- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- industrial bakery machines

Results for

Industrial bakery machines - Import export

DAMS MACHINE

Turkey

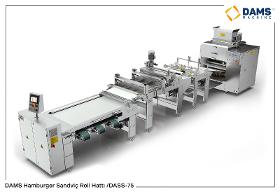

Sandwiches and burgers which are coming from the cooling unit are placed between the alignment units by two staff manually or automatically with unmanned feeding system. The aligned products are divided into groups of 4.5 and 6, thanks to two valves. The number of products is controlled by the sensors during the separation of the products and the control continues until it is finished. If desired; the slicing process takes place with the slicer system and the products reach the packaging for all grouped products. The products that reach the packaging are transferred to the relevant unit through the robot arm. The packaging unit is controlled by a single servo motor.

Request for a quote

DAMS MACHINE

Turkey

Roll, Sandwich Hamburger and similar sized products and Francala Bread are individually wrapped. Our machine has a servo motor system. Thanks to the touch screen and PLC on the machine, product package length, photocell adjustment and machine speed can be adjusted as desired. There is a sensor control system that prevents jamming of the product. If the product location is not correct, it stops the machine. All surfaces and covers that are in contact with the product in the machine are made of 304 quality chrome-nickel metal. Rotating jaw system. It packs 115 products per minute (roll, sandwich hamburger and similar products), and 83 products per minute in Francala Bread. It easy to use.

Request for a quote

DAMS MACHINE

Turkey

Roll, Sandwich Hamburger and similar sized products and Francala Bread are individually wrapped. Our machine has a servo motor system. Thanks to the touch screen and PLC on the machine, product package length, photocell adjustment and machine speed can be adjusted as desired. There is a sensor control system that prevents jamming of the product. If the product location is not correct, it stops the machine. All surfaces and covers that are in contact with the product in the machine are made of 304 quality chrome-nickel metal. Rotating jaw system. It packs 115 products per minute (roll, sandwich hamburger and similar products), and 83 products per minute in Francala Bread. It easy to use. Optionally, it is produced so that a coding device can be mounted on the machine. Cellophane bobbin is easy to disassemble and install, the place where it is mounted is an air system and PLC controlled shaft.

Request for a quote

DAMS MACHINE

Turkey

Roll Bread Packaging is done one by one. Thanks to the touch screen and PLC, there is easy access and intervention to the package size of the product, intelligent eye photocell adjustment and machine speed. Our Machine has intelligent motor system servo motor automation. There is a product control sensor that prevents the Roll Blower or other products from being jammed during packaging. During packing, the packaging does not crush the bread. If the location of the plant is not suitable, the intelligent eye sensor stops the machine. The machine is also made of 304 quality stainless chrome-nickel metal suitable for all surfaces that contact with the product and environmental protection covers. Our machine has been produced on the product in accordance with the operation of the device which outputs information such as date of production-serial number expiration date. This machine is optional. Emergency Stop has been put in place to provide user and machine security.

Request for a quote

DAMS MACHINE

Turkey

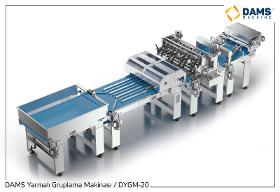

The settings are made easily from the PLC-controlled touch screen. Mechanical settings are simple to use and easy to learn. Information on usage can be stored in memory and used continuously. Daily cleaning is easy. It is easy to disassemble, install and replace belts and running parts. The speeds of all belts can be adjusted to the desired level. Electrical and electronic faults that may occur are displayed on the PLC screen with pic and text.

Request for a quote

DAMS MACHINE

Turkey

The settings are made easily from the PLC-controlled touch screen. Mechanical settings are simple to use and easy to learn. Information on usage can be stored in memory and used continuously. Daily cleaning is easy. It is easy to disassemble, install and replace belts and running parts. The speeds of all belts can be adjusted to the desired level. Electrical and electronic faults that may occur are displayed on the PLC screen with pic and text.

