- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- automatisms for welding

Results for

Automatisms for welding - Import export

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

Our metal work unit is equipped with all the equipment required to carry out the majority of operations related to the production and shaping of metal objects: mortising machine, press, drilling machines, rolling machines, semi-automatic welding stations and TIG/Plasma/Oxycutting workstations. Our vast range of metal work equipment and the adaptability of the workshop’s covered areas are ideal for performing almost every type of shaping.

Request for a quote

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

In addition to being able to work on site in an emergency to diagnose an unexpected breakdown and repair your installation, we are equipped with: a comprehensive machine fleet (numerically-controlled machining centres, lathes and milling machines, mortising machine, press, drilling machines, rolling machines, semi-automatic welding station, TIG/Plasma/Oxycutting station) meaning that we can manufacture products to measure and supply all your replacement and wear parts in an emergency an assembly workshop (mechanics, hydraulics, pneumatics, electrics, automation), lifting equipment and testing and programming stations, where mechanical and electrical assemblies and sub-assemblies can be produced urgently and with a high degree of flexibility

Request for a quote

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

Numerically-controlled hydraulic press brake, numerically-controlled hydraulic shearing machine, numerically-controlled machining centres, numerically-controlled lathes and milling machines, mortising machines, presses, drilling machines, rolling machines, semi-automatic welding station, TIG/Plasma/Oxycutting workstation, paint booth, assembly workshop (mechanics, hydraulics, pneumatics, electrics, automation), lifting equipment, testing and programming workstations, etc. With our diverse range of facilities and modular covered areas, we can manufacture practically any type of installation or equipment, with unlimited space and technological expertise. Our multidisciplinary team of highly qualified specialists, combining long-standing experience with the technical skills of youth, guarantees the optimal operation of our equipment and the quality of the facilities delivered to you.

Request for a quote

FERPLAST SNC

Italy

The PANDYNO FPPD vertical inserters allow to an operator to fill and seal the packs avoiding the use of preformed bags. The operator must in fact insert the product to be packaged in the magazine tube, on which a few meters of tubular film have been previously loaded. The product goes down into the tubular film up to the support surface. The operator manually closes the sealing bar by applying a slight pressure on the bar. The welding machine in a single operation carries out the welding of the package, the cutting of the film and the welding of the bottom of the next envelope. This operation takes place using an electromagnetic blocking device. By equipping the bagging machine with several loaders, it is possible to increase the productivity of the machine. To avoid waiting times it is also possible to pre-load different magazine tubes so that they can be quickly replaced once the film is finished. The standard model can be placed on a bench and comes with a charger of your choice.

Request for a quote

FERPLAST SNC

Italy

The fully automatic strapping machine mod. TP 201 with side sealing is particularly suitable for strapping furniture, household appliances, palletised loads and high packages. It can be inserted in lines where the available space or the limited height of the conveyor do not allow the use of a standard strapping machine. The strap is automatically launched, tensioned, welded and cut, speeding up the strapping operations. The strapping machine, suitably modified, can be easily inserted into automatic packaging lines and can also work without an operator.

Request for a quote

ELKON GMBH

Germany

ELKON Cement silos are precisely manufactured by the fully automatic welding robots in production molds in ELKON-3 factory which is dedicated only for the production of cement silos. For easy and efficient transportation, ELKON provides a wide range of bolted type cement silos with the capacity of 50, 75, 100, 150, 300 and 500 tons.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Mould parting agent for entire range of plastics processing if an adhesion-dependent further processing requiring silicone-free parting agent is carried out Welding parting agent for arc welding and inert-gas arc welding As nozzle spray for extended service life of welding nozzle and keeping nozzle opening clear on automatic welding units As workpiece protection against baking and burning on of weld spatters Advantages and benefits Silicone free release agent with high effective substances from renewable primary products Prevents from burning in of spatters at welding nozzles, on workpieces and robots and increases the lifetime of the welding torch Builts up an evenly thin, nearly dry film, no creation of pores Enables the fast change and cleaning of the welding nozzle Easily washable with OKS 2650 Additional painting, metallising and printing after prior degreasing without any difficulties possible

