- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- installation of packaging machines

Results for

Installation of packaging machines - Import export

BORNEMANN GMBH

Germany

Brass types for stamping paper, wood and synthetics. In the pharmaceutical industry brass types are installed in packaging machines with corresponding brass type holders and give the product the labelling. Batch labellings, manufacturer coding and process data are thereby stamped flexibly. If you request changes, the types used can be replaced.

Request for a quote

IGUS® GMBH

Germany

Other information Series 10 Inner height hi: 18 mm Inner widths Bi: 15 - 100 mm bending radii R: 28 - 180 mm Pitch: 30,5 mm E-Chain®, not-to-be-opened Series 11.031 Inner height hi: 23 mm Inner width Bi: 31 mm Bending radii R: 45 - 70 mm Pitch: 30.5 mm E-Chain®, not-to-be-opened Series 11.080 Inner height hi: 28 mm Inner width Bi: 80 mm Bending radius R: 38 mm Pitch: 30.5 mm E-Chain®, not-to-be-opened Series 11.1/11.2 Inner height hi: 41 mm Inner widths Bi: 15 - 25 mm bending radii R: 40 - 100 mm Pitch: 30,5 mm E-Chain®, not-to-be-opened Series 14 Inner height hi: 20 mm Inner widths Bi: 15 - 50 mm bending radii R: 28 - 125 mm Pitch: 30,5 mm E-Chain®, snap-open inside Series B15i Inner height hi: 17 mm Inner widths Bi: 15 - 100 mm bending radii R: 38 - 180 mm Pitch: 30,5 mm E-Chain®, snap-open inside Series B17i Inner height hi: 32 mm Inner widths Bi: 15 - 100 mm bending radii R: 48 - 125 mm Pitch: 30,5 mm E-Chain®, snap-open inside Series F17 Inner height hi: 32 mm Inner height Bi: 15 mm Bending radii R: 48 mm Pitch: 30,5 mm E-Chain®, snap-open inside Series B15 Inner height hi: 17 mm Inner widths Bi: 15 - 100 mm bending radii R: 38 - 180 mm Pitch: 30,5 mm E-Chain®, snap-open outside Series B17 Inner height hi: 32 mm Inner widths Bi: 15 - 100 mm bending radii R: 48 - 125 mm Pitch: 30,5 mm E-Chain®, snap-open outside UL94-V2 classifications Cleanroom class 1 (ISO class 3) Series 10 tested by Dryden Engineering Company, California Special version: Electrically conductive ESD/ATEX versions on request Other information Series 10 Inner height hi: 18 mm Inner widths Bi: 15 - 100 mm bending radii R: 28 - 180 mm Pitch: 30,5 mm E-Chain®, not-to-be-opened Series 11.031 Inner height hi: 23 mm Inner width Bi: 31 mm Bending radii R: 45 - 70 mm Pitch: 30.5 mm E-Chain®, not-to-be-opened Series 11.080 Inner height hi: 28 mm Inner width Bi: 80 mm Bending radius R: 38 mm Pitch: 30.5 mm E-Chain®, not-to-be-opened Series 11.1/11.2 Inner height hi: 41 mm Inner widths Bi: 15 - 25 mm bending radii R: 40 - 100 mm Pitch: 30,5 mm E-Chain®, not-to-be-opened Series 14 Inner height hi: 20 mm Inner widths Bi: 15 - 50 mm bending radii R: 28 - 125 mm Pitch: 30,5 mm E-Chain®, snap-open inside Series B15i Inner height hi: 17 mm Inner widths Bi: 15 - 100 mm bending radii R: 38 - 180 mm Pitch: 30,5 mm E-Chain®, snap-open inside Series B17i Inner height hi: 32 mm Inner widths Bi: 15 - 100 mm bending radii R: 48 - 125 mm Pitch: 30,5 mm E-Chain®, snap-open inside Series F17 Inner height hi: 32 mm Inner height Bi: 15 mm Bending radii R: 48 mm Pitch: 30,5 mm E-Chain®, snap-open inside Series B15 Inner height hi: 17 mm Inner widths Bi: 15 - 100 mm bending radii R: 38 - 180 mm Pitch: 30,5 mm E-Chain®, snap-open outside Series B17 Inner height hi: 32 mm Inner widths Bi: 15 - 100 mm bending radii R: 48 - 125 mm Pitch: 30,5 mm E-Chain®, snap-open outside E-Chain® selection aids You can find the right E-Chain® quickly by entering concrete parameters and with the aid of a comparison table. Selection aids Installation instructions Joining and separating of chain links Assembly Instructions Application examples Applications in various industrial sectors. E2 mini One-/Two-piece E-Chain® Small pitch for silent operation High torsion resistance Double stop system and large pins for long service life Optimized weight/stability ratio Easy to mount Manifold interior separation Typical industrial sectors and applications Construction machinery Handling systems Installation Packaging machines Textile machines Vehicle construction Wood machines Glass machines Machine construction General mechanical engineering etc. UL94-V2 classifications Cleanroom class 1 (ISO class 3) Series 10 tested by Dryden Engineering Company, California Special version: Electrically conductive ESD/ATEX versions on request

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

Our entry-level model for printing fixed text and graphics on (coated) paper or Tyvek. Suitable for installation on blister packaging machines and can be combined with our PM460 online inkjet printer for printing fixed and variable content at the same time.

