- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machining industry

Results for

Machining industry - Import export

FERPLAST SNC

Italy

Electric sewing machine mod. FPMP 83 (220 V and 12 V) with dual drive, built on the basis of the mod. FPMP 82. The upper and lower dragging allows high performance on all materials. Operation with double reciprocating motion, device "antiwear" with power highly efficient even with high thicknesses and slippery materials. The sewing machine is used in agricultural, chemical, food, packaging and textile applications. Suitable for closing bags of light fabric and for coupling pieces of fabric together. The FPMP 83 is also suitable for the sewing of nets, such as those for the collection of olives or antihail. For uses other than those listed please send us a test sample of your product.

Request for a quote

FERPLAST SNC

Italy

Electric sewing machine Mod. FPMP 82 (220 V and 12 V ) for bags particularly robust, vibration-free, usable in agricultural industries, chemical, food, packaging, textiles, for use in finishing. Suitable for sealing bags of a different type of paper, jute, fabric and plasticized, etc. such as bags of food or chemicals. The FPMP 82 can be used for the sewing of the collection nets of olives or antihail. The operation with reciprocating motion with "wear" arrangement allows a very efficient grip even on medium to high thicknesses. The machine works with standard 220 volt electric cable. It's also available in 12V that can be equipped with external battery and backpack. For uses other than those listed please send us a test sample of your product.

Request for a quote

FERPLAST SNC

Italy

Electric sewing machine Mod. FPMP 73 (220 V or 12 V) for the closure of bags of each type of paper, jute, fabric and plasticized, low thickness pvc, etc such as bags of salt or coffee. The operation with reciprocating motion with "wear" arrangement allows a very efficient grip even on medium to high thicknesses. The FPMP 73 is also suitable for the sewing of nets, such as those for the collection of olives or antihail. The machine works with standard 220 volt electric cable. It's also available in 12V and can be equipped with external battery and backpack.

Request for a quote

FERPLAST SNC

Italy

The electric sewing machines for bags series FPGK are reliable and economical. Recommended for production up to about 400 to 500 bags per day, can be easily handled and transported to various sewing locations. Simple and compact, are equipped with a structure in aluminum alloy and plastic of high quality and mechanical parts in steel. Staplers are suitable to close sacks made of jute, paper, fabric, plastic and network for sewing fabrics, nets for agriculture, cartons, etc. The material you can sew, if different from those listed must be low density (to avoid breaking of the needles). The standard model comes with 220 Volt and is equipped with kits transformer 12V / 220V, backpack, batteries and chargers. The transformer 12 volt / 220 volt is oversized and equipped with all the safety measures necessary to the safe operation and long-lasting equipment. Safety devices include: battery alarm, battery low shutdown, overload and overheating. The backpack allows you to move comfortably.

Request for a quote

FERPLAST SNC

Italy

The new FP GK-350 BB battery-operated sewing machine is light and easy to handle and is the best solution when you have to sew bags and nets in locations where it is not possible to use 220 volt current or where you want to have greater freedom of movement. The robust drive mechanism allows you to easily sew bags in jute, paper, fabric, plastic, net bags and anti-hail net and for olive harvesting. In principle, it is suitable for closing bags of any material thanks to the automatic dragging. For special processes, we recommend sending us a sample of the product so that we can test the machine in real conditions of use. The maximum sewing pass thickness is 10 mm and the thread tension can be easily adjusted using a knob. It is recommended to sew material with low density so as not to break the needles. The battery is 36V at 2.6 Ah and recharges in about 5-6 hours, the battery charger is supplied and works with a voltage of 220V at 50Hz.

Request for a quote

FERPLAST SNC

Italy

Electric sewing machine for sacks model FPGK 350. This model is recommended for production up to 450 sacks per day. New model of the FPGK series designed for the seam of juta, paper, fabric, plastic and net bags. The front part of the stapler is made of metal while the handle is made of plastic. Given its features this electric sewing machine is suitable for farms, warehouses, post offices and food and chemical industries. It is a good solution for the closure of bags of any material and dimension due to the automatic feed. This light and handy machine is the fastest in its class. The standard model must be connected to the electric current of 220V. The maximum span passage is 10 mm. The material you can sew, if different from those listed must be low density (to avoid breaking of the needles).

Request for a quote

FERPLAST SNC

Italy

Electric sewing machine for sacks model FPGK 2701 with metal and plastic structure to contain the weight and ensure maximum safety. The models FP GK are designed for the seam of juta, paper, fabric, plastic and net bags, and they are recommended for productions up to 400/500 sacks at day. The quality of the components guarantees high performance in every working condition and on each type of material. The weight, just 2700 gr and the ergonomic handle make it very handy. The standard model must be connected to the electric current of 220V. The maximum span passage is 8 mm. The material you can sew, if different from those listed must be low density (to avoid breaking of the needles).

