- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- heater band and cartridge

Results for

Heater band and cartridge - Import export

FRIEDR. FREEK GMBH

Germany

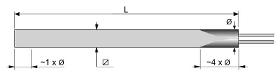

Square cartridge heaters are used where much power has to be installed near the surface of a tool, e.g. in cutting knives, sealing stations or hot plates. With a soft, malleable condition in stainless steel or nickel sheath square cartridge heaters can easily be pressed into common milled rectangular grooves. Apart from the advantageous heat transfer over ¾ of the sheath, it is not necessary to cement or cast in the heater which is imperative for round cartridge heaters. Unlike tubular heaters which are also available in square sections (see chapter Flexible Heating Pipes), the square cartridge heaters have the termination on one side and can be loaded with 16W/cm² (2.5W/in²) due to their special inside construction.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Occasionally also these terms are used for cartridge heates: heating cartridge, insertion heaters, spiral cartridge heaters. As a rule cartridge heaters consist of a cylindrical stainless steel tube and thus provide a high corrosion prevention. There is a heating wire inside which is wound onto a ceramic core. The number of coils varies depending on the power. In order to avoid a short-circuit, the cartridge heater is filled with magnesium oxide and compressed afterwards. Highly compacted they reach a surface watt density of up to 50 W/cm² and withstand highest stress. In the plastics industry cartridge heaters are used in hot runners in order to temper thermoplasts during injection moulding processes. Other areas of applications for process heat are e. g. packaging, diecasting or continuous casting in which zinc or aluminium are processed. Further applications are to be found in mechanical as well as medical and laboratory engineering.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Besides their own clamp-band designs Freek also manufactures original Rosemount clamp-bands that can be used as "Husky-replacement heaters" (see spare part cross-reference list). For example the two screw clamp band (FB) and the axial clamp band (FE). Freek has all the various industry standards for clamp-band nozzle heaters in Ø19,05 and Ø22,40 in their assortment, too. HotCoil minitubular heaters with clamp band are a highly demanded and very flexible clamping system, especially for heating larger nozzles and bushings with high power. The size-variable customizable clamp bands counteract the heating's thermal-related "lifting ambition" during heat-up and thus effectively prevent a possible critical overheating. For an even better protection all HotCoil heating elements can also be provided with an integrated thermocouple. As alternative to our standard clamping mechanism with welded clamping elements a space-saving lug clamping mechanism can be supplied.

Request for a quote

CARTRIDGE HEATER BY MAXIWATT

United States

Maxiwatt High Load cartridges, which have been have proven themselves for 50 years successfully performing in thousands of applications applications that very few manufacturers are currently manufacturers are currently capable of producing, have a maximum temperature of 1000º.

Request for a quote

CARTRIDGE HEATER BY MAXIWATT

United States

The expandable cartridge Heaters solve two major problems with conventional high density heaters , poor durability and proper fit extraction improving the accuracy of the temperature with hundreds of attachments and exits for all kind of processes . With the expandable cartridge heaters we join for the first time the best of the common cartridge heater with cartridge and an adaptive tuning quick and easy removal.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CARTRIDGE HEATER BY MAXIWATT

United States

They are especially designed for quick adaptation in molds or surfaces where the use of rivets either causes problems or impossibility to use. Cuadrawatt cartridges are the better choice. Cartridges with a low density of watts are most recommended for moderate heating up to a maximum temperatures of 300ºC. The square tube is made of prime quality stainless steel. All the tubes are perfectly calibrated both inside and outside, into which a long-life ceramic piece is inserted. The tube resists a continuous temperature variation and has the best possible thermal conductivity, as the ceramic piece is in contact with the wall of the tube, which makes the most perfect heat distribution possible. Special Cold Sections: Distributed Wattage Single Circuit Element Independent Heat Zones Three Phase Element Dual Voltage Designs Thermocouple A,B,C RTD Elements Thermostats

Request for a quote

CARTRIDGE HEATER BY MAXIWATT

United States

The exclusive manufacturing design guarantees a precise temperature distribution throughout the plastic filament, melting it all at the same time. Only the thread of the nozzle is heated, where the casting process has to be produced. We only produce Cylinder Heater Core with different volts, watts and control systems, we do not include hot ends.

