- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- coils

Results for

Coils - Import export

EMBRO GMBH

Germany

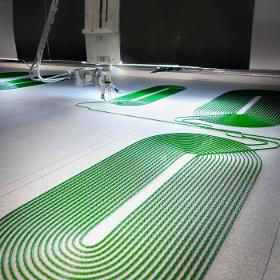

Where are magnetic field mats used? The coils currently manufactured by us are processed by our customers into so-called electromagnetic field mats. These mats are used in Pulsed Electromagnetic Field (PEMF) therapy. Many PEMF devices are suitable for private use at home. However, various health service providers including physical therapists as well as non-medical practitioners offer therapies based on magnetic fields. Why is our embroidery technology used for production? This technique creates circular-shaped structures that form the basis for a homogeneous flow/direction of the electric current. At the same time, the mechanical wire laying has an extremely high level of accuracy. The distances can also precisely be determined. How is the magnetic field created? Simply put, this is how electromagnetic fields are created: pulsating magnetic fields are generated by the electric current flowing through the wire. The more wire, the stronger the magnetic field.

Request for a quote

GSW SCHWABE AG

Germany

Safety for the workers, no damage to the coils Our practical hoists are easy to operate – for years at a time. On top of that suitable optional equipment is available.

Request for a quote

KAYADERELI CONSTRUCTION

Turkey

Coil pipes are produced in black; Polyethylene coil electrical installation pipes are Ø14 - Ø32mm in diameter, which can be used flexible, easily and safely in all kinds of light-duty type installations where the external pressure is low, on the surface, under plaster, in plasterboard, masonry or suspended ceiling.

Request for a quote

EUROQUARTZ LTD

United Kingdom

SMD helical filter, are custom wound and screened. The helical band pass filter coils are available from 45MHz to 2600MHz, triple pole, 50 Ohms or 75 Ohms matching impedance.

Request for a quote

KELVION HOLDING GMBH

Germany

The wide range of product portfolio of coils with different tube diameters, tube patterns, fin profiles, materials and options allows us to customize our coils for any specific application and fluids: air heaters, air coolers, condensers and evaporators for HVAC and various industrial applications. Kelvion heat exchanger coils are manufactured with copper tubes and aluminum or copper fins. The fins are equipped with special profiles developed at our R&D department enhancing heat transfer and keeping pressure drop at a moderate level. The customized fin spacing is achieved by collars which also provide the contact between the fin block and the tubes. Mechanical expansion of the tubes guarantees a perfect bond between the fins and the tubes leading to maximum heat transfer between both fluids.

Request for a quote

KEDY

Turkey

Lifting between 0-5 tons Hands-free operation Wide adjusting mechanism Safe and fast use with automatic lock mechanism No energy required CE certification The roll internal catching is inserted into the stocked roll horizontally, and the lifting process is performed with the "internal compression and bottom gripping method". The automatic locking mechanism is used while performing the transaction and can be used in a serial manner without the need for any outside intervention. It can be used to lift bobbins of any height with its height adjustment mechanism. It is used for transporting and stacking steel, sheet metal, paper and various round materials parallel to the ground. Stocking and shipping of sliced materials in sheet metal slitting plants always creates problems. Sliced roll materials are made horizontal by the tilting apparatus and placed on the pallets. Palletized horizontal rolls are made ready for shipment. Using a steel sling to load

Request for a quote

KEDY

Turkey

Lifting between 0-5 tons Hands-free operation Wide adjusting mechanism Safe and fast use with automatic lock mechanism No energy required CE certification The roll internal catching is inserted into the stocked roll horizontally, and the lifting process is performed with the "internal compression and bottom gripping method". The automatic locking mechanism is used while performing the transaction and can be used in a serial manner without the need for any outside intervention. It can be used to lift bobbins of any height with its height adjustment mechanism. It is used for transporting and stacking steel, sheet metal, paper and various round materials parallel to the ground. Stocking and shipping of sliced materials in sheet metal slitting plants always creates problems. Sliced roll materials are made horizontal by the tilting apparatus and placed on the pallets. Palletized horizontal rolls are made ready for shipment.As Per International Standard

Request for a quote

KEDY

Turkey

Standard capacity of 10 - 32 tons 800-2000 mm operating range Prevents tightening Balanced and safe lifting Motorized 359 degrees rotating system (Rotating period 2d/d) Electric handle with open/close feature Hook connecting pin stabilization attachment Light and sound warning indicator Remote control Spiral cable or cable reel option Load protection pads Stocking platform CE Certificate Coil lifting and carrying is the hardest thing for the businesses that make plate sheet business, coil cutting and manufacture plate sheets. Lots of businesses do these kinds of lifting and carrying operations with C hook which creates problems such as unbalanced lifting, load dropping risk, large stocking area, work safety problems and inefficiency. Our company which is expert about hook attachments saw these problems in the businesses and we developed quality and economical attachment solutions for the businesses.As Per International Standard

