- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- robot applications

Results for

Robot applications - Import export

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

LOAD CELL AND TORQUE SENSOR – X/Y/Z - Model 8565 In robotics and automation engineering, the requirements for precise, tactile handling are constantly increasing. The robust 8565 multi-axis sensor with its low crosstalk enables you to monitor and evaluate your process at any time, regardless of the sensor’s orientation. With just one sensor, you can obtain accurate three-dimensional load information. Its six independent outputs let you selectively evaluate the direction of action of the loads (axial force [Fz] / lateral forces [Fx/Fy] / torque [Mz] / bending moment [Mx/My]). Thanks to its compact design and adaptation via the standardized robot flange in accordance with DIN ISO 9049-1, the sensor can be integrated into many applications quickly and easily. When the slightest deviations are detected in your fast-moving and complex production processes, you can intervene immediately to make adjustments. This helps to prevent faulty parts and reduce manufacturing costs.

Request for a quote

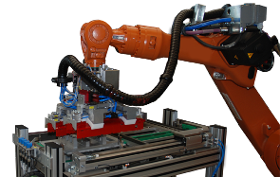

RUHLAMAT GMBH

Germany

Constant changes in our customers' markets mean that solutions must be quickly implemented. Robot applications by ruhlamat are characterized by extremely rapid handling times compared to the competition. Robots, as the core of automated solutions, offer the advantage of being easily convertible and have a high level of flexibility for the integration of variants and / or new processes. In doing so, ruhlamat integrates all popular robot applications from different manufacturers, depending on the requirements of the customer, or assimilates existing robotics expertise into your production and/or assembly. The application range is endless! Whether as a pure handling device (e.g. extraction cells from injection moulding machines, pick and place) or as the centrepiece of hybrid assembly cells (i.e. work content split between operator and robot): simple convertibility and operational flexibility guarantee the highest possible investment security with high operational...

Request for a quote

SFS GROUP GERMANY GMBH - GESIPA

Germany

Use by industry in robot-controlled applications Both versions of the GAV 8000 can be integrated into robot systems. Industrial robots are used almost everywhere in the production environment. They can be programmed to carry out various movements and can therefore be used highly effi ciently in combination with the GESIPA® rivet equipment. With the controlled, fast and secure production processes it is possible to achieve the following benefi ts by using a fully-automatic GAV combined with a multi-axle robot: • First rate precission • High effi ciency • Short cycle times • High fl exibility

Request for a quote

QUELLTECH GMBH

Germany

Particular challenges To correct the effect of the tolerances of the parts, the welding robots path in conventional applications is usually adjusted, by means of a time consuming manual correction (teaching). The warping effect caused by the thermal expansion however cannot be compensated this way. For this purpose, QuellTech offers a perfectly tailored seam tracking solution, which is based on a QuellTech 2D-Laserline Sensor of the Q4 family. The method consists in measurement of the real position and width immediately ahead of the welding process. The laser sensor captures the real dimension of the weld bead, and the software used for this process simultaneously sends the nominal position to the robot. The robot performs a correction movement in X or Z position according to this measurement. This way not only the deviation caused by tolerances, but also the warping effect can be compensated – and the weldment takes place exactly at the required position.

Request for a quote

ROLLON GMBH

Germany

1, 2 and 3 Cartesian axis linear modules with rack and pinion drive guarantee precise manipulation of loads from 10 up to 2000 kg with fast and silent functioning. Our main application fields are: robotics, palletization, production line, logistics and manufacturing machines with Cartesian axis movements. Our products stand out for their: easy and quick assembly; high quality and competitive performances; reduced and simplified maintenance; wide range of integrated solutions; possibility of customised solutions; constant technical support and CAD drawings available. Strong points include: hardened sloping tooth racks (ground on request); payloads from 10 to 2000 Kg; up to 12-m beams (longer lengths can be obtained with jointed versions), high level torsional rigidity, precise shape; precise machining of all profiles (on request: repeatability up to +/-0.05mm); hardened and ground steel guide rails, for rollers and ball slides with cage; easy installation of pre-assembled systems...