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

Online printing of variable data such as batch number, production date, etc. Suitable for installation on blister packaging machines. Can be equipped with different inkjet systems.

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

Suitable for online printing of large text and graphics directly onto the sealing film. Can be combined with our online inkjet printer PM460 for simultaneous printing of fixed and variable texts and graphics.

Request for a quote

FERPLAST SNC

Italy

To be installed at the exit of the packaging machines and welding machines. ROTATING TABLE OF ACCUMULATION WITH STAINLESS STEEL STRUCTURE AND NYLON PLAN The rotary table of accumulation is generally used in the final part of the packaging lines and facilitates the discharge of the packs, facilitating the sampling operations by the operator. The rotating tables with nylon plan are available with a diameter of 800, 1200 or 1400 mm, and are suitable for bottles, cans and products that can overturn in the concave or convex turntables. The flat rotating tables can be equipped with loading systems and automatic unloading and thus be used as "accumulation areas" between an automatic machine and another. Edges and sides nylon version Flat turntable with holding sides, polyethylene plan, useful height of 810 mm and a mechanical speed variator.

Request for a quote

JING HENG SING TECHNOLOGY CO., LTD.

Taiwan R.O.C.

Powder suction/powder receiver hoppers use air to convey the powdery material and can be specified in butterfly valve type and rotary valve type. The advantage of air conveyor/pneumatic conveyor system is the small residual amount of pipeline, which ensures that the pipeline is empty between the production of each batch to meet food production regulations. The powder suction/powder receiver hoppers are designed to be quickly dismantled and cleaned, without tools, which is convenient for maintenance to comply with food regulations. The powder suction hoppers/powder receiver can be installed on storage barrels, mixers, packaging machines and mills, they are suitable for powdered food materials, chemicals and plastics. There are many options for the top filter to accommodate various feeding systems.

Request for a quote

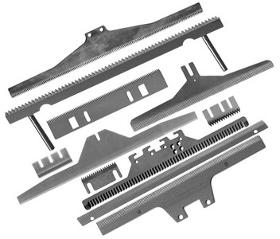

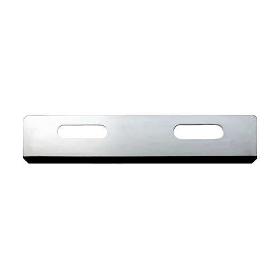

PRO COUPE INDUSTRIES

France

Thoothed blades for SIG® SANDIACRE® ROVEMA® FOREGROVE® PRASMATIC® OMORI® MULTIVAC® MIELE® MESOMA® MECAPACK® ILAPAK® HAYSSEN® COMMARME® BOSCH® AQUARIUS® TECNIMODERN® TETRA® TWINPACK® ULMA®

Request for a quote

FERPLAST SNC

Italy

HOOD PACKAGING MACHINES - FP 5540 – FP 7060 SERIES L-seal hood shrink packaging machine combines sealing with shrinking into one step. The operator places the product between the two layers of mono-fold film, then moves the package into the sealing area and lowers the hood. When the shrink time is completed, the hood is returned to the up position and the operator may remove the completed package . The transparent cover makes the process of sealing & cutting and shrinking be visible. Colours: dark gray or orange depending on availability. It suitable for PVC shrink films with max. thickness 30 my and POF shrink films with max. thickness 19 my. Two models are available with a support surface of mm. 500x400x250h - mm. 650x550x300h. The dimensions of the support surface are to be considered with the hood closed. The volume cannot be completely filled by the box or by the product to be packaged as space must always be left for the passage of hot air around the product.

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

This coin feeder enables continuous feeding of a coin sorting machine or a coin wrapping machine. Fill level controlled by detectors. Adaptation to your coin trolleys. - Robust frame made of epoxy painted steel - Hooking device for all types of trolleys - Specially designed trolley that is easily handled and adaptable to the forklift truck - Possibility of manufacturing to your dimensions depending on the quantity required - Height adjustable from 500 to 1300 mm - Dimensions can be changed on request - Speed: up to 7000 pieces/min - Speed control by variator The materials comply with the applicable EC standards.