Request for a quote

DAMS MACHINE

Turkey

The settings are made easily from the PLC-controlled touch screen. Mechanical settings are simple to use and easy to learn. Information on usage can be stored in memory and used continuously. Daily cleaning is easy. It is easy to disassemble, install and replace belts and running parts. The speeds of all belts can be adjusted to the desired level. Electrical and electronic faults that may occur are displayed on the PLC screen with pic and text.

Request for a quote

DAMS MACHINE

Turkey

The settings are made easily from the PLC-controlled touch screen. Mechanical settings are simple to use and easy to learn. Information on usage can be stored in memory and used continuously. Daily cleaning is easy. It is easy to disassemble, install and replace belts and running parts. The speeds of all belts can be adjusted to the desired level. Electrical and electronic faults that may occur are displayed on the PLC screen with pic and text.

Request for a quote

SHINYOUNG MECHANICS CO.,LTD

South Korea

RICE CAKE MACHINES (SYP Model) As this Shinyoung Mechanics is a company which specializes in production of the Rice Cake Popping Machines, we are keeping the No. 1 domestic sales through the 2007 SYP series and being recognized its excellence selling the product of over 1,500 units to 50 countries worldwide. Since our SYP Rice Cake Popping Machine is that design is compact and convenience is superior on the use and time, thickness, shape etc are possible to control easily, it is in wide use from store up to factory. As the 100% Grain Snack is that nutritious ingredient is excellent and consumer recognition is good, it is easy to commercialize. As of now a variety of products such as general snack (chocolate-coated, flavor-seasoned), cereal for meal substitution or diet, children snack etc are being developed and sold. Thank you

Request for a quote

SHINYOUNG MECHANICS CO.,LTD

South Korea

Our SYP model is designed such that it can produce Popping Snack using 100% natural grains. Currently many new mechanical devices are being made, but it is not able to handle the high pressure continuously and produces nonuniform products. Its parts such as chains and motors are worn out easily and causes frequent breakdowns. Our SYP model corrected these flaws and uses hydraulics to produce uniform products and significantly increased its durability. Additionally, variety of molds are available in different sizes and shapes to satisfy customer needs. Small machines can be produced for local shops and and larger machines can be produced as well for factories. Our 100% natural grain snack can replace meals, is excellent for kids, and is good as a diet food. Furthermore our rice cakes made with 100% brown rice is good as a snack for people with diabetes. For more information, please contact us !! Thank you

Request for a quote

TURKIYE MACHINES BAKERY MACHINES

Turkey

As we are Turkiye Machines company we produce Bakery Machines in TURKİYE. We have 4 type of Bakery Machines and also we offer 2 years warranty to our Bakery Machines intermediate prover , intermediate prover TURKİYE , intermediate p rover Producer intermediate prover Seller intermediate prover manufacturer intermediate prover for bakery intermediate prover from Turkey intermediate prover bakery machines intermediate prover oven machines intermediate prover price intermediate prover dealer intermediate prover suppilier intermediate prover machine intermediate prover eurupe intermediate prover parts intermediate prover parts intermediate prover machine PRODUCER intermediate prover machine SELLER intermediate prover machine DEALER intermediate prover machine FİRST QUALİTY intermediate prover parts TÜRKİYE

Request for a quote

ALFA BREAD

Turkey

all line is made of food-grade materials - the machines gained ISO and CE certificates - 0ne year warranty- it works by gas or diesel - it is fully automatic. - it works by the pneumatic system - the oven works by the infrared system and it withstands high temperatures. ability to fit big and medium places. our engineers are ready to plan your place.