Request for a quote

IGUS® GMBH

Germany

chainflex® robot cables are used in energy chains or 3D applications. The twistable robot cables meet extremely high industrial stress requirements and score points with properties such as resistance to hydrolysis and microbes, UV resistance and many, many others. Different types of robot cable are available, e.g. hybrid cables, fibre optic cables (FOCs), motor cables and servo cables. Typical application areas: - For heavy duty applications - Almost unlimited resistance to oil - Indoor and outdoor applications with average solar radiation - Unsupported travel distances and up to 100 m for gliding applications - Machining centres / machine tools, storage and retrieval systems, packaging industry, handling, refrigerating

Request for a quote

IGUS® GMBH

Germany

Overview for triflex® advantages Other information triflex® RSP Continuously adjustable retraction force triflex® RSP triflex® RSE Infinitely adjustable retraction force for small robots triflex® RSE Triflex® R-Set Universal module for all motions on the robot Triflex® R-Set Fiber rod modules Intelligent problem solution through directed pretension. Fiber rod modules Universal assembly kit Offers the potential to mount the fiber rod module in the desired position on the robotic arm. Universal assembly kit Strain reliefs for large cross sections Secure mounting also in the use of cables with large cross section. Strain reliefs Gliding feed-through Available with and without swivel bearing Gliding feed-through Protectors Well protected in extreme applications. Protectors Heat shield Protection against weld and metal spills up to 600°C Heat shield CF Robot special cables Special cables for long service life in robotic applications. CF Robot special cables iF-Design Award for "TRC"- and "TRL"-Design Cleanroom environments on request Series TRC electrically conductive ESD/TEX versions possible UL94-V2classification Overview for triflex® advantages Other information Application examples Interesting applications from a variety of industrial sectors Triflex® R Configure interior separation Define cables, select chain and configure interior separation. Now also for all Triflex® R series! Internal separation configurator Triflex® R QuickRobot Equipment support for various types of robots. Simplified ordering of complete systems. QuickRobot TRC.30 Inner height Bi 1: 12 mm Inner height Bi 2: 10 mm Bending radius R: 50 mm Pitch: 11.3 mm e-chain® TRC.40 Inner height Bi 1: 15 mm Inner height Bi 2: 13 mm Bending radius R: 58 mm Pitch: 13,9 mm e-chain® Installation instructions Instructions for the joining and separating of the triflex® R - TRC. Assembly Instructions TRC.60 Inner height Bi 1: 22,5 mm Inner height Bi 2: 19,5 mm Bending radius R: 87 mm Pitch: 20,4 mm e-chain® TRC.70 Inner height Bi 1: 28 mm Inner height Bi 2: 24 mm Bending radius R: 110 mm Pitch: 25,6 mm e-chain® TRC.85 Inner height Bi 1: 33 mm Inner height Bi 2: 28 mm Bending radius R: 135 mm Pitch: 30,6 mm e-chain® TRC.100 Inner height Bi 1: 37.5 mm Inner height Bi 2: 32.5 mm Bending radius R: 145 mm Pitch: 34.5 mm e-chain® TRC.125 Inner height Bi 1: 43,3 mm Inner height Bi 2: 43,3 mm Bending radius R: 182 mm Pitch: 44,6 mm e-chain® Standard mounting bracket for TRC / TRE / TRL. Also possible with strain reliefs and as intermediate connection. Standard mounting brackets Light mounting bracket Standard for the TRL version. Also compatible with TRC / TRE; possible with strain reliefs and as intermediate connection. Light mounting bracket TRCF.85 Inner height Bi 1: 30 mm Bending radius R: 135 mm Pitch: 30.6 mm e-chain® TRCF.100 Inner height Bi 1: 37,5 mm Bending radius R: 145 mm Pitch: 34,5 mm e-chain® Standard mounting bracket for TRC / TRE / TRL. Also possible with strain reliefs and as intermediate connection. Standard mounting brackets Light mounting bracket Standard for the TRL version. Also compatible with TRC / TRE; possible with strain reliefs and as intermediate connection. Light mounting bracket TRE.30 Inner height Bi 1: 12 mm Inner height Bi 2: 10 mm Bending radius R: 50 mm Pitch: 11,3 mm e-chain® TRE.40 Inner height Bi 1: 15 mm Inner height Bi 2: 13 mm Bending radius R: 58 mm Pitch: 13,9 mm e-chain® Installation instructions Instructions for the joining, separating and filling of the triflex® R - TRE. Assembly Instructions TRE.60 Inner height Bi 1: 22,5 mm Inner height Bi 2: 19,5 mm Bending radius R: 87 mm Pitch: 20,4 mm e-chain® TRE.70 Inner height Bi 1: 28 mm Inner height Bi 2: 24 mm Bending radius R: 110 mm Pitch: 25,6 mm e-chain®. TRE.85 Inner height Bi 1: 33 mm Inner height Bi 2: 28 mm Bending radius R: 135 mm Pitch: 30,6 mm e-chain® TRE.100 Inner height Bi 1: 37,5 mm Inner height Bi 2: 32,5 mm Bending radius R: 145 mm Pitch: 34,5 mm e-chain® TRE.125 Inner height Bi 1: 43,3 mm Inner height Bi 2: 43,3 mm Bending radius R: 182 mm Pitch: 44,6 mm e-chain® Standard mounting brackets for TRC / TRE / TRL. Also possible with strain reliefs and as intermediate connection. Standard