- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- industrial cutting of metals

Results for

Industrial cutting of metals - Import export

NOVELTY STEEL

Turkey

Sheet metal fabrication is the process of bending, cutting, punching, assembling sheet metal to form into the desired form. Special tools, such as band saws and chops saws, can also be used in the sheet metal fabrication process. These ensure even cutting throughout the process. Parts are fabricated from a single piece of sheet metal so designs should have a uniform thickness. Although carbon steel is the most prominent material for metal fabrication, stainless steel would be necessary for high corrosive environments whereas aluminium is primarily considered when weight of the product is a major limitation.

Request for a quote

ESTIMET SP Z O.O.

Poland

Metal plate CNC controlled gas cutting up to 6000 mm x 2000 mm, thickness of 150 mm We have over 30 years of experience in metal plategas cutting . Today, CNC controlled gas cutting is a very effective and economical method of cutting metal plate. Thanks to several cutting heads, we are able to guarantee a large quantity of finished products in a short time. Despite major progress in the development of other cutting methods (laser cutting, water jet cutting or plasma cutting), gas cutting continues to enjoy great popularity. It is a relatively slow method, but with the right technological approach it guarantees high efficiency of production at a very low cost of finished elements. Gas cutting has no competition in terms of cutting sheets of more than 60 mm. The only technology that can be used instead is water jet cutting, but gas cutting is by far cheaper.

Request for a quote

DEHA REKLAMCILIK SAN. VE TIC. LTD. STI.

Turkey

We are manufacturing your custom metal products. We cut, bend and weld metal sheets, profiles pipes in all sizes. Also, we offer PPC coating application in our large capacity factory.

Request for a quote

RHODIUS ABRASIVES GMBH

Germany

The industry-standard metal cutting disc for the cost-conscious professional. Cuts easily with a good service life. • High cutting speed • Easy cutting • Comfortable cutting behaviour

RHODIUS ABRASIVES GMBH

Germany

The industry-standard metal cutting disc for the cost-conscious professional. Cuts easily with a good service life. • High cutting speed • Easy cutting • Comfortable cutting behaviour

RAMAZAN AYCAN SAC VE CELIK ISLEME MERKEZI SAN. VE TIC. A.S.

Turkey

The cutting principle of guillotine shears is the same as the cutting principle of hand shears. The force applied on the moving blade of two blades one of which is fixed and the other is movable cuts off the part between the blades. The cutting capacities are highly variable. Depending on these variations, the production dimensions are made differently. As Ramazan Aycan Inc., we provide you with guaranteed services regarding guillotine cutting with our expert staff. We perform the following cutting operations of iron-steel, aluminum and other metal sheet types. Metal cutting using guillotine shears for metal and furniture industry Metal cutting using guillotine shears for steel construction and construction industry Metal cutting using guillotine shears for the white goods industry Metal cutting using guillotine shears for the heating, ventilation and air-conditioning equipment industry.

Request for a quote

RAMAZAN AYCAN SAC VE CELIK ISLEME MERKEZI SAN. VE TIC. A.S.

Turkey

Oxygen Cutting is the most widely used industrial thermal cutting process. After the metal material is heated to the ignition temperature with high heat obtained by burning in oxygen, the heated part is cut with pure oxygen gas jet. As Ramazan Aycan Inc., we can perform oxygen cutting from 35 mm to 150 mm with our new generation CNC oxygen cutting machines.

Request for a quote

MALKA REKLAMA LTD

Bulgaria

Laser cutting of stainless steel, carbon steel, any metal and non-metal sheets like wood, plexiglass, mdf, and other material.

Request for a quote

FATIH WROUGHT IRON

Turkey

Weight: 0,90 kg Height : 12 cm Width : 99,1 cm Material: 2 mm

Request for a quote

FATIH WROUGHT IRON

Turkey

Weight: 28,71 kg Height : 198 cm Width : 99 cm Material: 3 mm

Request for a quote

CNC-STEP GMBH & CO. KG

Germany

Thanks to the robust steel frame, our T-Rex CNC mill enables you to produce precisely, quickly and cleanly. Even with workpieces made of hard material, you will achieve ideal results, thanks to the high stability of the CNC machine, which is guaranteed by the robust construction. On this machine, you can even process thicker plate material, as the clearance height of the Z-axis is 200 mm. Versatile application possibilities: drilling, cutting or engraving in different materials such as plastic, wood, granite, marble, stone and metal can be done with high accuracy. Basic equipment: > vacuum table with several zones > manual central lubrication > KinetiC-NC control software > ergonomic control panel with integrated CNC control > full version of the design software ConstruCAM-3D > Estlcam software CE-compliant commissioning of our CNC machines requires the attachment of the protective housing and the exhaust connection.

