- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- spherical roller bearings

Results for

Spherical roller bearings - Import export

CRB CUSCINETTI VOLVENTI

Italy

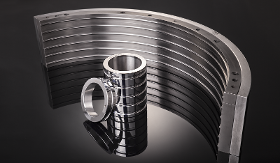

The unique construction of spherical roller bearings make them vital for heavy applications. Their performance is consistent even in extreme conditions, as in the case of high-stress environments and / or reduced lubrication. Spherical roller bearings can give a use life equal to twice that of traditional bearings, according to some estimates. Features of spherical roller bearings: ideal for reduced and medium speeds self-aligning and very robust able to bear radial and axial loads in both directions longer use life compared to traditional bearings excellent compensation for misalignments APPLICATIONS: Earth Moving Machinery Agricultural Machinery Fitness machines Steel working machines Marble processing machines Iron and Steel Industry Oil Industry Automatic opening systems Heavy machinery (eg machines for construction and mining) Bottling / filling carousels Steel mills Industrial transmissions Vibrating equipment / machines Vibrating sieves / vibrating screens

Request for a quote

TECNORULLI S.R.L. CON SOCIO UNICO

Italy

With PVC pipe and head, with steel tube and PVC head. They are mounted vertically with sliding guide functions; horizontally for special applications such as the mounting for tangential belts in motor-driven conveyors through driven base rollers or rollers with pulley for flat belt. With plastic wheels on steel axles, assembled in sequence, they are used as an alternative to tapered rollers in gravity curves for the handling of packages with a flat supporting surface and light loads. The wheels can be individually assembled, fixed on flatbeds by means of suitable brackets, in correspondence with exchanges between curves and tracks with idlers, in conjunction between tracks with ortogonal motor-driven rollers or with the function of guide-abutment of packages.

Request for a quote

IMETA SRL

Italy

Beader tooling can be manufactured for any machine, such as CEVOLANI, FMI, SIGKRUPP, Soudronic and more.

Request for a quote

CRB CUSCINETTI VOLVENTI

Italy

The slewing bearing, also known as slew(ing) ring, is a type of bearing for low-speed and high axial load applications. The slewing bearing is a mechanical component that is used in major industrial sectors. Harbor and deck cranes are one of the ideal applications for using slewing bearings – for example, for container handling. Additionally, for wind turbine blades, the use of slewing bearings ensures the highest level of reliability and efficiency, as required by this sector. APPLICATIONS: Earth Moving Machinery Concrete pumps Civil and Harbor Cranes Wind Turbines Radar Robotics Packaging Logistics Material handling Bottling / filling carousels Rotating tables Polyurethane Injection Systems Drilling Rigs Welding Plants Water Treatment Plants Lunapark Woodworking Machines Marble Cutting Machines Palletizers Aerial Platforms Roller Conveyors / Idle Rollers

Request for a quote

CRB CUSCINETTI VOLVENTI

Italy

Angular contact bearings are designed so that the contact angle between the raceways and the balls is formed while the bearing is in use. The ability of angular contact ball bearings to withstand axial loads increases proportionally as the contact angle increases. Features of angular contact ball bearings: high stiffness ideal for high-precision performance at high speed able to withstand heavy axial loads and moderate radial loads available with a single or double row, in the open or shielded / sealed versions Series Single row: 7200, 7300 Double row: 3200, 3300, 5200, 5300 APPLICATIONS: Agricultural Machinery Metal processing Oil Industry Paper making machines Wind sector Gearboxes Pumps and Compressors Ventilators /Fans Semiconductors Motorcycle Industry Machine tools Electromechanics Textile machinery Injection molding machines

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CRB CUSCINETTI VOLVENTI

Italy

Self-aligning ball bearings are radial bearings with two rows of balls, a common spherical track in the outer ring and a track with two deep and continuous grooves in the inner ring. They are particularly suitable for applications that are prone to alignment errors. Features of self-aligning ball bearings: low coefficient of friction exceptional performance at high speeds no overheating, lower operating temperatures excellent compensation for misalignments ideal for low to medium-high radial loads and reduced axial loads available in open or shielded versions (ZZ – 2RS) and with tapered bore (K) very low noise and limited vibrations minimal maintenance requirements Series: 1200, 1300, 2200, 2300, 11200, 11300 APPLICATIONS: Agricultural Machinery Oil Industry Electrical motors and gearboxes Medical devices Food processing machinery Chemical Industry Pumps

Request for a quote

CRB CUSCINETTI VOLVENTI

Italy

Deep groove ball bearings are the most commonly used type of bearing. Coming in many versions, varieties and dimensions, they are particularly versatile and can be used in a wide range of applications. They can withstand both radial and axial loads in both directions, even at high speed. They are especially suitable for all situations where high speed and low power loss are required. Features of deep groove ball bearings: ideal for high and very high speeds able to bear medium radial and axial loads in one or both directions easy to assemble, with minimal maintenance requirements Series: 600, 6000, 6200, 6300, 6400, 1600 Thin ring: 61800, 61900 APPLICATIONS: Earth Moving Machinery Electrical Motors and Gearboxes Iron and Steel Industry Agricultural Machinery Oil Industry Papermaking Machinery Wind Turbines Railways Semiconductors General mechanics Industrial Transmissions Pumps and Compressors Medical devices Food Processing Machinery

Request for a quoteResults for

Spherical roller bearings - Import exportNumber of results

8 ProductsCompany type