mounting brackets Light mounting bracket Standard for the TRL version. Also compatible with TRC / TRE; possible with strain reliefs and as intermediate connection. Light mounting bracket TRE.40.B Inner height Bi 1: 15 mm Inner height Bi 2: 13 mm Bending radius R: 58 mm Pitch: 13.9 mm e-chain® TRE.60.B Inner height Bi 1: 22,5 mm Inner height Bi 2: 19,5 mm Bending radius R: 87 mm Pitch: 20,4 mm e-chain® Assembly instruction Instructions for the joining, separating and filling of the Triflex® R - TRE-B version. Assembly instruction TRE.70.B Inner height Bi 1: 28 mm Inner height Bi 2: 24 mm Bending radius R: 110 mm Pitch: 25,6 mm e-chain® TRE.85.B Inner height Bi 1: 33 mm Inner height Bi 2: 28 mm Bending radius R: 135 mm Pitch: 30,6 mm e-chain® TRE.100.B Inner height Bi 1: 37,5 mm Inner height Bi 2: 32,5 mm Bending radius R: 145 mm Pitch: 34,5 mm e-chain® Standard mounting brackets for TRC / TRE / TRL. Also possible with strain reliefs and as intermediate connection. Standard mounting brackets Light mounting bracket Standard for the TRL version. Also compatible with TRC / TRE; possible with strain reliefs and as intermediate connection. Light mounting bracket Assembly tool triflex® R B-version Assembly tool for disassembly of triflex® R B-version Assembly tool triflex® R B-version TRL.30 Inner height Bi 1: 12 mm Inner height Bi 2: 10 mm bending radii R: 50 mm Pitch: 11,3 mm e-chain® TRL.40 Inner height Bi 1: 15 mm Bending radius R: 58 mm Pitch: 13.9 mm e-chain® Installation instructions Instructions for the joining, separating and filling of the Triflex® R - TRL. Assembly Instructions TRL.60 Inner height Bi 1: 23 mm. Bending radius R: 87 mm. Pitch: 20.4 mm e-chain® TRL.70 Inner height Bi 1: 28 mm Bending radius R: 110 mm Pitch: 25.6 mm e-chain® TRL.100 Inner height Bi 1: 38 mm Bending radius R: 145 mm Pitch: 34.5 mm e-chain® Standard mounting brackets for TRC / TRE / TRL. Also possible with strain reliefs and as intermediate connection. Standard mounting brackets Light mounting bracket Standard for the TRL version. Also compatible with TRC / TRE; possible with strain reliefs and as intermediate connection. Light mounting bracket TRLF. 65 Inner height Bi 1: 24.4 mm Bending radius R: 100 mm Pitch: 23.1 mm e-chain® TRLF. 85 Inner height Bi 1: 32.8 mm Bending radius R: 135 mm Pitch: 31 mm e-chain® Assembly instruction Instructions for the joining, separating and filling of the Triflex® R - TRLF. Assembly instruction TRLF. 100 Inner height Bi 1: 38 mm Bending radius R: 145 mm Pitch: 34,5 mm e-chain® Standard mounting brackets for TRC / TRE / TRL. Also possible with strain reliefs and as intermediate connection. Standard mounting brackets Light mounting bracket Standard for the TRL version. Also compatible with TRC / TRE; possible with strain reliefs and as intermediate connection. Light mounting bracket triflex® RSP Continuously adjustable retraction force triflex® RSP triflex® RSE Infinitely adjustable retraction force for small robots triflex® RSE Triflex® R-Set Universal module for all motions on the robot Triflex® R-Set Fiber rod modules Intelligent problem solution through directed pretension. Fiber rod modules Universal assembly kit Offers the potential to mount the fiber rod module in the desired position on the robotic arm. Universal assembly kit Strain reliefs for large cross sections Secure mounting also in the use of cables with large cross section. Strain reliefs Gliding feed-through Available with and without swivel bearing Gliding feed-through Protectors Well protected in extreme applications. Protectors Heat shield Protection against weld and metal spills up to 600°C Heat shield CF Robot special cables Special cables for long service life in robotic applications. CF Robot special cables This system is especially suited for: First choice for multi-axis industrial robots Three versions are available: TRC: closed design; TRE: "Easy" design, very easy to fill in from outside; and TRL: the "Light" version, likewise with "easy" design Universally applicable in general mechanical engineering Secure energy supply system Multi-axis (3D movements) High torsional stability Can be shortened and lengthened as required due to the individual elements Large filling space Doesn't get stuck in the interfering edges Small bending radius Simple cable routing for three-dimensional applications with ball-and-socket system for absorption of high tensile strength Cables easy to install and replace (TRE/TRL version) Fiber rod module for partial reinforcement and to give direction TRL - One-piece element, extremely light High tensile strength without additional elements like steel cables, spring elements, etc. Typical industrial sectors and applications First choice for industrial robots Machine tools Handling equipment 6-axis Material handling system General mechanical engineering iF-Design Award for "TRC"- and "TRL"-Design Cleanroom environments on request Series TRC electrically conductive ESD/TEX versions possible UL94-V2classification