Request for a quote

ESTIMET SP Z O.O.

Poland

Often used as an alternative to gas cutting, plasma cutting is a reliable method of cutting sheets of blackplate, stainless steel and aluminum up to a thickness of 40 mm. Our machine allows sheets with dimensions of 6000 mm x 2000 mm to be cut. Plasma cutting is one of the most popular steel sheet cutting methods. It is especially appreciated in the case of cutting thick sheets of aluminum or stainless steel. The large working area makes this method unbeatable by technologies such as laser cutting or water jet cutting. ESTIMET offers plasma cutting services for companies from many different industries across Europe. We carry out orders involving series of many thousands of elements, we also produce single elements we the needs of prototypes. Our factory has been created specifically for the needs of sheet metal processing services. Thanks to automation, as well as our committed staff, production is carried out 24 hours a day.

Request for a quote

ESTIMET SP Z O.O.

Poland

Our services include water sheet metal cutting. The parts we cut comply with the EN 1090 standard, and therefore with the CE mark. We use the waterjet cutting method for various types of parts whose dimensions do not exceed 2000 x 4000 m and whose thickness is up to 200 mm. We cut with a stream of water with an admixture of abrasive at a pressure of 60,000 PSI, without introducing heat into the material, so we can cut in addition to steel materials: - stone - marble - plastic - rubber - glass The WaterJet method, or waterjet sheet metal cutting, involves the use of a jet of water at very high pressure - often supplemented by the addition of an abrasive. The jet is directed at the surface to be processed, which makes it possible to cut a shape in it with the desired dimensions. Modern WaterJet technology is an attractive alternative to plasma or laser cutting.

Request for a quote

ESTIMET SP Z O.O.

Poland

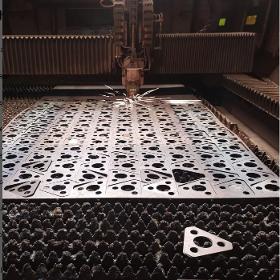

One of the areas of ESTIMET's offer is laser cutting, used for precision processing of sheet metal, pipes and profiles. In ESTIMET's machine park we have two fiber lasers of 6 kW and 8 kW. Thanks to these devices, we can precisely cut elements with maximum dimensions of 2000 x 4000 mm. Our laser cutting services comply with the EN 1090 standard, as confirmed by the CE mark. We are ready to take on even the most demanding orders, offering to cut sheet metal made of a variety of materials, such as carbon steel, stainless steel, aluminum, copper or bronze. We also have a gas burning machine, dedicated to metal sheets up to 150 mm thick. In addition, we have specialized machines for cutting pipes, profiles and sections with maximum dimensions of 450 x 450 mm. We can cut tubes and profiles in straight sections as well as at an angle. The range: steel: 0,5 - 25 mm INOX: 0,5 - 30 mm aluminum: 0,5 - 25 mm brass: 0.5 - 10 mm copper: 0.5 - 10 mm galvanized: 0.5 - 4 mm

Request for a quote

ESTIMET SP Z O.O.

Poland

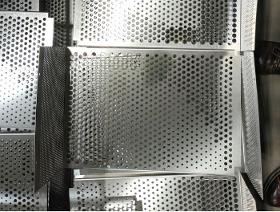

We are offering CNC laser cutting from alluminium. On the picture: alluminum - 15 mm. Our CNC controlled lasers with a power of up to 6 kW work 24 hours a day. We carry out services on our own or on customers’s material. We cut the whole range of various types of materials. Services are performed on cutting-edge machines with a working area of 4000 x 2000 mm and a cutting thickness of 25 mm. Laser cutting is becoming more popular as one on main methods of steel cutting. This is due to high precision, outstanding quality and amazing speed of cutting. Laser cutting technology easily cuts steel and other materials with a precision that is out of reach of other technologies. ESTIMET offers laser cutting services for companies from many different industries across Europe. We carry out orders involving series of many thousands of elements; we also produce single elements we the needs of prototypes. Our factory has been created specifically for the needs of sheet metal processing services.

