splitting and opening e-chains® and e-tubes. Installation instructions Application examples Applications in various industrial sectors and in the igus® test laboratory. E 4.1 E4.1-E-Chain® with 4-piece structure Smooth, cable friendly inner surfaces Low noise operation through integrated "brake" on the radial stop dogs Sound dampers as an additional noise-reducing option Wide application range Numerous interior separation options Large accessory kits Widths up to 2000 mm through extension links To open on both sides Max. travel distance: Over 200 m Typical industrial sectors and applications: Krane Indoor Cranes Composting systems Sewage treatment plants Machine tools General mechanical engineering Materials-Handling Technology Refrigeration engineering Construction machinery Wood working Robotics and handling systems IPA classification -Report IG 1303-640, tested E4.32.10.063.0 41 dB(A) determined at the igus® laboratory, v = 1.8 m/s unsupported ESD classification: Electrically conductive ESD/Atex versions on request System E4.1 proven in long travels e-tubes available as special design with HT material for 850°C hot chips

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

LUTZ PUMPEN GMBH

Germany

The first flowmeter with touch screen display and backlighting convinces with its simple, demand-oriented display and operability, the multilingual interface and the compact design: The rotating swash plate and a magnet enable the exact measurement of the flow rate and measures solvents, acids, alkalis, highly inflammable liquids, oils and neutral media precisely, quickly and above all efficiently. Optionally, the desired quantity can be preselected with the quantity preselection (relay module), so that the pump or the system switches off automatically after the selected quantity. This further simplifies and secures the operation of the systems. * Optional with volume preselection (relay module) * Media examples: Methanol, petrol, isopropanol, kerosene, formic acid, acetic acid, acetone, styrene, xylene, toluene, etc. * Mobile on a Drum pump or with a nozzle connection or stationary in plant engineering

Request for a quote

KENDRION KUHNKE AUTOMATION GMBH

Germany

This EtherCAT I/O module has been specifically designed with industrial environments in mind. Its IP 65 protection allows its installation anywhere at the machine making switching cabinets and further housings more or less redundant. You may mount the unit directly on a base plate. Due to the modules integral plug connector system, sensors and actuators are never far away from the modules. Standardised cable connections reduce mounting times while enhancing the security of the wiring. The IP65 EtherCAT I/O modules are intended for mechanical & plant engineering applications also in conjunction with systems other than those supplied by Kendrion Kuhnke Automation.

Request for a quote![GearSystems [2.0]](/filestore/vig280/opt/product/4c/de/de-dg-system_7cee2ba1.jpg)

NIDEC GRAESSNER GMBH & CO. KG THE GEAR COMPANY

Germany

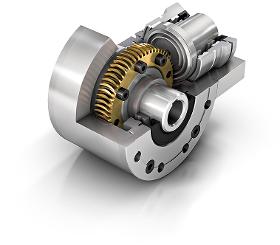

System Solutions for Rack and Pinion Applications As a supplement to the well-known gearbox product ranges, MS-Graessner offers system solutions in the field of rack and pinion applications for mechanical and plant engineering. The DynaGear, KS-TwinGear, DynaGear DG and DynaGear PL systems consist of precise system components developed for automation technology. These include: low-backlash precision gearboxes spur gears toothed racks lubrication systems 4 sizes from T2B= 53 Nm to390 Nm Feed forces up to 11 kN 2 precision classes Input speeds up to n1max = 6000 min-1 Feed speeds up 6 m/s Gear ratios from 5:1 to 15:1 Spur gear modules from to m2 bis m4

Request for a quote![GearSystems [2.0]](/filestore/vig280/opt/product/84/ee/dynaGear-Eco_0992140d.jpg)

NIDEC GRAESSNER GMBH & CO. KG THE GEAR COMPANY

Germany

System Solutions for Rack and Pinion Applications As a supplement to the well-known gearbox product ranges, MS-Graessner offers system solutions in the field of rack and pinion applications for mechanical and plant engineering. The DynaGear, KS-TwinGear, DynaGear DG and DynaGear PL systems consist of precise system components developed for automation technology. These include: low-backlash precision gearboxes spur gears toothed racks lubrication systems With planetary gear output flange 3 sizes from T2B= 53 Nm to 210 Nm Feed forces up to 8 kN 2 precision classes Input speeds up to n1max = 5000 min-1 Feed speeds up to 6 m/s Gear ratios from 5:1 to 15:1 Spur gear modules from m2 bis m4

Request for a quote![GearSystems [2.0]](/filestore/vig280/opt/product/6d/7d/ks30kh_815e350b.jpg)

NIDEC GRAESSNER GMBH & CO. KG THE GEAR COMPANY

Germany

System Solutions for Rack and Pinion Applications As a supplement to the well-known gearbox product ranges, MS-Graessner offers system solutions in the field of rack and pinion applications for mechanical and plant engineering. The DynaGear, KS-TwinGear, DynaGear DG and DynaGear PL systems consist of precise system components developed for automation technology. These include: low-backlash precision gearboxes spur gears toothed racks lubrication systems 8 sizes from T2B = 225 Nm to 11250 Nm Feed forces up to approximately 200 kN 3 precision classes Input speeds up to n1max = 8000 min-1 Feed speeds up to 4 m/s Gear transmission ratios from 15:1 to 75:1 Spur gear modules from m2 to m8

Request for a quote

NIDEC GRAESSNER GMBH & CO. KG THE GEAR COMPANY

Germany

Takeover of the Torus gear technology In September 2016, MS-GRAESSNER GmbH & Co. KG acquired the entire technical expertise of TEDEC AG, Zofingen/Switzerland. Read more ... This results in an ideal synergy effect: state-of-the-art gear meshing technology combined with many years of experience in gear engineering. The further development of the TORUS gearbox (TorusGear), including series development, is thus guaranteed - also from the perspective of customer-specific applications. The owner-managed company MS-GRAESSNER GmbH & Co. KG is a manufacturer of high-precision servo angular gearboxes, with over 60 years of experience in drive technology. The products are used in particular in the fields of automation, robotics, electromotive, and mechanical and plant engineering.