Request for a quote

FERPLAST SNC

Italy

Stackable and suitable for forks lift. Available industry version (industrial gray) or food version (RAL 7001). Ideal for textile industry, pharmaceutical industry, metalworking, plastics processing and food industry. Easy to clean, does not absorb smells and humidity. Storable outdoors. Available with feet, runners or wheels. Are movable with pallet trucks and forklift. Approximate weight 17 kg. The bins can be ordered with 4 legs, runners and 4 wheels without brakes. The version with 4 wheels without brake can be transformed into the version with 2 or 4 wheels with brake by purchasing the relative accessory. This is only a surcharge that must be applied to the bins that already has wheels (it cannot be applied to the bins with the feet).

Request for a quote

SCHNELL SPA

Italy

Bidirectional automatic stirrup bender from coil for the production of stirrups and cuttosize bars using wires up to Ø 16 mm (#5). Driven by digital electric servomotors. Also available HS version machine. Coil 16 automatic stirrup benders are equipped with Max. pulling speed 140 m/min (460 ft/min) HS Version 200 m/min (660 ft/min) AntiTwist device (Optional) 4 pulling drive wheels Cutting with Brushless motors with adjustable wire guide, reversible mobile and fixed cutting blades Pneumatic stirrup collector flap Web Teleassistance 3D version for the production of tridimensional pieces. COIL 16 Pack 1 N. 2 groups of straighteners (horizontalsverticals) with independent position and adjustment displays for the 2 wires.

Request for a quote

SCHNELL SPA

Italy

Bidirectional automatic stirrup bender from coil for the production of stirrups and cuttosize bars using wires up to Ø 20 mm (#6). Driven by digital electric servomotors. Coil 20 automatic stirrup benders are equipped with Max. pulling speed 140 m/min (460 ft/min) Straighteners (horizontalsverticals) with electronic and independent adjustment for the 2 wires with Joystick AntiTwist electronic device (Optional) Pulling with 4 motors and 4 pulling drive wheels Cutting unit with adjustable wire guide, reversible mobile and fixed cutting blades Web Teleassistance

Request for a quote

SCHNELL SPA

Italy

Stirrup bender and bar shaping machine from coil with 2 bending heads for the production of stirrups and shaped wires with bends at both ends using wires up to Ø 20 mm (#6). Driven by electric servomotors. These automatic stirrup benders and bar shaping machines are equipped with Max. pulling speed 140 m/min (460 ft/min) Straighteners (horizontalvertical) with electronic and independent setting for the 2 wires with Joystick AntiTwist electronic device (Optional) Patented feed unit that allows independent advancement for single o double wire (Optional) 2 bending unit (upper and lower) Pulling with 4 motors and 4 pulling drive wheels Cutting unit with adjustable wire guide, reversible mobile and fixed cutting blades Web Teleassistance Prestraightening Feeding Unit (Optional) Automatic motorized wire change (Optional) 3D version for the production of tridimensional pieces.

Request for a quote

SCHNELL SPA

Italy

Stirrup bender and bar shaping machine from coil with 2 bending heads, allows to produce stirrups and shaped wires with bends at both ends using wires up to Ø 25 mm (#8). Driven by electric servomotors. These automatic stirrup benders and bar shaping machines are equipped with Max. pulling speed 160 m/min (525 ft/min) Straighteners (horizontalvertical) with electronic and independent setting for the 2 wires with Joystick Patented feed unit that allows independent advancement for single o double wire (Optional) 2 bending unit Automatic motorized wire change Automatic adjustable wireguide Web Teleassistance Prestraightening Feeding Unit (Optional).

Request for a quote

SCHNELL SPA

Italy

Bidirectional automatic stirrup bender for the production of stirrups and shaped wires both from bars (up to Ø 22 mm #7) and from coils (up to Ø 16 mm #5). The lower bending unit performs downward bends. Driven by electric servomotors. These automatic stirrup benders are equipped with Max. pulling speed 100 m/min (330 ft/min) External and internal straightening unit Semiautomatic cycle for shaped wires with bends on both ends Barholding clamp for downward bends Virtual mandrel for the upper processing unit Web Teleassistance

Request for a quote

SCHNELL SPA

Italy

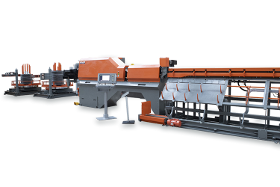

Electromechanical automatic bar cutting bench with 5 transfer roller tracks and a second additional rebar conveyor. Thanks to the second transfer track, parallel to the cutting unit, cutbars can be placed along the whole length of the roller track optimizing the use. This means that the same roller track can be used to store different orders. Basically, it is as if you had a much greater number of roller tracks allowing a better cutting optimization thus reducing the quantity of scraps. The bar cutting bench "OPTIBAT 5" represents the ideal solution for those working large numbers of smallsized orders and it is especially designed for civil housing. Besides being flexible and fast, its electromechanical technology ensures high accuracy; minimum noise production; reduced power and air consumption; reduced maintenance.