Request for a quote

CALDOR INDUSTRIAL HEATING SYSTEMS SRL

Romania

Introducing Caldor's Cartridge Heaters, the ultimate high-performance heating solution designed for a wide range of industrial applications. Our cartridge heaters deliver exceptional heat transfer, uniform temperatures, and long-lasting durability to meet the most demanding process requirements. Built with top-quality materials, Caldor's Cartridge Heaters feature a robust construction and high watt density, ensuring rapid heat-up times and excellent heat distribution. The innovative swaged design ensures superior heat transfer, while the built-in thermocouple ensures precise temperature control for consistent results. Key Features: Customizable dimensions to fit various applications Temperature range: up to 1400°F (760°C) Wattage: up to 200 watts per square inch Superior heat transfer and uniformity Long service life and reliable performance Easy installation and maintenance

Request for a quote

CARTRIDGE HEATER BY MAXIWATT

United States

Cartridge Heaters by Maxiwatt is characterised by its flexibility in the production of exclusive orders for its customers, adapting all its manufacturing processes in order to obtain better productivity and efficiency when delivering orders in short periods of time. We do not use these 4 types of materials: Tantalum, Tin, Gold and Tungsten. If you would like to place an order or make a customised enquiry, please fill in the Customised Heaters form and we will contact you once we have analysed your needs.

Request for a quote

CALDOR INDUSTRIAL HEATING SYSTEMS SRL

Romania

Caldor's Ceramic Insulated Band Heaters offer efficient heating for industrial applications like plastic processing and molding. Featuring high-quality ceramic insulation, they ensure exceptional heat distribution, thermal efficiency, and durability. Designed for optimal performance, these heaters provide rapid heat-up and precise temperature control, boosting productivity and process quality. Their low-mass design enables quick response times and minimal heat loss, reducing energy consumption. Built with corrosion-resistant materials, Caldor's Ceramic Insulated Band Heaters have a sturdy clamping mechanism for secure attachment to cylindrical surfaces. With various sizes and wattages, they cater to diverse application requirements. Choose Caldor for reliable heating solutions that enhance industrial processes and improve overall efficiency. Trust our commitment to quality and customer satisfaction with each Ceramic Insulated Band Heater we manufacture.

Request for a quote

CALDOR INDUSTRIAL HEATING SYSTEMS SRL

Romania

Introducing Caldor's Nozzle Band Heaters, the ultimate solution for precise and efficient heat transfer in injection molding and extrusion processes. Our robust heaters are engineered to deliver outstanding performance in various industrial applications, ensuring optimal material processing and end-product quality. These heaters are constructed with high-quality materials, providing a compact design and excellent heat distribution. The use of advanced ceramic insulation minimizes heat loss and enhances energy efficiency, while the built-in thermocouple ensures precise temperature control. Key Features: Customizable dimensions to fit various nozzle sizes Temperature range: up to 450°C Wattage: up to 100 watts per square inch Uniform heat distribution for consistent results Durable construction for long service life Easy installation and maintenance

Request for a quote

CRC PROGETTI SRL

Italy

Standard power, size and shape or as indicated by the customer. Stainless steel casing. TYPE CERAMIC FIBRE: WORKING TEMPERATURE: MAX 850°C Armour in stainless steel or ALUSI sheets Internal insulation in ceramic fibre. Resistive wire* internal insulating TYPE MICANITE: WORKING TEMPERATURE: MAX 280°C Armour in stainless steel or ALUSI sheets Internal insulation in micanite Resistive wire* internal insulating ARMOURED TYPE: WORKING TEMPERATURE: MAX 700°C Armour in stainless steel Heater*, consisting of a ARMOURED heating element with stainless steel tube. Element development up to 8.00 m. Resistive internal filament* insulated with first choice MAGNESIUM OXIDE.

Request for a quoteResults for

Heater band and cartridge - Import exportNumber of results

13 ProductsCountries

Company type