Request for a quote

ESTIMET SP Z O.O.

Poland

Laserskjæring av konstruksjons-, rustfrie, aluminium- og forzinket plater. Maksimal platestørrelse: 4000mm x 2000mm, tykkelse opptil 25mm.

Request for a quote

ILK IHRACAT AS.

Turkey

Up to 70 mm! We offer laser precision from 0.5 mm to 70 mm. Experienced Team: Expert and experienced laser cutting operators. Advanced Technology: We guarantee cutting quality and precision using the latest laser cutting technologies. Custom Solutions: We offer customized cutting solutions that fit customer needs. Fast Delivery: We support your production processes with timely and swift deliveries. Get a Quote Now Contact us immediately for the most suitable laser cutting solutions for your needs. Our professional team is ready to provide you with exclusive offers. Steeling.Net carries out partner export activities in the Turkish metal industry. Our partner manufacturers are companies that specialize in sheet and steel processing and have a wide product range.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PIANEX

Poland

Erhardt+Leimer type: MD 1003 Working width 2700mm Detector speed from 0.5m / min to 400m / min Detects metals below 2mg with a diameter of 0.8mm

Request for a quote

VIRMER

Netherlands

WATTSAN 1325 BASIC fiber laser machine is an economical and practical machine for cutting thin sheet metal. The metal cutting machine works with stainless and carbon steel, copper, aluminum, titanium and other materials. This machine is often purchased for manufacture, such as aviation, astronautics and mechanical engineering. We can install Maxphotonics / Raycus / IPG fiber laser emitter for choice. The main advantage of a fiber laser over a gas laser is its high speed and accuracy of operation, as well as durability: the life of the ignition unit is 100,000 hours, i.e. years of continuous operation. The machine has a working table 1300x2500 mm. WATTSAN 1325 BASIC laser machine is a high-precision device with a reliable control system. It has a high-quality fiber laser emitter. Of course, such a device will last a long time, because the declared service life of the frame is 20 years.

Request for a quote

VIRMER

Netherlands

Fiber metal cutting machine WATTSAN 1325 TABLECHANGE is a large and high-precision machine for cutting stainless and carbon steel, copper, aluminum, galvanized plates and other materials. On this machine, it is possible to install emitters of the following powers: 300/500/750/1000 Watts, and from 1500-5000 Watts with a protective cabin. One of the main advantages of all fiber lasers is durability: the life of the ignition unit reaches 100 000 hours. And this is about 10 years of continuous work. The manufacturer also claims that the bed of this machine can last 20 years. There are two options for the working field for this machine: 1300x2500 mm and 1500x3000 mm (1530 TABLECHANGE). For smaller workpieces, the 1300x2500 mm option is suitable; for industrial production, it is recommended to purchase a larger working area. If you have any doubts about the choice of the working field, please contact our specialists for advice.

Request for a quote

VIRMER

Netherlands

WATTSAN 1530 ROTATORY has a rotary device for cutting cylindrical products. This machine is purchased for cutting steel tubes, galvanized and stainless steel, aluminum, brass and other materials. The machine is most often used in aviation, aerospace and mechanical engineering, as well as for the manufacture of auto parts, advertising products and household appliances. You can install a radiator of any power: 300/500/750/1000/1500/2000/3000/4000/5000 Watts. Important: the machine is equipped with a protective cabin with a power of 1000 Watts. Optional fiber laser emitter: Max / Raycus / IPG. Each of them is distinguished by high accuracy and speed of work, durability, but there are also differences. IPG is considered a premium model, it gives the best result and speed. The service life of the emitter ignition unit is about 100 000 hours. The protective glass for the lens, which must be changed at least once a month. The lens itself needs to be renewed approximately once a year.