Request for a quote

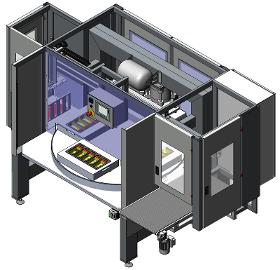

CUPASO DEUTSCHLAND GMBH

Germany

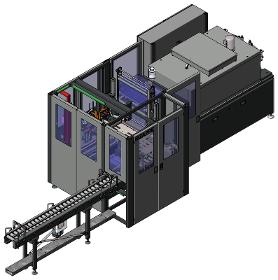

System for bundling coin rolls of 5 or 10 pieces and shrinking in PE film. Elements of serial production: - Robust steel frame, painted grey in RAL 9006 - Welding frame with Teflon-coated heating rods with constant temperature controlled by temperature controllers with digital display - Motorised unwinding of the coil - Control generated by a programmable logic controller - Touch screen display - Storage of programmes - Automatic change of designations - Detection of the end of the spool - Translucent housing - Material according to current EC standards Foils that can be used: Polyethylene

Request for a quote

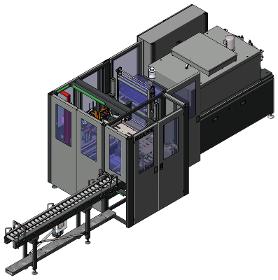

ZAPPE PACKAGING TECHNOLOGY GMBH & CO. KG

Germany

Sleeve Wrapping Machines by Zappe – wrapping machines and shrink tunnels that adapt to your needs

Request for a quote

ZAPPE PACKAGING TECHNOLOGY GMBH & CO. KG

Germany

Zappe configures your blister machine to measure, regardless of whether it is a manual, fully automatic or semi automatic blister sealing machine.

Request for a quote

ZAPPE PACKAGING TECHNOLOGY GMBH & CO. KG

Germany

Sleeve Wrapping Machines by Zappe – wrapping machines and shrink tunnels that adapt to your needs

Request for a quote

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

It’s a fully automatic counting and packing machine for Furniture kits and hardware spare parts. Widely used in fasteners, hardware, furniture, and bathroom field. You only need to put the spare parts into the hopper and roll film on the packing machine, set in the quantity that you need to in the bag and open the machine. The machine will automatically count the spare parts and make the film to be a bag, filling the spare parts into the bag, sealing, and cutting. Feature: 1. According to screw/special parts sample tailored to the vibration plates with a precise count control device, to ensure that every bag is accurate and correct. 2. Adopts pneumatic structure, the whole machine is more secure, stable, and reliable. 3. Advanced PLC control system and various automatic alarm protection functions, convenient for daily maintenance and reduced wastage. 4. It completes the whole procedure of metering, filling, bagging, date printing, charging(exhausting), and counting automatically.

KALENDER MAKINA

Turkey

FULL MOTION CONTROLLED WET WIPES PRODUCTION LINE WITH TEN SERVOS AND TWO COILS Wet cleaning, towel (baby) wipes, etc. production can be made.

Request for a quote

SOLLEX AB

Sweden

Ceramic coated injector blade in stainless steel for plastic film manufacturing. The fine structure enables the coating to protect the edge as long as possible. Ceramic coating is therefore advantageously used to cut white plastics. The injector blade with a thickness of 0.25 mm is a strong and small blade with high durability. For finer and thinner cuts, Sollex recommends ceramic coated industrial razor blade (2-013-K). Suitable for: White plastic film with a high percentage of chalk Dimensions: 38 x 8 x 0.25mm Grinding: Single edge Two sided Single bevel

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HARKOM MAKINA SAN. TIC. LTD. ŞTI

Turkey

Suitable for granule type of products. The target weight is controlled by linear vibration units. With respect to product type and desired speed; 2 or 4 line types are available. The magnitude of vibration level for each line is adjustable. The accuracy of each filling is controlled by tuning each line vibration magnitude. The average accuracy is depend on product type. All surfaces touching to products are AISI 304 stainless steel. Easy dismountable collar set design. Package length should be controlled by print mark or feeding duration. Printer state is checked continiously. Wrapping material is feed by Servo motors. Servo Motor Controlled Horizontal sealing and cutting. Impulse or heat sealing units for different type of wrapping materials. Wrapping material tension is controlled continiously. Auotamic lateral adjustment of wrappin material. Suitable for CE standarts. 7 inch touch screen wtih several languages.

