- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- special belts

Results for

Special belts - Import export

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

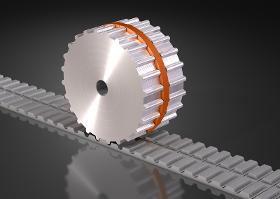

easy drive® track timing belts can be made from the complete range of polyurethane and neoprene timing belts: in open lengths, endless welded, for form belts, endless Flex or wide timing belts, in almost any length and width. The directional guiding, with groove in tooth, is either already integrated in the timing belt during production or added later. These timing belts exhibit the same properties as standard timing belts. However, in addition, axial movement is prevented and the zero-play guiding leads to high directional stability. Advantages • Universal application instead of flanged pulleys or special toothed belt guides • Can be used with any tooth shape or belt pitch • Can be combined with any material – steel, aluminium, grey cast-iron or plastics • For polyurethane and also for neoprene timing belts • Maximum directional stability, without lateral play, inaccurate running or drift

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

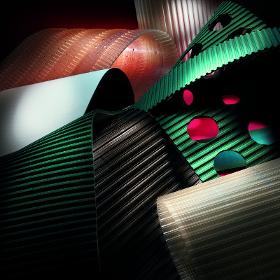

Keiper PU wide timing belts are made of abrasion-resistant polyurethane and high-strength aramid cords in widths up to 600mm. These timing belts are specially designed for synchronous transport applications. In view of the production width as well as outstanding mechanical and chemical properties, they can be used for many applications. Moreover, it is possible to use special materials such as, for example, polyurethane that is suitable for contact with foodstuffs, or a nylon coating on the tooth facing and back side. Properties and special features: High-strength aramid tension cords Parallel arrangement of tension cords for even distribution of tension Form-fit, synchronous running Low-noise, high abrasion resistance and flexibility Applications: As a substitute for transport belts for synchronous positioning Applications in the foodstuffs industry Sausage, meat and cheese processing Conveying of bulk goods

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

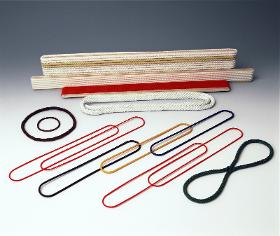

Our endless turned round belts are wound either out of one homogeneous strand or one cord and spliced endlessly without thickening. For special applications, it is possible to vulcanize the inner splice or to make a special splice based on our in-house engineering methods. This increases the tensile strength by up to 60%. In elastic types, the core is welded. In view of their special structure, twisted round belts exhibit very quiet running properties, are extremely flexible and, thus, make possible very small minimum pulley diameters of 3x belt diameter. For several types, speed up to 70,000 rpm is possible; however, the speed of 60m/s should not be exceeded. Elastic types: PU, Vulkollan Semi-elastic types: PA.6, Set-Polyester, Nylon, HE Types with limited extensibility: Polyester, Nomex, Nomex-PTFE, Polyester-PTFE, Kevlar/Twaron, PA.6 anti-static, PBO

Request for a quote

FORBO SIEGLING GMBH

Germany

Building materials, wood and stone Whether the wood, marble or brick industry, Forbo conveyor and processing belts as well as high efficiency flat belts fulfill the special requirements of these important sectors.

Request for a quote

FORBO SIEGLING GMBH

Germany

Siegling Extremultus drag belts are special developments with superior mechanical and electrostatic characteristics which make conveying and handling electronic components more efficient and safe: due to the HC or HC+ characteristics (highly conductive or highly conductive plus) the static electricity that builds up in the conveyor can be discharged better in a controlled manner; due to simplified accumulation with TT types which produce consistently low friction coefficients on the top face and underside; due to a particularly high level of abrasion resistance, as well as stable, lint-free belt edges. Siegling Extremultus drag belts are supplied endless, prepared for splicing, or as roll material.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FORBO SIEGLING GMBH

Germany

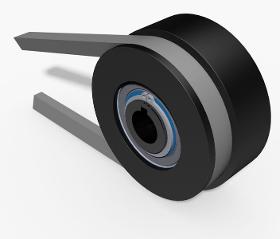

Siegling Extremultus live roller belts are energy-saving, durable components of driven live rollers. The quality and performance of the belts determine how quickly and reliably items our customers’ items are distributed. The belt’s tension member plays a key role in this process. Today’s standard is polyester fabric (E). But polyamide sheet (P) or aramide fabric (A) are also used. The tension member is embedded in a thermoplastic intermediate layer. Rubber elastomer or urethane coat the two friction layers, which are the top face of the belt (towards the roller) and the underside of the belt (towards the drive and in some cases to the idler roller). The combination of tension member and coating lends the belt its special characteristics – tailored to conveyor type and purpose. The splice requires no extra adhesives (in the Aramid and Polyester line) and can be made quickly, easily and cleanly on site.

