- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- turning

Results for

Turning - Import export

CIC - KLAUS CZERWONKA

Germany

Turned parts with mechanical finishing. Ground, hardened, welded, soldered. Pre-assembled with sealing elements and O-rings.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

The ultraprecision turning machine (UP-Turning machine) MTC 650 is currently our largest series machine. Our customers can machine workpieces up to 200 kg in UP quality. The travelling distances are 400 mm in the Z-axis and 650 mm in the X-axis. Workpieces with a diameter of up to 800 mm in diameter (optionally 1000 mm) can be machined. The extended X travel offers more space for additional accessories, further tool holders or special bodies/ constructions. The MTC 6500 is based on a T-shaped natural granite bed. X- and Z-axis slides, as well as the housing of the main spindle are made of granite too. Both slides and the optional B-axis use hydrostatic (oil) bearings. The main spindle features an air bearing and is mounted to the X-slide. Different vacuum chucks for workpieces of up to 800 mm (31.5’’) in diameter are available.

Request for a quote

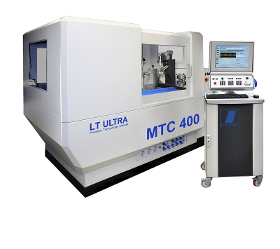

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

The ultraprecision turning machine (UP-Turning machine) MTC 400 (Micro Turning Center) is designed to hold heavy weight workpieces up to 100 kg. The travelling distances of the X- and Z-axis are 400 mm and provide the machining of workpieces up to 800 mm in diameter. The MTC 400 is based on a T-shaped natural granite bed. X- and Z-axis slides, as well as the housing of the main spindle are made of granite too. Both slides and the optional B-axis use hydrostatic (oil) bearings. The main spindle features an air bearing and is mounted to the X-slide. Different vacuum chucks for workpieces of up to 800 mm (31.5’’) in diameter are available. Besides many other accessories, that make the MTC 250 an all-purpose tool, there is the possibility to make customized solutions, to adapt the machine to your needs. Please do not hesitate to contact us.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

The ultraprecision turning machine (UP-Turning machine) MTC 350 (Micro Turning Center) combines dynamic use with an increased work space, thus resulting in a wide range of products to be manufactured. The travelling distances of the X- and Z-axis are 350 mm and provide the machining of workpieces up to 700 mm in diameter. The MTC 350 is based on a T-shaped natural granite bed. X- and Z-axis slides, as well as the housing of the main spindle are made of granite too. Both slides and the optional B-axis use hydrostatic (oil) bearings. The main spindle features an air bearing and is mounted to the X-slide. In addition to the X- and Z-axis there is the option to have an additional linear axis. This A-axis allows to do micro milling or raster flycutting operations on the machine. Besides many other accessories, that make the MTC 350 an all-purpose tool, there is the possibility to make customized solutions, to adapt the machine to your needs. Please do not hesitate to contact us.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

The ultraprecision turning machine (UP-Turning machine) MTC 250 (Micro Turning Center) has a lightweight construction of the moving parts and thus enables the machine axes to be used in a dynamic mode (Slow Tool). This machine is our standard machine with the smallest footprint. The travelling distances of the X- and Z-axis are 250 mm and provide the machining of workpieces up to 500 mm in diameter. The MTC 250 is based on a T-shaped natural granite bed. X- and Z-axis slides, as well as the housing of the main spindle are made of granite too. Both slides and the optional B-axis use hydrostatic (oil) bearings. The main spindle features an air bearing and is mounted to the X-slide. Besides many other accessories, that make the MTC 250 an all-purpose tool, there is the possibility to make customized solutions, to adapt the machine to your needs. Please do not hesitate to contact us.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KEBA FASTENINGS

