- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- household washing-machines

Results for

Household washing-machines - Import export

THOMSON MACHINERY BV

Netherlands

Wholesale washing machines

Request for a quote

KMS-PT, S.R.O.

Slovakia

Pair of socks for the washing machine - Mix colors and separate colors sets

Request for a quote

JUST FIXED

United Kingdom

Our washing machine services are available regardless of where you bought it.

Request for a quote

BETA VALVE SYSTEMS LTD

United Kingdom

These water inlet solenoid valves from RPE are suitable for household appliances (such as washing machines and dishwashers) applications and other equipment requiring a water supply cut-off valve. The R Series includes many different configurations: versions with one, two, three or four outlets arranged at 180º or 90º to the inlet are available. The standard inlet connection is 3/4"BSP male, outlet connection option including hosetail, threaded and John Guest push-fit. A mounting bracket is standard with most versions. The R Series is WRAS approved for potable water use.

Request for a quote

THOMSON MACHINERY BV

Netherlands

D7 is a tunnel car washing machine with 7 washing brushes, which is the economic version of D9. This tunnel type of equipment can wash cars quickly and continuously, and it can wash 50-60 cars per hour. Its production greatly meets the needs of customers with large business sites and a large amount of car washing. Now many customers with a daily car washing volume of more than 500 cars are using this equipment. This tunnel type of equipment is sturdy and durable. Its appearance takes into account the likes of domestic and foreign customers. It covers a relatively small area, has strong adaptability to the site, and has excellent performance. It is favored by some customers who are limited by the site and want to install tunnel machines.

Request for a quote

THOMSON MACHINERY BV

Netherlands

* Adopts fully automatic PLC computer control system, which has faster operation speed, lower failure rate, and can be upgraded remotely. * Adopts thickened hot dipped galvanized steel material, sturdy and durable. * 5 brushes (1 vertical lift top brush + 2 small vertical brushes + 2 large vertical brushes). * Strong water cleaning system and foam pump system. * Multiple functions: water washing-----foam-----brushing-----wax water washing. * With fault identification code, the fault is easy to identify and eliminate.

Request for a quote

SOJET, LDA

Portugal

Heavy-duty 2-wheel cart with handle Triplex pump with ceramic pistons and Connecting rod system Automatic pressure by-pass valve with pressure relief from pump head Three-phase induction motor with Thermal protector Adjustment Pressure gauge Flanged pressure relief Integrated detergent suction Adjustable detergent injector Built-in detergent tank with 3L capacity Inspectable water filter Electric cable length 5 m General characteristics Standard accessories

Request for a quote

KITTNER ANLAGEN - UND MASCHINENBAU

Bulgaria

The machine is designed for quick, easy and effective cleaning of KLT crates and forms in the automotive industry. The device consists of the main washing zone followed by a rinsing zone and one blowing-off unit. The water from the washing and rinsing tanks are continuously filtered via two oil skimmers – one for each tank. Refreshing the water in the main tank with hot rinse water reduces the water and energy consumption. The filling of detergent in the washing tank is automatic via a dosing pump. Both main and rinsing tanks are equipped with filters for capturing the metal particles with size up to 100 μm. The machine is equipped with two 2.2 kW fans for vapour exhausting. The collected vapour from the fans passes through two condensers where it has been liquefied and returned into the main tank. There are four fans x 3 kW for removing residual rinsing water from the crates. The crates transportation speed is adjusted via a frequency controller.

Request for a quote

WE PLUS GROUP

Turkey

Elevate your laundry game with our 1.4kg Turkish-made detergent powder. Crafted with precision in Turkey, it offers unmatched cleaning power, fabric care, and a delightful fragrance. Tough on stains, gentle on clothes, and eco-friendly, it's the ultimate laundry solution.

Request for a quote

WE PLUS GROUP

Turkey

Elevate your laundry game with our 9kg Turkish-made detergent powder. Crafted with precision in Turkey, it offers unmatched cleaning power, fabric care, and a delightful fragrance. Tough on stains, gentle on clothes, and eco-friendly, it's the ultimate laundry solution.