Request for a quote

IGUS® GMBH

Germany

Other information Series 210 Inner height hi: 21 mm Inner widths Bi: 30 - 120 mm bending radii R: 38 - 200 mm Pitch: 30.5 mm The E4.21 series is identical to 210 series and replaces it. E4.21 - E-Chain® with crossbars at every link Series 220 Inner height hi: 28 mm Inner widths Bi: 40 - 300 mm bending radii R: 55 - 250 mm Pitch: 46 mm E-Chain® with crossbars at every link Series 280 Inner height hi: 32 mm Inner widths Bi: 50 - 400 mm bending radii R: 63 - 300 mm Pitch: 56 mm E-Chain® with crossbars at every link Series 380 Inner height hi: 42 mm Inner widths Bi: 50 - 400 mm bending radii R: 75 - 350 mm Pitch: 67 mm E-Chain® with crossbars at every link Series 400 Inner height hi: 56 mm Inner widths Bi: 50 - 600 mm bending radii R: 135 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every link Series 600 Inner height hi: 108 mm Inner widths Bi: 200 - 600 mm bending radii R: 200 - 1000 mm Pitch: 143 mm E-Chain® with crossbars at every link Series 640 Inner height hi: 112 mm Inner widths Bi: 87 - 562 mm bending radii R: 200 - 1000 mm Pitch: 143 mm E-Chain® with crossbars at every link Series 290 Inner height hi: 32 mm Inner widths Bi: 50 - 400 mm bending radii R: 63 - 300 mm Pitch: 56 mm E-Chain® with crossbars at every other link Series 390 Inner height hi: 42 mm Inner widths Bi: 50 - 400 mm bending radii R: 75 - 350 mm Pitch: 67 mm E-Chain® with crossbars at every other link Series 410 Inner height hi: 56 mm Inner widths Bi: 50 - 600 mm bending radii R: 135 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every other link Series 601 Inner height hi: 108 mm Inner widths Bi: 200 - 600 mm bending radii R: 200 - 1000 mm Pitch: 143 mm E-Chain® with crossbars at every other link Series R760 Inner height hi: 28 mm Inner widths Bi: 50 - 300 mm bending radii R: 63 - 250 mm Pitch: 46 mm E-Tube, swivel lid Series R770 Inner height hi: 32 mm Inner widths Bi: 50 - 300 mm bending radii R: 125 - 300 mm Pitch: 56 mm E-Tube, swivel lid Series R780 Inner height hi: 42 mm Inner widths Bi: 50 - 300 mm bending radii R: 125 - 350 mm Pitch: 67 mm E-Tube, swivel lid Series R880 Inner height hi: 56 mm Inner widths Bi: 75 - 462 mm bending radii R: 150 - 500 mm Pitch: 91 mm E-Tube, swivel lid Series R608 Inner height hi: 108 mm Inner widths Bi: 200 - 500 mm bending radii R: 250 - 1000 mm Pitch: 143 mm E-Tube, swivel lid Assembly tool for E4-series For the practical opening and closing of the E4 series. Big savings in assembly time Assembly tool for E4-series IPA certificate: Clean room ISO class 3 (DIN 14644-1) at v = 1 m/s for Series 280.10.100.0 tested ESD classification: Electrically conductive ESD/Atex versions on request Other information Series 210 Inner height hi: 21 mm Inner widths Bi: 30 - 120 mm bending radii R: 38 - 200 mm Pitch: 30.5 mm The E4.21 series is identical to 210 series and replaces it. E4.21 - E-Chain® with crossbars at every link Series 220 Inner height hi: 28 mm Inner widths Bi: 40 - 300 mm bending radii R: 55 - 250 mm Pitch: 46 mm E-Chain® with crossbars at every link Series 280 Inner height hi: 32 mm Inner widths Bi: 50 - 400 mm bending radii R: 63 - 300 mm Pitch: 56 mm E-Chain® with crossbars at every link Series 380 Inner height hi: 42 mm Inner widths Bi: 50 - 400 mm bending radii R: 75 - 350 mm Pitch: 67 mm E-Chain® with crossbars at every link Series 400 Inner height hi: 56 mm Inner widths Bi: 50 - 600 mm bending radii R: 135 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every link Series 600 Inner height hi: 108 mm Inner widths Bi: 200 - 600 mm bending radii R: 200 - 1000 mm Pitch: 143 mm E-Chain® with crossbars at every link Series 640 Inner height hi: 112 mm Inner widths Bi: 87 - 562 mm bending radii R: 200 - 1000 mm Pitch: 143 mm E-Chain® with crossbars at every link Series 290 Inner height hi: 32 mm Inner widths Bi: 50 - 400 mm bending radii R: 63 - 300 mm Pitch: 56 mm E-Chain® with crossbars at every other link Series 390 Inner height hi: 42 mm Inner widths Bi: 50 - 400 mm bending radii R: 75 - 350 mm Pitch: 67 mm E-Chain® with crossbars at every other link Series 410 Inner height hi: 56 mm Inner widths Bi: 50 - 600 mm bending radii R: 135 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every other link Series 601 Inner height hi: 108 mm Inner widths Bi: 200 - 600 mm bending radii R: 200 - 1000 mm Pitch: 143 mm E-Chain® with crossbars at every other link Series R760 Inner height hi: 28 mm Inner widths Bi: 50 - 300 mm bending radii R: 63 - 250 mm Pitch: 46 mm E-Tube, swivel lid Series R770 Inner height hi: 32 mm Inner widths Bi: 50 - 300 mm bending radii R: 125 - 300 mm Pitch: 56 mm E-Tube, swivel lid Series R780 Inner height hi: 42 mm Inner widths Bi: 50 - 300 mm bending radii R: 125 - 350 mm Pitch: 67 mm E-Tube, swivel lid Series R880 Inner height hi: 56 mm Inner widths Bi: 75 - 462 mm bending radii R: 150 - 500 mm Pitch: 91 mm E-Tube, swivel lid Series R608 Inner height hi: 108 mm Inner widths Bi: 200 - 500 mm bending radii R: 250 - 1000 mm Pitch: 143 mm E-Tube, swivel lid Assembly tool for E4-series For the practical opening and closing of the E4 series. Big savings in assembly time Assembly tool for E4-series E-Chain® selection aids You can find the right E-Chain® quickly by entering concrete parameters and with the aid of a comparison table. Selection aids Installation instructions Joining, separating and opening of the E-Chain® and E-Tubes. Assembly Instructions Application examples Applications in various industrial sectors and in the igus® test laboratory. System E4/00 E4/00-E-Chain® with 4-piece structure The low-noise E4 chain Further noise reduction with sound dampers (E4/101 series) Wide application range Numerous interior separation options Large accessory kits Widths up to 2000 mm through extension links Snap-open along both sides Max. travel distance: Over 200 m Typical industrial sectors and applications Robotics and handling systems Materials-Handling Technology Refrigeration engineering Construction machinery Machine tools Wood working Any type of machines Semiconductor Clean room applications cold storage houses Welding machines Maritime applications General mechanical engineering etc. IPA certificate: Clean room ISO class 3 (DIN 14644-1) at v = 1 m/s for Series 280.10.100.0 tested ESD classification: Electrically conductive ESD/Atex versions on request

