- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- winding technology

Results for

Winding technology - Import export

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

ZWP manufactures large gears, sun wheels, sun pinions and gear rings for planetary gears, which are used in wind turbines. We already supply renowned customers from wind power. ZWP is one of Germany’s largest independent contract manufacturers for transmission parts and mechanical engineering. Summary of our production: Internal toothed rings Gears shaft pinions Other types of production on request. We manufacture according to customer drawings. We already supply renowned companies and export worldwide. We have our own hardening facility. This saves time and costs in the manufacturing process. References to our customers in the industry on request. We look forward to hearing from you.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Our fully automated winding centres for fine and self-bonding wire make us the perfect partner for any tasks you require. Our coils are tinned with lead-free coatings (RoHS). At PRUFREX, single-chamber and multi-chamber coils can also be achieved using two-wire windings. For specific magnetic flux requirements, we apply wires of different thicknesses to the coil form. Two different wire thicknesses, from 0.045 to 0.71 millimetres, on coil forms with press-in ferrite or metallic cores.

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

We also supply renowned customers on an international level with our products for conveying technology (gas and oil extraction) and their gear units. Here is an overview of our production possibilities: Overview about the capabilities for production: Gears internal and external toothed hardened and grinded Module 2 – 50 mm Diameter 100 – 2,000 mm Internal toothed rings / rim gears hardened and grinded Module up to 20 mm - more on request Diameter 100 to 1,800mm Pinions and shafts internal and external toothed hardened and grinded Module 1 – 50 mm Diameter 50 – 500 mm Length up to 1,500 mm Hardening and balancing inhouse possible We manufacture for different customers: railway, wind power, shipping, conveyor technology, industry and special machine construction. Production is carried out according to customer drawings and standards. Further information in the first interview. We look forward hearing from you.

Request for a quote

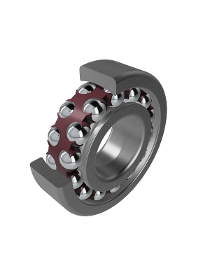

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

Our self-aligning ball bearings are characterised by their high load capacity and long service life. The KIS range includes both open and sealed self-aligning ball bearings, depending on the requirement. They are particularly suitable for applications with high demands on load performance and wear protection and are used, for example, in industrial machinery, wind turbines and conveyor technology. With low maintenance requirements, they offer long-lasting wear protection. Two rows of balls, two deep raceways in the inner ring and a hollow ball raceway in the outer ring combined for both rows characterise the design of self-aligning ball bearings. Due to the spherical raceway in the outer ring, self-aligning ball bearings are insensitive to misalignments of the shaft to the housing, compensating for static and dynamic angular errors within certain angular limits in a rotating shaft system. We are happy to develop the ideal KIS solution for your application requirements!

Request for a quote

ELECTRONICON KONDENSATOREN GMBH

Germany

With our long year know how and first-class production facilities, we are manufacturing capacitors in two basic technologies: MKP and MKPg™. In MKP capacitors, the winding elements are surrounded by poison-free vegetable oil, in MKPg™, capacitors, they are immersed by neutral insulation gas. When designing our product ranges, we focussed on the best possible technical features combined with eco-friendliness and operational safety, using special metallizing patterns, our SINECUT slitting technology and optimized winding geometries. Besides excellent ratio of capacitance to volume, our power capacitors distinguish themselves by high AC-voltage load capacity and outstanding suitability for high rms and surge currents. Unlike some of our competitors who proudly quote fantasy ratings, we have really tested our capacitors to their rated values, allowing for sufficient reserves and guaranteeing flawless operation within the specifications.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ELECTRONICON KONDENSATOREN GMBH

Germany

E53 and E55 capacitors have a particularly low series resistance and high pulse strength. Using sophisticated metallizing patterns, our SINECUT slitting technology and clever winding geometries, they are especially suited for the damping of GTO thyristors and low-inductance buffer circuits with high rms currents. Along with their very good ratio of capacitance to volume, these components do also have very good self-healing characteristics without loss of capacitance. Their very low self-inductance makes them suitable for use in high-current applications with medium frequencies. The capacitors of the E53 product family are housed in flame-retardant plastic cans (V0) and filled with solid resin. Special care has been taken both in terms of design and conservative electrical rating to ensure reliable operation even under tough environmental conditions. Connection is usually made through robust axial terminals with internal thread.

Request for a quote

ELECTRONICON KONDENSATOREN GMBH

Germany

The winding elements in our MKP(D) capacitors are surrounded by poison-free vegetable oil. Like our premium ranges of MKPg and MKP, the MKP(D) combines the best possible technical features with eco-friendliness and operational safety, using special metallizing patterns, our SINECUT slitting technology and optimized winding geometries. Besides excellent ratio of capacitance to volume, our MKP(D) capacitors distinguish themselves by high AC-voltage load capacity and suitability for high rms and surge currents. Our MKP(D) are available as single and three-phase capacitors and well-suited for all conventional applications in power factor correction. They have a self-healing dielectric and are provided with an irreversible overpressure disconnector (break-action mechanism, " BAM "). Connection is made through convenient standard 6.3mm tab connectors. Technical layout, testing and application accord to IEC60831, UL810 and CSA 22.2.

Request for a quote

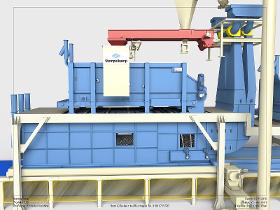

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Wind formers convey especially ne particles to the top faces, thus creating ne board surfaces. This is because ner particles are conveyed much farther in an air ow than coarser ones. The forming system of a particleboard line usually comprises two wind formers located at its front and rear ends, as they form the top and the rear board surfaces. The ecoFormer SL by CMC Texpan has been developed from the traditional wind former technology. This was because we wanted to improve the separation of coarse and nes particles to create the optimal board surface. The air ow was simulated using the CFD method (Computational Fluid Dynamics) and optimised with respect to its aerodynamic behaviour thus improving its energy eciency. The ecoFormer SL can also be easily retrotted into existing mat formers, since its outer dimensions are compatible with the conventional wind formers oered by CMC. Features, function

Request for a quoteResults for

Winding technology - Import exportNumber of results

9 ProductsCountries

Company type

Category

- Condensers (2)

- Passive electronic components and printed circuits (2)

- Bearings, roller (1)

- Coil winders (1)

- Electrical & Electronic Components (1)

- Gas and oil - exploitation (1)

- Oil - drilling and extraction (1)

- Toothed wheels (1)

- Transmission elements (1)

- Turbines (1)

- Wood veneer - machinery and equipment (1)