Germany

PRODUCTION CAPABILITIES KEBA Fastenings’ processing capacity for Turned-Parts comprised of steel, brass, aluminum, and stainless steel bars ranges between Ø 1mm to Ø 60mm via CNC Auto Lathe, Index, and Sliding Automat machinery. The manufacturing technology and team capabilities allow for custom made parts according to customer-specific drawings. SURFACE TREATMENT • Browning • Anodised • KTL • Zinc - Lamella • Galvanized (blue, yellow, black) • Zinc - Iron • Zinc - Nickle Powder • Phosphating • Chrome • Copper

Request for a quote

METO INTERNATIONAL GMBH

Germany

Managing queue times smartly Turn-O-Matic touch is the perfect queue solution for shops, retail market and public areas, that aim for efficient organization. It helps reducing their cost, creates up selling and provides satisfied customer and employees. The main touch and ticket unit of Turn-O-Matic touch plus now allows to maintain up to 3 queues simultaneously.

Request for a quote

GEMÜ GEBRÜDER MÜLLER APPARATEBAU GMBH & CO. KG

Germany

GEMÜ ADA is a pneumatic double acting quarter turn actuator. It works according to the double piston rack and pinion principle and is suitable for mounting to butterfly valves or ball valves. —ATEX version available as an option —Tried and tested actuator design —Easy setting of switch points —Simple installation —Flexible and versatile —Stroke limiter available (optional) —Robust design —Diverse accessories

Request for a quote

MASCHINENFABRIK BERTHOLD HERMLE AG

Germany

5-axis/5-sided machining means the C 42 lends itself to be used in every application area. With traverse paths adapted to the workpiece size and perfectly designed for 5-axis applications, the C 42 is ideal wherever complex, close-tolerance components are required. This includes various applications in the tool and mould making, medical, aerospace, motorsport, machine sectors and other industries: The C 42 machining centre is at home in every area. The space-saving circular tool magazine integrated into the base body of the machine works according to the pick-up principle - thus enabling quick tool changes. In the standard version, the C 42 can hold 42 tools and can be extended to 192 pockets. The control panel can be easily adjusted to the respective user. Milling and turning in one clamping with the C 42 U MT dynamic model. Fully integrated rotary table that does not interfere with demanding milling processes and 5 axes simultaneously.

Request for a quote

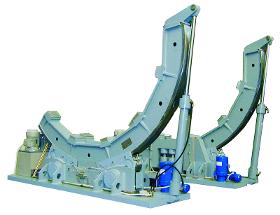

AERO-LIFT VAKUUMTECHNIK GMBH

Germany

Our 180° turnable vacuum lifters are ideal, for instance, for being able to paint both sides of metal panels. The load can be variably swivelled manually or using an electric motor and comfortably transported in one step to be processed on the front and back. Previous Next Functionality turning devices enables processing from 2 sides. Transported materials can be pivoted from 0 to 180° with ease. Control both side of a plate for a quality check or fitting of veneer on both side. Turning heavy loads 180° only with a push button. Sample applications Technical Data of standard turning devices Description Article.No. Carrying capacity Main beam L Cross beam B Saugplatten Anzahl / Ø" AERO 125/4R-180° 1030736 125 kg 2200 mm 1000 mm 4 / 210 mm AERO 125/4R-180° 1030745 125 kg 1800 mm 1000 mm 4 / 210 mm AERO 125/4R-180° 1030746 125 kg 3000 mm 1000 mm 4 /...

Request for a quote

SAR GRÖPLER GMBH

Germany

This machine tests turn signals and installs with positive validating a frame cover.

Request for a quote

SNK GMBH

Germany

・Rigid structure with a flat, wide beds built for heavy cutting ・High-precision headstock with thermal balance function ・Adjustable control panel for operator convenience ・Ideal for a wide variety of turning processes ・Large diameter built-in center standard on tailstock. ・Ideal for long work processing with various follower rest attachments ・Maximum Swing Diameter: 1,600mm – 2,500mm (standard); up to 4,000mm ・Center Distance: 6,000mm (standard); customizable ・Workpiece Capacity: 70,000kg (standard); up to 400 Tons

Request for a quoteResults for

Turning - Import exportNumber of results

14 ProductsCompany type