Request for a quote

IGUS® GMBH

Germany

PMA cable protection systems are used wherever the mechanical protection of electrical lines and cables is needed. Highly flexible cable protection tubes are specifically suited for the additional protection of cable guides in e-chain® systems. Due to the combination of technical knowhow and the strictest international safety guidelines, PMA fulfils the worldwide requirements of industrial markets in application areas like mechanical engineering, automotive construction, fiber optics, solar systems as well as applications in the robot sector with high speeds and millions of alternate bending cycles.

Request for a quote

IGUS® GMBH

Germany

Other information IF -Design Award for Triflex®-Design Torsional movements possible Other information Installation instructions Joining, separating and filling of the Triflex®. Assembly Instructions Application examples Applications in various industrial sectors and in the igus® test laboratory. Triflex® 332.16 Inner height hi: 16 mm Inner width Bi: 16 mm Bending radii R: 38 - 100 mm Pitch: 13.3 mm E-Chain®. 332.32 Inner height hi: 32 mm Inner width Bi: 32 mm Bending radii R: 75 - 250 mm Pitch: 25 mm E-Chain®. 332.50 Inner height hi: 50 mm Inner width Bi: 50 mm Bending radii R: 100 - 250 mm Pitch: 30 mm E-Chain®. 332.75 Inner height hi: 75 mm Inner width Bi: 75 mm Bending radii R: 140 - 300 mm Pitch: 36 mm E-Chain®. 352.50 Inner height hi: 50 mm Inner width Bi: 50 mm Bending radii R: 10 - 250 mm Pitch: 30 mm E-Chain®, snap-open 333.16 Inner height hi: 16 mm Inner width Bi: 16 mm Bending radii R: 38 - 100 mm Pitch: 13.3 mm E-Chain®. 333.32 Inner height hi: 32 mm Inner width Bi: 32 mm Bending radii R: 75 - 250 mm Pitch: 25 mm E-Chain®. 333.50 Inner height hi: 50 mm Inner width Bi: 50 mm Bending radii R: 100 - 250 mm Pitch: 30 mm E-Chain®. 333.75 Inner height hi: 75 mm Inner width Bi: 75 mm Bending radii R: 140 - 300 mm Pitch: 36 mm E-Chain®. 353.50 Inner height hi: 50 mm Inner width Bi: 50 mm Bending radii R: 10 - 250 mm Pitch: 30 mm E-Chain®, snap-open This modular, rugged joint system is suitable for: Three-axis movements for machines of any type For dirt-filled environments High tensile strength Where rectangular shapes are requested Completely closed - reliable protection against dirt and chips Combination of different bending radii and axes Connection and separation possible at any chain Flanged mounting brackets or brackets, galvanized steel Snap-open Series 352 and 353 Combination of Series 353/333 possible Typical industrial sectors and applications Machine tools Robotics Material handling system Plastics industry Construction machinery Vehicle manufacturing Medical equipment IF -Design Award for Triflex®-Design Torsional movements possible