Request for a quote

KEDY

Turkey

Handle grips for easy usage Doesn’t require power Lifting without damaging the load CE Certificated, fully domestic product Manufacturing of 0.5-23 tons Light and easy usage This product is used for moving and lifting sliced or unsliced coils. Operates with counterweight system. Notch is inserted the top of the load to prevent dropping from the top side. There is shaft system that easily insertable to crane hook.As Per International Standard

Request for a quote

VERFAHRENSTECHNIK HÜBERS GMBH

Germany

System for the impregnation of electomagnetic coils, e.g. of electric motors, transformers, generators Impregnating in electricla engineering means applying an impregnating agent in gaseous or fluid form to a porous body in order to insulate it electrically, i.e. that reliable protection against electrical breakdown is provided even when the thickness of the insulating layer is small. For each application HÜBERS provides appropriate process. HÜBERS offers all relevant process variants including vacuum impregnation, vacuum-pressure impregnation and atmospheric impregnation and of these coupled with the use of the many different impregnating agents such as varnish, resin, oil, wax, gas etc. The processes of evacuating the parts prior to impregnation and if necessary of vacuum-drying the impregnated parts are matched to the properties of the parts and ensure that the agent wets the walls of the pores properly and fills the cavities completely.

Request for a quote

KUK COILS SLOVAKIA S.R.O.

Slovakia

KUK manufactures air coils for a wide variety of applications, e.g. RFID antennas, control coils or transponder coils. To produce self-supporting coils, self-bonding wire is also used, which is superficially bonded (glued) together during or after winding. Air coils are usually made of enamelled copper wire or high-frequency litz wire. So-called self-bonding wire is used to manufacture self-supporting air coils. It has an outer layer whose melting point is lower than the melting point of the insulation. After winding the air core coil, the turns of the coil are "baked" (glued) together by heating, usually by increased current flow. Thanks to our in-house plant engineering, we can optimally align our production lines to your needs, even for air core coils. - Ultra-fine wires starting at 0.020 mm - Single-layer flat coils in cylindrical or rectangular shape - single, bifilar or trifilar winding - Winding with HF litz wires

Request for a quote

SEMZ - SMILA ELECTROMECHANICAL PLANT

Ukraine

different parts for traction motors and generators

Request for a quote

FREEDOM GLOBAL TRADE LTD

Ukraine

Our company has all standarts of Steel with our product you can see on our website.

Request for a quote

FREEDOM GLOBAL TRADE LTD

Ukraine

Contact WhatsApp +380949454661, email: office@freedom-global-trade.pw

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Product name: 3003 3004 3105 alloy H14 extra width aluminum coil Place of Origin: China Width:10-2800mm Grade: 3000 Series Surface Treatment: Coated Tolerance: ±1% Processing Service: Cutting International certs: ISO9001-2008/SGS/ROHS etc Alloy: 3003 3004 3005 3105 3103 Temper: O H12 H14 H22 H24 H16 H18 etc Application: Industry Surface quality: super clean and flat Trade Term: FOB CIF CFR Supply Ability: 10000 Metric Ton/Metric Tons per Month Lead time: 15-30days Packaging Detail:standard export packing Port of shipment: Xiamen

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GSW SCHWABE AG

Germany

Movable keeper arms for coil guidance and centering Most durable hydraulic wedge type expansion, easily operable even under weight Highestquality reel arbor with doubled maintenancefree bearing and minimal deflection Sturdy and warp resistant body in welded construction for highest stability SHH Series PullOff Reel with manually adjustable brake and auxiliary drive to support coil setup SHR Series Payoff Reel with threephase motor and frequency inverter for continuous operation Pneumatic or hydraulic hold down arm Electropneumatic brake system Electromotive or hydraulic traveling feature Hydraulic coil car Concical keeper rolls w optional motorized travel Larger mandrel segments Different mandrel heights Fullsize back plate Vectorcontrolled drive system for heavy coil weights Servo drive and control system Loop control systems...etc. Double End Coil Reels w 180° turning radius Horizontal Coil Reels Recoilers Custom Layouts and Features