Request for a quote

FERPLAST SNC

Italy

The shrink tunnel, equipped with temperature adjustments, height and speed, is incorporated in order to make the machine compact and versatile, suitable for series production. The welding time is electronically set and the absence of fumes is ensured by teflon-coated blades. The sealing bar motorized, equipped with security system, the closed circuit cooling plant and motorized scrap-winder, are part of the standard equipment of the machine. FEATURES Digital panel with 6 programs Descent sealing bar manual or automatic Discharge conveyor for product Legs with locking wheels Only welding and welding + retraction Sealing bars with closed-circuit cooling system and patented safety system Emergency switch Teflon coated sealing bars Electromechanical automats Welding speed automatic controller Motorized conveyor belt with adjustable height Motorized scrap-winder Air flow shrink tunnel swiveling Adjustable temperature with electronic temperature controller

Request for a quote

ELKON GMBH

Germany

ELKON twin shaft mixers, which successfully produce concrete for various projects all around the world, has been manufacturing in ELKON’s technological factories for long time. ELKON is capable of producing 500 twin shaft mixers per shift annually thanks to its fully automated robotic welding lines. Advanced Features of ELKON Twin Shaft Mixers - Longer lifetime with robust mixer body manufactured by fully automatic welding robots - Able to produce of all kinds of concrete (Ready-mixed concrete, precast concrete, roller-compacted concrete-RCC, heavy concrete, etc.) - High homogeneity even in shorter mixing times - Highly wear-resistant, durable wearing parts - Easy maintenance due to wide maintenance gates and bolted type replaceable linings - Heavy duty gearbox (Brevini or Bonfiglioli from Italy) - Automatic lubrication system (Lincoln - Germany) - Universal compatibility to existing concrete plants with compact design

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Mould parting agent for entire range of plastics processing if an adhesion-dependent further processing requiring silicone-free parting agent is carried out Welding parting agent for arc welding and inert-gas arc welding As nozzle spray for extended service life of welding nozzle and keeping nozzle opening clear on automatic welding units As workpiece protection against baking and burning on of weld spatters Advantages and benefits Silicone free release agent with high effective substances from renewable primary products Prevents from burning in of spatters at welding nozzles, on workpieces and robots and increases the lifetime of the welding torch Builts up an evenly thin, nearly dry film, no creation of pores Enables the fast change and cleaning of the welding nozzle Easily washable with OKS 2650 Additional painting, metallising and printing after prior degreasing without any difficulties possible

Request for a quote

SCHMALE MASCHINENBAU GMBH

Germany

A clamping ring machine is a system for the automatic production of clamping rings. Schmale Maschinenbau Gmbh is one of the leading manufacturers of clamping ring machines in Europe. On our clamping ring machines, the strip material is profiled, bent and cut. Automatically closures are supplied and welded. The finished clamping ring is calibrated and stored. Via a servo-electric transfer, all processing stations are connected to each other and operated simultaneously. Thus, cycle rates of up to 28 clamping rings per minute can be realized.

Request for a quote

MAGAGER, UNIPESSOAL, LDA

Portugal

Discover the BesterMIG 200-S Inverter, a technological innovation that will radically change your approach to welding. Synergy technology transforms welding by automatically adjusting parameters . With Synergy, the difficulties of determining the ideal current, wire feed speed and correct material thickness are a thing of the past. This adaptive technology assists your welding needs, ensuring remarkable results with minimal effort. By reducing the margin for error, Synergy offers high quality welds with reduced costs. Increase your efficiency and productivity with automatic adjustments that save time and facilitate the welding process. Portable and compact multi-process equipment: MIG/MAG, FCAW, MMA and TIG Lift. Equipped with SYNERGY based on automatic selection of welding parameters Perfect solution for hobbyists and DIY enthusiasts: makes welding faster and more effective

Request for a quote

SCHNELL SPA

Italy

Cage making machine for the production of cylindrical cages with variable pitch welded spiral wrap; max cage Ø 2500 mm. High productivity and flexibility is guaranteed by the configuration of the machine and by the fully automatic welding unit SAF 3000. WIth the machine to produce cylindrical poles CM PRO 2500 it is also possible to produce on the machine square or rectangular cages and cages with the bars bent on the end (90 °bends, bottle necks and pointed).

Request for a quote

SCHNELL SPA

Italy

Cage welding machine for the production of cylindrical cages with variable pitch welded spiral wrap; max cage Ø 2000 mm. High productivity and flexibility is guaranteed by the configuration of the machine and by the fully automatic welding unit SAF 3000. With the machine to produce cylindrical poles CM PRO 1600/2000 it is also possible to produce on the machine square or rectangular cages and cages with the bars bent on the end (90 °bends, bottle necks and pointed).