Request for a quote

IGUS® GMBH

Germany

Other information iF-Design Award for easy triflex® Design UL94-V2 classification Torsional movements possible Other information Installation instructions Join, separate and fill the easy triflex®. Assembly Instructions Application examples Applications in various industrial sectors and in the igus® test laboratory. Triflex® E332.25 Inner height hi: 25 mm Inner width Bi: 25 mm Bending radii R: 48 - 200 mm Pitch: 14.5 mm e-chain® E332.32 Inner height hi: 32 mm Inner width Bi: 32 mm Bending radii R: 75 - 250 mm Pitch: 25 mm e-chain® E332.50 Inner height hi: 50 mm Inner width Bi: 50 mm Bending radii R: 100 - 250 mm Pitch: 30 mm e-chain®. E332.75 Inner height hi: 75 mm Inner width Bi: 75 mm Bending radii R: 140 - 300 mm Pitch: 36 mm e-chain® E333.25 Inner height hi: 25 mm Inner width Bi: 25 mm Bending radii R: 48 - 200 mm Pitch: 14.5 mm e-chain® E333.32 Inner height hi: 32 mm Inner width Bi: 32 mm Bending radii R: 75 - 250 mm Pitch: 25 mm e-chain® E333.50 Inner height hi: 50 mm Inner width Bi: 50 mm Bending radii R: 100 - 250 mm Pitch: 30 mm e-chain®. E333.75 Inner height hi: 75 mm Inner width Bi: 75 mm Bending radii R: 140 - 300 mm Pitch: 36 mm e-chain® This modular joint system is especially suited for: Three-axis movements of machines For simple robotic applications Quick installation of cables with "easy" system Simple filling from both sides Where rectangular shapes are required Combination of different bending radii and moving directions Shortening or lengthening possible at "any point" KMA mounting brackets with integrated strain relief Typical industrial sectors and applications Machine tools Robotics Handling equipment Material handling system Plastics industry Construction machinery Vehicle manufacturing General mechanical engineering Medical Equipment Office furniture iF-Design Award for easy triflex® Design UL94-V2 classification Torsional movements possible

Request for a quote

SAMSYS GMBH

Germany

The automatic drawer system ProFeeder X from EasyRobotics with its up to 10 drawers is perfectly suited for productions from small to large series. It shines not only because of its performance thanks to the included software, but also because of its changeover times. The software, which has been specially created for the ProFeeder X, makes it easier to write the robot programs in the palletizing area. This reduces tiresome programming times and increases productivity at the same time.

Request for a quote

SAMSYS GMBH

Germany

The mobile robot ER Work from EasyRobotics is a compact robot station which can be used for handling work or CNC assembly. The ER Work is most often used in combination with the ProFeeder Compact. Here the ProFeeder Compact serves as a kind of parts store. In this case the ER Work loads and unloads the machine. Of course, the ER Work can also do its work alone in front of a CNC machine.

Request for a quote

SAMSYS GMBH

Germany

The Quick Changer system enables quick and easy tool change. It has a low weight, a low installation height and is designed for a payload of up to 20 kg. It is patented, reliable and equipped with a user-friendly connection mechanism. Particularly secure locking structure and locking springs. The Quick Changer system is a unique product and ideal for all collaborative robotic applications. The Quick Changer is the easiest and fastest tool changer. Simply everything you need in one package. Not only suitable for OnRobot products. It can also be combined with tools from other manufacturers. It can also be used for own constructions. Another example is the use of existing tools. These can also be equipped with OnRobot’s quick change system. The Quick Changer is alternatively also available as Dual Quick Changer. This makes it easy to install two tools on one robot arm.