Request for a quote

SCHNELL SPA

Italy

Integrated plant to cut and stock precut bars made of fast automatic straighteners with rollers (such as RETA) and coil processing up to Ø 20 mm. Pulling speed up to 300 m/min. The plant is fully customizable and modular thanks to a wide range of available accessories. Fast Coil change patented system of automatic horizontal wire change (Optional); Straighteners (horizontalvertical) with electronic and independent setting for double wire feeding; Cutting with Brushless motors with adjustable wire guide, fixed and mobile cutting blades; Rollers for the extraction of the last part of the coil; Teleassistance.

Request for a quote

SCHNELL SPA

Italy

Automatic rebar bending machine for bars up to Ø 40 mm. It works automatically and bends any kind of shapes, positive and negative bends included. Automatic system for bars feeding and discharging 2 adjustable bending speeds

Request for a quote

SCHNELL SPA

Italy

Fast automatic wire straightening machine, with rollers, for the production of cuttosize wires up to Ø 13 mm (#4), equipped with Senso Technology.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SCHNELL SPA

Italy

Fast automatic wire straightening and cutting machine, with rollers, for the production of cuttosize wires up to Ø 16 mm (#5). Driven by digital electric servomotors. Max pulling speed 240 m/min (790 ft/min) Straighteners (horizontalvertical) with electronic setting Rollers for the extraction of the last part of the coil (Optional) Automatic 6inlets motorized wire change and insertion unit (Optional) Patented motorized horizontal wire change unit which allows to change the diameter and the coil in "Zero time" (Optional) Web Teleassistance

Request for a quote

SCHNELL SPA

Italy

Automatic wire straightening machine, with rollers, for the production of cuttosize wires up to Ø 20 mm (#6). Driven by digital electric servomotors. Capacity 2 Ø 16 mm (#5) Max pulling speed 200 m/min (660 ft/min) Straighteners (horizontalsverticals) with electronic adjustment and independent position for the 2 wires Motorized wire change unit (Optional) Prestraightening Feeding Unit (Optional) Web Teleassistance

Request for a quote

SCHNELL SPA

Italy

Cage making machine for the production of cylindrical cages with variable pitch welded spiral wrap; max cage Ø 1100 mm. High productivity and flexibility is guaranteed by the configuration of the machine and by the fully automatic welding unit SAF 3000. With the machine to produce cylindrical poles CM PRO 1100 is also possible to produce on the machine square or rectangular cages and cages with the bars bent on the end (90 °bends, bottle necks and pointed).

Request for a quote

SCHNELL SPA

Italy

Rebar cutting machine for fast bars cutting. Cutting antirepetitiveness system. Capacity 1 bar Ø 26 mm 100 cuts/minute

Request for a quote

SCHNELL SPA

Italy

Bar bending machine. Bending disk and adjustable strength steel saddles. Capacity 1 bar Ø 36 mm (#11) Plate revolving speed 8 RPM

Request for a quote

SCHNELL SPA

Italy

Ring bending machine for rings of unlimited radius (rib rings) and spirals. Driven by a variablespeed electric motor min 20; max 30 rpm. Adjustable bending radius from a minimum 15 cm (with small diameters) and over. For Ø 6 mm (#3) Ø 32 mm (#10) wires.