Request for a quote

SCHNELL SPA

Italy

Cage making machine for the production of cylindrical cages with variable pitch welded spiral wrap; max cage Ø 1100 mm. High productivity and flexibility is guaranteed by the configuration of the machine and by the fully automatic welding unit SAF 3000. With the machine to produce cylindrical poles CM PRO 1100 is also possible to produce on the machine square or rectangular cages and cages with the bars bent on the end (90 °bends, bottle necks and pointed).

Request for a quote

SCHNELL SPA

Italy

Mesh welding machine for the production of electrowelded mesh fed by wires. The automatic wire mesh welding machine can manufacture electrowelded mesh from prestraightened wire, both longitudinal and transversal. The mesh maximum width is equal to 1250 mm, the length is variable between 2000 mm and 6000 mm. These electrowelded mesh are used for the production of prefabricated sandwich panels.

Request for a quote

YUTIAN FUTAI INTERNATIONAL TRADE CO., LTD.

China

*Aailable Sizes: -2.25x0.5m -2.25x0.55m -2.25x0.6m -2.25x0.65m -other dimensions also are available as buyer's request or drawing * Material : (1) Crate: 2mm hot dip galvanized tube (2) Sow feeder : Cast iron / stainless steel (3) Drinker :Stainless steel

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

LVD

Belgium

TL 8525 is a high-capacity tube laser cutting machine designed for top productivity. It handles lengths up to 8500 mm and diameters up to 250 mm round or square. The TL 8525 comes equipped with leading-edge features, including a 45-degree tilt-axis cutting head with NC-Focus, 6-position front loader, 2 kW IPG fiber laser, and a large X-axis cutting head range of 1190 mm to maximize material usage. KEY FEATURES Accommodates tube and profile lengths up to 8500 mm, diameters up to 250 mm High-performance cutting head with NC-Focus and bevel function +/- 45 degrees Magazine style 6-position automatic tube load system Leading edge detection for variable tube lengths Automatic bow detection and compensation system Automatic twist compensation system Outfeed tube support with accompanying conveyor table Siemens CNC control is PC-based with touchscreen PERFORMANCE-ENHANCING OPTIONS 4 kW fiber laser source 6100 mm outfeed extension Part evacuation conveyor Automatic weld seam detection

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

1. Capacities range from 1,000 to 6,000 kilograms. 2. For pipes or vessels rotation. 3. Metallic rollers bounded with polyurethane. 4. Quick, accurate roll centering adjustment. 5. High frequency protected. *CE Conformity

Request for a quote

EKO WELDING & MACHINE AUTOMATION SYSTEMS

Turkey

It’s designed upon you weld cylindrical, conical and rectangle shaped bended frameworks and in shape of flat slab metal sheet and plaque linearly. Frameworks that are between 200-3000 mm diameters can be welded on different types of machines easily. Its production can be made from the length of 0.5 meter to 4 meters. Upon customer demand the length can be increased. As to application method, TIG, MIG and submerged welds can be adapted. Materials’ like boiler, thermosiphon, solar power boilers, cooling tanks, natural gas funnels, lpg tubes etc., height welds are made on this machine.

Request for a quote

EKO WELDING & MACHINE AUTOMATION SYSTEMS

Turkey

The Frame Welding Machine is made of welded parts of different sizes and is designed to obtain the desired special H profiles. The machine body and the welding heads are fixed and the workpiece provide to be welded on both sides of the part to be welded by moving by means of driven conveyors. The hydraulic cylinders in the system provide the positioning of the H profile placing and fixing during welding.The system has adjustable backrests and accessories for the roofing of the conveyor group.The system has a hydraulic piston loading unit. The system might turn beam 90 degree with maximum weight and maximum dimensions by means of chain or mechanical structure.

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

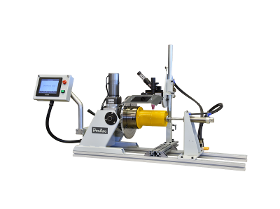

4 Major Advantage: 1. Cost effective and modular design.to increase welding productivity. 2. Set up with CB-107-1 Sequence controller : * User-friendly sequence controller. * Save 100 sets of programs * Even a non-experienced user can learn how to operate in few minutes. 3. High frequency protected 4. Suitable for different welding processes like TIG, MIG and plasma welding. 5. 2 year warranty *CE Conformity

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

1. For pipes or vessels rotation. 2. Metallic rollers bounded with polyurethane. 3. Quick, accurate roll centering adjustment. 4. Standard hand pendant with Forward-Stop-Reverse, speed potentiometer. 5. High frequency protected. *CE Conformity

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

TR-KB Series 1. Capacities range from 15,000 to 60,000 kilograms. 2. Superior worm gears reducer designed to provide high torque and low backlash. 3. Synchronized AC inverter drive control for two motors. 4. Metallic rollers bounded with natural rubber. 5. TR-KB series designed with symmetrical roller for quick and accurate centering adjustment. 6. Adjustment bolt for different work diameter. 7. Standard hand pendant with Forward-Stop-Reverse, speed potentiometer. 8. High frequency protected control box. 9. Fast/Slow footswitch - optional.