Request for a quote

WE PLUS GROUP

Turkey

Elevate your laundry game with our 4kg Turkish-made detergent powder. Crafted with precision in Turkey, it offers unmatched cleaning power, fabric care, and a delightful fragrance. Tough on stains, gentle on clothes, and eco-friendly, it's the ultimate laundry solution.

Request for a quote

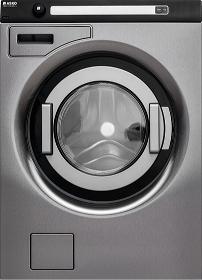

DC PRODUCTS

United Kingdom

Maximum spin speed: 1400rpm Finish: Light grey 28 programmes including three custom programmes Anti-leakage system and child lock ECO cold and hot water connection – saves up to 70% of electrical consumption and 20% of the programme time Connection: 400V / 3ph / 16A / 50Hz / Max effect: 4.6kW Can be reconfigured to: 230V / 1ph / 13A / 50Hz / Max effect: 2.4kW Available with pump or valve drain system

Request for a quote

DC PRODUCTS

United Kingdom

Maximum spin speed: 1400rpm Finish: Touch Proof™ Stainless steel 28 programmes including three custom programmes Relay card for auto dosing with three signals Anti-leakage system and child lock ECO cold and hot water connection – saves up to 70% of electrical consumption and 20% of the programme time Connection: 230V / 1ph / 16A / 50Hz / Max effect: 3.2kW Can be reconfigured to: 230V / 1ph / 10A / 50Hz / Max effect: 2.2kW or 400V / 3ph / 10A / 50Hz / Max effect: 3.2kW Available with pump or valve drain system

Request for a quote

DOLFIN INDUSTRIAL PARTS WASHING MACHINE AND SYSTEMS

Turkey

DOLFİN- VDL series Drum (Spiral) parts washing machines are used especially for cleaning small parts with high production quantities and produced in bulk. The materials poured from the inlet part of the spiralised drum in the device are directed towards the outlet part of the drum by the spirals inside the drum. While the drum moves on its own axis according to the set rotation speed, the parts are subjected to washing (degreasing), rinsing, passivation and drying processes respectively (depending on the model). Since these processes are sequential and continuous, all processes are completed quickly and effectively in a single device. Full penetration is achieved by pressurised spraying and immersion effects in each section. It is a very functional model used especially for washing bolts, nuts, washers, or small parts of this type, and fittings, nipples, couplings and fittings processed in high quantities on cnc and automat machines.

Request for a quote

DURAN D.D.

Croatia

Duran d.d. hand made production manufactures on demand glass articles from DURANᵀᴹ borosilicate glass 3.3. Our glass products are heat, stress, explosion, high/low temperatures and high pressure resistant. Hygienic in use due to smooth and pore-free surface. Taste and odour neutral. The glass panels are produced according to the drawings and technical features of washing machine manufacturers in conjunction with our technologists. For example, this glass is found in the following applications: Washing machine glass panels for industrial washing machines Spare parts for domestic washing machines "O" series Please contact us for precise specifications and options. Processing technology Drilling Sand blasting We'll be pleased to receive your enquires.

KERMAK MACHINERY

Turkey

The machine parts are made of 304 AISI stainless chrome material. High pressure water pump 800 crate washing capacity per hour Pressurized water spraying on the case is provided by special spray nozzles. Speed controlled conveyor system Visor and safety bars that can be adjusted according to the size of the frame Removable side covers for easy cleaning Internal water tank with a capacity of 500 liters. Anti-clogging sediment collector mechanical screening system 380V 50Hz 10kw electricity requirement Speed control panel for conveyor Electric control control panel Machine total length is 4 meters Washing Tunnel length is 3 meters. Height 165cm Width 100cm + 30cm electrical panel It can wash up to 600 * 400 * 350mm sized crates.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DOLFIN INDUSTRIAL PARTS WASHING MACHINE AND SYSTEMS

Turkey

Dolfin KNV series conveyor belt washing machines are parts washing machines used for washing parts produced in series in large quantities. The parts placed at the entry point are moved towards the exit point of the device by means of the conveyor. The parts guided on the conveyor line are washed with high pressure, pre-washing, washing, rinsing, spraying with passivation liquids. At the end of the cleaning process, these parts are dried with pressurised hot air and discharged at the exit point. If desired, it can be integrated into production processes and robotic loading and unloading options are also available. While the entire device is fully automatic, all washing details are parametric. Cleaning is provided at any desired level by means of spray nozzles specially designed according to the part geometry.