Request for a quote

SCHNELL SPA

Italy

The “Coldrive” 2MV is a cold rolling line with multiple vertical drawing capstan for the production of smooth and ribbed wires from Ø 3,4 to Ø 12 mm. This cold drawing line is completely modular and the rolling process is made through drawing capstan and rollers cassettes for rolling/profiling. Driven by electric asynchronous servomotors digitally controlled. Max. pulling speed 12 m/s (higher speeds on demand) Compact Layout Highly customizable "Asynchronous servomotor" low highpower consumption User friendly software for cold rolling process management Web Teleassistance Other cold rolling lines Line at 1 or 2 passes with single vertical drawing capstan MV 4 12 mm (12 m/s) Multipass line and multiple vertical drawing capstan 3MV 3,4 10 mm (16 m/s) 4MV 3 8 mm (16 m/s)

Request for a quote

SCHNELL SPA

Italy

The “Coldrive” 3MV is a cold rolling line with multiple vertical drawing capstan for the production of smooth and ribbed wires from Ø 3,4 to Ø 10 mm. This cold drawing line is completely modular and the rolling process is made through drawing capstan and rollers cassettes for rolling/profiling. Driven by electric asynchronous servomotors digitally controlled. Max. pulling speed 16 m/s (higher speeds on demand) Compact Layout Highly customizable "Asynchronous servomotor" low highpower consumption User friendly software for cold rolling process management Web Teleassistance Other cold rolling lines Line at 1 or 2 passes with single vertical drawing capstan MV 4 12 mm (12 m/s) Multipass line and multiple vertical drawing capstan 2MV 3,4 12 mm (12 m/s) 4MV 3 8 mm (16 m/s) “Coldrive” MO with single horizontal drawing capstan MO 4,5 12 mm (8 m/s) MO 4 12 mm (8 m/s) MO 4 16 mm (8 m/s)

Request for a quote

SCHNELL SPA

Italy

The Coldrive MO is a cold rolling line with single horizontal drawing capstan for the production of smooth and ribbed wires from Ø 4 to Ø 16 mm. This cold drawing line is completely modular and the rolling process is made through drawing capstan and rollers cassettes for rolling/profiling. Driven by electric asynchronous servomotors digitally controlled. Max. pulling speed 8 m/s (higher speeds on demand) Compact Layout Highly customizable "Asynchronous vector motor" low consumption, high power User friendly software for cold rolling process management Web Teleassistance Other cold rolling lines Line at 1 or 2 passes with single vertical drawing capstan MV 4 12 mm (12 m/s) Multipass line and multiple vertical drawing capstan 2MV 3,4 12 mm (12 m/s) 3MV 3,4 10 mm (16 m/s) 4MV 3 8 mm (16 m/s) “Coldrive” MO with single horizontal drawing capstan MO 4,5 12 mm (8 m/s) MO 4 12 mm (8 m/s)

Request for a quote

SCHNELL SPA

Italy

STRETCH DRIVE MO is a Cold Rolling and Stretching Line with single horizontal drawing capstan for the production of both smooth and ribbed, colddrawn wire with low carbon content and hot rolled high ductility ribbed wire. Stretching Process Stretch Drive MO 6 16 mm (8 m/s) Cold Rolling Process Stretch Drive MO Cold 1 4,5 12 mm (8 m/s) Stretch Drive MO Cold 2 4 12 mm (8 m/s)

Request for a quote

SCHNELL SPA

Italy

Rotor type wire straightening machine for the production of cuttosize wires up to Ø 12 mm (#3). Driven by digital electric servomotors. Max pulling speed 160 m/ min (525 ft/ min) High speed cutting unit with brushless (less than 0.1 sec) Web Teleassistance Available versions Fixed cut with adjustable backstop length for a maximum cutting precision (± 0.5 mm). Rotating cut system with automatic measurement via encoder for higher productivity (± 0.5 mm/m).

Request for a quote

SCHNELL SPA

Italy

The rotor type wire straightening machine RI 8 is suitable for processing a wide range of smooth cold drawn industrial wires from Ø 3mm to Ø 8mm. The 4 independent servomotors allow Excellent straightening quality; Max. pulling speed 160 m/min; Burrfree highprecision cutting (tolerance of ±0.1 mm). A wide range of wires can be processed depending on the machine configuration from mild steel to annealed and galvanized wire, highstrength steels such as stainless steel, springs steel and nonferrous wires such as brass, bronze, copper and aluminum using special equipment. The wide range of accessories allows you to customize the machine to the different needs of the industrial market. Available versions RI 8/ML The manual setting of the mechanical lengthstop will enable processing wires with a bar length accuracy of ±0,1 mm. This newly designed contactless lengthstop enables to action the cut without the conventional

Request for a quoteResults for

Machining industry - Import exportNumber of results

108 ProductsCountries

Company type

Category

- Industrial cutting machine tools (85)

- Machine tools - metal machining (85)

- Food Industry - Machines & Equipment (7)

- Sewing machines and accessories - industrial (7)

- Sweeping machines, industrial (2)

- Cleaning machines, industrial (1)

- Cleaning - steel and metals (1)

- Dry-cleaning machines (1)

- Food industry - machinery and equipment (1)

- Hydraulic equipment (1)