Request for a quote

TRAPO GMBH

Germany

Our high-capacity portal palletizers act in a material-caring manner on three servo-linear axes within cubic space. We develop, design and manufacture portal robots in our in-house production facility in Gescher-Hochmoor. We are a specialist in the high-care segment -with portal robots made of high-grade steel.

Request for a quote

WEBER ULTRASONICS AG

Germany

The product innovation for continuous cutting: Ultrasonically enhanced cutting tools require less energy and shorter set-up times. They are especially suited for robot applications and use in the food industry.

Request for a quote

WEBER ULTRASONICS AG

Germany

Flange converters are available for all common frequencies (20 to 35 kHz) and power requirements (200 to 5,000 W). They are designed to keep weight at a minimum and their standardized quick disconnect allows for easy and fast integration with robot applications.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BIZLINK ROBOTIC SOLUTIONS GERMANY GMBH

Germany

With the SPE cable products, BizLink offers a solution which is standardized according to IEC 61156-x for trailing, torsion and robotic applications as well as special solutions that combine Single Pair Ethernet with various other elements (hybrid cables). The product portfolio includes two basic types with 22 AWG and 26 AWG conductors. The 22 AWG variant is characterised by exceptionally good loss. The cable with 26 AWG is particularly suitable if less space is available for the cable

MOOG GAT GMBH

Germany

Rotospray: The air bearing rotary atomizers have been specifically designed for the paint atomization in automated paint streets. The sprayer’s micro-jets ensure finest and consistent spraying at speeds up to 70,000 rpm. Thanks to its high-performance turbine that has been aerodynamically optimized for low air consumption, ROTOSPRAY achieves an enormous performance boost. The air bearing rotary atomizer can handle high loads, making the ROTOSPRAY system especially suitable for use in robotized applications. To cater for individual requirements, the rotary atomizer is available with specific connection layouts and housing variants.

Request for a quote

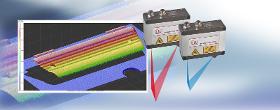

MICRO-EPSILON MESSTECHNIK GMBH & CO. KG

Germany

scanCONTROL 3D scanners are used for precise inline 3D measurements in numerous applications. Scans are performed by moving the scanner or the target. Due to their low weight, the scanners are ideally suited both for robotic applications and inline production monitoring. These 3D laser scanners are characterized by high dynamics, absolute precision and their compact size. With the scanCONTROL 3000 and the new scanCONTROL 3002 series, Micro-Epsilon offers a comprehensive portfolio with numerous measurement areas, Red and Blue laser technologies and extensive accessories. The scanCONTROL 3D laser scanners are based on the latest GigE Vision and GenICam standards and can therefore be integrated into a wide range of image processing environments. The powerful 3DInspect software is available for parameter setting, evaluation and output.

Request for a quote

MICRO-EPSILON MESSTECHNIK GMBH & CO. KG

Germany

The new generation of Micro-Epsilon’s 3D sensors impresses with high accuracy during measurement and assessment of components and surfaces. The surfaceCONTROL and reflectCONTROL inspection systems from Micro-Epsilon are intended for matt and shiny surfaces respectively. The 3D snapshots are recorded in a short time and provide detailed 3D point clouds. These 3D sensors are used, e.g., for geometric component testing, position determination, presence checks and the measurement of flatness or planarity. Thanks to their high performance, the sensors are used for inline applications, on robots and also for offline inspection.

Request for a quote

SFS GROUP GERMANY GMBH - GESIPA

Germany

With the GESIPA® FireRex® it is possible for the first time to set huge numbers of blind rivet nuts fast and fully automatically. Since neither a camera nor any kind of optical device, which are usually dust-prone, are necessary to find the drilled hole, the system allows stable operation even in adverse production environments without requiring huge maintenance efforts. The setting tool can also be integrated into already existing production systems without a problem, thus allowing to make the systems more economical. Also available as FireRex® 2 C WinTech with setting process monitoring.

Request for a quote

FORMHAND AUTOMATION GMBH

Germany

The ability to gently handle components of different dimensions, geometries and surface structures opens up completely new possibilities. The small gripping head offers flexible and simple cooperation between man and machine. Benefit from ✅ Increased efficiency of your processes ✅ Increased availability of your personnel ✅ Increase in the production speed ✅ Simple plug & play commissioning thanks to decentralized blower technology ✅ Modular design to increase performance Minimize ❌ Set-up times ❌ Maintenance costs ❌ Personnel deployment ❌ Process complexity Possible applications of the FH-R80 ✅ Industrial robot applications for components up to 2 kg ✅ Loading and unloading of machines (e.g. press shop and body shop) ✅ Bin picking applications ✅ Transportation of fragile parts ✅ Use in systems with high component variability ✅ Use with collaborative robots