Request for a quote

HARKOM MAKINA SAN. TIC. LTD. ŞTI

Turkey

Volumetric filling system is suitable for products which are able to free falling and homogeneous in density.the Weight of each filling is controlled by adjusting the dimensions of filling cups. Different cups with adjustable dimension should be used for different type of products.The sensitivity of target weight is equal to sensitivity of product density. All surfaces touching to products are AISI 304 stainless steel. Easy dismountable collar set design. Package length should be controlled by print mark or feeding duration. Printer state is checked continuously. The wrapping material is feed by Servo motors. Servo Motor Controlled Horizontal sealing and cutting. Impulse or heat sealing units for different type of wrapping materials. Wrapping material tension is controlled continuously. Automatic lateral adjustment of wrapping material. Suitable for CE standards. 7 inch touch screen wtih several languages.

Request for a quote

HARKOM MAKINA SAN. TIC. LTD. ŞTI

Turkey

Suitable for granule type of products. The weighing unit iscontrolled by a seperate microprocessor and touch screen.Supports many usefull functions such as multi dumping,automatic product conveyor control, self cleaning,reciperecord for different products, different language and etc. Different amount of weighing buckets in different dimensions should be provided with respect to type of product. Parts touching to products are easy to dismount and cleaning. All surfaces touching to products are AISI 304 stainless steel. Easy dismountable collar set design. Package length should be controlled by print mark or feeding duration. Printer state is checked continiously. Wrapping material is driven by AC motors. Pneumatic driven horizontal sealing and cutting. Impulse or heat sealing units for different type of wrapping materials. Suitable for CE standarts. 7 inch touch screen wtih several languages.

Request for a quote

HARKOM MAKINA SAN. TIC. LTD. ŞTI

Turkey

Suitable for granule type of products. The target weight is controlled by linear vibration units. With respect to product type and desired speed; 2 or 4 line types are available. The magnitude of vibration level for each line is adjustable. The accuracy of each filling is controlled by tuning each line vibration magnitude. The average accuracy is depend on product type. All surfaces touching to products are AISI 304 stainless steel. Easy dismountable collar set design. Package length should be controlled by print mark or feeding duration. Printer state is checked continiously. Wrapping material is driven by AC motors. Pneumatic driven horizontal sealing and cutting. Impulse or heat sealing units for different type of wrapping materials. Suitable for CE standarts. 7 inch touch screen wtih several languages.

Request for a quote

HARKOM MAKINA SAN. TIC. LTD. ŞTI

Turkey

The machine is designed for powder and similar fine products. The target weight of each filling is controlledwith fast and accurate servo driven specific auger (wormscrew). The auger type and diameter changes with respect to product type and target weight. · All surfaces touching to products are AISI 304 stainless steel. · Easy dismountable collar set design. · Package length should be controlled by print mark or feeding duration. Printer state is checked continously. · Wrapping material is feed by Servo motors. · Servo Motor Controlled Horizontal sealing and cutting. · Impulse or heat sealing units for different type of wrapping materials. Wrapping material tension is controlled continously. · Autamic lateral adjustment of wrappin material. · Suitable for CE standarts. · 7 inch touch screen wtih several languages.

Request for a quote

HARKOM MAKINA SAN. TIC. LTD. ŞTI

Turkey

The machine is designed for powder and similar fine products. The target weight of each filling is controlled with fast and accurate servo driven specific auger (worm screw). The auger type and diameter Changes with respect to product type and target weight. All surfaces touching to products are AISI 304 stainless steel. · Sutiable for quadseal packages · Easy dismountable collar set design. · Package length should be controlled by print mark or feeding duration. · Printer state is checked continiously. · Wrapping material is feed by Servo motors. · Servo Motor Controlled Horizontal sealing and cutting. Impulse or heat sealing units for different type of wrapping materials. · Wrapping material tension is controlled continiously. · Auotamic lateral adjustment of wrappin material. · Suitable for CE standarts. · 7 inch touch screen wtih several languages.

Request for a quote

HARKOM MAKINA SAN. TIC. LTD. ŞTI

Turkey

Suitable for granule type of products. The target weight is controlled by linear vibration units. With respect to product type and desired speed; 2 or 4 line types are available. The magnitude of vibration level for each line is adjustable. The accuracy of each filling is controlled by tuning each line vibration magnitude. The average accuracy is depend on product type. All surfaces touching to products are AISI 304 stainless steel. Easy dismountable collar set design. Package length should be controlled by print mark or feeding duration. Printer state is checked continiously. Wrapping material is feed by Servo motors. Servo Motor Controlled Horizontal sealing and cutting. Impulse or heat sealing units for different type of wrapping materials. Wrapping material tension is controlled continiously. Auotamic lateral adjustment of wrappin material. Suitable for CE standarts. 7 inch touch screen wtih several languages.

Request for a quoteResults for

Installation of packaging machines - Import exportNumber of results

25 Products