Request for a quote

GSW SCHWABE AG

Germany

Movable keeper arms for coil guidance and centering Crank expansion via directionally stable joints, easily operable even under weight Highestquality arbor with maintenancefree bearing and minimal deflection Boxshaped stand with welded base plate for great stability LMH Series PullOff Reel with manually adjustable brake LMHM Series Payoff Reel with threephase motor for start / stop operation LMHR Series Payoff Reel with threephase motor and frequency inverter for continuous operation Pneumatic hold down arm Electropneumatic brake system Larger mandrel segments Conical mandrel Traveling feature Different mandrel heights Various expansion ranges Different back plate sizes Loop control systems...etc. Double End Coil Reels w 180° turning radius Horizontal Coil Reels Recoilers Custom Layouts and Features

Request for a quote

GSW SCHWABE AG

Germany

Strong plasmaburned back plate provides smooth and straight operation Removable and adjustable hub disk Fast and precise expansion via bevel gear with exceptionally wide ranges, allows clamping of all internationally common coil sizes LH Series PullOff Reel with manually adjustable brake LHM Series Payoff Reel with threephase motor for start / stop operation LHR Series Payoff Reel with threephase motor and frequency inverter for continuous operation Pneumatic hold down arm Electropneumatic brake system Larger mandrel segments Conical mandrel Traveling feature Different mandrel heights Various expansion ranges Different back plate sizes Loop control systems Double End Coil Reels w 180° turning radius Horizontal Coil Reels Recoilers Custom Layouts and Features

Request for a quote

GSW SCHWABE AG

Germany

No coil expansion needed Selfcentering of coils through continuously adjustable coil side guides Machine body in rigid steelplate design Cradle rollers of hardened steel, driven synchronously Clockspring guard Hydraulic threading system with prebending roller and peeler wedge Hydraulic hold down arm (optional w powered endwheel) Motorized coil guides Ultrasonic loop control Cradle rollers with separate threephase motor

Request for a quote

SPIROL

Germany

SPIROL’s heavy duty & fatigue resistant Coiled Spring Pins are available in diameters ranging from 1.5mm (.062") up to 20mm (.750"). Standard materials include high carbon steel, 302/304 nickel (austenitic) stainless steel, and 420 chrome (martensitic) stainless steel. Diameters larger than 12mm (.500") are available in 6150 alloy steel. SPIROL invented the Coiled Spring Pin in 1948. Coiled Pins are available in light duty, standard duty and heavy duty to match the required strength and flexibility for each application. A pin too strong for the applied load will not flex and may damage the hole. A pin that is too flexible may fatigue prematurely within the assembly. The Coiled Pin with the optimal balance of strength, flexibility and diameter will result in the prolonged useful life of the assembly.

Request for a quote

DANA LUBRICANTS FACTORY LLC

United Arab Emirates

DANA STEEL is the leading manufacturer & exporter of high quality Hot Dip Galvanized Steel Coils & Sheets ( GI Coils & Sheets) as per International Standards & Specifications. Below is the Chart of our Continuous Galvanizing Line – CGL#1’s Process Capabilities,which shows the thickness,width,weight ranges and different finishes of Galvanized Coils,Sheets & Slits which are manufactured in our factory in Dubai UAE. Product Type & Applicable Specifications of Galvanized(GI) Steel Coils & Sheets DescriptionGALVANIZED STEEL SpecificationASTM A 653/A 653M – 18 CS Type A,B,C FS Type A,B DDS Type A,B SS Grade 33, 37,40, 50,55,80 EN 10346 :2015 which supersedes EN 10327 : 2004 DX51D, DX52D , DX53D EN 10346 :2015 which supersedes EN 10326 : 2004 S220GD, S250GD, S280GD,S320GD, S350GD, S550GD JIS G 3302 -2010 SGCC, SGCD1, SGCD2, SGC – 340, 400, 440, 490, 570 All our products are PROUDLY MADE IN UAE and exported to more than 60 countries across Africa & America

Request for a quote

SCHNIEWINDT GMBH & CO. KG

Germany

The CSN® AirCoil is a special design based on the physical construction of a Rogowski Coil. Due to the ironfree design the coil does not have any saturation which allows to use only one CSN® AirCoil Module for both metering and protection arrays. Additionally the CSN® Aircoil shows linear transmission behaviour over a wide frequency range. A current range of hundred amperes up to several hundreds kiloamperes is easy to realize. CSN® AirCoil Modules are combinable and hence the output voltage level is adjustable to customer request. The very compact design with an excellent longterm stability are additional benefits for special applications. Further information about our CSN® AirCoil