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

The sliding gate valve type 8040 in the long design is universally applicable for neutral and aggressive media in the chemical industry, process engineering and plant construction. This sliding gate valve with its small stroke achieves a very high switching capacity with extremely short switching times.

Request for a quote

XBK-KABEL XAVER BECHTOLD GMBH

Germany

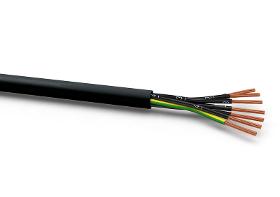

Used as control cables and supply lines in machine engineering, plant engineering, enameling lines, power stations, air conditioning, cool systems, office machines and data precessing systems. Mainly suitable for dry, damp or wet interiors, especially in industrial environments at medium mechanical stress. Outdoor use with UV-protection only and in observance of the temperature ranges. Suitable for free, not continously returning movement without tensile stress or compulsory guidance as well as for fixed laying. GLOBALFLEX®-COLD is mainly used for cold-flexible applications due to cold-resistance up to -30°C.

Request for a quote![GearSystems [2.0]](/filestore/vig280/opt/product/af/c8/dynaGear-Ritzel_67543e7d.jpg)

NIDEC GRAESSNER GMBH & CO. KG THE GEAR COMPANY

Germany

System Solutions for Rack and Pinion Applications As a supplement to the well-known gearbox product ranges, MS-Graessner offers system solutions in the field of rack and pinion applications for mechanical and plant engineering. The DynaGear, KS-TwinGear, DynaGear DG and DynaGear PL systems consist of precise system components developed for automation technology. These include: low-backlash precision gearboxes spur gears toothed racks lubrication systems 8 sizes from T2B= 53 Nm to 2160 Nm Feed forces up to approximately 35 kN 3 precision classes Input speeds up to n1max = 8000 min-1 Feed speeds up to 10 m/s Gear ratios from 3:1 to 100:1 Spur gear modules from m2 to m6

Request for a quote

LUTZ PUMPEN GMBH

Germany

The first flowmeter with touch screen display and backlighting convinces with its simple, demand-oriented display and operability, the multilingual interface and the compact design: The rotating swash plate and a magnet enable the exact measurement of the flow rate and measures acids and alkalis, almost all solvents and highly inflammable liquids precisely, quickly and above all efficiently. As an option, the desired quantity can be preselected with the quantity preselection (relay module), so that the pump or the system switches off automatically after the selected quantity has been reached, thus further simplifying and securing the operation of the systems. * Optional with volume preselection (relay module) * Media examples: Hydrochloric acid, nitric acid, styrene, petrol, acetone etc. * Mobile on a Drum pump or with a nozzle connection or stationary in plant engineering

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

SYSTEM SOLUTIONS FOR MUNICIPAL WASTE WATER TREATMENT Lipp has for many decades been an established partner of municipal waste water treatment plants, engineers and general contractors in the field of tank and system solutions for municipal waste water treatment. Due to their method of construction as well as flexibility in the choice of materials and ideal diameter – height ratios, Lipp tank and system solutions are especially suitable for the needs of small to large sewage treatment plants. They are ideally tailored to one another, but may also be embedded as individual island solutions into existing systems and are therefore equally popular with planners and end users alike. The stainless steels used and the double seaming guarantee maximum water tightness and durability with low maintenance for a wide variety of waste waters, slurries, process liquids and gases. The versatility in terms of the system solutions offered for municipal waste water treatment plants

Request for a quote

XBK-KABEL XAVER BECHTOLD GMBH

Germany

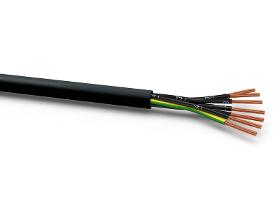

Used as control cables and suply lines in machine engineering, plant engineering, enameling lines, power stations, air conditioning, cooling systems, office machines and data precessing systems. Mainly suitable for dry, damp or wet interiors, especially in industrial environments at medium mechanical stress. Outdoor use with UV protection only and in observance of the temperature ranges.Suitable for free, not continously returning movement without tensile stress or compulsory guidance as well as for fixed laying. GLOBALFLEX®-JZ/OZ 0,6/1kV is UV-resistant and mainly used for applications in southern European countries, Arabic countries and eastern European contries.

Request for a quoteResults for

Plant engineering - Import exportNumber of results

92 ProductsCountries

Category

- Measurement and regulation equipment and instruments - pressure (7)

- Valves for pneumatic equipment (7)

- Flow meters (5)

- Metallurgy and iron and steel industry - machinery and installations (4)

- Tanks, metal (4)

- Automation - systems and equipment (3)

- Sensors (3)

- Copper wires and cables (2)

- Pumps (2)

- Temperature sensing devices (2)

- Mechanical engineering - custom work (1)

- 3D scanner (1)

- Acoustic panels (1)

- Anti-vibration supports (1)

- Bending - steels and metals (1)

- Chemical and pharmaceutical industry - machinery and equipment (1)

- Compensators (1)

- Electrical components and parts (1)

- Erection and dismantling of industrial plants (1)

- Forming - steels and metals (1)