Request for a quote

VIRMER

Netherlands

WATTSAN 1530 ROTATORY CABINE is a powerful fiber laser machine, also known as a tube cutter. The device is equipped with a protective cabin for safe operation, as well as a rotary device. The rotary device takes the capabilities of your equipment to a whole new level. You can use the metal cutter like a regular cutter, and in a few minutes switch to the task of cutting tubes. The protective cabin is installed on machines from 1000 watts. This ensures the safety of the laser cutting operator, as well as minimizes the dangers of external influences. The machine is equipped with a fiber optic emitter: Max or Raycus or IPG. Such an emitter will last up to 100 000 hours of the most intensive work. If we talk about the intensity of work — the stand is weighted, crushes vibrations and will last 20 years, according to the manufacturer's information.

Request for a quote

VIRMER

Netherlands

WATTSAN 1530 TABLECHANGE is a high precision fiber laser cutting machine. It is equipped with an automatic change table. This design allows you to quickly change sheet metal while another workpiece is being cut. Such a system saves time and money for its owners. Such a machine has long been used in aircraft construction, mechanical engineering, light industry and medical equipment. The machine is equipped with a laser solid-state emitter to choose from: Max / Raycus / IPG. All three have proven themselves: Max is standard, Raycus is more expensive and better, and IPG is considered a premium series. All three types of emitters have a resource of about 100,000 hours. The automatic change table has a size of 1500×3000 mm for metal. The bed is made with a margin of safety, and the heavy weight dampens vibrations. Vibration mounts can be installed for added stability.

Request for a quote

BIZERBA SE & CO. KG

Germany

Fully automatic slicer with integrated weighing technology for portioning and weighing of individual slices. With fully automatic product fixation. Easy to service and very robust – perfect for industrial use. Area of Use Robust slicer for industrial production

Request for a quote

ELECTROALFA

Romania

Made of galvanized steel sheet 1-2 mm Standard color: RAL 7035 (powder paint) Door fitted with locks and polyurethane gasket Door opening angle: 120° Protection degree up to IP66 IEC60529

Request for a quote

MARXAM PROJECT

Poland

Water jet cutting services allow to ensure high quality of the machined surface for details with large thicknesses and complex geometric shapes (high density of cutting lines on a small area, small diameters of holes – of even 1mm). The use of aqua cutting with high pressure, containing fine abrasives, allows to achieve new production effects, which were impossible or time-consuming and expensive using other methods. Using this method, we can process, materials such as: - Ceramic materials - Glass - Plastics - Titanium and its alloys - Materials sensitive to high processing temperatures - Structural, alloy and tool steels (of any degree of hardening) - Cast iron, steel - Copper, brasses, bronzes - Molybdenum and its alloys - Wood and wood-based materials Waterjet cutting technology is one of the most environmentally friendly processing methods. The abrasives used are of natural origin and are chemically inert, and the process itself does not generate any harmful waste.

Request for a quote

MARXAM PROJECT

Poland

Laser cut companies have become quite prominent in metalworking industries. Choosing Marxam Project, you are choosing a reliable partner with decades of experience. Sheet metal laser cutting is a technology that allows you to quickly and cheaply obtain an element of any complex shape from various types of flat sheets. The undoubted advantages of laser cutting are: - cutting laser offers freedom of shapes, limited only by the properties of a material; - cutting metal with repeatability of details at the level of 100%; - for given types of materials and their thickness, the laser cut surface is of a quality that allows the elimination of the finishing process; - the best possible use of the surface of the material – thanks to the use of appropriate computer programs, with our laser cutting services, we obtain a large percentage of sheet metal use, and we can properly optimize the production process; - it allows to reduce the effect of heat on the deformation of the cut material

Request for a quote

ROKVELAS, UAB

Lithuania

- Band saw cutting by automatic machines up to 400x400 mm, L12000 mm; - Sheet cutting by plasma by CNC machine up to 50x3000x10000.

Request for a quote

ROKVELAS, UAB

Lithuania

- Band saw cutting by automatic machines up to 400x400 mm, L12000 mm; - Sheet cutting by plasma by CNC machine up to 50x3000x10000.

Request for a quoteResults for

Industrial cutting of metals - Import exportNumber of results

48 ProductsCountries

Category

- Cutting - steels and metals (27)

- Steels and metals - forming and cutting (14)

- Industrial sheet metal work (6)

- Laser - cutting and welding machines (2)

- Engraving, industrial - steels and metals (1)

- Food Processing (1)

- Mechanical engineering - custom work (1)

- Metal detectors (1)

- Metallurgy - machinery and installations (1)

- Straightening - steels and metals (1)