Request for a quote

ENERCON INDUSTRIES LTD

United Kingdom

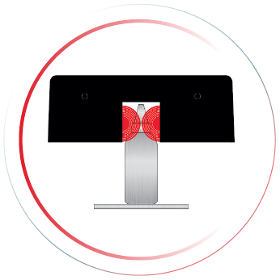

Enercon has two coil design types, each with several variations, to ensure the perfect coil is available for the size and type of your container and cap for your application to deliver perfect, consistent seals. Tunnel coils facilitate higher throughputs than the more traditional flat coils. The Deep Tunnel Coil is used for conical, spouted and other shaped caps. The All-in-One Coil is a variation of the Flat Coil. It is available with the Super Seal™ range and Super Seal™ Touch. This flat sealing head can be pivoted to accommodate various applications. Capable of sealing containers with cap diameters ranging from 20mm to 140mm, it is ideal for packagers who seal a variety of containers and offer the highest degree of sealing versatility. Packagers often don’t realise that the efficiency of the sealing operation depends on the design of the sealing head.

Request for a quote

SPIROL

Germany

SPIROL invented the Coiled Spring Pin in 1948. Truly an engineered fasteners, the Coiled Pin is available in three duties, light, standard and heavy, to enable the designer to choose from the optimum combination of strength, flexibility and diameter to suit different host materials and application requirements. Their shock absorbing design dampens forces and vibration to prevent hole damage and prolong assembly life. Light Duty Coiled Spring Pins are generally recommended for soft, brittle or thin materials such as plastics, aluminium, die castings, ceramics, and where holes are located close to an edge of the assembly. In situations not subjected to significant loads, such as when used purely for alignment or as an axle, light duty Coiled Pins are often used because of easy installation resulting from lower insertion force.

Request for a quote

SPIROL

Germany

While Coiled Spring Pins are extremely versatile self-retaining fasteners that can be used for many different functions, SPIROL has designed several series of Coiled Pins to meet the nuances and performance requirements of some particular niche applications. These Coiled Spring Pins are variations of our standard product either manufactured from special material, have a special finish or undergo specific processing to meet performance, corrosion, compatibility and assembly requirements for the specific application. These pre-designed application-specific series of Coiled Pins help companies shorten the design cycle to confidently launch their product quickly to their market with a pinning solution that has been tested and proven within their assembly.

Request for a quote

PIERON GMBH

Germany

Dimensions Wire diameter: from 0,2 mm Spring geometry after consultation Material Stainless steel Copper alloy Customized solutions Coating Additional coatings through external services (e. g. gold-plated, silver-plated, tin-plated) Specialities Highest precision because of laser-welded spring ends Optimal contact properties because of inclined coils Automated manufacturing Customer specific packaging Rapid prototyping

Request for a quote

SPIROL

Germany

The Series 500 Extra Light Duty Coiled Pins were specifically designed for use in soft or fragile materials. The 1½ coil formation ensures that the radial force exerted against the hole wall does not exceed the strength of the hole material to prevent deformation. These pins are also an economical solution where pin strength is not a major design consideration. Typical applications for Series 500 Extra Light Duty Pins include: hinge pins in plastic or ceramic assemblies, alignment pins, and fastening applications where the hole is close to an edge of an assembly component.

Request for a quoteResults for

Coils - Import exportNumber of results

376 ProductsCountries

- Germany (145)

- Turkey (113)

- United Kingdom (35)

- Italy (14)

- China (11)

- France (9)

- Lithuania (9)

- Ukraine (7)

- Slovakia (4)

- United States (4)

- Japan (3)

- Latvia (3)

- Switzerland (3)

- Luxembourg (2)

- Poland (2)

- Russia (2)

- United Arab Emirates (2)

- Australia (1)

- Austria (1)

- Belarus (1)

- Bulgaria (1)

- Greece (1)

- Ireland (1)

- Portugal (1)

- Taiwan R.O.C. (1)

Company type

Category

- Metal straightening machines (25)

- Bedroom furniture (22)

- Cutting - machine tools (16)

- Coil Springs (14)

- Lifting equipment (13)

- Metal brushes (13)

- Industrial cutting machine tools (11)

- Screw cutting - steels and metals (11)

- Coils and solenoids (10)

- Aluminium sheets and bands (10)

- Coil winders (10)

- Copper and copper alloys (8)

- Buckets and grabs, crane (7)

- Heat exchangers (7)

- Machine tools, metal shaping - parts and accessories (7)

- Stainless steels (7)

- Steels and metals - surface treatment and coating (7)

- Water-heaters, domestic (7)

- Electroheat - machines and equipment (6)

- Mechanical surface treatment - machinery (6)