Request for a quote

GURTEC GMBH

Germany

Jackdown frames in 3, 5, 6 or 10 roll arrangements Retractable frames Other special loading frames available – for example impact roller cassettes Dimensions: Includes Jackdown, retractable and other special impact arrangements Belt widths from 350 to 3,500 mm (14” to 138”) Various trough angles available

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

AViTEQ Belt Scales are ideal for the precise dynamic weighing of raw materials in your process environment. You receive reliable results at affordable prices. Our devices can be used in applications subject to low or high loads, also in rough and difficult conditions. Depending on the application and requirements profile, Belt Scales are available with one, two, or multiple rollers. Advantages and benefits For continuous weighing of a wide range of bulk materials on belt conveyors. Flexible implementation depending on accuracy requirements and actual lay out of belt conveyor. Special solutions for legal-for-trade applications Long term repeatable accuracy due to robust construction and direct load transmission design that eliminates pivots and lever arms Easy installation and alignment with minimum modifications required to existing conveyor structure and components Application Weighbridge Speed sensor Junction box Load cell cable (depending on distance to weighing controller) Integr

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

Flexible and powerful: the conveyor derinder ASB 600 for artisanal and medium-sized companies with a wide range of applications. The combination machine can be used open with a carriage table or closed with a height-adjustable pressure device and infeed belt. In conveyor operation, all cuts, such as cheek, belly and loin of pork, as well as fat on shoulder and ham are derinded automatically. In open operation, suitable for derinding all round cuts, such as ham, shoulder or knuckle. Advantages Optimal results: clean removal of the rind without residues Infinite adjustment of the rind/cutting thickness Equipped with two operating speeds as standard Compact, movable via fixed and guide rollers Option: Pressure rollers in various hardnesses and air pressing roller Discharge belt Special voltage

Request for a quote

BEHA INNOVATION GMBH

Germany

If a standard profile does not meet the requirements of your application, BEHAbelt offers you the unique opportunity to develop a customerspecific product. According to your specifications and your design! Examples of possible uses are the following French fries, sorting solutions for fruit and vegetables, gentle transport of glass, spreading applications for sweets, for conveying grains and similar goods.

Request for a quote

AMSBECK MASCHINENTECHNIK GMBH

Germany

The centrifugal clutch with belt output is the most frequently used build of Amsbeck centrifugal clutches. This type of centrifugal clutch has the pulley installed in the clutch bell already. This leads to a compact and space-saving, as well as cost-efficient, build. A centrifugal clutch with belt output can generally use any standardised belt profile and pulley diameter. The number of belt grooves can be chosen freely as well. Of course, a centrifugal clutch with belt output can also be delivered with special belt profiles and V-rib belt profiles at the customer's request. We also offer matching counter-pulleys on request."

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The drum plastic scraper is for use on light to heavy conveyor belt systems. High quality PU segments for particularly high time of exposure also suitable on spherically rotated drums high flexibility due to PU segments also specially suitable for reversing conveyors belt speeds up to 5 m/s especially for badly damaged belts and PVC belts well suited for use in narrow space conditions limiting damage to the belt longer life expectancy and therefore significant cost savings due to new type of segment shape elastic segments with permanently consistent contact pressure with compression springs (for the automatic regulation of the contact pressure)

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

FTK primary scrapers for pollution abatement in conveyor belt systems The primary scraper is used for light to heavy conveyor belt systems high tech hard metal for particularly high time of exposure also suitable on spherically rotated drums high flexibility due to PU hard metal segments also specially suitable for reversing conveyors belt speeds up to 5 m/s specially for extremely adherent materials or in difficult or narrow space conditions significantly improved cleaning performance limiting damage to the belt longer life expectancy and therefore significant cost savings due to special segment shape elastic segments with permanently consistent contact pressure with compression springs (for the automatic regulation of the contact pressure) Areas of use sand plants, gravel plants, clay plants, brick plants, asphalt mixing plants and in the gypsum, cement and glass industries etc Any products adhering to the belt reduce the life expectancy of the conveyor due to the heavy soiling.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

For the special requirements of your belt conveyor system, we manufacture for you idler pulleys, carrying idlers, throbbing drums, lift pulleys with or without internally located cone. With diameters up to max. 1,000 mm and lengths up to max. 4,500 mm, these are suitable for all types of belt conveyor system. All pulleys are turned cylindrically or spherically. The axle connections can be delivered in alternative designs with internal bearings, welded, with wedged connections or with clamping set shaft connections. Special designs such as stainless steel and/or friction linings (ceramic, rubber) and accessories (pedestal bearings) can be delivered upon request.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

For the special requirements of your belt conveyor system, we manufacture for you drive pulleys, carrying idlers, throbbing drums, lift pulleys with or without internally located cone. With diameters up to max. 1,000 mm and lengths up to max. 4,500 mm, these are suitable for all types of belt conveyor system. All pulleys are turned cylindrically or spherically. The axle connections can be delivered in alternative designs with internal bearings, welded, with wedged connections or with clamping set shaft connections. Special designs such as stainless steel and/or friction linings (ceramic, rubber) and accessories (pedestal bearings) can be delivered upon request.

Request for a quoteResults for

Special belts - Import exportNumber of results

16 ProductsCountries

Company type