Request for a quote

TURKIYE MACHINES BAKERY MACHINES

Turkey

Spiral kneading machines are commonly preferred by bakery and pastry shops in order to shorten the usual kneading time. Also homogenous dough mixture is obtained thus volume of bread becomes even bigger. Machine can be worked as manual and automatic cycle with two programmable timers. The bowl, spiral arm, bar are made of stainless steel. The bowl can be rotated in reverse motion. Machine works as silent via belt transmissions of main power. It is a mobile machine and the wheels have locking system. Optionally, the temperature measuring unit may be added. process and allows to remove the bowl by user. The bowl is fasten to the mixer`s body with a locking system. By the way kneading standardization is always assured. The other specifications of removable bowl mixer are as follow: stainless steel bowl, knife and spiral hook, automatic and manual control, silence in mechanical system and power transfer, mechan-ical system and security system according to CE standards.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

USTUNELLER MAKINA

Turkey

The cutting-weighing machine, which is the newest system of dough processing technology, cuts the dough in the desired weight without compressing and wearing it. All surfaces in contact with the dough are made of stainless steel. It cuts the dough with its own weight, thanks to the vacuum created by the piston-cylinder movement. The lubrication system works automatically. Thus, it is ensured that the machine has a longer life. All surfaces are lubricated with food compatible oil. Weight adjustment can be produced automatically or mechanically, optionally. Standard 50-150 gr, 60-200 gr, 70-250 gr, 80-350 gr, 90-500 gr, 100-600 gr, 150-750 gr, 200-1000 gr, 250-1150 gr, 300-1300 gr 10 types of machines that cut and weigh the dough are produced.

Request for a quote

DAMS MACHINE

Turkey

DIVIDER & ROUNDER Upto 7000 pcs/hour capacity Weight range 40-140 grams (±2 gr) 4 pieces 50mm diameter pistons Changable outer drum for different weights 4 rows outlet belts. Automatic oil lubrication Variable speed controlsfor main drive and rounding unit Flour duster Dough bunker capacity is 140 kg Safety switches on doors Total power 5 kW 7 inc HMI Touch Panel PLC control INTERMEDIATE PROOFER Proofing time 10 minutes (for 4000pcs/hour) 4 pockets stainless steel dough carrier tray 146 pieces active tray 584 active pockets Removable and washable UHMWPE mesh pockets 2″ roller chain for tray transport Main frame is stainless steel tube Total power 1.1 kW Easy Access for maintenance Safety switches on doors

Request for a quote

DAMS MACHINE

Turkey

DIVIDER & ROUNDER Upto 11000 pcs/hour capacity Weigh trange 40-140 grams (±2 gr) 6 pieces 50mm diameter pistons Changable outer drum for different weights 6 row outlet belts Automatic oil lubrication Variable speed controls for main drive and rounding unit Flour duster Dough bunker capacity is 210 kg Total power 5 kW 7 inc HMI TouchPanel , PLC control INTERMEDIATE PROOFER Proofing time 10 minutes (for 6000pcs/hour) 6 pockets stainless steel dough carrier tray 139 pieces active tray 834 active pockets Removable and washable UHMWPE mesh pockets 2″ roller chainfortray transport Main frame is stainless steel tube. Total power 1.5 kW Easy Access for maintenance Safety switches on doors.

Request for a quote

DAMS MACHINE

Turkey

DIVIDER & ROUNDER Up to 11000 pcs/hour capacity Weight range 40-140 grams (±2 gr) 6 pieces 50mm diameter pistons Changable outer drum for different weights 6 row outlet belts Automatic oil lubrication Variable speed controls for main drive and rounding unit Flour duster Dough bunker capacity is 210 kg Total power 5 kW 7 inc HMI Touch Panel PLC control INTERMEDIATE PROOFER Proofing time 10 minutes (for10.000pcs/hour) 6 pocket stainless steel dough carrier tray 278 pieces active tray 1668 active pockets Removable and washable UHMWPE mesh pockets 2″roller chain for tray transport Main frame is stainless steel tube. Total power 1.5 kW.

Request for a quote

DAMS MACHINE

Turkey

Dough balls which are prepared according to the diameter of the desired product are released one by one into the hopper of the machine. The dough is crushed between two homogeneously heated plates with the hot pressing techniques. When the plates are spacing the rolled dough slides out of the machine. When the plates are spaced, the new dough roll falls between the plates from the hopper. Temperature of each plate; It is controlled by measuring separately. Product thickness can be adjusted manually.