Request for a quote

DOLFIN INDUSTRIAL PARTS WASHING MACHINE AND SYSTEMS

Turkey

"DOLFİN- VDL series Drum (Spiral) parts washing machines are used especially for cleaning small parts with high production quantities and produced in bulk. The materials poured from the inlet part of the spiralised drum in the device are directed towards the outlet part of the drum by the spirals inside the drum. While the drum moves on its own axis according to the set rotation speed, the parts are subjected to washing (degreasing), rinsing, passivation and drying processes respectively (depending on the model). Since these processes are sequential and continuous, all processes are completed quickly and effectively in a single device. Full penetration is achieved by pressurised spraying and immersion effects in each section. It is a very functional model used especially for washing bolts, nuts, washers, or small parts of this type, and fittings, nipples, couplings and fittings processed in high quantities on cnc and automat machines.

Request for a quote

EUROMACK

Turkey

AREAS OF USE - Automotive industry - Aircraft industry - Ship industry - Defense industry - Metal industry PRINCIPLE OF OPERATION The parts to be washed on the basket placed on a stainless rotary platform with a sliding system are subjected to rotary basket washing with water with high pressure detergent in a closed cabin to be placed. Washing process is carried out to clean oil, sawdust, dirt and waste from dirty surfaces from different angles by means of time-adjustable pressure water nozzles according to the part structure and pollution rate. By filtering the water with the cycle permanent system, it is designed to reduce the consumption of water, detergent, electricity and time (labor) with the least consumption of parts. OPTIONAL FEATURES - Steam Evacuation Unit - Stainless chrome body structure - Basket structure - Number of nozzles - Liquid level control system All kinds of parts washing machines can be manufactured in our company upon request.

Request for a quote

GEYSER LLC

Russia

Fully automated spray jet cleaning system with rotating ramps, upward-opening curtain and roll-out worktable. It may include several stages of cleaning: washing, rinsing, drying. All stages are performed in one chamber. The washer is designed for cleaning large parts weighing up to 1,5 ton starting from cooling mixtures, dust, shavings, composites, oil after stamping, conservation lubricants, polishing pastes, emulsions, oil products. The efficient cleaning of surfaces that helps to remove a wide variety of contaminants is carried out with an alkaline cleaning solution heated to a predetermined temperature.

Request for a quote

DOLFIN INDUSTRIAL PARTS WASHING MACHINE AND SYSTEMS

Turkey

DOLFİN-KBN1 series parts washing machines are used before and after overhaul in repair and maintenance services, especially for washing large and heavy parts. Apart from revision workshops, it is also used for cleaning the surfaces before assembly or packaging in enterprises and factories that produce parts in series. They are special devices designed for large sized and heavy parts such as engines and parts of construction machines, power plant turbines. While the parts placed in the device are rotated on its own axis by means of the washing basket, pressurised detergent hot water is sprayed. Thanks to the pressure, temperature and chemical effect, all oil and dirt on the parts are cleaned.

Request for a quote

ATAC ELEKTRIK VE MAKINA SANAYI TICARET LTD STI

Turkey

Designed for washing the dyed textile samples with the same process as in the bulk production machines. Available with 3 chemical addition pumps and reserves. Automatic filling and draining and temperature gradient control helps the operator to create the cycle as per demand. The sample holder movement speed is adjustable and effects positively to optimize the wash effect. According to the design of the machine bleaching, desizing and Atmospheric dyeings can be made as well.

Request for a quoteResults for

Household washing-machines - Import exportNumber of results

24 ProductsCountries

Company type

Category

- Industrial washing facilities (7)

- Washing machines and spin dryers, industrial (4)

- Detergents, household (3)

- Washing machines, domestic (3)

- Laundry and dry cleaning machinery and equipment (2)

- Components and parts for large household appliances (1)

- Domestic appliances - large (1)

- Food packaging (1)

- High-pressure cleaning machines (1)

- Pumps (1)