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

ProArc provides plug-and-play longitudinal seam welding machine for tubes, cylinders, vacuum components, water tanks, cones, flat sheets, etc. Advantages 1. Servo motor drive carriage and double linear guide way provides great precision of 0.05mm accuracy (0.002”). Motion speed reach to 2-16,000mm/min (1~640ipm). 2. Mandrel adopts with our special design copper backing-bar and copper clamper to dissipate heat quickly. 3.Strong machine structure provides large working capacity from thickness 0.1 to 10mm 4. Smart control box, you can get started quicker than you think with it. 5. High accuracy motion for laser welding standard. Welding process: All weldable metals by TIG, MIG, Plasma, Submerged arc welding and laser welding. *CE conformity.

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

ServoArc welding package can be simply applied in ProArc standard welding product by changing servo motor and integrate with advanced control box CB 500 or CB 600. 4 major advantages you will get 1. Equipped with servo motor 2. Welding program can be edited and stored 3. 0~10V analog interface available to control welding current 4. 3 additional dry contacts available for accessories such as Cold Wire Feeder, Arc Voltage control, Welding Oscillator etc.

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

ProArc manipulators are heavy duty and precise automatic welding systems. It can support both circumferential and longitudinal welding application from small tube to big tank. Our welding manipulator has maximized both safety and productivity. The stroke of column and boom is available from 2m x 2m to 7m x 7m. All welding manipulators (Column and boom) can work on different welding process. Special design manipulators are available at request.

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

1. ProArc manipulators are heavy duty and precise automatic welding systems. It can support both circumferential and longitudinal welding application from small tube to big tank. 2. The stroke of column and boom is available from 2m x 2m to 7m x 7m. 3. ProArc manipulators are heavy duty, precise automatic welding systems. They are designed for circumferential or longitudinal welds of great length. 4. All manipulators are available as bolt-down or free standing base, and heavy duty table bearing mount for column rotation or be mounted on to travel car. 5. All ProArc manipulators have anti-fallen device. 6. Controls include up/down, right/left travel switch speed potentiometer and high rapid travel.

Request for a quote

ALPHA LASER GMBH

Germany

The laser welding systems of the AL series can be used universally. They might be integrated into existing machine structures or used with an application device for manual welding. In combination with our NC-controlled laser machining table AL-T you get a real professional solution. We offer the required performance class for every application. You can choose between 75 and 900 W. There is a wide range of processing lenses and equipment options for these laser systems. Regardless of whether you use a simple 90 ° deflection lens, the tilt-swivel lens or our circular welding lens - the laser beam always reaches the desired point on the workpiece with pinpoint accuracy. Additional equipment options are optionally available for the AL, such as: • Micro welding device for a welding spot diameter <100 µm • Rotary axis module for cylindrical welds • automatic wire feeder • Workpiece holder • camera system •…and much more

Request for a quoteResults for

Automatisms for welding - Import exportNumber of results

53 ProductsCountries

Company type

Category

- Welding, electric - equipment and supplies (7)

- Industrial cutting machine tools (7)

- Laser - cutting and welding machines (6)

- Welding work - steels and metal (4)

- Motor mechanics - hand tools, non power (3)

- Autogenous welding machines (2)

- Concrete mixers (2)

- Electron beam welding - equipment (2)

- Machines for the manufacture of PVC and Aluminium Doors and Windows (2)

- Packing and packaging - machinery and equipment (2)

- Silicones (2)

- Welding, soldering and brazing - equipment and supplies (2)

- Copper wires and cables (1)

- Electromagnetic compatibility measuring equipment (1)

- Fabrics for technical use (1)

- Forming - steels and metals (1)

- Harvesting machinery and equipment (1)

- Package sealing machinery (1)

- Poultry farming - machinery and equipment (1)

- Welding robots (1)