Request for a quote

DAMS MACHINE

Turkey

The settings are made easily from the PLC-controlled touch screen. Mechanical settings are simple to use and easy to learn. Information on usage can be stored in memory and used continuously. Daily cleaning is easy. It is easy to disassemble, install and replace belts and running parts. The speeds of all belts can be adjusted to the desired level. Electrical and electronic faults that may occur are displayed on the PLC screen with pic and text. In case of malfunction, remote access can be performed with PLC program (Optional) CUTTING SECTION Machine body is 304 crom. The contact surfaces of the dough are 304 crom and crom coating.

Request for a quote

DAMS MACHINE

Turkey

The settings are made easily from the PLC-controlled touch screen. Mechanical settings are simple to use and easy to learn. Information on usage can be stored in memory and used continuously. Daily cleaning is easy. It is easy to disassemble, install and replace belts and running parts. The speeds of all belts can be adjusted to the desired level. Electrical and electronic faults that may occur are displayed on the PLC screen with pic and text.

Request for a quote

DAMS MACHINE

Turkey

The settings are made easily from the PLC-controlled touch screen. Mechanical settings are simple to use and easy to learn. Information on usage can be stored in memory and used continuously. Daily cleaning is easy. It is easy to disassemble, install and replace belts and running parts. The speeds of all belts can be adjusted to the desired level. Electrical and electronic faults that may occur are displayed on the PLC screen with pic and text.

Request for a quote

DAMS MACHINE

Turkey

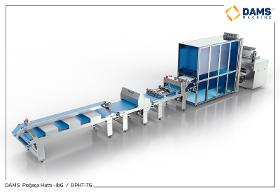

GENERAL CHARACTERISTICS Sandwich and hamburgers coming from the cooling tower or in bulk are placed manually between the product sorting slides with the help of two personnel. When the products are divided into groups, the numbers are checked with the sensors, and if there are missing rows, they wait until the order is completed. The queues are divided into groups by the help of two flaps, and the number of packages depends on desired grouping (sandwich 4, 5, 6, Hamburger 4, 6, 8).

Request for a quote

DAMS MACHINE

Turkey

It can cut sandwiches and hamburgers, flatbread, bagels, baguettes and similar products. It is used in the slicing (cutting) process of sandwich and hamburger breads before packaging. The slicing machine has wheels and can be taken anywhere easily. The chassis is completely chrome nickel. Used strip blade, easy to disassemble and install. The surfaces that the product comes into contact with are made of tape suitable for food. Product feeding is done manually.

Request for a quote

DAMS MACHINE

Turkey

It is used in splitting (cutting/ slicing) the sandwich and hamburger breads before packaging. Circular blade is used, this blade is easy to remove and install. 304 Cr-Ni is manufactured on the surfaces that the product touches. The bands used are suitable for food. Product feeding is done manually. There are three adjustment arms; First Setting Arm It is top pressing setting. The top band is adjusted according to the thickness of the bread to be split and the bread is prevented from flying during cutting.

Request for a quote

DAMS MACHINE

Turkey

It is used in splitting (cutting/ slicing) the sandwich and hamburger breads before packaging. Circular blade is used, this blade is easy to remove and install. 304 Cr-Ni is manufactured on the surfaces that the product touches. The bands used are suitable for food. Product feeding is done manually. There are three adjustment arms; First Setting Arm It is top pressing setting. The top band is adjusted according to the thickness of the bread to be split and the bread is prevented from flying during cutting.

Request for a quoteResults for

Industrial bakery machines - Import exportNumber of results

58 ProductsCountries

Category

- Bakery and confectionery industry - machinery and equipment (45)

- Bakery - machinery and equipment (39)

- Bakery ovens (14)

- Bakery - machinery and equipment (8)

- Food Industry - Machines & Equipment (2)

- Agglomeration and emulsification machines for the food processing industry (1)

- Bottling and filling - machinery and equipment (1)

- Cleaning machines, industrial (1)

- Confectionery - machinery and equipment (1)

- Ironing machines, industrial (1)

- Laundry and dry cleaning machinery and equipment (1)

- Mixers and grinders for the food processing industry (1)

- Sweeping machines, industrial (1)

- Tumble dryers and spin dryers, industrial (1)