Request for a quote

FORMHAND AUTOMATION GMBH

Germany

The ability to gently handle components of different dimensions, geometries and surface structures opens up completely new possibilities. The small gripping head offers flexible and simple cooperation between man and machine. Benefit from ✅ Increased efficiency of your processes ✅ Increased availability of your personnel ✅ Increase in the production speed ✅ Simple plug & play commissioning thanks to decentralized blower technology ✅ Modular design to increase performance Minimize ❌ Set-up times ❌ Maintenance costs ❌ Personnel deployment ❌ Process complexity Possible applications of the FH-R40 ✅ Industrial robot applications for components up to 1 kg ✅ Loading and unloading of machines (e.g. press shop and body shop) ✅ Bin picking applications ✅ Transportation of fragile parts ✅ Use in systems with high component variability ✅ Use with collaborative robots

Request for a quote

FORMHAND AUTOMATION GMBH

Germany

The ability to gently grip components of different dimensions, geometries and surface structures opens up completely new possibilities. Benefit from ✅ Increased efficiency of your processes ✅ Higher availability of your personnel ✅ Increased production speed ✅ Simple plug & play commissioning thanks to decentralized blower technology ✅ Modular design to increase performance Minimize ❌ Set-up times ❌ Maintenance costs ❌ Employment of personnel ❌ Process complexity Possible applications of the FH-E3020 ✅ Industrial robot applications for components up to 25 kg ✅ Loading and unloading of machines (e.g. press shop and body shop) ✅ Transporting parts (e.g. large, flat sheet metal parts such as fenders or hoods) ✅ Transportation of fragile parts ✅ Use in systems with high component variability ✅ Tube lifter applications

Request for a quote

FORMHAND AUTOMATION GMBH

Germany

The ability to gently grip components of different dimensions, geometries and surface structures opens up completely new possibilities for you. Benefit from ✅ Increased efficiency of your processes ✅ Higher availability of your personnel ✅ Increased production speed ✅ Simple plug & play commissioning thanks to decentralized blower technology ✅ Modular design to increase performance Minimize ❌ Set-up times ❌ Maintenance costs ❌ Personnel deployment ❌ Process complexity Possible applications of the FH-R15 ✅ Industrial robot applications for components up to 8 kg ✅ Loading and unloading of machines (e.g. press shop and body shop) ✅ Transporting parts (e.g. large sheet metal parts such as fenders or hoods) ✅ Transportation of fragile parts ✅ Use in systems with high component variability ✅ Use with collaborative robots

Request for a quote

KENDRION (VILLINGEN) GMBH

Germany

The spring-applied brakes which are ideally suited for robotics is designed for robotics solutions and loads of up to appr. 20 kg, but it can also be used in other applications requiring small geometrical dimensions. With regard to their power density the slim single-disc brakes are flatter and lighter than the market standard, and due to their large inner diameter they are well suited for hollow-shaft drives. This makes them perfect for applications in lightweight robots with integrated drives. There is a growing demand for safety technology in order to avoid injuries by collisions, especially if the control technology or even the power supply fails. In this case electromagnetic brakes are usually the method of choice. As safety brakes they bring moving masses to a stop, keep loads in position and therefore prevent humans and material assets from being affected.

Request for a quote

IAI INDUSTRIEROBOTER GMBH

Germany

Water and dust protected SCARA robots SCARA robots are also a popular option for small robotic assembly applications in harsh environments with suspended dust, moisture or water spray. IAI offers water and dust protected SCARA robots with 24 V stepper motor or 230 V servo motor. They can be used without further construction measures. The danger of leakage is not given here. One reason for the uncomplicated installation without the need for additional aggregates are their flexibility and the small footprint, which reduces the cost and time required for commissioning.

Request for a quote

IAI INDUSTRIEROBOTER GMBH

Germany

SCARA Robot in Cleanroom-compatible Design IAI offers compact and powerful SCARA robots in cleanroom-ready design according to ISO standard 14644-1:2015. They are a popular option for small robotic assembly applications. These robots generate minimal dust, making them ideal for use in a cleanroom environment. The air inside the robot can be exhausted to create a negative pressure when ISO cleanroom class 3 conditions must be met.

Request for a quoteResults for

Robot applications - Import exportNumber of results

54 ProductsCountries

Category

- Industrial robots (17)

- Painting robots (12)

- Automation - systems and equipment (11)

- Robotics (6)

- Sensors (6)

- Assembly robots (5)

- Electric cables (5)

- Welding robots (3)

- Brakes, servo-brakes and accessories (1)

- Compressed air tools and systems (1)

- Goods handling systems, continuous (1)

- Hoses, pipes and tubes - plastic (1)

- Industrial cabling (1)

- Internal transport systems (1)

- Mechanical transmission systems and components (1)

- Metals - Machines & Equipment (1)

- Steels and metals - welding and brazing (1)